All detached houses must have heating; gas, solid or liquid fuel boilers are installed in them. Such units provide for the presence of chimney pipes to remove fuel combustion products. Boilers can only operate when there is sufficient draft to supply fresh air and remove combustion products. Chimney calculations are carried out only by professional specialists; the results of their calculations are given in the form of tables and are required for use during the installation of boilers for space heating and chimney pipes.

Pipe height relative to roof ridge

Types of products for chimneys

Currently, several versions of stainless steel smoke exhaust ducts are produced.

Pipe products are:

- corrugated;

- smooth single-walled;

- sandwich.

In terms of their structure, the first and last versions of the products are exclusively round in cross-section. Single-wall products can be oval or rectangular in shape.

Products with a rectangular shape are rarely used. They are designed for installation inside brick chimneys. In most cases, these products are manufactured only to order.

Chimney pipes are made from several types of metal.

The most popular steel grades are:

- AISI 304;

- AISI 310;

- AISI 316.

The first steel grade on the list is characterized by a high level of resistance to acids. It performs its function perfectly at temperatures up to two hundred and fifty thousand degrees. When working with non-aggressive gases, this material can withstand temperatures up to six hundred degrees. In most cases, it is used to construct single-wall structures or sandwiches used to service low-temperature heating units.

AISI 310 is a heat-resistant steel grade. It can withstand heat up to a thousand degrees. At the same time, a pipe product made of this metal does not lose its shape. The acid resistance of this material is not very high. But it is suitable for installing chimneys intended for installing solid fuel boilers.

AISI 316 is the best steel grade. Various types of chimney ducts are made from this material. It has good acid resistance and high heat resistance. This grade of steel can withstand temperatures of nine hundred degrees. It can be used with any type of boiler.

Pipe products for arranging chimney ducts are often equipped with additional thermal insulation. This property is typical for pipes of all types discussed above. As a rule, manufacturers offer product options both without additional thermal insulation and with it. In the second case, its role is played by basalt fiber mats.

Collective chimney: correct connection

The dimensions of a chimney used simultaneously for several heating devices is a separate topic for discussion.

If smoke removal from a number of heating devices is necessary, then the chimney calculation is made taking into account all heating devices used in the system, their type, power, and fuel consumption.

- For example, in a house with a single chimney, several heating devices, a boiler for a common heating system and a fireplace are installed.

- It immediately becomes clear that we are facing completely different systems. The diameter of the fireplace chimney does not correspond at all to the diameter of the boiler chimney.

- As a rule, fireplaces run on wood fuel, and home heating boilers run on natural gas.

Is it possible to combine these 2 completely different systems? Can. Moreover, with the correct placement of heating devices, they will not only not create problems, but will also complement each other.

How does this happen?

- One chimney includes a boiler and fireplace. During operation, the boiler periodically turns off and goes into standby mode. At this time our fireplace is on. Therefore, the chimney maintains a normal temperature and the gases do not cool down.

- Hence the absence of condensation and good draft when the boiler is subsequently started.

- But the size of the chimney for a fireplace must be significantly larger than for a boiler. And if we only use the boiler without starting the fireplace, we may have problems with excess draft, leading to improper operation of the boiler.

- As we know, the diameter of the chimney for a fireplace is calculated in a ratio of 1:10 to its firebox. It becomes clear that this chimney diameter is very large for the boiler. People use the fireplace infrequently, and the heating boiler runs constantly in the winter.

- So, you need to make a chimney of a smaller diameter, suitable for the boiler?

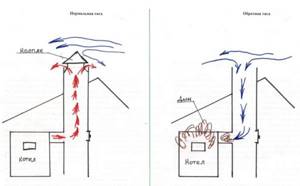

No, that would be a big mistake. When the boiler works independently, everything will be fine. When the fireplace starts, increased aerodynamic resistance will be created in the chimney. Two-way chimney. Rice. 1

As a result:

- improper operation of heating devices;

- ingress of carbon monoxide into the room.

This is already life-threatening. Carbon monoxide poisoning is often fatal.

Two-way chimney - solution to the problem

How to solve this issue?

Our advice is to use a two-pass chimney.

Advantages of a two-pass chimney:

Two-way chimney. Fig.2

- the ability to use various heating appliances simultaneously and separately in one chimney;

- stable operation of each device;

- savings during construction and installation;

- space saving.

When installing such a chimney, all conditions must be met for the correct operation of each device. If the fireplace can function perfectly with a brick chimney, then the boiler needs to be lined. This will protect the brick from the alkaline effects of condensation.

Before you undertake the installation and installation of a chimney for several systems, familiarize yourself with the operating parameters of each heating device. The best solution would be to purchase a special industrial-made two-way chimney. This way you will protect yourself from possible design errors. Even for an experienced specialist, connecting different types of heating devices into one chimney is a difficult task.

Calculation of the chimney cross-section

If the boiler equipment is incorrectly calculated, a reverse draft effect will occur when flue gases are not discharged into the atmosphere, but enter the living rooms. In such a situation, there is even the possibility of creating a fire hazard if hot smoke enters the room. As a result, when building a chimney, it is important to accurately calculate its geometric characteristics, which guarantee the creation of a working draft sufficient to completely remove flue gases and ensure a high efficiency of a heating unit running on natural fuel.

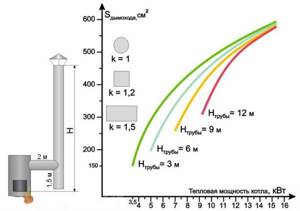

The operation of a thermal energy source operating on solid, liquid or gaseous fuel depends entirely on the following parameters of the chimney:

- Pipe length. First, you will need to establish the greatest height of the building, as well as the size in meters to the roof ridge at the point where the design chimney is planned to be installed. As a result, all the most important parameters of the chimney system under construction are associated with this indicator. It must be taken into account that excessively high smoke channels will literally “eat up” the vacuum in the smoke ventilation tract; as a result, the source of thermal energy will not be able to efficiently burn the fuel from the pipe and black smoke will pour out of all the cracks. Exorbitantly low pipes in relation to the roof are no less dangerous.

- Chimney diameter for a wood-burning stove. With regard to this size, it is not the specific number that will need to be taken into account, but rather the geometry of the chimney. Stove-maker specialists say that a high-quality smoke exhaust system, functioning according to all the laws of aerodynamics and thermal engineering, has a circular cross-section. In this case, soot deposits are not retained in the channels to such an extent, so such a system requires less cleaning. Regarding the specific size, it should be selected according to the cross-section of the main outlet pipe of the boiler or other heat source. The use of larger or smaller pipes is not recommended by the manufacturer due to the high risk of depressurization.

- In addition to determining the D of the pipe, it is necessary to take into account the traction force. To do this, Bernoulli's law is used, data on the temperature of the external and internal air, as well as the pressure of the environment, is entered into the formula. The final calculation takes into account the total loss of air pressure at two points: in the combustion chamber and at the exit from the chimney. The final size of the draft for furnaces must exceed all pressure losses in the gas-air path.

Calculation rules have their own tolerances; you need to know them before calculating the diameter of the pipe. There are several calculation methods, they depend on who and for what conditions they will be fulfilled:

- High-precision, used in the production of boilers and carried out by the design departments of equipment manufacturers.

- Approximate calculations performed by non-specialists based on graphs, diagrams and tables.

- Automatic, obtained on the basis of online calculation.

Accurate calculations are understood as those in which many factors are taken into account: the temperature of the flue gases at the outlet of the boiler and from the pipe, the speed of movement of gases in the furnace and in sections of the smoke exhaust system, the loss of gas pressure along the movement in the gas-air tract. Most of these parameters were obtained experimentally by manufacturers of boiler equipment and depend on the brand of the boiler, so this type of calculation is practically not available to users.

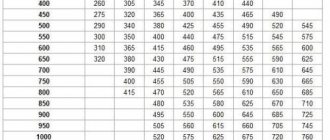

With regard to the indicative method, before calculating the diameter of the chimney, the volume characteristics of the combustion chamber are taken into account. To determine the geometric parameters of pipes, there are various tables and graphs. For example, with a firebox with dimensions of 500x400 mm, a round pipe from 180 to 190 mm will be required.

The third method is based on the use of special online calculators. They take into account almost all important parameters, so they produce very accurate results. In order to use them, the operator will need to know a lot of starting data.

Exact method

Accurate calculations are based on a rather labor-intensive mathematical base. To do this, you will need to know the fundamental geometric characteristics of the pipe, heat generator and fuel used. For this calculation, you can use the following method for determining the diameter of a round pipe for a wood-burning stove.

Calculation input parameters:

- Gas T readings at the boiler outlet t – 151 C.

- The average speed of flue gases is 2.0 m/s.

- The estimated length of the pipe, which is standard for stoves, is 5 m.

- Mass of burned wood B= 10.0 kg/hour.

V=[B*V*(1 t/272)]/3600 m3/sec

Where V is the volume of air masses that are necessary for complete combustion of fuel - 10 m3/kg.

We invite you to find out which stones are best for a steam bath

V=10*10*1.55/3600=0.043 m3/sec

d=√4*V/3.14*2=0.166 mm

Swedish method

Chimney calculations are often performed using this method, although it is more accurate when calculating smoke exhaust systems for fireplaces with open fireboxes.

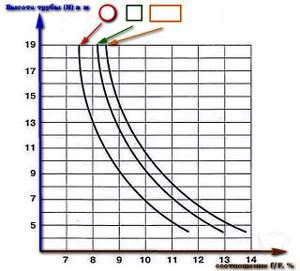

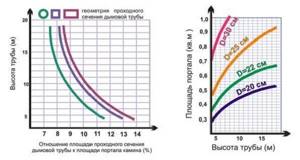

Swedish method

According to this method, the size of the combustion chamber and its gas volume are used for calculation. For example, for a fireplace with a portal, the height is 8 masonry heights and 3 masonry widths, which corresponds to the size F = 75.0 x 58.0 cm = 4350 cm2. The ratio F/f = 7.6% is calculated and it is determined from the graph that a rectangular chimney of this size cannot work; it is possible to use a structure with a circular cross-section, but its length must be at least 17 meters, which is not really high.

F/f ratio = 8.4%. f = Fх 0.085 = 370.0 cm2

D= √4 x 370 / 3.14 = 21.7 cm.

So, we have decided on the height, now let’s talk about the cross-section, because both indicators are inextricably linked with each other.

To begin calculating thrust, we determine the diameter. If we talk about mathematical calculations, they are too complex to attempt without proper training. Therefore, we will focus on the recommendations of experts, without going too deep into the jungle.

- The power of the heating equipment does not exceed 3.5 kW - a chimney with a side section of 14x14 cm will be sufficient.

- If the heating boiler has a power of 4 to 5 kW, the cross-section will be larger - 14x20 cm.

- For power values from 5 to 7 kW, the cross-section is selected to be no less than 14x27 cm.

Let us immediately clarify that the given values are the minimum possible.

The ratio of the flue area of the chimney to the area of the fireplace portal

Let's try to understand the basic principles of such calculations. To work, you will need to know the following information.

- The amount of fuel that burns in the device in 1 hour of use - you can perform an experiment or still find the technical specifications (B).

- The volume of gases released during fuel combustion - this value can be found from various summary tables, according to the type of fuel (V).

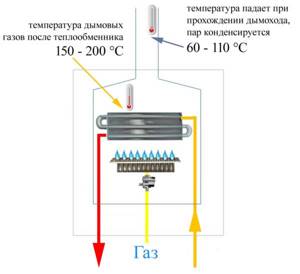

- Gas temperature at the inlet to the chimney. Most often, this value fluctuates between 150-200 degrees Celsius (t). For household stoves, the calculations take a lower value from the specified range, although in fact it can be 130 or 120 degrees, but not lower, otherwise a dew point will appear at the outlet of the chimney and condensation will form.

Gas boiler diagram and flue gas temperature - The height of the chimney - we have already discussed this in detail in the previous chapter.

- The speed of gas passing through the pipe - this indicator is taken by default to be 2 m/s.

- Natural draft indicator - this parameter is usually considered equal to 4 Pa for each meter of chimney height.

The process of removing combustion products

Now that we know what the calculations require, let's try to do them ourselves. To do this, remember that the draft in the chimney is nothing more than the difference in the densities of the exiting gas and air, multiplied by the height of the structure. That is, this is where the fact comes from that the volume of burned fuel directly affects the diameter of the structure.

Why is it important to check chimney draft?

So, all calculations are performed in the following sequence.

- We know what the power of heating equipment is. Using these data, we can accurately determine the volume of gas entering the system: Vg = BxVx(1 t/273)/360, (in m³/sec).

- We also know the speed of gas movement through the chimney. This parameter will help us determine the cross-sectional area of the pipe: (F=πхd²/4)=S (in m²).

- If you remember your school geometry course, then you probably know that there is a formula for calculating the area of a circle, with which we can easily determine the diameter of the pipe: dt = √4xBxVx (1 t/273)/πxωx360 (in meters).

Area of a circle

Now we will carry out a test calculation using the specified algorithm for a chimney for domestic use. Let's assume that in the combustion chamber, on the grate, 10 kg of fuel can burn in an hour (maximum value). The fuel used is firewood with a moisture content of 25%. When this fuel is burned, 10 m³/kg of gas will be released. We have all the necessary data, so we can get started.

- So, first we find the volume of gas at the inlet: Vg = 10x10x(1,150/273)/360 = 0.043 m³/sec.

- We find the cross-sectional area of the pipe sufficient to remove such a volume of gas: S = (4x0.043)/3.14x2 = 0.027 m2.

- And we take the formula for calculating the diameter, substituting the resulting values into it: √4x0.34x0.043x(1,150/273)/3.14x10x360=0.165 m.

Calculation of the cross-section and height of the chimney

Great, we know the diameter, now we can move on to calculating the chimney draft.

- We also need the power value - we find it using the established coefficients and the knowledge that 10 kg of fuel burns in an hour: Q = 10x3300x1.16 = 38.28 kW.

- Next is the value of the heat loss of the pipe per 1 meter of length. For this purpose, we use the indicator of heat loss of a pipe per 1 meter of its length, footage and actual heat loss: 0.34/0.196 = 1.73 degrees of loss per meter.

- We know that the minimum pipe length is 5 meters. We remove from here two meters of the height of the stove itself and what remains is 3 m of a clean chimney. We calculate the drop in the temperature of the gases passing through this section: 150 - (1.73x3) = 144.8 degrees - the temperature of the gases at the outlet of the pipe.

- We take as a basis the density indicators at zero temperature 1.2932 and at the resulting 144.8 degrees - 0.8452, we obtain a natural gas pressure of 1.34 mmH2O. This draft will ensure good combustion of wood in the firebox.

Traction concept

How to calculate the pipe height yourself

Next, a method of independent calculation will be given - it is focused on SNiP 41-01-2003 “Heating, ventilation and air conditioning” . According to this document, we have the following information:

- the minimum height of the chimney, which is calculated from the top to the grate, is 5 m;

- the optimal height should be 6 m.

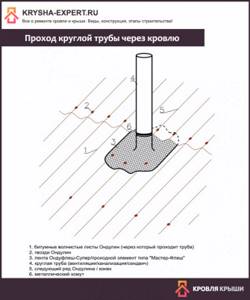

Passage of a round pipe through the roof

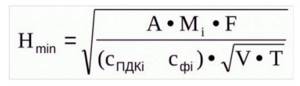

However, this data says absolutely nothing about which parameter to choose in a particular case, for specific equipment. Therefore, experts use the following formula.

Formula for calculating pipe height

Based on the presented formula, we will derive the main parameters that are necessary for accurate calculations.

- A – meteorological conditions of the surrounding area. This refers to a certain coefficient that has already been calculated by professionals and presented in descriptive documents. For example, for the northern regions the value of this parameter is set to 160.

- Mi is the mass of substances passing through the chimney in a certain unit of time. This parameter can be found in the documentation supplied with the heater.

- F is the settling rate of particles that are formed during fuel combustion. This indicator can be found in regulatory documents for the type of fuel used. Let's take firewood and an electric heater as an example. In the first case, the calculated value is 25 units, and in the second - 1.

- (Спдкi and Сфi) – the concentration of different substances in the gas that needs to be removed. Both indicators are also taken from the instructions supplied with the heating equipment.

- V is the volume of exhaust gas.

- T is the temperature difference between the incoming air and the gas leaving the pipe.

Calculation of chimney height

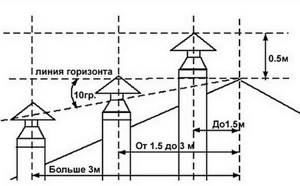

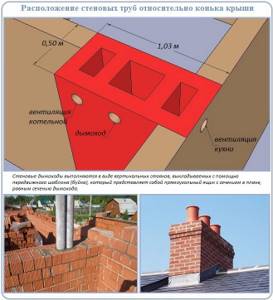

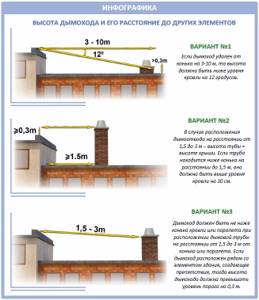

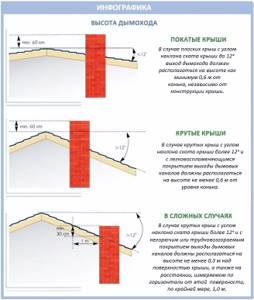

The height of the chimney above the roof is also a very important parameter. It is determined based on the shape of the roof - all data is also taken from the above SNiP.

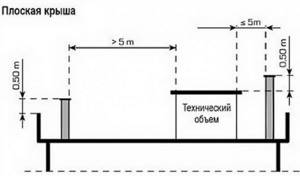

Flat roof of a building

If the roof of the building is flat, then the height of the pipe is determined as follows.

Table. Pipe height for flat roofing.

| Conditions | Established height above the roof |

| The roof has no parapets or other installed devices. | 120 cm. |

| There are protective curbs and other equipment on the roof. | 1 m is added to the maximum height of installed equipment. |

| A ventilation pipe is installed on the roof. | The height of the chimney should be 50 cm greater than the height of the ventilation pipe. In this case, the minimum distance between them should be 5 m. |

Chimney height on a flat roof

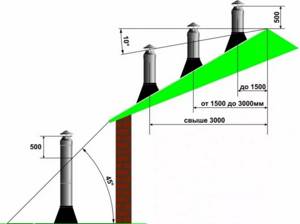

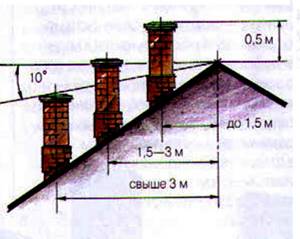

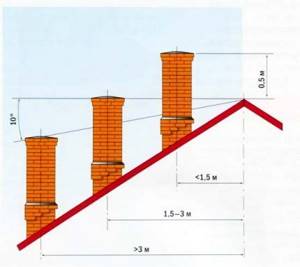

If you have a pitched roof, then the height of the chimney will be affected by its location relative to the ridge of the roof - this means the distance (distance between them).

Table. Pipe height for pitched roof.

| Conditions | Established height above the roof |

| The distance from the ridge to the chimney is 1.5 m or less. | The minimum height is 50 cm. |

| The distance is 1.5-3 m. | The height of the chimney is set at the highest point of the roof. |

| Distance more than 3 m. | In this case, it is necessary to measure the angle between the horizontal line drawn along the level of the ridge and the top point of the chimney - it should be exactly 10 degrees. |

The minimum height of the chimney must always be 5 m

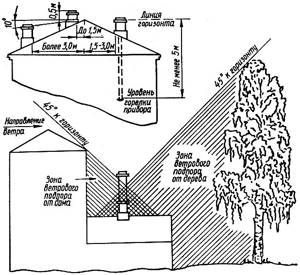

Also, the height of the chimney above the ridge can be affected by third-party factors, such as buildings located in the immediate vicinity and tall trees. The presence of such interference forms a zone of wind pressure. In this zone it is almost impossible to create good draft, which will be sufficient for the normal operation of the heating device. To get out of this wind zone, you need to increase the height of the chimney by at least 50 cm.

To ensure stable traction, it is important that the head of the pipe on the roof has sufficient height relative to the ridge and does not fall into the wind pressure zone

A similar situation will occur if the heating equipment is located in a low utility room attached to the house or located in the immediate vicinity. Both options are shown in the diagram above.

Prices for different types of roofing ridges

Roofing ridge

Ridge height calculator

Go to calculations

The ridge is an important part of the rafter system

Corrugated pipes

A corrugated tube is a kind of “spring” made of iron wire, which is wrapped in foil. Moreover, the last element is attached to the main structure using a special technology. The corrugation wall is quite thin.

This gives pipelines from it the following features:

- cheapness;

- flexibility;

- low installation cost;

- Possibility of installation outside buildings;

- ability to stretch and compress;

- the possibility of refurbishment of old brick gas ducts.

This type of steel pipes also has its disadvantages. Due to the too thin wall thickness (up to 0.1 mm), the corrugation has a short service life. On average, products of this type can be used for ten years. Therefore, it is permissible to install them inside structures only in a fireproof shell. It is imperative to ensure that such pipes can be replaced.

The flexible stainless steel channel has high aerodynamic resistance. Therefore, the draft force in such chimneys is lower than in smooth-walled analogues. It is possible to create a gas duct from this material only for arranging old brick channels. It should be remembered that installation of this structure will reduce the flow area of a rectangular pipeline by approximately twenty-five percent.

We invite you to familiarize yourself with Calculation of the chimney cross-section in wood-burning stoves

How is a brick chimney constructed?

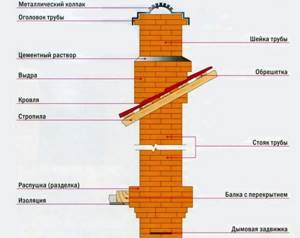

A brick chimney consists of several sections, some of which are located indoors, and some in the open air.

The design features are such that when passing through the attic floor, the walls of the pipes must be thickened as much as possible in order to reduce the risk of fire in the rafter system. At the same time, going beyond the roof, the chimney structure itself must cover the hole in the roof so that precipitation does not penetrate into it.

- In most cases, the chimney pipe is a continuation of the stove, i.e. on top of it the required number of rows of bricks are built up to the attic floor.

- The next element is fluff. When fluffed, the width of the pipe is 2-3 times greater than its normal size while maintaining a constant internal cross-section. The thick walls of the pipe are a kind of buffer that protects flammable elements of the attic system from contact with the heat passing through the pipe. At this level the air is still too hot due to the close proximity of the furnace.

- Next comes the riser - a section of pipe from the attic floor to the top of the roof. It is a brick pipe in its usual cross-section.

- According to technology, there should be an “otter” at the place where the pipe exits the roof, but it is often neglected. The element is similar to a fluff, but is installed in such a way that a brick canopy is formed above the roof, repeating the angle of inclination of the roof. The otter is needed to close the hole through which the pipe comes out from precipitation. Usually a special apron (metal or other material) is placed around the otter to provide better protection.

- Next, the neck of the pipe rises above the roof - the external analogue of the riser.

- The entire structure ends with a cap, which is a small visor. This is rather a decorative traditional element of the pipe, since its protective functions are minimal. For this reason, the head is also often neglected.

- A metal cap is installed on top of the head, which protects the chimney from precipitation and debris getting inside.

We recommend that you read: How to calculate and install heating registers yourself

Important! The internal cross-section of the brick pipe remains the same throughout its entire length, only the wall thickness changes.

Subtleties of designing a smoke channel

A complete calculation of a chimney is quite difficult for a non-specialist to perform. To do this, it is better to use the advice of heating engineers on choosing the optimal indicator:

- With a maximum thermal power of the heating device of up to 3.0 kW, pipes with a diameter of 140 mm will be sufficient.

- If the boiler has a power of up to 4.5 kW, the optimal dimensions of the chimney are no less than 140 mm.

- When using a high-power boiler device of 7.5 kW, the diameter of the chimney pipe must be at least 150 mm.

A user who knows the thermal power of the boiler can make an approximate calculation of the chimney using the optimal values and coordinate it with the indicator of the boiler outlet pipe. You can also refer to the manufacturer's instructions, which regulate the installation diagram with all the parameters of the smoke ventilation system.

An equally important indicator for accurate calculation of the geometric parameters of the chimney is the temperature of the flue gases at the entrance to the pipe part. This parameter is related to the type and quality of the fuel burned and the efficiency of the boiler heating surfaces. For properly configured equipment it should be within 150-200 C.

For fireplaces, the indicator of the optimal speed of gas movement through the smoke exhaust system is also important; usually this indicator is taken to be 2 m/s with an indicator of natural stove draft of 4 Pa per 1 m of chimney.

Regarding the parameters of the chimney pipe, it is impossible to say that the higher it is, the more preferable. An extremely long or wide flue increases the cost of building chimneys. A boiler or stove with such a chimney will begin to wear out when there is excess draft, the fuel will be burned quickly, and a significant part of it will be uselessly released into the atmosphere, reducing the efficiency of the heating system.

The cross-sectional size only partially affects the length of the chimney pipe. In other words, the user will not be able to increase its diameter to increase efficiency. In this connection, experts do not advise experimenting with the cross-sectional sizes of stove pipes, adjusting them to certain height indicators, for example, making them below 5 m or above 7 m.

Calculating the length of the pipe depends more on the height of the object on which it is placed and the type of roofing. The indicator above the roof level is a more important indicator for calculating the optimal pipe section.

Calculation of the chimney diameter for the stove

The length of the chimney pipe from the grate to the exit point must be at least 5 m. If the roof is made in the form of a flat structure, then the height of the pipe must be at least 50.0 cm. On pitched structures, when it is located at a distance from the ridge to 1.5 m, it must rise at least 50.

In some cases, the pipe is located further than 3 m from the ridge line, then its minimum height is calculated at an angle of 10 degrees relative to the horizon. In case there are large high-rise buildings nearby, and the boiler or fireplace runs on wood, then the height of the chimney is chosen higher than the roof of nearby houses.

Recommendations for pipe placement and construction:

- There is no need to install chimneys close to the attic windows so that the occasional wind does not blow combustion products into the attic.

- It is also not recommended to install exhaust pipes and ventilation ducts in the valleys, so as not to create snow pockets.

- When the outer section of the chimney exits, there is no need to rigidly strengthen it with the roof structure and rafters, since if the pipe collapses in a hurricane, the entire roof will be damaged.

A competent calculation of all the characteristics of the future chimney exhaust system is a guarantee of its performance and the efficient operation of all boiler equipment. A lack of calculations, which can be made at the design stage, will lead to an emergency mode with subsequent destruction of the system. Simple calculations, based on the long-term experience of specialists, enable the user to perform them efficiently to determine the technical parameters of the chimney pipe.

When designing a chimney, everything matters: its size, configuration, cross-section, slope, and other parameters. When installing a smoke exhaust from a gas boiler, it is necessary to strictly adhere to the requirements of regulatory documents: SNiP 2.04.05-91 and DBN V.2.5-20-2001.

The cross-section of the chimney duct must be no smaller in area than the cross-section of the gas boiler pipe through which the device is connected to the chimney.

When constructing and connecting chimneys for gas boilers along their entire length, narrowing of the channel, curvature and the use of modules that are not suitable for the cross-section are unacceptable.

When simultaneously connecting two devices to the chimney, the cross-section should be increased, taking into account the likelihood of simultaneous operation of two devices. Those. the cross-section of the channel must be equal to the total dimensions of the pipes of both units of equipment.

Modern gas boilers are designed in such a way that the maximum amount of heat is supplied to the heat exchanger. Such a high efficiency contributes to the production of combustion products with a relatively low temperature.

As a result, moisture forms on the walls of the chimney. An increased amount of condensate, including aggressive substances, can have a destructive effect on the integrity of the walls of chimneys.

To connect a gas boiler to the chimney structure, use a special tee on which a device for collecting condensate is mounted

At the bottom of the chimney, there must be a condensate collector in the form of a removable container made of plastic or stainless steel. A glass made of galvanized steel is also not prohibited from use, but it will have to be changed frequently.

To protect the structure, it is recommended not only to lay the chimney out of brick, but also to line it, i.e. insert a special stainless steel pipe inside. Such pipes are durable and well resistant to corrosion.

An alternative solution to combat condensate can be lining, i.e. installation of a special flexible chimney. A special container is used to collect condensate. It is installed just below the place where the boiler pipe connects to the chimney.

We invite you to familiarize yourself with Broom - a green friend.. Tips for building a bathhouse

The traditional cylindrical shape of the chimney is considered optimal for efficient removal of combustion products. In addition, it is easier to carry out preventive cleaning in such a chimney.

Chimneys with a cross-section in the form of an oval are considered quite acceptable, although not so convenient. Square designs also have a right to exist, but their traction indicators are usually reduced.

A vertical chimney without ledges is considered optimal for a floor-standing gas boiler. In practice, it is not always possible to achieve such a design arrangement.

Deviation from the vertical is allowed no more than 30 degrees. In this case, you should make sure that the cross-sectional dimensions of the inclined section comply with regulatory requirements.

In this case, the pipe itself connecting the chimney and the boiler must include a strictly vertical section with a height of half a meter or more. Of course, if necessary, some sections of the chimney can be made horizontal, but there should not be too many of them.

When installing a chimney structure for a gas boiler, the presence of inclined sections is allowed, the slope must be 60° or more degrees relative to the horizon, the length of the inclined section is up to 1 m

For example, if the height of the room in which the chimney is installed is about three meters, then the total length of the horizontal sections of the chimney should not exceed these dimensions.

Although, as mentioned earlier, the closer the chimney design is to the vertical, the better. It is not allowed that the slope of the chimney towards the boiler be more than 0.1 degrees. As for the turns of the chimney structure, their maximum number is three turns, no more.

To connect individual parts of the chimney structure, special clamps are used. The slope of the chimney structure can be 15-90 degrees. A certain distance must be maintained between the connecting pipes and other surfaces.

It depends on what materials these surfaces are covered with. In places where flammable or even difficult-to-burn materials are used, it is recommended to maintain a distance of at least 25 cm.

The distance from surfaces coated with fire-resistant materials must be at least 5-10 cm. To protect the chimney from flammable materials, use asbestos cardboard, brickwork, etc.

When installing a chimney for a gas boiler, all its elements must be securely fastened, maintaining the correct spacing between fasteners

Particular attention should be paid to the junctions of individual sections of the chimney structure. They must be made of durable materials that do not bend under external influence.

All chimney fastening elements must have the same characteristics. Horizontal or inclined sections of the chimney should not be under load.

The chimney elements are inserted into each other to a depth that is equal to half the diameter of the pipe or exceeds this figure. No gaps in these places are allowed; the connection must be tight and airtight.

If the tightness of the connection of individual chimney elements is broken, carbon monoxide can enter the room unnoticed. Therefore, the condition of the chimney should be periodically checked, and good ventilation should be organized in all rooms where chimney pipes are laid.

Chimney pipes should rise above the roof ridge by 50 cm or more, while the distance from the edge of the parapet to the chimney pipe should be no more than 150 cm. If the axis of the chimney pipe is located at a distance of 1-1.5 m from the roof ridge, then it should rise above the ridge level by 50 cm or more.

This diagram clearly demonstrates how, in accordance with technical standards, the height of the chimney pipe relative to the roof ridge is determined so that it does not interfere with the formation of draft

Area of a circle

Traction concept

Features of the pipe depending on the type of fuel and material of manufacture

Whatever type of raw material you use (gas, firewood, coal, fuel oil), any of them requires an individual approach to maximize the extraction of “warm” gigacalories, or more precisely, ensuring the optimal yield of combustion products. A chimney for a private home must ensure 100% combustion of fuel without excessive consumption. It must be strong and durable, easy to repair and clean.

Depending on what type of fuel material is used, the type of chimney is selected. For example, if you are going to burn with wood, a brick pipe would be your best option. The main thing is to choose the right fire-resistant material for masonry and insulation. Built according to all the rules, such a chimney perfectly accumulates heat.

However, there are certain disadvantages:

- Brick chimneys are large in weight and bulky. When installing them, additional requirements are imposed on the foundation of a building for private houses;

- the rough inner surface is prone to contamination, is often clogged with soot, and requires repair and cleaning;

- the use of other types of fuel material or the use of modern heating devices for the boiler room leads to condensation settling, which destroys the chimney;

- short service life. As practice shows, destructive processes in the chimney begin to occur after 2-5 years of operation.

Steel pipes are one of the best chimney options for modern stoves and boilers

Single wall pipes

This product option is traditional. In terms of price, single-wall stainless steel pipes will cost more than corrugated pipes. However, they are characterized by a longer service life. In addition, there are oval flue ducts and fittings for them. They greatly facilitate the installation of ducts in difficult areas and improve the aerodynamic properties of chimneys.

It has been proven that oval pipes are much more efficient than round ones. It takes up less space with a larger cross-sectional area. This not only simplifies installation, but improves the appearance of the structure. However, if you connect a single-wall structure to a boiler with an efficiency of more than 90%, it can quickly deteriorate. We are talking about pellet, gas and diesel units. They need to select products with good thermal insulation.

The fact is that the temperature of the exhaust gases of the considered units is low. This leads to condensation. Because of it, black streaks appear on the outer part of the channels. These designs are ideal for arranging chimneys in bathhouses since the efficiency of the boilers used in them does not exceed sixty percent.

Single-wall stainless steel pipes can also be used when installing solid fuel units. But in this case it is necessary to use thermal insulation. Otherwise, condensation cannot be avoided.

Types of gas boilers

The type of chimney selected, as well as its performance indicators, directly depends on the heating device. All gas boilers are divided into two large groups by design:

- With open burners

. Quite bulky boilers, comparable in size to a fireplace and installed on the floor. A working device consumes oxygen from the room. For stable operation you need constant high-quality air exchange. If not enough air enters the room, carbon dioxide released during combustion leaks into the house from the boiler.For boilers with an open burner, it is recommended to use a vertical chimney. Such a system is brought out at right angles to the section of the roof under which the boiler room is located.

- With closed type burners

. Such devices are installed on compact low-power boilers (up to 40 kW). Fuel combustion occurs in a sealed chamber. A coaxial type chimney is optimal for such a boiler. The chimney is mounted in a horizontal plane.

Now it’s time to study the requirements of GOSTs and SNiPs regarding heating equipment. With them, the algorithm for calculating chimneys for solid fuel boilers, as well as for gas boilers, will become a little more understandable.

Sandwich pipes

This version of stainless steel pipes is the most expensive. However, it is characterized by versatility and reliable operation. Sandwich pipes for chimneys are suitable for installing any type of equipment. Among the disadvantages, in addition to the high cost, the significant size of such structures should be highlighted.

Some homeowners, instead of sandwich structures, use conventional single-wall products, which they insulate themselves using basalt wool. This method of arranging chimneys has one serious drawback - low fire safety.

It is best to use factory sandwich structures. Options with an outer layer made of galvanized steel are especially good. They not only have high performance characteristics, but also an aesthetic appearance.

Advantages and disadvantages of bricks for chimney installations

Brick is a traditional material for chimney equipment. The advantages of this material are its relative cheapness (for example, compared to sandwich pipes) and long service life. In addition, a brick chimney goes well with old buildings, and with modern buildings, and with wooden buildings, and with concrete, and with brick.

The disadvantages include rather long installation and heavy weight of the structure. Also, the aerodynamic properties of brick chimneys (which can be either square or rectangular) are worse than those of round pipes.

In addition, the surface of the brick and cement joints are not ideally smooth, so soot and other solid combustion products settle on them more quickly.

Pipeline installation

To install a chimney, it is permissible to use any of the pipe products we have considered. But for this you need to follow certain rules. The diagram below will help you cope with this task.

Chimney installation diagram

If you decide to carry out the installation yourself, pay attention to:

- The minimum height from the grate to the cut of the vertical tube should be six meters.

- The length of the horizontal channel from the insertion into the tee to the branch pipe of the unit is equal to one meter. In this case, installation is performed at an angle to the tee. This is necessary to prevent condensation from getting inside the heating equipment.

- The maximum number of turns should not exceed three.

- Pipe joints should not be located in areas where they pass through ceilings.

- If the gas pipeline passes through flammable building materials, the size of the opening must be significant. The distance between the walls and ceilings should be about two hundred millimeters. This gap is filled with insulation.

- The size of the chimney pipes should not be less than the diameter of the outlet pipe.

- A condensate collector is placed at the bottom of the vertical sections.

- The upper part of the pipe is mounted at a certain height shown in the figure above.

Why is a chimney calculation required?

It is the chimney that ensures the safety of residents. An improperly designed chimney is unable to completely remove toxic combustion products (carbon dioxide and carbon monoxide, sulfur oxides), smoke and soot. There can even be a fire if hot smoke enters the room. Particularly dangerous is the overturning of the draft - turning the movement of smoke in the opposite direction.

Therefore, when installing a chimney, it is necessary to correctly calculate its parameters - they ensure the creation of ideal draft and complete removal of harmful substances.

Alternative to stainless steel: asbestos cement

Asbestos pipes are an alternative to steel structures. But they cannot be used for all types of gas ducts. Products made from the materials in question can be used in operating conditions up to three hundred degrees.

The key advantage of asbestos-cement pipelines is their low price. The cost of these products is significantly cheaper than stainless steel pipes. However, in terms of its performance qualities it is inferior to the products discussed in this article. If you want to create a truly reliable pipeline, use stainless steel pipes.

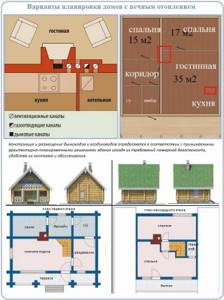

Rules and nuances of planning

Calculations and construction alone are not enough to create a flawless project. After all, the vertical chimney channel crosses the interior spaces, which means it influences the layout.

Despite the desire to install it closer to the ridge, it is not always possible to implement the plan. It often happens that it has to be located at a considerable distance.

The location of the chimney inside the room and, as a result, the height of the outer section of the chimney is influenced by the following factors:

- Internal layout of the equipped box.

- Chimney type.

- Number of floors.

- Ease of installation of the smoke channel.

- Providing access for maintenance.

- A type of material used in the construction of walls and rafter structures.

- Number of units connected to one smoke channel.

Note that according to the rules for installing heating systems in private houses, a single unit must be connected to one chimney. Only in exceptional cases is it permissible to collect flue gases from two furnaces in one pipe. However, in such situations, for the proper operation of the combustion product removal system, a cut is made inside.

The stoves of two or three-story houses are located one above the other. Their chimneys are built so that they exit through one shaft. Naturally, only the stove pipe on the top floor can be perfectly straight. All the rest are performed by withdrawals. The slip slope is 60º, its maximum length is allowed to be no more than 1 m.

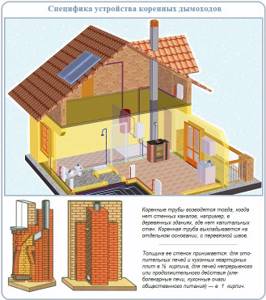

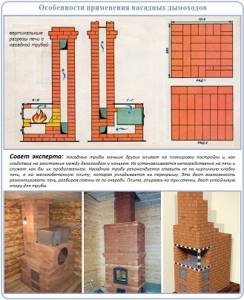

According to their structural type, chimneys are divided into:

- Wall. The most economical, easy to construct and operate option, installed in permanent internal walls. They are used in brick and stone buildings - where it is possible to lay a channel in a load-bearing wall.

- Indigenous. A variety constructed in the form of risers separate from the furnace. A more expensive design, but in some cases the only possible one. They are constructed if there are no technical prerequisites for constructing a wall channel. They are mainly used in the construction of chimneys in stacks folded with timber or logs.

- Mounted. The type of chimneys is placed directly on the ceiling - a reinforced concrete slab installed on the ceiling of the stove. They are used in small-sized buildings that dictate the need to save usable space.

Designers give priority to wall smoke ducts - risers, because... their construction is carried out during the laying of walls and allows saving an impressive amount of building materials. True, it is impossible to arrange them in a box without an internal main wall. But if there are prerequisites for construction, the wall smoke channel will be as close as possible to the ridge girder.

The wall chimney is laid using a buoy template, which is simply covered with brick around the perimeter. This is a kind of wooden box with a cross-section in plan equivalent to the cross-section of the smoke duct. Having reached the upper edge of the template during the laying process, it is moved higher and covered again. So until the construction of the load-bearing wall is completed.

Wall brick pipes are located mainly in internal main walls. This heats the house better and reduces heating costs. There are situations when wall risers are laid in external walls, but this solution is uneconomical and difficult to operate. When installing a chimney in an external wall, its thickness increases.

Naturally, the construction of a pipe in an external wall will force you to calculate the height of the chimney relative to the ridge using the methods described above. The height of the outer section of the chimney constructed during the construction of the internal main wall, according to standard rules, is half a meter.

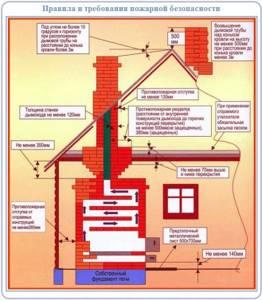

It is important to remember that smoke channels in walls made of foam concrete blocks or sand-lime bricks are laid out only from ordinary solid red brick. This is subject to fire safety requirements. The same standards indicate the distances between chimneys and combustible structures.

You should retreat from an unprotected wooden ridge girder and rafter legs by 0.5 m, from protected analogues by 0.38 m. Metal pipes should be removed from flammable structures at a distance of 0.7 m or more. Fire regulations must be observed when determining the distance between the chimney and the wooden components of the rafter system.

There are no equally strict rules in the design of main and casing pipes. Their location is more focused on architectural and planning specifics, ease of installation and future maintenance. The location of the chimney relative to the ridge can be whatever the owner of the house prefers, but taking into account the requirements of firefighters.

The part of the chimney that rises above the roofing should be plastered with a cement composition. The thickness of the plaster layer should be 2-3 cm. Within the attic space, the chimney must be whitewashed so that the location of the gas leak can be quickly determined and the dangerous area can be repaired.

Dependence of the chimney height on other roof elements

Of great importance is also how close the chimney itself is located to the ridge of the roof, parapet or its other elements:

So, regarding the elevation of chimneys above the roof, there are the following rules:

- No less than 1.2 meters above a flat roof.

- No less than 50 cm above the roof ridge, if the pipe is located up to 1.5 meters from the ridge.

- Not lower than the ridge level if the pipe is located from 1.5 to 3 m from the ridge.

- Not lower than the line that can be drawn from the ridge down to the horizon at an angle of 10 degrees, if the pipe is located more than 3 meters from the ridge.

In this case, the smoke duct must be located at a certain distance from other elements of the building, minimum:

- 150 mm for pipes with insulation;

- 500 mm for pipes without insulation.

The minimum permitted pipe height is 50 cm. But these are too low pipes, which are only allowed to be installed on flat roofs without any protrusions. If the roof has a more complex configuration, you will have to tinker and take into account all the protruding parts.

So, if all these parts are located at a distance of 1.5 meters from the pipe itself, then the pipe only needs to be higher than all these elements. If they are closer than 1.5 meters, then the chimney must exceed their height by at least 59 cm:

Criteria for determining the height of the chimney above the ridge with a table

There are many conditions that must be taken into account in order to calculate the length of the chimney. Some of them are more important, others less. Here's what you should pay close attention to first:

- Where will the chimney be located relative to the ridge fin?

- What wind rose is typical for the area in which the house is built, how intense the gusts are at different times of the year.

- How much precipitation falls in the region and what form is dominant. Snow, or more precisely, the thickness of its coverage in winter, is of great importance.

- What angle of inclination of the ceiling is planned to be arranged.

- Are there any obstacles near the roof that could change the strength and direction of air flow?

All of these factors should be correlated with the type of fuel that is planned to be used for stove heating and other construction features.

| Distance of the chimney from the vault | Height of the pipe in relation to the roof |

| 150-300 cm | equal to |

| less than 150 cm | 50 cm higher |

| more than 300 cm | is a horizontal line drawn from the ridge and a straight line connecting it to the chimney, forming an angle of 10˚ |

Main types of chimneys

Common types of chimneys:

- Brick. As a rule, an asbestos pipe is installed in a brick shaft. The key disadvantage of a brick chimney is the need to install a foundation for it. In addition, this design impairs traction and also promotes the formation of debris and condensation products. This destroys the system and makes the room damp. The advantages are high heat capacity and fire safety.

- Ceramic. The most expensive and high-quality option. Made from fire-resistant ceramics. A layer of thermal insulation of non-combustible material is required. Pros: they do not require frequent cleaning, have smooth walls and a round cross-section (provides good traction), have high sealing and thermal insulation rates, are heat-resistant, durable, and easy to install. Disadvantages: the foundation is required and the high price.

- Modular made of steel. They are assembled from tees, adapters, elbows, etc. Stainless steel structures are often installed with brick channels (the aforementioned sleeve). However, you can install such a chimney separately. Stainless steel must be resistant to acids and be heat-resistant so that corrosion does not appear in the chimney (wall thickness is from 0.6 to 1 mm). Galvanized steel is not suitable because zinc quickly burns out at high temperatures. Disadvantages of steel structures - increased thermal conductivity leads to rapid cooling of gases, a large volume of condensate is formed, the service life does not exceed 15 years. The advantages are good traction due to the rounded shape, no separate foundation is needed, and no soot accumulation occurs.

- Corrugated steel. They are a flexible pipe made of metal tape. Used for lining brick structures with curves. Easy to install, but do not last long.

- Sandwich structures made of steel. They are two pipes inserted into each other. The area between them is filled with special non-flammable insulation. Cons: high cost. Pros: reduced thermal conductivity and slow cooling of gases, rapid smoke passage, minimum condensation, ease of installation.

- Asbestos-cement. Suitable if the resulting heating gases are not hotter than 300 degrees. Not suitable for standard ovens due to poor heat resistance. Disadvantages - fragility, lack of thermal insulation and unsatisfactory heat resistance, porosity, the need for frequent cleaning, weak rubber connection. Pros: lightweight, round cross-section, low cost and easy installation.

- Polymer. Manufactured from composite polymers. Used for lining channels made of brick or concrete. Due to poor heat resistance, it is not suitable for hot gases with temperatures above 250 degrees (furnaces). Only for geysers or boilers with increased efficiency. Disadvantages: instability to high temperatures, fragility, lack of thermal insulation. Pros: flexibility and light weight, low cost, long service life.

We hope the material was useful to you. As you understand, calculating the height of the chimney is quite simple. Apply these solutions and your home will always be warm.

Checking the planned pipe for the amount of natural draft

In fact, we have already determined the main parameters of the chimney - the sufficient cross-section of its channel and height.

But for devices with natural draft, it is never a bad idea to check the strength of this very draft. So that it does not happen that the constructed chimney suddenly refuses to perform its main functions. Draft is essentially the difference in pressure between hot gases in the pipe and the outside air. It is this difference that stimulates the movement of gas flow through the chimney channel.

It is believed that for normal operation of a chimney with natural draft, this difference must be at least 4 pascals for each meter of pipe height (0.408 mm of water column or 0.03 mm of mercury). That is, for a five-meter pipe (our minimum), the thrust should be at least 20 Pa. This ensures both normal gas removal and the necessary air flow for continuous combustion of the fuel.

How to calculate this thrust. Naturally, it largely depends on the densities of gases, which, in turn, are closely related to temperature. You can verify this by looking at the formula with which we will work:

ΔP = Htr × g × Patm × (1 / TV – 1 / Tds) / 287.1

ΔP is the natural draft in the pipe, Pa.

Htr—chimney height, m.

g—gravitational acceleration (9.8 m/s²);

Patm - atmospheric pressure. A value of 750 mmHg is considered normal. However, the area for which the calculation is carried out may have its own specifics. We must understand correctly that sea level is considered the norm. And with increasing altitude, this rate begins to decrease. And quite significantly. So when making calculations you will need to be guided by the norm for your region of residence.

Atmospheric pressure is usually measured in millimeters of mercury. However, to calculate in the SI system it is necessary to convert it to pascals. This is not difficult if you know that 1 mm Hg. Art. = 133.3 Pa.

TV - outside air temperature. Moreover, reduced to the Kelvin scale, that is, C° + 273.

Tds is the average temperature of gases in the chimney. Defined as the arithmetic average of the input and output indicators, followed by conversion to the Kelvin scale.

287.1 is the gas constant of air. It would be more correct to select this value for the specific chemical composition of the exhaust gases. But in our case, the error will not be significant, greatly affecting the final result.

A few important notes on inlet and outlet temperatures.

You should always strive for its optimal values. Statistics show that most fires occur with sauna stoves, into which there is practically no heat removal; the heat in the steam room builds up in a short time, and the chimney usually heats up to dangerous temperatures. Therefore, you need to be able to control the temperatures in the pipe using available means - gate valves, valves, additional heat recovery devices (for example, water heating tanks).

In household and heating stoves this is easier, but control is still necessary. In boilers, where the very essence of the work is the constant transfer of heat to the circulating coolant, these issues are not so pressing.

The 900 ÷ 600 ℃ (input and output) mode, found on some sauna stoves, is extremely dangerous in all respects, and should not even be considered! Reasonable limits (and even then their upper limit) are 600 ÷ 400 degrees for household brick and metal stoves. Usually they try to maintain it in the range of 400 ÷ 200 ℃. For gas equipment, the lower limit can fall below 100 degrees.

If all the initial values for substitution into the formula are known, you can proceed to the calculation. To do this, we again suggest using the capabilities of a special online calculator.

Calculator for calculating the natural draft of a chimney.

If the resulting pressure difference falls within the norm (more than 4 Pa per meter of pipe height), then the test can be called successful.

The main parameters of the chimney have been obtained - you can proceed to the selection of materials and detailed design.

This video will tell you about many other subtleties of independent chimney design: