How to cover a roof with waterproofing yourself? The question is quite appropriate given the widespread popularity that this modern material has recently gained. Combining high water-repellent ability with reliability and durability, waterproofing has taken its rightful place in the construction of structures for a wide variety of purposes, incl. to protect the roofs of residential buildings. Ease of installation makes it possible to do all the work yourself, which significantly reduces overall costs.

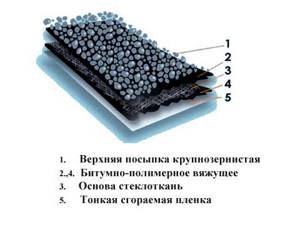

Structure of waterproofing agent.

Features of the material

Gidroizol is a roofing material based on fiberglass with waterproofing made of asbestos paper impregnated with petroleum bitumen and a protective coating.

Fiberglass fabric (marked as T) or fiberglass (X) can be used as a base. The base is covered on both sides with a film impregnated with bitumen with the addition of a plasticizer.

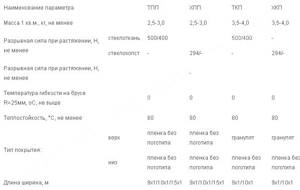

Characteristics of waterproofing agent.

Then protective layers are made both from the outside and from the inside. The protective layers are formed from a polymer film (designation - P), and the top layer in contact with the external environment is most often made in the form of a mineral coarse-grained powder (K).

The roof is covered with waterproofing using the following grades of material:

- TKP: fiberglass with a bottom polymer film and top mineral powder - for the outer covering of the roof.

- TPP: fiberglass fabric coated on both sides with a polymer protective film - for internal waterproofing and roof insulation.

- HKP and HPP: analogues of TKP and TPP, but with a fiberglass base.

Waterproofing is available in the form of rolls 95 cm wide. The total length per roll is 10 and 20 m. When arranging a roof, such material can serve as the main roof covering or be used as an additional waterproofing and thermal insulation layer under the outer roof covering (slate, tiles, etc.) .d.). It is most widespread as the main roofing covering of a flat roof.

Main properties and advantages of the material

First of all, waterproofing is a material that protects roofs from moisture; this is one of the most important aspects for a roof to serve for decades.

Hydroisol is a material that consists of fiberglass or fiberglass. Therefore, it is not characterized by such troubles as rotting and decomposition.

More often it is a roll-type material, with a polymer-bitumen composition applied on both sides. This makes it quite flexible and not susceptible to cracking.

There are varieties of waterproofing in which paper or cardboard is used as a basis. Sometimes liquid waterproofing is used; it is produced in the form of bitumen mastic.

As a rule, it is used to prevent corrosion of building structures.

It adheres to the roof surface by melting the lower part of the material or using mastic.

In addition to roof insulation, it is also often used when laying foundations, walls in basements, various ceilings, in swimming pools and pipelines.

Depending on the purpose, it can be divided into two types: roofing and waterproofing.

The main advantages of waterproofing include:

- simple installation and operation;

- flexibility;

- waterproof;

- durability.

Hydroisol can be used on the following types of surfaces:

- concrete;

- wooden;

- roofing;

- metal, etc.

Video:

Material specifications:

- When tensioned, the force at which rupture occurs can range from 37 to 60 kgf;

- One hundred percent hydrophobic;

- Elasticity;

- The brittleness temperature of the top layer material is 15 degrees;

- It is able to withstand temperatures of +85 degrees for two hours;

- The minimum service life is 15 years.

The characteristics of liquid waterproofing are slightly different:

- Withstands temperatures up to 100 degrees;

- Hygroscopicity is 0.2%;

- Dry residue - 65%;

- Dries completely from 15 hours to two days;

- Density is 0.9 g/cm³;

- Can serve for more than 30 years.

- Quite often, waterproofing agent, which is used for roofing work, is called hydrostekloizol.

Tools required for working with waterproofing:

- construction hair dryer;

- gas-burner;

- blowtorch.

The choice of waterproofing as a roofing material will be fully justified, since this material has a lot of positive qualities and can serve you for decades.

The price of waterproofing varies from 400 to 700 rubles per roll. The cost of the material depends on the thickness and length of the roll.

The width is usually the same, but sometimes varies slightly. But the thickness and length already depend on the type of waterproofing and the purposes for which it is intended.

What determines the choice of material?

Thanks to its multilayer structure, the material has a number of undeniable advantages. The fiberglass base provides mechanical strength and durability. Bituminous layers guarantee high waterproofing ability, and the addition of plasticizers helps provide the necessary flexibility to the material.

The protective polymer layer protects the bitumen composition from destruction under the influence of various temperatures and creates an important property - resistance to aggressive environments.

The mastic must be applied to a dry, clean and grease-free surface.

To protect the waterproofing material from external influences, a coarse-grained mineral powder is provided, which is highly resistant to all atmospheric manifestations: solar ultraviolet radiation, air pollution, precipitation, frost, etc.

As a result of such design features, waterproofing has the following advantages: it is considered excellent waterproofing at temperatures from minus 50 to plus 50 degrees, sudden temperature changes, and heavy precipitation of any type. At the same time, it has good elasticity, strength and durability (guaranteed service life of more than 15 years), and is resistant to cracking, rotting and decomposition. Manufacturing the material in roll form simplifies the installation process. In addition, waterproofing can be used as additional insulation. Such a roof can be laid both in hot summer and in winter.

The use of waterproofing in roofing work

The use of roll waterproofing for roofing has long been traditional. Today, both modern PVC-based fabrics and older bitumen-based materials, such as roofing felt, are used as a water-protective layer.

Waterproofing is one of the types of waterproofing that allows you to create a durable and at the same time effective water-repellent layer on various types of roofs. However, you should know for which types of roofs the material is suitable, as well as in the situations of recommended use. And when choosing a waterproofing agent, you need to focus on the brands of rolls.

Preparatory stage

Before starting work, it is necessary to take careful measurements and determine the required roofing area, and also take into account the following features:

- type of installation (external or internal);

- number of layers of installation (1 or 2);

- type of roof (concrete surface, wood flooring, etc.).

Most often, waterproofing is applied to a concrete base. When purchasing material, it is necessary to ensure correct storage conditions: rolls should be placed under a canopy in a vertical position.

Preparing the roof surface includes a number of necessary measures. First of all, it is thoroughly cleaned of debris and dust. All defective areas (cracks, dents, chips, delaminations, etc.) are eliminated on the surface intended for coating.

Depending on the type of roofing material, the appropriate methods are used: putty, putty, gluing. After eliminating the defects, it is advisable to carry out an important operation - a thin primer using a special liquid primer composition (primer) or bitumen brought to a liquid state with gasoline. This type of priming is usually done with a paint roller.

Areas of use ↑

Despite the universal capabilities for laying and fastening to various types of material, the main area of application of waterproofing is the protection of concrete bases from moisture.

As a result, such roll waterproofing is used on flat types of roofs, most often not in use.

If you use this material on slopes collected from wood. Then you first need to assemble a continuous sheathing from OSB boards or boards. In the latter option, the gaps between the lumber should not exceed 10 mm!

For waterproofing coatings of foundations, separate brands of waterproofing agent are used!

Laying waterproofing

There are three ways to lay waterproofing on a leveled and prepared roof surface: mechanically, hot, or using mastic. The simplest method of installation is considered to be mechanical, which does not require additional operations. The roll simply rolls out over the surface. The tape is laid with an overlap of about 14-16 cm. The layout of the material begins from the lower edge of the roof and rises up along one line parallel to the side cut of the roof. This method can be used on a flat roof or a roof with a slight slope. After installation is completed, it is advisable to coat the seams between the strips with mastic, varnish or bitumen.

Hot styling. The hot method of laying waterproofing is more labor-intensive, but provides increased reliability. Work on implementing this method is carried out by two people, as it requires simultaneous heating of the tape and its layout. The main essence of hot technology is to heat the lower bitumen layer, which ensures its adhesion to the primer layer on the roofing surface.

With the hot installation method, the waterproofing material will need to be heated using a burner.

Work is carried out in a certain order. The roll layout starts from the bottom edge of the roof. As it unwinds, the inner layer of waterproofing is heated using a gas torch or blowtorch. The melted layer of material is pressed against the roofing primer layer. Gradually, by unwinding the roll and heating the tape, the material is laid over the entire roof.

The tape is laid with an overlap of about 9-12 cm. To make a roofing covering of increased reliability, a second layer of waterproofing can be applied. In this case, the second layer can be laid using the described mechanical technology. In the process of implementing the hot technique, it is necessary to control the duration of heating - excessive heating, which can damage the base and outer layer, should not be allowed.

The temperature effect should ensure only surface melting of the lower bitumen layer. In addition, it should be borne in mind that waterproofing is a flammable material and can ignite when exposed to an open flame.

The most expensive, but at the same time the most reliable method is to apply waterproofing tape to the mastic.

This technique can even be used on a pitched roof. The essence of the technology is to apply a layer of mastic to the roof surface, on top of which a waterproofing layer is laid. The work is carried out in the following order: a special ready-made mastic is applied to the roof surface in a strip slightly wider than the width of the roll. The roll, starting from the bottom edge of the roof, is laid out on top of the mastic and compressed using a weighted roller. The strips are applied with an overlap of 8-12 cm. The main advantage of this technology is the absence of an open flame.

Advantages of using the material in construction ↑

All types of waterproofing are universal; in addition to roofing coatings, they can be used for anti-corrosion and moisture-proof effects when arranging:

- swimming pools;

- pipes;

- foundations;

- walls;

- floors;

- basements.

Important! Waterproofing based on bitumen mastic has proven itself well when working with various types of building materials: metal, concrete, wood.

Roofing with waterproofing

Covering the roof with waterproofing is very beneficial from a technical and financial point of view. Based on the technical characteristics, as well as practical experience in using such material, we can draw the following conclusions:

- Flexibility and elasticity make it easy to equip any building structures, even complex configurations and large sizes, with a high degree of tightness.

- These same properties, combined with strength, make it possible to smooth out surface unevenness and remove defects without laborious preparatory work.

- The simplicity of the installation technology and the ability to choose a more acceptable method of roofing ensures strict adherence to the allocated budget and time for construction.

- Temperature operational capabilities eliminate restrictions on the choice of season and time of laying the material - construction and repair work can be carried out even in winter, when the temperature is below zero.

- During long-term operation, inexpensive local repairs of the coating with your own hands are possible, without the involvement of professional specialists and the use of expensive equipment and tools.

- When installed on roofs, waterproofing provides a sound-proofing effect, which makes it possible to save on additional consumables and reduce discomfort during operation of the entire building.

High quality insulation

Necessary tool

When covering a roof with waterproofing yourself, you will need the following tool:

- knife;

- scissors;

- gas burner or blowtorch;

- weighted roller;

- paint roller;

- putty knife;

- paint brush;

- roulette;

- metal ruler.

Gidroizol is a modern, reliable material that can provide roof waterproofing on structures for various purposes. It is highly technological, which makes it easy to install with your own hands.

Methods for laying insulation depending on the type of material ↑

Depending on whether you prefer waterproofing based on bitumen mastic or roll coating, the installation methods will also differ.

Option 1: coating technology ↑

This method is suitable if you used a bitumen-based waterproofing system to install the roof. The method of using the liquid product is extremely simple - the solution is applied evenly in several layers.

For convenience, based on the expected processing area, use:

- paint roller;

- brush;

- special equipment that sprays the solution.

To get a high-quality result, before applying liquid waterproofing, familiarize yourself with the following features of the process:

- The solution is sold in ready-to-use form. The only thing that needs to be done immediately before application is to thoroughly mix the mixture directly into the storage container.

- To increase adhesion, a primer is applied as the first layer. You can buy it separately or prepare it yourself, as indicated above, from the same product.

- Each layer is dried for at least two hours. Optimally, wait 5-10 hours.

Option 2: self-adhesive roll material ↑

To lay rolled hydroisolas with an adhesive layer, no auxiliary solutions or devices are required, except for a roller. When working, the following sequence of actions is maintained:

- Immediately before laying the material, the protective polymer film is removed from the inside.

- The strips are laid overlapping with a gap of up to 10 cm.

- The roller presses the material tightly against the base of the roof.

- A technical pause is waited for final setting.

Important! To ensure that the installation of roll insulation is carried out correctly and reliably, it is necessary to carry out work only in sunny, warm weather. Under the influence of ultraviolet rays, the adhesive mass on the inside of the material will melt naturally, providing high-quality adhesion.

Option 3: fastening without full fixation ↑

This technology is the simplest when laying roll coverings. All roofing work with this approach takes a minimum of time.

Important! Roll covering can also be laid in several layers. The determining factor in this case, according to current building codes, is the angle of inclination of the roof slopes.

The rules here are:

- 2 layers – for a tilt of more than 15°;

- 3 layers – if the slope corresponds to 5-15°;

- more than 3 layers - for a flat roof with an angle of 0-5°.

The work algorithm looks like this:

- Strips of material are laid with an overlap of 8-15 cm.

- The joints are coated with cold bitumen mastic and pressed tightly to the base for reliable fixation.

This technology for laying waterproofing on the roof will be beneficial and safe when finishing a pitched roof with a slight angle of inclination.

Option 4: installation with full fixation ↑

The essence of this method is the same as in the previous technology. The only difference is that not only the seams and joints are coated with bitumen mastic, but also the entire surface under the roll roofing. The process will take a little longer, but there are no complications or additional costs.

Due to the complete fixation of the canvas on the roof surface, a more reliable result and absolute tightness of the structure are obtained. As a result, the service life of the entire building in general and the roof in particular will be much longer.

To further improve the quality characteristics of the finished coating, you can use hot applied mastic. But we must take into account the working scope of the solution after heating in order to use it on time. Accordingly, the pace of installation must be appropriate.

Option 5: insulation with preheating ↑

The most complex and unsafe technology, but the only correct option for installing waterproofing on the roof if you need to perform work in the cold season or get a perfectly high-quality result.

A hair dryer or gas burner is used as an auxiliary heating tool.

- One master sequentially very carefully rolls out the rolled covering over the surface and, after laying it, presses it to the surface with a special stick.

- The second, simultaneously with rolling out the canvas, warms up its inner surface with the available tool.

Important! It is necessary to carry out installation in this way as carefully and carefully as possible, since the material based on petroleum products is flammable. The main task is to achieve rapid melting of the adhesive mass, to properly seal the strips on the roof and at the same time to prevent fire.

As you have already seen, neither the application, nor the cost of waterproofing, nor its characteristics raise doubts about the advisability of using such a coating for roofing. Choose the right material, using professional advice from the store’s specialists, and you will definitely be able to create a reliable roof that will serve as excellent protection for your home for a long time.

Waterproofing metal roofing

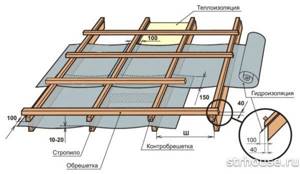

Waterproofing the roof of a house under metal tiles deserves special attention, since during its operation the humidity and temperature of the under-roof space are of great importance. The insulation film used for metal tile roofs is a reinforced woven lattice made of polyethylene fiber, covered on both sides with polyethylene film. Thus, the material has strength as well as excellent waterproofing characteristics. It is not cheap, but at the same time it is able to ensure the long-term performance of the roofing functions.

Waterproofing a metal tile roof is carried out so that fresh air has the opportunity to move from the eaves to the ridge, and then exit through the ventilation holes. Before laying waterproofing on the roof, a gap of 4-5 cm should be created between it and the insulation to ensure ventilation, for which it is necessary to fill the rafters with bars of the appropriate cross-section. The same gap must be provided between the tiles and the waterproofing material, which is also achieved by using bars.

A ventilation gap of 5 cm is required along the ridge, and the lower edge of the waterproofing must reach the gutter so that moisture can easily flow into the drainage system. The only material that is laid directly on the insulation is a superdiffusion membrane.

It is important to understand that the correct choice and subsequent installation of waterproofing will bring no less benefit than the roofing material itself, providing the roof and the entire house with effective protection and durability.

Source

Purpose of base waterproofing

Reasons for protecting the foundation:

- Moisture accumulates in the upper layers of the earth. Penetration into the foundation has a destructive effect. There is pressure on the base. This poses a great danger to the structure;

- the occurrence of groundwater in a separate area may be close to the surface of the earth. Excess water negatively affects the foundation of the house;

- water in the soil may contain harmful substances. The latter, as a destroyer, will contribute to the destruction of the foundation from the inside.

Price

The price of waterproofing depends on the specific type and footage. The price range starts from 300 to 1000 rubles. Compared to other materials, it is inexpensive, so it is important to use it for work on large volumes.

It is necessary to read the instructions, where you can find out the heating temperature, installation features, and manufacturer’s recommendations. This applies to both rolled materials and mastic, which is sold in liquid form.

Whatever price you are offered for the material, know that you will need the help of a qualified specialist. You can do the installation yourself, but you need to read reviews and chat on forums about installing waterproofing. It is necessary to prime the surface, including cleaning it from dust and foreign debris, of which a lot accumulates on flat roofs.

Advantages and disadvantages

As for the advantages, the following advantages can be highlighted:

- The structure of the material does not contain organic elements. This means that using waterproofing on the surface, or burying it along with the pipeline and metal structural elements, foundation and other elements underground, it will not rot. Thus, you will be protected from destruction for 10-20 years, so you will not have to remove it for further replacement.

- Unlike other materials with similar waterproofing criteria, waterproofing is distinguished by its affordable price. This allows it to be used in large volumes. At the same time, at a low cost per square meter, you guarantee complete tightness when making roll joints or using mastic. It is important to follow the technological process, including the use of the correct auxiliary elements, including heating and other nuances.

- The advantages include high mechanical resistance. That is, your material will have high tensile strength, including protection from external loads on the roof. But, this only applies to those rolls that are sprinkled with fine-grained crumbs. It also protects from solar radiation, as well as from rain and other weather conditions. It is important that the waterproofing material does not burn, so if during a fire the fire begins to move towards the roofing material, you will have time to call the fire brigade, since the flame will not move intensively.

- Advantages include the ability to resist high and low temperatures. For example, on a roof, bitumen waterproofing faces critically high temperatures because it is black and heats up beyond normal. As for working underground, it often freezes here. The material tolerates temperature changes well, if the installation technology is followed, it is not destroyed even by wind, and is noise-free, which allows you to live in the house comfortably. By using waterproofing in your roof structure, you can reduce noise levels from rain and other weather conditions.

- Rolls weigh little and take up little space. This allows you to buy them individually or in large quantities. For transportation, you can use your own car, placing several rolls in the trunk, or using a trailer. This will additionally save money on transportation. To work on the roofing surface, you will need a heating burner, which also takes up a lot of space. You can transport waterproofing along with the necessary work equipment.

- Installation does not take much time. Working on a flat surface, you do not need permission to work at heights, and you do not need specialized tools. Two people are needed as one will roll and hold, the other will heat the surface until optimal adhesion is achieved.

As you can see, hydroisol is a full-fledged leader in insulation based on bituminous material. It is resistant to light, does not absorb water, does not rot, does not harbor insects, and does not mold. Thus, the waterproofing will last a long time, since there is no need to change it, because it does not collapse, and the material itself is non-toxic.

Types of waterproofing colors

There are practically no disadvantages. It is easy to process, since it can be cut to the required sizes even with a knife, but more often it is made with nylon threads. Detailed cutting technology is used to work with roofing felt. As for the disadvantages, this includes the cost being slightly higher than the cost of roofing felt, but the latter does not have such high-quality waterproofing properties.

Another disadvantage is the need to overlap one sheet with another, which leads to costs due to loss of area. An overlap of 15 cm is often made. The scope of application here is not limited, although statistics show the use of waterproofing specifically in roofing work.

On the other hand, if such waterproofing is used, it is for a horizontal surface. Before laying waterproofing, it is necessary to clean the surface from dirt; it is recommended to prime the base, which will increase adhesion.

One of the disadvantages is the delicate storage conditions. For example, it is recommended to store waterproofing only in a vertical position. For this purpose, special pallets should be used. It is important to match the stored grades of material.

The premises must be closed. It is not recommended to buy rolls and store them in the sun, as this may lead to increased work time. It is better to buy waterproofing from fresh batches to prevent damage to the material during storage.

Waterproofing the foundation with waterproofing

The material has a black tint, so if you use it outside somewhere, then do not forget about it and decode it on any possible surfaces. Wear gloves as you can cut yourself on the edges. In addition, the material itself is sticky, making it difficult to wash your hands later.

How to properly lay waterproofing on a roof

Installation of roof waterproofing is carried out along the rafter structures from the outside. Rolls of material are rolled out, starting from the bottom of the roof, across the rafters, fixed with a construction stapler. The next layer of insulation is laid with an overlap of about 10-15 cm over the previous one, after which the joint is taped. With this layout and overlaps, moisture will not be able to seep between the layers of material, but will flow down the roof into the drainage system.

When installing roof waterproofing, there is no need to stretch the film; it should be installed with a slight sag between the rafters, which subsequently compensates for the “play” of the rafter system, and also prevents it from breaking when the size decreases in the cold season.

It is important to consider that it also matters which side the waterproofing is placed on the roof, because it retains moisture in only one direction. For this reason, the material should be laid on the rafters with the side on which there are no inscriptions or in accordance with the instructions described in the instructions. Otherwise, moisture falling on the waterproofing material will freely reach the insulation.

One of the most important parameters of the film is vapor permeability. If the roof is planned to be insulated, a conventional waterproofing film will not be suitable for the work, since the insulation will not last long when used. For a warm roof, it is necessary for steam to escape outside without receiving resistance from the film, which is why a vapor-permeable material is used. Read about proper roof vapor barrier in the article “Installation of roof vapor barrier - why vapor barrier is needed and installation instructions”