Danger of air bubbles in the pipeline

Water hammer can rupture a pipe.

Bubbles, especially large ones, can destroy even strong elements of the pipeline. The main troubles they cause to owners of private houses:

- They accumulate in the same areas, leading to breakdowns of pipe sections and adapters. They also pose a risk for turning and twisting pipe sections where air is trapped.

- They break the water flow, which is inconvenient for the user. The taps “spit out” water all the time and vibrate.

- Causes water hammer.

Water hammer leads to the formation of longitudinal cracks, which causes the pipes to gradually collapse. As time passes, the pipe breaks at the point of cracking and the system stops functioning.

Therefore, it is important to equip additional elements that allow you to quickly get rid of dangerous bubbles

How dangerous is the air in the water supply?

consequence of water hammer

Air bubbles crush the water flow, causing inconvenience to the consumer. The taps constantly “spit” and behave unpredictably;- Air pockets accumulate in the same places, causing rapid destruction of pipes and adapters. Turns and bends of pipes, where there is an opportunity for an air bubble to linger, are at risk;

- Air in water supply pipes can cause water hammer. This unpleasant phenomenon gradually destroys the pipes, causing longitudinal cracks. Over time, the pipe bursts in the damaged area. The owner may not notice the destruction for quite a long time; this is the main danger of water hammer.

Causes

Most often, water hammer occurs when a shut-off valve is suddenly closed. When water flows through the pipes and pours out of the tap, a constant pressure value is maintained in the water supply system, but at the moment of sudden shutoff of the fittings, this value can increase several times, as a result of which the pipe walls cannot withstand the pressure and burst.

Water hammer can also be caused by:

- Abrupt switching on or off of a powerful pump.

- There are air pockets in the water supply or heating circuit.

Turning the pump on and off can be triggered by an unstable power supply to a facility where there are powerful pumping stations for pumping water. Air locks also play an important role in the occurrence of such a dangerous phenomenon, therefore, before operating closed systems with liquid, you should make sure that there is a complete absence of air in them.

Types of wells for private water supply

The undrinkable water is quite suitable for watering the garden, cleaning and similar needs. It is easier and cheaper to obtain it by constructing a needle well, also called an Abyssinian well. It is a column of thick-walled VGP pipes Ø from 25 to 40 mm.

The first link of the column is equipped with a tip and a filter located directly in the walls of the water-gas pipe. The Abyssinian well is not drilled, but driven into the ground using a heavy borehole, which is attached to a cable thrown over a block.

This is the cheapest and easiest way to obtain water for temporary water supply. For summer residents who need exclusively technical water and only in the summer.

In water supply networks, air accumulations disrupt the constancy and uniformity of fluid (water) flow, and can also cause accelerated corrosion of pipelines and fittings. Therefore, it is very important to combat the formation of air locks and bubbles. In pressure systems, such gas either comes out of the water itself or is introduced from the atmosphere when the circuit is not completely sealed.

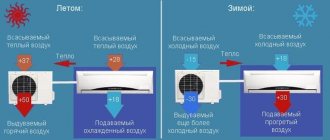

A correctly calculated project and its competent execution completely eliminate air suction, and also do not give it a chance to accumulate in specific, permanent places (bends, turns or kinks in pipelines). As for the liquid itself, for every ton of resource there are about 30 grams of air mixture. Accordingly, the air in the water supply system is released more actively, the lower the pressure and the higher the temperature.

How to prevent air from forming in the heating system

Even at the design stage of the heating system, it is necessary to install all the elements in such a way as to ensure the free, unhindered “circulation” of the air that is formed when the coolant is heated.

All closed systems must be equipped with air vents.

Air and sludge separator Honeywell HF49.

In closed heating systems, air separators can be used, which allow you to completely clean the coolant, both from dissolved air and from air in the form of small and large bubbles. The design of the separator allows you to retain and remove air particles.

How to get rid of an air lock

Unfortunately, the air lock is not always in an easily accessible place. If there are design or installation errors, air can accumulate in the pipes. It is very difficult to get him out of there. First we determine the location of the plug. In the area of the plug, the pipes are cold and a babbling sound can be heard. If there are no obvious signs, they check the pipes by sound - tapping on the pipes. In a place where air accumulates, the sound will be louder and louder.

Any air lock found must be removed. If we are talking about the heating system of a private house, this is done by raising the temperature and/or pressure. Let's start with pressure. Open the nearest drain valve (in the direction of flow of the coolant) and the make-up tap. Water begins to flow into the system, increasing the pressure. It forces the traffic jam to move forward. When air gets to the bleeder, it comes out. Stop feeding after all the air has escaped - the drain valve stops hissing.

This is a security group. An automatic air vent is installed at the middle outlet

Not all air locks give up so easily. For particularly stubborn ones, it is necessary to simultaneously raise the temperature and pressure. These parameters are brought to values close to maximum. You cannot exceed them - it is too dangerous. If the plug does not go away after this, you can try to open the drain valve (to drain the system) and the make-up valve at the same time. Maybe this way it will be possible to move the air lock or get rid of it altogether.

If a similar problem occurs constantly in one place, there is an error in the design or wiring. In order not to suffer every heating season, a valve is installed in the problem area to remove air. You can cut a tee into the main line and install an air vent at the free entrance. In this case, the problem will be solved simply.

The main causes of air jams

The appearance of bubbles in the water supply lines is associated with an internal physical and chemical reaction or penetration from the outside. In the first case, gas escapes from the water flow itself, because approximately 30 grams of air are dissolved in 1000 liters of water. The release of a gaseous substance occurs faster if the liquid flows slowly and if it is heated. It is for this reason that voids and cavities occur much more often in hot water pipes. In the second case, air from the external environment leaks into the main networks.

The main reasons for the appearance of air from outside in the water supply system of a private home:

- when the liquid level decreases, air can be sucked in through the non-return valve;

- the fitting elements with rubber sealing parts are poorly covered, depressurization occurs at the joints;

- the air in the water supply lines was not removed from the first start-up of the system.

In vertically directed pipes, air rises upward or is absorbed throughout the cavity. In horizontal ones, it accumulates in the highest places, which is unfavorable for the entire system.

The destruction of air bubbles occurs at a flow speed of a quarter of a meter per second. If it is smaller, the traffic jams may remain in one place for a long time.

Technical means of protection

The system must be maximally protected from rash human actions, improper operation and untimely and incomplete maintenance. To achieve this, there are a number of technical solutions to minimize the consequences of fluid pressure surges in water supply and heating networks and prevent their occurrence.

Pipe replacement

To do this, it is necessary to inspect the entire pipeline; old steel pipes should be replaced with modern ones made of polymer materials. They are more reliable, practically resistant to corrosion and last longer. In this case, pipes must be selected taking into account operating conditions (pressure and temperature in the network) with a small margin in parameters. To reduce the flow rate, it is advisable to choose products with the maximum possible diameter for the pressure. Find a middle ground.

Modern reliable pipes and connecting elements made of polymer materialsSource santehnika-nk.ru

Replacing shut-off valves

Replacing ball valves with valve valves can be called a return to the past, but this will avoid sudden pressure changes regardless of how the shut-off valves open and close. It is not necessary to change all locking devices; you can limit yourself to only those that are critical to the system.

Installation of shock-absorbing elements

The use of reinforced plastic or rubber inserts that can stretch or compress during pressure surges will reduce the deforming effects on the remaining parts of the pipeline. The walls of shock absorbers, unlike rigid pipes, do not deform when compressed or expanded and return to their original state, taking the bulk of the impact of the liquid upon themselves. For most systems, a section of 20 to 40 centimeters is sufficient.

Application of compensators

Compensators are cylindrical containers (an inverted glass) inside which there is a spring. One end of it rests against the upper fixed part of the inverted “glass”, and the lower end rests against a movable plastic disk. When the pressure in the system increases, the water presses on the disk, compressing the spring; when it decreases, the elastic force of the spring compensates for the loss of pressure.

Local water hammer compensator (mechanical) for water supply systemsSource gothac.rickyhil.com

Compensating protection against water hammer in the water supply system is also carried out using hydraulic accumulators. This device is a tank of a certain volume divided into two parts (with water and air) by a rubber membrane. In case of excess pressure, it will be released into the tank due to stretching of the rubber membrane and reducing the volume of air inside the tank.

Using pumps with frequency converters

Such pumping equipment, due to automation, allows for smooth starting and stopping of working parts. This makes it possible to avoid a rapid increase in pressure, which causes water hammer. The frequency converter regulates and sets the number of rotations of the pump wheel per unit time by changing the frequency of the alternating current received from the electrical network. The adjustment is carried out automatically depending on the values of the parameters transmitted by the sensors.

Safety valves

The operating principle of these devices is quite simple. When pressure values at the valve installation points reach values above critical parameters, the valves open and liquid is discharged.

Main safety valve for relieving pressure at critical values Source ultra-term.ru

They can be standalone devices whose opening occurs due to the operation of mechanisms or electronic sensors, or be part of a system consisting of many sensors and valves controlled by a computer.

Why does air appear in the water supply?

There are two reasons for the appearance of air in the water supply system of a home:

- Outside . Air enters the pipes through leaky connections;

- From the inside . Approximately 30 grams of air per 1 ton of water is dissolved in the water flow passing through the pipes. Gradually the air is released. The slower the water flows and the hotter it is, the faster the process goes. That is, in hot water supply systems the likelihood of air locks occurring is higher.

Air appears in the water supply systems of private houses for the following reasons:

- when the water level drops, air can be sucked in through the check valve;

- fittings with rubber seals are not tightened well;

- in hot water supply systems, a process of cavitation is observed: steam is formed, air bubbles collect in the water, forming voids or cavities;

- air in the water supply pipes remained from the first start-up of the equipment.

Air bubbles contain 30% more oxygen than atmospheric air. This explains the high oxidizing capacity of air in hot water supply systems. Air bubbles can be of various shapes: spherical - small, no more than 1 millimeter in diameter, mushroom-shaped, oval.

In vertical pipes, bubbles rush upward or are distributed throughout the volume. In horizontal highways they stop at the highest points where they carry out destructive work.

When the water speed in the pipes is more than 0.5 meters per second, the bubbles move without stopping. When the speed exceeds 1 meter per second, the bubbles break into very small bubbles. It turns out like an emulsion of water and air. Air bubbles in the water supply system of a private house begin to collapse at a fluid speed of 0.25 meters per second. If it is lower, traffic jams may stagnate in some places for quite a long time.

Video description

For an example of protective equipment for damping water hammer in a water supply system, see the video:

Pressure surges or water hammer are a dangerous phenomenon inherently associated with the operation of plumbing or heating systems. Their number and negative impact can be minimized using preventive measures and technical solutions. In order to comprehensively solve this problem, to prevent as much as possible the risks of danger to people and material damage, it is better to turn to professionals.

How to eliminate water hammer

To prevent water hammer from occurring in heating pipes and water supply systems, several methods are used.

Smoothly close the tap

If the valve moves slowly, then it is permissible to move it in small jerks.

The impact occurs, but is broken into several weak ones. Which has no consequences.

Depreciation

Mechanical shut-off can be done safely, but systems equipped with automation (heating) do not have this.

To soften the impact, a shock absorption device is installed in the line. A piece of elastic pipeline (reinforced plastic or rubber resistant to high temperatures) is installed in front of the thermostat.

Due to stretching, during a pressure surge, the pipe temporarily increases and relieves pressure.

0.2-0.3 m is a sufficient length of shock absorption.

Bypass surgery

This is a manual modification of the thermal valve.

A tube with a diameter of 0.2-0.4 mm is inserted into the valve in the direction of travel. It does not affect the performance of the system, but if there is a pressure surge it can transfer it over the valve into the pipeline.

For your information

The method is productive only in a new system and not made of metal. The presence of corrosion is all gone.

Compensators

The lower part contains liquid, the upper part contains air under pressure. A similar system is installed on automatic pumps to regulate pressure.

In a heating system, the compressor is installed at a weak point where shock is possible. When there is a pressure surge, the water presses on the membrane and displaces it towards the air, as a result the pressure is extinguished.

When the pressure returns to normal, the water hammer stops and the membrane returns to its original place.

Special dampers are also used in the water main.

Safety valves

In the old days, the patient's blood pressure was lowered by bloodletting. The operation of the safety valve is similar.

Installation takes place in potentially hazardous locations. They work autonomously or from a controller.

When the pressure increases, the valve releases water; of course, the liquid is discharged in permissible places.

After the pressure returns to normal, the tap closes.

Automatic adjustment

Turning pumping equipment off and on is an “excellent” provocateur of water hammer.

The pump creates pressure, which is directly related to the rotation speed. Acceleration occurs at lightning speed. Forced slowing down of the process of increasing speed in the pump stops the occurrence of water hammer.

It will not be possible to regulate the speed; it is possible to change the frequency, which will give the required result.

This function is performed by the UUE (electric motor control device), frequency converters and soft starters. Water hammers disappear when installing the UUE.

Pursuing this goal, a pressure sensor is connected to the converter; it will change the pump rotation speed depending on the specified indicators. As a bonus, energy savings occur.

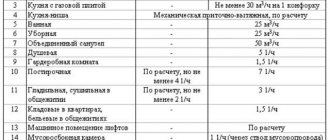

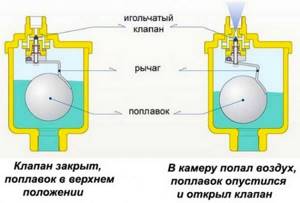

Automatic air vents

Devices for removing air from water supply systems are widely available on the market. Float valves are permanent air vents

. They protect the operating system from the accumulation of air and gases. When the system pressure drops to atmospheric pressure, the float valve allows air into the pipes. To eliminate the cause of air in the water supply system of the house, a check valve is additionally installed. There are models of air vents already equipped with a check valve.

Starting air vents

used to remove air when filling the system with water or to start air during drainage work.

Combined action air vents

have the properties of both previously described devices.

When choosing an air vent, the volume of air released is taken into account. This indicator can be found in the characteristics of the device. You should not select a more powerful automatic air vent. Working half-heartedly, it will wear out faster.

For the correct operation of the air vent, the operating pressure in the water supply and the quality of the liquid are important. If the resource density is below 960 kilograms per cubic meter, specially designed floats are installed.

Video clip about the simplest air vent - the Mayevsky valve:

Manual and automatic air vents

How to remove air from a water supply system after it has been reset? The most logical solution is to bleed the air through an air vent installed directly on the jumper between the risers.

There you can find an air vent belonging to one of two types:

| Image | Description |

Mayevsky brass tap | Manual (Mayevsky faucet) - a plug with a screw-in valve using a key or a screwdriver. To eliminate air from the hot water supply system, just unscrew the valve a couple of turns, wait until the air coming out of the hole on the tap is replaced by water, and screw the valve back on. Sometimes you have to bleed the air two or three times as the water displaces new air bubbles into the upper part of the circuit. |

Automatic air vent device | An automatic air vent for water supply does the same without the intervention of the owner. When its chamber is filled with air, the float connected to the spool lowers - after which the water pressure displaces the air plug. The floating float hermetically closes the spool. |

The photo shows a brass water tap that can successfully replace the Mayevsky tap

The obvious advantage of the Mayevsky crane is its low cost. That is why, in Soviet-built houses, exclusively manual air vents were used.

However, from the point of view of ease of use, they are much inferior to automatic air vents:

- Some residents of the upper floors are simply afraid to use shut-off valves that are unfamiliar to them;

- Keys to Mayevsky taps with valves of complex shapes are constantly lost;

Key to Mayevsky's tap

Manifestations of excessive enthusiasm by residents, coupled with technical illiteracy, often lead to flooding of apartments. The fact is that a completely unscrewed valve (and even more so the tap itself) is almost impossible to screw in under pressure. Especially when scalding hot water is gushing out of the hole.

Enthusiasm + illiteracy = accident

How to get rid of air in pipes

If there is already air in the water supply system of a private house, but it is not equipped with bleeders, you must:

- Turn off the pumping station.

- Open all drain taps and release water and air from the water supply system. After which the pipes are filled again.

You can remove air from the water supply system once and for all using bleed or drain devices:

- mechanical valves such as the Mayevsky valve;

- automatic air vents;

- ball valves;

- valves

Mechanical air release valve device

from the water supply system is as follows: a cylindrical box, closed with a lid at the top, and a thread at the bottom for connecting to the water supply. There is a threaded plug in the middle of the lid. A plastic float in the shape of a ball is suspended inside the cylinder. If there is no air in the hot water supply system, the ball rises to the hole in the plug and closes it tightly under network pressure. As soon as air enters the device, the ball moves away and the air is released. Air can enter the system through the bleeders, which is useful when repairing or inspecting networks and speeds up the drainage of water.

Air removal devices are installed in certain places in the water supply system: at the very top ends, at bends or bends. That is, where there is an increased likelihood of air accumulation.

Homemade air accumulator

In rural water pipes, air often flows mixed with water. Using such a water supply is difficult and inconvenient, and the automation does not always cope: if there is a lot of air, the water overflows like a fountain directly from the valve. Therefore, instead of an automatic air bleeder, an air accumulator

. You can make it yourself; it is a tank with an outlet pipe and a tap. The diameter of the storage tank must be 5 times larger than the diameter of the water pipe, then it can work effectively.

The air accumulator is installed at the highest point of the water supply system, where it is convenient to bleed air manually. Air storage tanks are widely used in multi-storey buildings in hot water supply systems.

Danger of air bubbles in the pipeline

Water hammer can rupture a pipe

Bubbles, especially large ones, can destroy even strong elements of the highway. The main troubles they cause to owners of private houses:

- They accumulate in the same areas, leading to breakdowns of pipe sections and adapters. They also pose a risk for turning and twisting pipe sections where air is trapped.

- They break the water flow, which is inconvenient for the user. The taps “spit out” water all the time and vibrate.

- Causes water hammer.

Water hammer leads to the formation of longitudinal cracks, which causes the pipes to gradually collapse. As time passes, the pipe breaks at the point of cracking and the system stops functioning.

Therefore, it is important to equip additional elements that allow you to quickly get rid of dangerous bubbles

Air lock is the cause of stagnation of drains

An air lock formed in the sewer system of a house can also disable the operation of the sewer collector. The air that has stopped in the system simply prevents the drains from leaving through the riser and either returns them back or passes them through, but very slowly and at the same time throws sharp unpleasant odors into the room.

The reasons for the formation of an air lock in the sewer can be as follows:

- Mistakes made when installing a plastic manifold (insufficient tightness of the pipeline, lack of connecting fittings, etc.);

- Excessive manifold turns, incorrect pipeline drops or incorrectly selected elbow angles;

- Lack of a water seal in the installed sewage system;

- Possible blockage or icing of the drain pipe in the attic or roof area.

Ways to get rid of air

An air lock in the heating system will not become a constant companion of the heating season if the design and installation of all its elements were carried out correctly, and the circuit was regularly cleaned and correctly filled. But the question of how to remove an air lock from a heating system never loses its relevance. The procedure is determined by the features of a particular design. There are two types of structures based on the nature of coolant circulation:

- with natural movement;

- with forced movement.

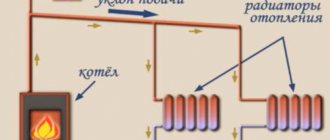

If natural circulation of the coolant is assumed in the circuit, then the expansion tank, which is installed at the highest point of the system, will allow the air present to be expelled. The installation of pipelines and batteries is carried out so that the line through which the coolant is supplied rises vertically into the tank.

If forced circulation is assumed in the circuit, then the method of removing air will be different. An open type tank is installed in the same way at the top point, a closed type is placed directly in front of the boiler on the return pipe. The main line responsible for supplying the coolant is made without a slope, since the pump is responsible for circulation. It is better to remove the resulting plug with two people, so that one person monitors the pressure level.

Additionally, devices are installed to eliminate air jams. The following devices are provided to help get rid of a number of problems:

- automatic air vents installed at pipeline bends and at the highest points of the circuit;

- Mayevsky taps installed directly on radiators;

- air separators used in large systems.

How to get rid of air in a water supply

If air bubbles are interfering with the operation of the pipeline, but the bleeder elements have not yet been installed, turn off the pumping station that pumps water from the well. Then open all the drain taps and drain the water along with the bubbles from the network. After this, connect the pressure equipment and let the water flow.

Bleeding and draining devices will help you get rid of air locks in the water supply of a private house forever:

- mechanical valves, such as Mayevsky's device;

- ball valves and valves;

- automatic air vents.

You have to bleed air using shut-off valves manually, which is quite labor-intensive. Therefore, it is better to choose alternative options.

Mechanical valve

The device is not complicated, but the device is able to quickly and effectively rid the line of bubbles. The operating principle of a mechanical valve is as follows:

- A hollow cylinder with a lid, in which a threaded plug is mounted, is connected to the water supply with a threaded connection.

- A plastic float ball is suspended inside the cylindrical box. When there is only water in the pipeline, the float rises to the plug hole and, thanks to the pressure of the water flow, tightly blocks it.

- As soon as air leaks into the device, the ball goes down and releases the air plug.

Devices capable of removing air are installed in the highest, turning and curved places of the highway - where there is a high risk of air accumulations.

Automatic air vent

There are three types of automatic machines for removing air from water supply networks:

- float valves;

- starting devices;

- combined type devices.

When choosing a diverter, they look at the volume of potential plugs, operating pressure in the network and water quality indicators. These data can be found in the technical manual of the device. You should not take a machine with maximum power. When working at a minimum, it is more likely to wear out.

Homemade air accumulator

Automatic devices do not always cope with air removal in country houses. Usually there are a lot of air bubbles in such lines, and water gushes out of the valve device.

Instead of an automatic air vent, a storage tank is installed, which is a tank with a tube and a tap.

You can build the device yourself. For effective operation, the cross-section of the air accumulator must be five times larger than that of the pipeline. The storage tank is installed at the highest point of the aquifer.

When installing water supply networks in a country cottage, it is important to provide for the installation of air elimination devices. They protect the operating system from water hammer and rapid destruction.

Fixing the problem

You can solve the air lock problem yourself. The main thing is to identify the reason for its formation.

- First, it is worth inspecting the pipeline along its entire length for cracks or depressurization (provided that the sewerage system has a water seal). If any are found, it is worth replacing the collector section with a whole one. In this case, the air will freely flow into the drain pipe during a volley discharge of water into the system. That is, the water seal cover will close when the pressure in the pipeline increases and thereby prevent stagnation of water.

- If an air lock is observed in the area of a specific plumbing fixture, then perhaps the slope of the pipes towards the riser was not observed during installation. To do this, you need to reposition the pipeline section to create the required slope or, if possible, raise the plumbing fixture to create the optimal level of slope for the drains.

- If the sewerage system basically does not have a drain pipe, then it will have to be installed with the installation of water seals near each plumbing fixture.

And always remember that if you are not confident in your abilities and think that you are prone to make mistakes when installing sewerage in your home, it is better to use the services of professionals. The craftsmen will create a reliable drainage system with a properly functioning drain pipe,

Most often, clogged sewer systems occur in old houses, and the reasons for this phenomenon can be completely different.

For example, due to the owner’s negligence, a rag or some hard object may get stuck in the system. Over time, the diameter of the pipe narrows as fat deposits form on its walls. Therefore, a minor blockage can cause a big problem.

Depending on the nature of the problem, there are several solutions that can be used to effectively clean the sewer with your own hands without calling a professional

Therefore, a minor blockage can cause a big problem. Depending on the nature of the problem, there are several solutions that can be used to effectively clean the sewer with your own hands without calling a professional.

Mayevsky crane

Design of the Mayevsky crane

It is designed to eliminate air lock in the heating battery. Despite its small size, the Mayevsky faucet helps to effectively remove accumulated steam not only in radiators, but also in pipes.

Structurally, it is a needle valve enclosed in a metal housing. How to remove an air lock from a heating system using it? First you need to decide on the device model.

Manual taps

After installation in the upper radiator pipe, air is released after turning the union nut on the tap. Removing an air lock from the heating system using a Mayevsky manual tap is carried out according to the following scheme:

- Filling the system with coolant. The taps on the radiators are closed;

- When the maximum level is reached, the water supply stops;

- Having set the required gap of the needle limiter in the devices, the taps are opened;

- At the same time, the coolant supply is restored.

Water is added to the system until liquid begins to flow from all Mayevsky taps. Be sure to check that there is no air flow. This method is effective for removing air locks in heating radiators when starting the system for the first time, before the season, or when airiness appears during operation.

Manual models will effectively eliminate air lock in the radiator for both autonomous and central heating. The main thing is to choose the right mounting thread. In most cases it is 1/2", but there are models with a non-standard size of 3/4".

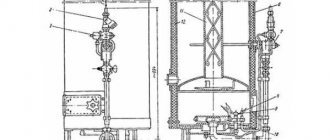

Automatic taps

Mayevsky automatic crane

Unlike the model described above, in their design, a seat with a certain surface area is installed on the end of the needle valve. In combination with a return spring, the degree of pressure of which determines the critical pressure value at which the valve opens. A detailed device is designed to automatically break through a heating plug when a critical temperature value and, as a result, pressure is exceeded.

However, before installation you should familiarize yourself with the specifics of this model:

- To prevent water from getting onto the floor, the structure must have a pipe to drain excess water into the sewer;

- If it sits for a long time, the valve seat may become covered with limescale, which will make it difficult to open. Therefore, it is recommended to open the tap manually once every 2-3 months. The steps of the procedure must be done before starting the heating for the first time;

- The set maximum opening pressure should not exceed the critical pressure of the entire system. In order to remove an air lock from the heating in automatic mode, the pressure value on the tap should be 5-10% less than the maximum.

What is better to install: an automatic or manual Mayevsky crane? If the operation of the system does not involve sudden pressure surges, manual models can be installed on the radiators. For autonomous heating, preference is given to automatic ones.

It is best to choose models made of brass. During the expulsion of an air lock from the heating, they can withstand not only a critical pressure value, but also a temperature. The steel body is subject to destruction and rusting.

HOW TO REMOVE AIR FROM A WELL

The method of effectively removing air from an autonomous water supply system depends on what exactly caused this phenomenon. If the reason lies in contamination of the bottom of the water intake, which disrupts the normal operation of the pumping equipment, it is enough to simply clean the hydraulic structure using one of the most suitable methods. Despite the fact that there are many cleaning methods, the most popular today are: electrohydropulse well cleaning, as well as well cleaning using the airlift method. They have a similar operating principle, but differ in the equipment used in their work. Among other effective cleaning methods, several other types of flushing of an autonomous water intake can be noted.

Gelonding

Cleaning water wells using a bailer is preferably used for water intakes whose depth does not exceed 12-15 meters, since due to its design features, a device with a bailer will not be able to cover a larger range. This is justified by the fact that the bailer itself is a piece of steel pipe up to two meters long. The lower part of this pipe is equipped with teeth and a special ball valve or flap, between which a spring is located. Due to the relatively large weight of the cylinder, which traps dirt, it is lifted using a simple but reliable structure - a tripod made of steel pipes or a wooden beam.

The principle of this well cleaning method is that the bailer, while immersed in the casing, enters a formation with mud deposits, after which a flap or valve opens at the bottom of the pipe to capture silt or sand. When the bailer begins to rise, the valve closes and the trapped dirt remains inside the pipe. The bailer is immersed inside the water intake until the amount of dirt raised to the surface becomes minimal. At the end, the hydraulic installation is washed with a large amount of water to completely clean the bottom and water intake filters. In addition to the minimum operating radius, the disadvantage of this cleaning method is the risk of damaging the mesh filter.

Cleaning with a vibration pump

There are several options for performing this manipulation - with one pump or with two. If the depth of the hydraulic installation is relatively small, up to ten meters, then one pump for flushing the well of silt and sand will cope with the task, but for sources deeper than ten meters it is necessary to use two devices.

In the first case, the removal of blockages in wells is carried out with a standard household vibration pump, which is lowered several times to the bottom of the hydraulic installation to agitate the mud sediments. Remove dirt by immersing the pump in a container of clean water, after which it is turned on.

Removing contamination from a deeper water intake using two pumps involves using one device to supply dirty water and a second to pump it out. The water supply pump must be self-priming, and pumping requires a powerful deep-well pump. The equipment must be turned on sequentially: initially, the liquid is pumped out by one device, and then supplied to the surface by the second. It is imperative to attach a special weight to the end of the hose for supplying water to the surface to prevent uncontrolled lifting of this hose during cleaning.

Other methods of cleaning water wells

If the first two methods of cleaning wells are popular due to their versatility and ease of execution, then the remaining methods are used much less frequently, since they are not suitable for all types of autonomous water intakes. In any case, for high-quality and reliable operation of an independent water supply system, it is necessary to periodically carry out its maintenance and preventive repairs.

Prices for well cleaning in the Moscow region

How much does it cost to clean a well at a dacha in the Moscow region?

Why does the well run out of water?

Well cleaning in the Lyubertsy district of the Moscow region

Prices for cleaning water wells of various depths

Water well cleaning in Voskresensk

Well cleaning in the Klin region

Why does water come out of a well in spurts?

Well cleaning in Zaraysk

Well cleaning in Balashikha

Well cleaning in the Voskresensky district

Why is there no water coming from the well?

What to do if there is bad water coming from the well

Why does dirty water come from a well?

What to do if the water in the well disappears

Well cleaning in Krasnoznamensk

How to increase water pressure from a well

Well cleaning in Dolgoprudny

Well cleaning in the Leninsky district

Well cleaning in the Pavlovo-Posad district of the Moscow region

Is it possible to restore an old well in a country house?

Well cleaning in Shcherbinka

Well cleaning in Protvino

Restoration of wells when flow rate decreases

Ways to solve the problem

In order to prevent the heating system from becoming airy, it should be properly designed and installed, periodically cleaned and filled with coolant without undue haste. Let's consider the main ways to help avoid such negative manifestations.

Correct installation

In heating systems in which the coolant circulates naturally, with the upper type of wiring, air is removed through the cover of the expansion tank. When installing such a system, the supply line is installed so that it approaches the tank vertically.

The tank, which provides free space for the expansion of the heated coolant, must be installed at the top point of the entire system to ensure the natural flow of liquid into the system circuit.

The return line is also installed with a slope along which the liquid moves freely.

Correct installation will help prevent air from entering the heating system.

If the installation of the heating system is carried out without errors, then the air appearing inside the circuit will be gradually squeezed out by the hot liquid to the top point, leaving the pipes through the open cover of the expansion tank.

Installation of air vents

How to promptly remove air accumulated in the heating system?

An open expansion tank must be installed in the upper part of the heating system, and a hermetically sealed one must be placed in the place where the return flow enters the boiler (before the pipe enters).

In such a system, supply pipes can be mounted without tilting, and the coolant will move under the influence of a circulation pump. In addition, other devices are installed through which air is discharged.

Air can be vented from the heating system itself through special air vents operating in automatic mode, installed on the rotating sections of pipes and at the highest point of the system. The plugs are removed from the radiators using a Mayevsky tap. Using the same principle, air is removed from the circuit through which water circulates naturally, but in this case, lower pipe routing must be done.

If everything is installed correctly, then there will be no problems with how to expel air from the heating system. It is enough to open the necessary taps, and as soon as the air leaves the system, close them again. Air vents operating in automatic mode do not need to be opened at all - their operating principle is based on changes in pressure.

If a closed heating system is installed, an automatic air vent must be installed in it. They are installed along the contour in certain places so that air pockets are removed locally. The idea is that each part of the heating system circuit must have the ability to vent air. An example of this is Mayevsky taps, which are installed on all radiators. Open them with a key or a screwdriver, allowing air to escape from the system. The procedure is quite simple, but with its help you can distribute the coolant evenly throughout the radiator.

An air vent can solve the problem with air in the heating system

To extend the operational life of the automatic air vent, it is necessary to install good filters and regularly flush the system.

Coolant heating

Sometimes, in order to remove excess air naturally, the coolant is simply heated strongly. An increase in temperature stimulates the release of air and its movement along the system circuit. It is allowed to heat the liquid in the pipes up to one hundred degrees.

If after such an operation air pockets appear again, it is necessary to check all connecting areas for leaks. Almost always, near the place where the air jam forms, there is a small gap from which water oozes out in small drops and into which air gradually penetrates. By sealing such a gap, you will immediately get rid of the annoying problem.

Radiators made of aluminum material are considered the most vulnerable places through which air passes. When an alloy is exposed to hot water, corrosion processes develop, accompanied by gas emissions.

If such radiators often become airy, it is recommended to simply replace them.

Other reasons for the appearance of air bubbles in the well and ways to eliminate them

When using a well to pump out small volumes of water or seasonal operation of the structure, several possible causes and ways to eliminate them are possible. So, why does the pump pump not only water, but also air:

Suction of air mass in the suction section. In this case, water and air flow for a long time, but the problem can only be “cured” by completely replacing the pipeline and all related elements. You can check by removing the pipeline from the well and pumping water, for example, in the bathroom. Low filling of the aquifer with large pumping. Reducing volumes or drilling a new well would be the best solution

It is only important not to break through to the old thin aquifer, so as not to get water again with air from the well. Pump failure when the gland seal is weak, as a result of which air bubbles end up in the discharge chamber and water flows with the air. You will have to disassemble the device yourself or it’s easier to take it to a repair shop.

Hydraulic systems are similar to electric systems - the laws are the same. Understanding the problem of why a pumping station pumps air is sometimes only possible with a series of technical measures. And if the proposed options for identifying the problem and eliminating deficiencies did not help and the water also comes with air, it is better to contact the professionals who service the pumps. The cost of the service starts from $50, but you will be freed from the problem and will be able to find out exactly why your pump does not pump water as you would like.

In water supply networks, air accumulations disrupt the constancy and uniformity of fluid (water) flow, and can also cause accelerated corrosion of pipelines and fittings

Therefore, it is very important to combat the formation of air locks and bubbles. In pressure systems, such gas either comes out of the water itself or is introduced from the atmosphere when the circuit is not completely sealed

A correctly calculated project and its competent execution completely eliminate air suction, and also do not give it a chance to accumulate in specific, permanent places (bends, turns or kinks in pipelines). As for the liquid itself, for every ton of resource there are about 30 grams of air mixture. Accordingly, the air in the water supply system is released more actively, the lower the pressure and the higher the temperature.

MAIN REASONS FOR THE APPEARANCE OF AIR IN A WELL

Air in the water supply system from a well is a fairly serious problem that can lead to irreversible consequences if it is not eliminated in a timely manner. First of all, this phenomenon will cause everyday discomfort to the owner of the hydraulic structure and all residents, since the water from the well will flow in spurts, which, alas, will lead to serious breakdowns of household appliances and a significant deterioration in the quality of liquid from a private water intake.

It is noteworthy that the appearance of air in an autonomous water supply system is considered a very common phenomenon, especially if the hydraulic structure was recently equipped. That is why most owners of independent water intakes, when faced with this phenomenon for the first time, do not attach much importance to it, since they consider the problem to be insignificant. However, if measures are not taken promptly to eliminate the existing problem, not only household appliances may break down, but also the pumping equipment inside the hydraulic installation. And, as you know, major repairs of water wells today are not cheap.

Therefore, if you notice the first signs of air in the autonomous water supply system, you should immediately contact a specialist. Contact the professionals! Employees will not only be able to efficiently and quickly restore and repair a water well, but will also understand the cause of air intake. In addition, prices for well cleaning in the Moscow region are the lowest in the Moscow region.

The appearance of air in the autonomous water supply system occurs due to the following factors:

- severe drying out of the bottom of the autonomous water intake;

- the appearance of voltage surges during operation of pumping equipment;

- destabilization of pressure inside the autonomous water supply system;

- significant changes in the degree of humidity inside a hydraulic structure.

It is worth noting that when the pump is started, an uneven descent of liquid occurs in the water intake due to destabilization of the balance between the arrival and pumping of water from the source. The water stops only when these parameters stabilize. If this balance decreases, air appears in the liquid, since the flow of water itself simply cannot suddenly and sharply disappear. It is precisely because of the large capture by the pump, which cannot satisfy the small balance of water inside the water intake, that airing of the water occurs. Teleinspection of a water well using specialized modern equipment will help to establish the cause of air in the autonomous water supply system as quickly and accurately as possible.

Cavitation as a cause

Before you start clarifying the issue, it is important to know: pumps are installed depending on the diameter of the well! For sizes of 100 mm, a submersible pump is suitable; smaller diameters require a circular or plunger pump. What is cavitation? This is a violation of the continuity of liquid flow, otherwise it is the filling of water with bubbles

Cavitation occurs in those areas where the pressure drop reaches a critical level. The process is accompanied by the formation of voids in the flow, the release of air bubbles that appear as a result of vapors and gases released from the liquid. Being in an area of reduced pressure, bubbles can increase and collect into large empty cavities, which are carried away by the flow of liquid and, in the presence of high pressure, are destroyed without a trace, and in the conditions of an ordinary domestic well, they often remain and it turns out that the pump pumps air bubbles from the wells not producing the required volume of water

What is cavitation? This is a violation of the continuity of the fluid flow, otherwise it is the filling of water with bubbles. Cavitation occurs in those areas where the pressure drop reaches a critical level. The process is accompanied by the formation of voids in the flow, the release of air bubbles that appear as a result of vapors and gases released from the liquid. Being in an area of reduced pressure, bubbles can increase and collect into large empty cavities, which are carried away by the flow of liquid and, in the presence of high pressure, are destroyed without a trace, and in the conditions of an ordinary domestic well, they often remain and it turns out that the pump pumps air bubbles from the wells without producing the required volume of water.

Identifying a cavitation zone is sometimes impossible due to the lack of special instruments, but it is important to know that such a zone may be unstable. If the deficiency is not eliminated, the consequences can be devastating: vibration, dynamic effects on the flow - all this leads to breakdown of the pumps, because each device is characterized by a specified value of the cavitation reserve

Otherwise, the pump has a minimum pressure within which water entering the device retains its density properties. When pressure changes, cavities and air voids are inevitable. Therefore, the selection of a pump should be carried out depending on the volume of water needed to meet economic and domestic needs.

Types of sewer clogs

If the sewer system in a house is operated in violation of all the rules for its use, then over time, blockages and plugs inevitably appear in the collector, which impede or completely stop the flow of wastewater. As a result, either someone from an apartment building or the owners of a private building will suffer from at least an unpleasant odor in the living space. The maximum possible flooding of the kitchen or bathroom with fecal water. This is not very pleasant, so to avoid such situations you need to use the collector correctly, namely:

- It is strictly forbidden to flush used personal hygiene items, such as pads, diapers, tampons, etc., down the toilet. Only flushing toilet paper is allowed.

- It is prohibited to flush bulk construction mixtures such as cement, sand, chalk, clay, etc. down the drain.

- Accidental flushing of rags and other similar items down the drain should be avoided.

- It is advisable to install grease traps in the kitchen, which will prevent the deposition of heavy greasy deposits on the walls of the collector. This, in turn, can create fecal growths-stalactites in the system and impede the flow of gray water.

It is always worth remembering that a traffic jam can form either in a specific place in the sewer system in an apartment or in a private house, or at any point in the central riser. If the last option is checked, then the drains will have nowhere to go but to return back from the blockage under the influence of hydraulic force. As a result, fecal or gray water will try to escape through the unoccupied openings of the bathtub, sink, and other plumbing fixtures.