Have you installed a ventilation system, but you still can’t breathe in the house, and it’s also damp? This means it’s time to think about how to get rid of condensation in the ventilation pipe and prevent its formation in the future. Agree, it is better to solve the problem immediately than to endure discomfort for a long time.

We will tell you what to do so that you don’t have to spend money on replacing ventilation pipes and fighting mold in living rooms. From our article you will learn how best to prevent and eliminate condensation. Our recommendations will help independent home craftsmen.

What is condensation and what harm does it cause?

Air masses contain water in a vapor state. When cooled, the steam transforms into liquid water and settles on the internal surfaces of the air ducts in the form of droplets, which can flow down to form streams and puddles.

Reasons for condensation formation:

- errors in the design and installation of the ventilation system;

- increased humidity in the premises;

- proximity to bodies of water;

- large temperature difference between inside and outside the house.

Not only puddles on the floor should be of concern, but also rust on pipes, decreased flow of fresh air, and accumulation of moisture in walls and ceilings through which air ducts are laid.

Condensation in the ventilation system leads to increased air humidity in the house itself, with effects such as fogging of windows

Condensation is a source of dampness in the house. It serves as a breeding ground for the development of mold and other microorganisms that negatively affect human health. Metal air ducts are destroyed by ventilation condensation. Even concrete walls can “feel” the harmful effects of high humidity.

Conducting a test

How do you know if your exhaust pipe is working properly? Can we hope that she will save her household from troubles? It's simple, do the following test. Close windows and doors tightly. “Arm yourself” with toilet paper, you will need a small piece. Bring the paper close to the hood. Observe what happens to the leaf. He fell? This means the system has failed.

In apartment buildings, this test can also be used to check ventilation communications. It happens that the paper flies off the grid with force during the test. This means the following: it is not fresh air that enters your apartment, but exhaust air from your neighbors.

Removing condensate outside the ventilation ducts

Condensate collection in vertical and inclined sections of air ducts is carried out in their lower part. On horizontal air ducts, condensate collection can be organized almost anywhere, except for areas laid in the walls.

A tee socket is installed in the ventilation pipe so that the outlet is directed downwards. The outlet is equipped with a special container - a condensate collector.

You can find various types of condensate collectors for ventilation on the open market. They differ in design and materials of manufacture. They can be transparent, which makes it easier to control the filling, but are more often made of stainless or galvanized steel.

When filled with condensate, containers with a screw-on lid are emptied manually, which is not always convenient. Moreover, at an outside air temperature of -20º C and below, condensation forms especially abundantly and the container is filled in a short period of time.

Before installing a container for collecting condensate, determine the lowest point in the air duct system, but if they are horizontal, installation of the condensate collector is possible in almost any convenient place

In this case, a conical condensate collector-watering can would be a good option. It is easy to attach a hose to it and drain the condensate into the sewer. If it is necessary to organize liquid drainage in a hard-to-reach place, a model with a watering can is also used.

When organizing the collection and removal of condensate, the configuration of the ventilation system is taken into account. With multiple turns of pipes, you will have to install not one, but several condensate collectors.

Sorbents - moisture-retaining substances - also help to collect and remove condensation. They have the form of cassettes and are installed in the filtration section of the supply air duct. Periodically, the sorbent must be removed for drying, after which it is again ready for use.

Removing condensate is considered a temporary measure, primarily due to the possibility of ice jams forming in winter. Insulation of veterinary ducts helps to radically solve the problem.

Basic troubleshooting methods

Insufficient traction

The following signs (one or more) may indicate a malfunction in the air exchange:

- the room smells of dampness, rot or diaper rash;

- on the windowsill, walls, in crevices, mold begins to actively multiply, fungus is visible, which concentrates both in open areas and in hard-to-reach places (under the baseboard, behind cabinets, carpets and peeled wallpaper);

- condensation is visible on the surface of the walls, wallpaper and even on furniture;

- the rooms are constantly cool, damp and musty feel;

- the supply of oxygen ceases to be replenished, which is expressed in rapid breathing of residents and a desire to go outside;

- extraneous sounds are heard in the ventilation system in the form of hum, noise, creaking;

- There is a burning smell coming from the air duct.

The premises are usually made as airtight as possible. The natural ventilation system works through cracks in doors and windows. Decorative grilles are used to cover large gaps. If the exhaust hood is difficult, which is forcibly installed in the bathroom, kitchen, or toilet, the reasons may be corrosion in the system and compromised integrity of parts.

To eliminate the problem, you need to replace damaged soft inserts and wafer seals. In this case, it may be necessary to replace air duct elements with visible defects. To achieve tight connections, they need to be adjusted.

Attention The problem may be increased resistance of the branch channels. Contaminants can accumulate in the air duct, causing filters to be ineffective

Maximum cleaning of the ventilation duct from debris will be required. It needs to be dried well and washed from dirt. Sometimes it's better to replace it with a new one.

Noise

Loud noise from the ventilation duct is evidence of clogged valves. There may be other reasons for increased noise:

- Small insects, rodents and even birds can enter the pipeline. The problem is solved by installing a protective mesh on the outlet pipes. It is secured with self-tapping screws.

- Noise can occur due to insufficient lubrication of moving parts of the equipment and, finally, due to strong wind. At least 4 times a month you need to remove the grill and lubricate the moving parts with a special lubricant.

- To get rid of wind noise, you can wrap the pipe with soundproofing material. You should choose a reliable one that is not affected by temperatures and moisture. In addition, you can install several silencers that will absorb extraneous sounds.

The noise can be mechanical or aerodynamic. The first appears due to poor depreciation, unsatisfactory condition of components, friction and violation of balancing parameters. The second is as a result of the operation of electric motors and fans (read about how to repair a kitchen hood motor with your own hands here). The following actions will help reduce noise:

- install the fan on special vibration-isolating bases;

- balance rotating elements and parts;

- firmly fix movable valves, gate valves and clamps;

- install a removable soundproof casing;

- You can insert tarpaulin pads or rubber ties between the duct and the fan;

- Lining the internal surfaces of air ducts with durable materials that absorb sound (mineral felt, fiberglass) will also help;

- You can lubricate the moving parts of the compressor.

Tip An effective way to dampen vibrations is to install a concrete frame around the roof duct. If technical reasons do not allow such an operation to be performed, the channel is wrapped with insulation.

Filter system

Filters can constantly become clogged with dust, small debris and kitchen grease.

It is important to carry out routine cleaning every 4-6 months. If the filter system is completely clogged and prevents the air duct system from functioning normally, then you need to perform the following actions:

- prepare a stable stepladder, table or chair and put on protective gloves;

- Having removed all the ventilation grilles, they need to be thoroughly cleaned and washed with detergent;

- when parts are worn out, which will be visible at first glance, they are replaced with new, higher quality ones;

- use a spatula to clean the inner walls of various types of settled dirt;

- you need to act very carefully so as not to damage the surface of the protective mesh.

The deep channel needs to be cleaned well. To do this, use a long stick with a hard base wound around its end, preferably a damp terry cloth. You need to move inward gradually, with rotational movements. At the end of the work, a final draft check is made with a sheet of paper or an anemometer.

Here

Requirements for thermal insulation materials

To insulate air ducts in a ventilation system, materials with the following properties are required:

- low thermal conductivity;

- vapor tightness;

- fire resistance;

- noise absorption capacity;

- biostability.

Thermal conductivity coefficient is the most important parameter of a thermal insulation material.

Even with proper installation of all elements of the ventilation system, condensate removal is not always effective, since it may freeze and form an ice plug.

The second most important indicator is vapor permeability. Many materials used for ventilation insulation have the ability to release moisture accumulated underneath them when the voltage limit for them is exceeded.

By filling the pores of the material, moisture increases its thermal conductivity, thereby reducing the effectiveness of insulation. To prevent this from happening, a waterproofing coating is mounted on top of the heat insulator - a membrane that can allow steam to pass out, blocking its access inside.

Fire resistance determines how fireproof the insulation will be. There are 6 fire resistance classes in total.

For air ducts, zero class insulation is required, that is, it has the highest fire resistance, and therefore the most fireproof. With multi-layer thermal insulation and a number of additional conditions are met, the use of materials of the first fire resistance class is allowed

As the air flows through the ducts, it creates noise. In forced ventilation systems, the operating fan also makes noise and vibrates. To prevent noise and vibrations from being transmitted through rigid structures and spreading throughout residential premises, damping devices and gaskets are used.

But most heat-insulating materials also have sound-proofing properties and, in addition to their main function, help protect the house from unpleasant acoustic effects.

Mineral wool is one of the most popular thermal insulation materials in low-rise construction and is also used for insulation of air ducts

The materials used should not be a favorable environment for the life of insects, molds, rotting bacteria and other harmful microorganisms.

Penetrating through air ducts into living spaces, they can cause diseases and also damage the material itself, which may require its premature replacement. There are microorganisms whose waste products are so aggressive that they can burn through steel sheets 1.5 mm thick.

The materials used in the installation of ventilation communications must comply with sanitary and hygienic standards. The insulation should not emit substances hazardous to humans and the environment. Environmental friendliness means the absence of a threat of contamination of the natural environment during disposal.

How to block the smell from neighbors?

The appearance of an unpleasant odor from the air exchange system can be due to various reasons. Professionals recommend finding out and eliminating them, rather than dealing with the consequences. For example, when a hood is installed near the entrance to a room, moist air is blocked. As a result, unpleasant odors and mold may appear.

When figuring out how to quickly stop the smell from the ventilation system, it is important to understand that the measures must be comprehensive, otherwise you will soon have to deal with the problem again

No. 1 - installation of a supply valve

After installing plastic windows, the natural flow of air into the apartment is practically excluded. As a result, the rate of gas exchange sharply decreases, waste products are not removed, and the microclimate in the apartment worsens. Installing a supply valve on a window or wall will help partially solve the problem.

The user can choose the simplest device or purchase an automatic system. It will not only provide air supply to the room, but also heat it up. If there is a supply valve, you will not need to open the windows every day. In this case, the amount of air entering the room will be quite sufficient.

Installing a supply valve will be a simple solution that will provide sufficient flow of fresh air into the apartment and help solve the problem associated with a decrease in the rate of gas exchange

A wide variety of models and a flexible pricing policy will help you choose a supply valve that meets the customer’s needs and budget.

No. 2 - installing a fan in the bathroom

The smell from the bathroom ventilation is easily eliminated after installing an exhaust fan.

Manufacturers offer three device options:

- centrifugal;

- axial;

- centrifugal-axial.

Fans have design features and differ in power. Their installation is relevant when the dimensions of the ventilation pipe exceed 3 meters.

Installing a fan will speed up air exchange, solve the problem of high humidity after bathing, and also eliminate unpleasant odors

When choosing a suitable model, you should not settle for overly powerful options. At a high intensity of air intake, a rarefaction effect may occur, which negatively affects health

Acceptable thermal insulation options

Many mineral fiber materials, hydrocarbon polymers, and foam elastomers meet the above requirements, including:

- mineral wool;

- polyvinyl chloride;

- expanded polystyrene;

- polyurethane.

Foam elastomers are produced by extrusion and vulcanization. They have a porous structure, and the pores are vesicular, that is, closed, which reduces moisture absorption and makes them vapor-tight. By polymerizing hydrocarbons, insulation materials such as polyurethane and polyvinyl chloride are obtained.

Thermal insulators are supplied for sale in the form of rolls, sheets (mats), hollow cylinders (shells). Rolled materials and shells are suitable for thermal insulation of pipes and round air ducts. Rectangular air ducts can be insulated with sheet material.

The air duct is insulated in all areas located in unheated rooms and ventilation ducts passing through walls, ceilings and roofs require special attention

Sheet and roll insulation is highly flexible, it is easy to give it the required shape, one side can be smooth. Thanks to the combination of these properties, the installation of thermal insulation is greatly facilitated. Many materials are not only fire-resistant, but also self-extinguishing, which increases fire safety.

Insulation is selected taking into account the environmental conditions in which it will be used, including operating temperature. For central Russia, materials that can withstand ambient temperatures in the range from -30° C to 60° C are suitable for insulating ventilation systems.

Polyethylene (PE) film and polyvinyl chloride (PVC) membrane are used as waterproofing protection. From external damage, insulated ventilation ducts are covered with boxes lined with boards, plywood or aluminum sheets.

Expert advice

What should I do to prevent condensation from occurring?

Experts in this field give some useful advice:

- when installing horizontal sections, it is necessary to observe the slope of the air ducts towards the street, otherwise water collects there and flows into the room;

- be sure to install a condensate drain;

- the upper end of the ventilation pipe must be protected by a visor or deflector;

- it is necessary to insulate all sections of ventilation ducts passing through unheated rooms and the street, as well as the additional devices and accessories included in them.

Features of insulating the air duct from the inside

It is necessary to insulate all air ducts located outside heated rooms, including areas in the walls. It is possible to insulate both external and internal surfaces of air ducts.

If insulation is carried out from the inside, already at the design stage it is envisaged to increase the cross-section of the air duct in accordance with the thickness of the heat-insulating layer. Otherwise, its throughput will decrease.

Mineral wool fibers are strengthened using adhesives. This is necessary to prevent the fibers from peeling off under the influence of a stream of air. The adhesive used for this purpose should not affect the level of fire resistance of the insulation and its environmental friendliness.

In order not to reduce the aeration properties of the ventilation duct, it is better to carry out insulation from the inside according to the “pipe-in-pipe” scheme. This is how sandwich pipes for chimneys are made. If you don’t have the time or desire to make them yourself, you can buy them ready-made

Thermal insulation laid on the inside should not increase aerodynamic resistance, slowing down the movement of air masses. That is, it is necessary to make its surface smooth.

Due to the additional requirements for internal thermal insulation, its use is often impractical. Including if it is necessary to insulate an already built ventilation system with a given cross-section of air ducts. In such cases, the air ducts are insulated from the outside.

Possible reasons

Water does not form in canals just like that. There are always some reasons for this. Let's first briefly list them:

- poor insulation of ventilation pipes;

- system malfunction;

- leakage of pipes;

- The humidity level in the house is too high.

Let's take it in order. As for poor insulation, there is such a thing as dew point. Roughly speaking, this is where warm and cold air meet. The first, naturally, is drawn out of the room, and it usually has a fairly high level of humidity. The second one is outside. When they come into contact, the moisture contained in the warm air falls out in the form of sediment.

Actually, you can observe the same phenomenon when you go out into the yard early in the morning - the grass at this time is covered with tiny spots of moisture, that is, dew. It looks beautiful and is extremely beneficial for the plants. But when it comes to pipes, everything is not so rosy, as was already mentioned above.

As for the malfunction of the system, most often we are talking about clogged channels. Various debris sometimes accumulates in them - for example, bird's nests, leaves, and the like. As a result, cravings are disrupted and the consequences are unpredictable. These include the formation of condensation.

Violation of the tightness of the pipes leads to the same problems with performance, and to improper air circulation - in general, this is understandable. As with excessively high humidity. If water-saturated air does not leave quickly enough, moisture can settle on the inner surface of the channels.

The reasons have been sorted out. Any of them can become a reason for the formation of condensation, and even more so in their combination. For example, if hot and very humid air constantly enters the duct, and it is cold outside, and the pipes are not equipped with insulation, then it may simply leak from the ventilation. Let's now look at how to prevent such effects from occurring.

The procedure for installing thermal insulation outside

The most economical thermal insulation material for a private home is time-tested mineral wool. It comes in rolls of various widths and can have one or two outer foil layers.

Thermal insulation material is installed on the ventilation pipe with an overlap so that there are no unprotected areas left; the joints at the top are taped

When determining the thickness of the heat-insulating layer, they are guided by SNiP 2.04.14–88. Heating engineers perform complex calculations taking into account the diameters of the pipes and the thermal conductivity coefficient of the heat-insulating material used.

They take into account the average annual air temperature and even possible heat loss through joints and fastenings, as well as other parameters, most of which can be found in reference books and the above-mentioned SNiP.

If we talk specifically about mineral wool, then when insulating ventilation systems in private houses located in central Russia, roll material 100 mm thick is usually used. You can buy mineral wool 50 mm thick and wrap the pipe twice.

To determine the required width of the insulation, measure the diameter of the pipe and add the thickness of the mineral wool multiplied by two to the resulting value. Multiply the resulting amount by 3.14 (Pi).

When starting work, prepare in advance a rubber spatula, a construction knife, a stapler, aluminum tape 7-8 cm wide, a marker and measuring tools - a square, a ruler and a tape measure (preferably metal). Be sure to wear protective clothing.

To work outdoors, choose a day without precipitation. Otherwise, the mineral wool may get wet. The roll is unrolled, marked and cut to obtain the required size. The foil is separated along the edge so that the pipe can be wrapped with mineral wool overlapping and the connecting seam can be covered with a foil layer.

In hard-to-reach places, a modern type of heat insulator is used - the so-called shell, which must be selected taking into account the outer diameter of the pipe

Then the connecting seam is fixed in increments of 10 cm using a stapler and taped along its entire length. To fix the insulation to the pipe, both special fasteners and ordinary wire are used.

To protect the joints of the air ducts, the insulation is cut into fragments of the appropriate shape and size. Don’t forget to clean the pipe of any dirt before insulating it.

Insulation can also be done using segmental insulation. The monolithic casing has the shape of a pipe and is threaded onto the air duct. It is used mainly during the installation of a ventilation system from scratch.

Having measured the geometric parameters of the air duct, select a casing that is suitable in size and stretch it along the entire length of the pipe. Foil is wound over the top and secured with stainless steel or copper clamps.

The collapsible shell consists of two half-cylinders, which are applied to the pipe on both sides and fixed. In areas running through the wall, it is difficult to wrap the pipe in roll insulation, but putting on the shell is much easier. The collapsible shell can be placed on an existing air duct.

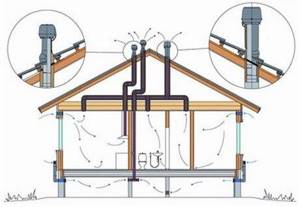

Fighting condensation using an example

Let's consider a specific situation. A one-story private house has a ventilation system that provides air exchange in the bathroom and kitchen. Metal ventilation pipes are connected to these rooms.

They are laid through the attic with subsequent access to the roof. With daily temperature fluctuations, condensation forms in the pipes. But a particularly large amount of it is observed in winter, when water drips from the hood, collecting in a puddle.

Attics are usually not heated, so ventilation pipes laid in this room need to be insulated along their entire length

The problem is solved comprehensively. The exhaust and supply pipes are insulated. The pipes are insulated from the entrance to the ceiling to the exit to the outside. In areas passing through an unheated attic, pipes are insulated with rolled mineral wool 70-100 mm thick.

A shell is used in places where it passes through the ceiling and ceiling. A tee with a condenser collector is installed at the lowest point.

If the ventilation ducts do not pass through the roof, but through the wall, the section in the wall is insulated using the shell. Outside the house, a 90-degree tee is installed on the ventilation pipe, a condensate collector and an umbrella (deflector) are mounted.

How everything works

As a rule, the installation of an exhaust pipe in a private house, as well as a ventilation system, is planned at the design stage of the building. Meanwhile, if you find that in the purchased house not everything is in order with such communications, there is no need to panic - everything can be corrected. To make the picture in your head complete, let's get acquainted with all types of air exchange present in the house.

So, systems of this type are:

- natural;

- supply;

- supply and exhaust.

In current buildings, replete with plastic windows, doors and artificial materials, unfortunately, natural ventilation works poorly. Plastic blocks air circulation. In addition, the lack of temperature changes also reduces the effectiveness of natural ventilation, this is especially noticeable in the summer. Meanwhile, in multi-apartment buildings, natural ventilation works better, but we are talking about mansions, and we will return to them.

In houses with an area not exceeding 300 m², it is sufficient to install an air supply system; for owners of large mansions, there is only one solution - to install a supply and exhaust system. Communications should not only remove air, but also pump it in.

The exhaust pipe on the roof becomes visible, while its lower part may be hidden from view, although it is invariably present in the kitchen, boiler room, and possibly in other rooms. By the way, you can easily learn to distinguish between these structures, because the height of the chimney exhaust pipe above the roof is always less than that of its “sister” ventilation pipe. There is a rule: the shorter the chimney ventilation pipe, the less condensate accumulates in the structure. Although, of course, this reason for the appearance of “poisonous” drops is not the only one.

Construction of a new ventilation system

Due to errors in design and installation, if low-quality pipes are used, all measures to combat condensate may be in vain.

In this case, it is economically feasible to shut down the old one and install a new ventilation system that would cope with its functions of removing contaminated air and supplying fresh air masses.

Design is carried out only after analysis of air exchange processes and calculations in accordance with the standards specified in SNiP, based on the characteristics of the ventilated premises and the number of residents. It may be necessary to abandon natural ventilation in favor of forced ventilation by changing the configuration of ventilation ducts and installing equipment for heating the supply air.

The appearance of moisture in double-circuit boilers

In addition to the chimney, condensation can occur in the water pipes of 2-circuit gas boilers. It's all about the temperature difference, due to which the pipe can rust and fail.

The problem may occur for one of the following reasons:

- Ventilation is not working correctly (the exhaust power is insufficient).

- The climate in the room is unfavorable - the humidity level is consistently exceeded.

- The equipment operates in an incorrect (erroneously calculated) mode.

Unfortunately, the features of the boiler do not allow you to completely get rid of condensate, but insulating the pipes and insulating the chimney can reduce the rate of moisture accumulation.