The basement is the coldest part of any private home, regardless of what material it is built from. Therefore, thermal insulation of the bottom of the house is a mandatory measure, which is carried out either at the construction stage or immediately after construction. For wooden houses, insulation of the subfloor is a vital necessity. The tree instantly absorbs moisture from the soil and atmosphere. To prevent rotting processes from developing in the wood, it is necessary to equip a high-quality insulation system, which, in addition to thermal protection, includes waterproofing, protection against vapor penetration and ventilation. In the article we publish instructions on how to insulate the underground in a wooden house; you will also learn the various nuances of this work.

The need for basement insulation

Under the influence of humidity and dampness coming from the ground, as well as condensation formed on wooden elements due to temperature differences, the wood becomes moldy, becomes covered with fungus, and cracks appear on it.

In such conditions, wood becomes a conductor of cold, although initially it is a good heat insulator. In addition, the wood begins to rot and its structure is destroyed. All this requires careful consideration of the issues of basement insulation, without which the service life of the house will be noticeably reduced.

Thermal protection of the floor and upper ceiling

We can talk about high-quality insulation of the subfloor if only a full range of work has been completed, including, in addition to wall insulation, also thermal protection of the floor and upper ceiling. To achieve maximum effect, it is best to insulate the floor with extruded polystyrene foam (EPS), and the ceiling with mineral wool.

We insulate the subfloor

When choosing a material for floor insulation, you need to focus on the following points:

- high level of thermal conductivity;

- minimal water absorption;

- strength with low weight;

- minimum difficulties during installation;

- durability;

- safety for human health.

Most of all, these conditions correspond to Penoplex F slabs (in particular, Penoplex-Foundation) with an L-shaped edge for high-quality joining.

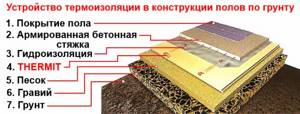

The work is carried out in the following order:

- select excess soil to create a floor of the required thickness;

- compact the base;

- lay sand on the base in a layer of about 10 cm and compact it too;

- lay lightweight reinforcement mesh (cells 100 by 100 mm);

- lay a rough concrete screed 5 cm thick on top of the reinforcing mesh and wait until it dries completely;

- lay the EPS slabs tightly, securing them on top with a reinforcing mesh with an even finer cell (50 by 50 mm);

- pour a clean concrete screed 6-7 cm thick.

Stages of insulation

It is important to note here that work on thermal insulation of the subfloor must be carried out comprehensively. It is advisable to carry out insulation during construction, since it will be much more difficult to do later.

Basement insulation is carried out in stages:

- organization of good ventilation;

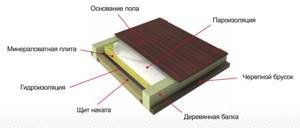

- arrangement of an insulation cake, including heat, hydro and vapor barrier;

- insulation of the foundation and basement of the house.

It should be noted that for good insulation, the distance between the ground and the floors is of great importance. An air layer is formed under the house, which serves as additional protection for the house from the cold coming from the ground. In this regard, it is advisable to locate the basement at a height of at least one meter from the ground.

Tricks when installing ventilation

Photo. Ventilation device in the basement of a house

When carrying out work, the distance between the ceiling and the ground is important - the basement must have a height of at least 1.2 - 1.5 meters for better thermal insulation. Basement ventilation should be considered at the design stage. Ventilation holes are made in the basement on opposite sides of the house. In the winter, the ventilation holes are tightly closed, and in the summer they are opened to ventilate the basement from excess moisture.

Many people build a country house with an additional ventilation hood going through the roof. The hood is equipped with a damper; it will help ventilate the basement of the house during the winter season. Today, there are devices that monitor the level of humidity in the basement and automatically open the damper when the levels reach a critical value. Such devices are quite expensive, but there is a way out.

Ventilation system design

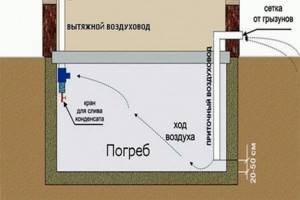

Proper basement ventilation system

To create an optimal microclimate in the basement, good ventilation is needed, the main function of which is to ensure air circulation. If there is no movement of air masses, dampness and humidity will constantly be present in the basement, which, even with high-quality insulation, threatens the appearance of mold and fungal colonies.

To install a ventilation system in the basement, two pipes are installed on different sides, usually on the south and north. One pipe serves to bring in fresh cold air, the other removes warm air from the room.

When installing pipes, you must be guided by the laws of physics, according to which cold air always tends downward, and as it heats up, it rises to the ceiling.

Therefore, the lower part of the supply pipe is located at a distance of 20-30 cm from the basement floor, and the upper part - 40 cm from the ground. The hole in the pipe that goes outside is covered with a fine metal mesh to prevent rodents. The lower part of the exhaust pipe should be 30 cm below the ceiling of the cellar, and its upper part should lead to the roof.

Technology and features of floor insulation from below in a wooden house

For each type of insulation, there are some specific features of use.

Mineral wool

The sizes of rolls and slabs are usually multiples of 60 cm, which makes this distance the optimal step between the logs. Mineral wool is cut to size with a cutter and placed in the space between the joists. For a tight fit, the size should be 1–2 cm larger than the distance between the joists. Cotton wool should not be pressed down forcefully as this may affect its characteristics.

The best option would be to lay two layers of insulation. The second layer is laid so that the joint of the lower layer falls on the center of the upper piece. This method of installation will prevent cold air from entering the room.

Choice of insulation

The first question that arises before starting work is: how to insulate the basement from the inside? Today there are many materials suitable for cellar insulation. Let's list them:

- Styrofoam;

- mineral wool;

- ecowool;

- polyurethane foam;

- expanded polystyrene

- expanded clay

Each insulation has both pros and cons. Polystyrene foam is an inexpensive and durable material, but it is highly flammable and releases toxic substances when ignited.

Ecowool and polyurethane foam are sprayed insulation materials that have excellent thermal insulation characteristics. The materials are able to completely cover the entire surface, right down to the most inaccessible areas and small crevices. But their application requires special equipment, as well as skills to work with it, so insulation is quite difficult to do with your own hands.

Mineral wool has low thermal conductivity, retains heat well, but strongly absorbs moisture and steam. In this regard, it is undesirable to use it for thermal insulation of baths and saunas. When using this material to insulate a log house, it is necessary to install high-quality hydro- and vapor barrier. It is best to finish the top of the heat insulator with water-repellent materials.

Extruded polystyrene foam. It practically does not absorb moisture, has low thermal conductivity and light weight, and is easy to install. But the material breaks easily, so you need to be careful when working, and after installation the insulation must be reinforced with mesh.

Insulating the basement floor with expanded clay also gives good results. This natural insulation consists of porous granules with excellent thermal insulation characteristics. The advantages of the material are also non-flammability, low cost, and low weight. Disadvantages: fragility of granules and high water absorption.

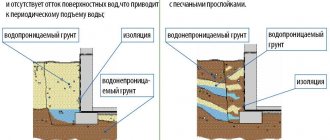

Is it necessary to insulate the underground?

The answer to this question is twofold, and very much depends on the climate, soil, and the design of the basement itself in a particular house. In some cases, an ordinary cement-sand screed is enough, in other cases, such a basement fills with water during a thaw and floods. Insulating a basement in a wooden house also involves waterproofing using plastic film or other materials.

At the same time, if you want to make proper thermal insulation with your own hands, you should already know how the basement behaves at different times of the year in order to choose the best option.

Methods of thermal insulation of a basement

The main source of cold is the floor, so when insulating this area, special attention is paid.

There are two ways to insulate a basement floor:

- With the creation of a floor on the ground.

- With bulk insulation.

The first option will require a lot of money and time; it involves arranging a complex insulation pie, which is covered with a cement screed. Typically, this method is used when it is necessary to equip a warm basement, which will be used for household needs and storage of household supplies.

Often, owners of country houses made of timber or logs are limited to a simpler option with bulk insulation. It is much simpler and faster and does not require large investments.

Arrangement of the floor on the ground

This method is best used during the construction phase. This technology can also be used during the operation of the house, but only when there is enough empty space under the base. Of course, if the insulation of the underground space is carried out in an old house, it is necessary to completely dismantle the basement floor.

Important point! Insulation of the floor on the ground is possible if the depth of the foundation from the floor line is at least 70 cm.

Layout of a floor on the ground

Stages of floor insulation work:

- Before starting work, it is necessary to compact the soil under the house well.

- One layer of roofing material is laid on a flat area. The strips must lie on top of each other with an overlap of at least 20 cm. The material must be laid so that its edges extend to the sides of the foundation by 15-20 cm.

- The seams between the sheets need to be filled with bitumen, and the edges of the roofing felt that extend onto the wall should also be coated with mastic.

- Gravel is poured on top in a layer of 5-7 m, leveled and covered with another layer of roofing felt. It must be laid in the same way as on the ground, but the panels overlap each other and the side edges can be made within 5-6 cm.

- Then thermal insulation is laid. The thickness of the layer depends on the selected material. Below are data on the thickness of different types of insulation.

- The thermal insulation is covered with a vapor barrier film or membrane, the panels of which are laid overlapping each other and glued with tape.

- A cement screed with a thickness of 6-8 cm is poured. For strength, it must be reinforced with a metal mesh made of wire 10x10 cm.

- The flooring is laid on top.

Thickness of layers of different types of insulation:

- polyurethane foam – 50 mm;

- mineral wool – 100 mm;

- expanded polystyrene – 80 mm;

- expanded clay – 200-220 mm.

Bulk insulation

Using this method, you can eliminate cold bridges coming from the ground, but the basement will not be as warm as in the first case.

The work is performed as follows:

- The soil is compacted and covered with roofing felt as described above.

- The joints between the sheets and the edges of the roofing material adjacent to the side surfaces of the foundation are coated with melted bitumen.

- If the site is located in a place where groundwater lies high, it is necessary to coat the entire floor area with bitumen.

- Sand is poured over the waterproofing; the thickness of the layer should be in the range of 50-100 mm.

- The sand is leveled and expanded clay with a thickness of 300-500 mm is laid on it.

If the basement is not intended to be used for economic purposes, you can leave everything as is. You can also make a concrete screed on top of the expanded clay. In this case, before pouring the solution, the insulation is reinforced with a metal mesh.

DIY basement insulation technology

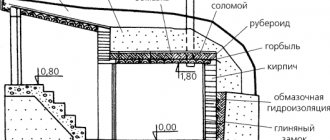

Let's figure out how to insulate the underground in a wooden house. This must be done at the stage of construction, finishing the house or repairing, in the case of an already completed building. During construction, the situation is as follows:

- Formation of the walls and floor of the future basement from clay.

- Compacting the floor soil.

- Place a cushion of sand and then compact it.

- Filling the floor with a layer of concrete (10-15 cm).

- Formation of walls, floors and subfloors from bricks, concrete slabs and iron channels (for the ceiling).

This is the simplest subfloor option for a private home. It should have several ventilation holes, located on different walls. They are called vents. The location on opposite walls will provide excellent ventilation, with one acting as a supply and the other as an exhaust. In large basements their number can reach 4 or more.

In severe frosts (-10 degrees or more), ventilation must be partially or completely blocked to avoid a drop in temperature; The task of the underground is to preserve its contents. If severe frosts occur, it is better to close the ventilation ducts completely, while ensuring periodic ventilation, at least for half an hour every few days. There are automated ventilation systems for this, but you can do it yourself.

If you have an old house with a basement in poor condition, you can insulate it using: min. cotton wool, polystyrene foam, polystyrene foam and having previously covered the walls or intermediate layers with a waterproof material, for example, polyethylene. This will also provide waterproofing. If the floor is made of soil, then it must first be compacted, covered with sand and concreted. An alternative to mineral wool is penoizol - it is more difficult to apply, but it insulates the room better.

Insulation of the foundation and basement

Thermal insulation of the underground must be carried out both inside and outside.

The foundation is insulated from the outside with cement-bonded particle boards 12-20 mm thick or polystyrene foam, which is placed on a special glue. The insulation on top is reinforced and lined with natural stone or covered with decorative plaster. The basement floor is usually insulated from the inside so as not to spoil the external attractiveness of the log house. This is done in the following sequence:

- To improve thermal insulation, the lower crowns of the log house are lined with felt or tow.

- A slatted frame is placed on the basement walls, into which insulation is laid in the form of slabs with a thickness of at least 60 mm.

- Then the structure is reinforced with mesh and plastered.

Thermal insulation of the basement ceiling, as a rule, is not done, since the floor of the first floor, if there is a basement, is usually insulated in a wooden house from below. You can read more about this in the article “How to properly insulate the floor from below - rules and nuances.”

Watch our video about choosing thermal insulation

In a private house, there is often a cellar in which food for the winter is stored. It is a cavity under the house with ventilation and entrance from the house or from the street. Insulation of the subfloor in a wooden house is necessary so that your supplies during winter frosts are stored until spring, and if the ventilation is poor or non-existent, vegetables can rot from the increased temperature and humidity.

The subfloor must be dry and ventilated. There are many options for how to insulate the subfloor in an old wooden house, some of them require a complete rebuild, some allow you to get by only by laying thermal insulation materials.

Basement ventilation system in a wooden house

In rooms with limited ventilation, moisture accumulates much faster and remains there for a long time. Wood tends to absorb this moisture, which over time leads to its deterioration.

It is important to know! If you do not take care of ventilating the basement in a timely manner, the subfloor in the house will very quickly rot and the floor may collapse right under the owner.

The first thing that needs to be done in the foundation being laid is to provide space for future wooden ventilation grilles.

If the foundation is composite, that is, assembled from cinder blocks, then the grate can be placed in the place of one of them. In the case of a poured foundation, this moment will have to be foreseen in advance and, when pouring, the place of the future ventilation window will have to be blocked in the formwork. In total, at least two wooden ventilation grilles will be needed per basement, provided that they are located opposite each other.

Fungal organisms developing in a humid environment pose a direct threat not only to the subfloor, but also to human health. Inhaling air filled with fungal spores can cause serious lung and liver diseases.

How does the insulation process work?

Previously, when houses were heated with stoves, there was no insulation or waterproofing of floors in buildings. The fact is that stove heating requires breathable walls and floors that provide adequate ventilation. With this option, the soil will not freeze even in cold winter, the house will be warm enough in cold weather and cool in hot weather. Therefore, our ancestors managed perfectly well without air conditioning and forced ventilation.

In addition, potatoes or some kind of utensils were often stored under the floor in old houses, so no one would have covered it with sawdust and peat - the most common insulation materials of that time.

Having dismantled the floors in such a house, you can see well-trodden clay between the joists, on which winter supplies lay.

They put rugs on the floor and walked around the house in some kind of knitted or felted shoes. It never occurred to anyone to walk on the boards barefoot. Many people lived in the house, and sometimes there were pets, so the floor was not sparkling clean.

Thermal insulators used

The modern construction market offers a huge number of heat-insulating materials that can be used to insulate concrete and wooden floors. To make it easier for you to choose the appropriate option, I will list the main requirements that I consider important:

- light weight - this parameter is especially important in a log house, where I would advise minimizing the load on the enclosing and supporting structures;

- hydrophobicity – water often gets on the floor, not to mention air humidity, so it is desirable that the technical characteristics of the insulation do not deteriorate when wet;

- long service life - after all, you don’t want to carry out floor insulation measures every 2-3 years, especially after retirement, when you just want to babysit your grandchildren;

- environmental safety - I certainly don’t want my descendants to breathe the chemicals emitted by cheap or low-quality heat insulators.

Sawdust is one of the most environmentally friendly insulation materials.

If the price of the material is very important to you, then to choose, you can use the table in which I have summarized the cheapest, but quite effective options.

| Insulation | Description |

| Dry sawdust | They have a minimal price, but their performance properties deteriorate greatly when wet. Therefore, I highly recommend taking care of high-quality waterproofing on both sides, especially since the material has a high water absorption coefficient. But environmental friendliness is at its best. |

| Sawdust granules | A more advanced version of the previous insulation. Granules are made from sawdust, to which water-repellent substances, antiseptics and fire retardants are added. All this makes them more practical to use, but reduces their environmental friendliness. |

| Slag | A good material that attracts builders with its low cost and low thermal conductivity. However, due to its weight, I would advise using it only for insulating floors installed on the ground (without a basement). |

| Expanded clay | Mineral granules, which are quite environmentally friendly, are light in weight and inexpensive. But in order to properly insulate the floors, you will have to pour a considerable layer of material (in some cases up to 30 cm), which is not always acceptable due to the height of the ceilings. |

| Mineral wool | Only the simplest varieties, devoid of heat-reflecting additives and other modifiers that improve performance properties, are inexpensive. But the material is non-flammable and environmentally friendly, as it is made from basalt. |

| Glass wool | This material is currently practically not used for residential premises, as it requires careful waterproofing and is harmful to health. I highly recommend choosing something more suitable, especially since there are many options. |

| Styrofoam | Lightweight, porous and cheap material with low thermal conductivity. Personally, I consider the disadvantages to be low fire-fighting properties and the fact that mice like to chew foam plastic. And one more point - low strength, therefore, for example, it cannot be used under a screed. |

The floor can also be insulated with foam plastic.

In principle, there are many options, so you can choose something suitable.

All these materials are inexpensive, but to install them you will have to buy additional materials and expend considerable effort. Take this into account when choosing insulation. It is possible that the entire insulation operation will be much more expensive than you expect.

However, I will be insulating the house for my own children and grandchildren, so I am not going to save money. If you share the same opinion, then I advise you to pay attention to the following thermal insulator options:

- Vermiculite . A material for which the raw materials are processed hydrated micas, characterized by a very low thermal conductivity coefficient and a long guaranteed service life.

Vermiculite is a loose floor insulation material.

- Penoplex. This is extruded polystyrene foam, which is a distant relative of polystyrene foam. Like the latter, it consists of small closed cells filled with air, but is distinguished by its highest strength, high hydrophobic properties and non-flammability.

Penoplex is an insulating material with excellent performance properties.

- Fiber insulation with additives. We are talking about mineral wool from such manufacturers as Ursa, Isovent, Penofol and so on. They are treated with various additives and modifiers, which give the material water-repellent properties and increase wear resistance.

Ursa is a fiber insulation with improved performance properties.

Some materials have a protective heat-reflecting layer of metal foil, which increases the effectiveness of basalt wool.

For myself, I chose basalt mats, which are sold already cut into pieces. They are easier to install between joists. In my case, Izover KL37 or KT37 (one in rolls, pipe mats) came up.

What surfaces are insulated in the basement?

To understand how to insulate a basement, including in a private home, you need to know about all the ways to establish and maintain the indoor microclimate. If everything is done correctly, then in the end you will be able to create a warm, comfortable and cozy room, suitable also for arranging a living room.

Current methods of internal basement insulation are insulation:

- walls;

- ceiling;

- floor.

And it doesn’t matter, you need to find out how to insulate a cellar or basement for equipping a workshop in a private house. The main thing is to adhere to the work algorithm and select the necessary set of tools. For insulation you will need:

- Insulation.

- Bitumen mastic.

- Plastic mesh.

- Glue.

- Cement mortar for screed.

- Brushes and rollers.

Correctly carried out thermal insulation will eliminate the formation of dampness in the basement, significantly increase the temperature, and reduce heat loss.

How does the insulation process work?

Previously, when houses were heated with stoves, there was no insulation or waterproofing of floors in buildings. The fact is that stove heating requires breathable walls and floors that provide adequate ventilation. With this option, the soil will not freeze even in cold winter, the house will be warm enough in cold weather and cool in hot weather. Therefore, our ancestors managed perfectly well without air conditioning and forced ventilation.

In addition, potatoes or some kind of utensils were often stored under the floor in old houses, so no one would have covered it with sawdust and peat - the most common insulation materials of that time.

Having dismantled the floors in such a house, you can see well-trodden clay between the joists, on which winter supplies lay.

They put rugs on the floor and walked around the house in some kind of knitted or felted shoes. It never occurred to anyone to walk on the boards barefoot. Many people lived in the house, and sometimes there were pets, so the floor was not sparkling clean.