Underground installation of heating mains for industrial purposes is not uncommon, since it is often impossible to place large-diameter pipes above ground level, especially within the city. It is better to lay the heat supply pipeline for a personal home, if the heat generating unit is located in an individual building, above the ground, but sometimes circumstances also force it to be done in a trench.

Laying heating pipes in the ground deprives the consumer of the opportunity to visually monitor the condition of the pipeline, due to this, quite high demands are placed on the quality of work in this case. Also, a heating pipe buried in the soil is influenced by a number of additional, non-standard factors, which are very important to understand. Let's consider these points and the current rules for performing work that are very necessary to correctly lay the pipes of the heating system underground.

How to lay pipes underground: options and means

Laying a pipeline is a job that almost any owner of a summer house or country house faces. The fact is that ground installation of plumbing or heating is allowed only in undeveloped areas where the structure does not bother anyone or where it is not possible to place the system underground. In all other cases, underground installation is assumed.

Methods for heating water pipes

Another way to heat the system is heating using various energy sources. There are different types of heating.

Through fluid circulation

Water has been used as an energy source for a long time. It must have a higher temperature than the insulated section of the pipeline. By constantly replacing cold water with warm water, the pipes do not freeze. The method is called a “half-open tap”; water moves slowly and constantly through the pipes. In private houses, from time to time they organize the supply of warm water through the system instead of cold. With a central water supply, warm water should be periodically drained in small volumes, thus replacing cold water.

Attention! For these purposes, you can use a special tank in the house, which acts as a sump; the water from it can be used for domestic needs.

When pumping water from a well, pumping equipment should be connected more often. To store water, a water tank is installed. You can install a gravity flow system for water back into the well. If the structure has metal parts, then this method is not suitable. When changing air and liquid, corrosion forms on the elements faster, so the quality of the water will decrease.

If water is extracted from a well, then the source itself requires thermal insulation, like water pipes. During long periods of inactivity of the liquid, which leads to freezing of pipes, then in addition to insulating material, other heating methods should be used.

Electrical cable

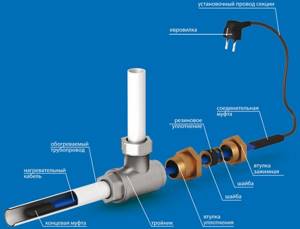

An electric cable is used as a method of heating underground water supply.

It is pulled outside the pipeline or inside the pipes. Heating occurs when thermal energy is released by electricity. If the cable is laid inside the pipe, then it has a higher level of efficiency because it directly heats the liquid. Installing these cable routing methods is equally difficult. The internal heating cable is sold with a coupling for installation at the end. The cable is connected using a tee. The cable is attached to the outside of the pipe with aluminum tape, and the pipe is hidden in a shell for insulation to retain heat inside the structure.

A thermostat should be installed with a resistive type heating cable to automatically regulate the operation of the cable, which will save electricity. With a self-regulating cable, there is no need to install a device that regulates the temperature. Some manufacturers produce rolled pipes that have insulation, a hard shell made of material that does not absorb water, and an internal cable to heat the system. These designs make installation work easier, but they are more expensive to build than purchasing all the parts separately.

Attention! Using a heating cable, you can heat a separate section of the system, or the entire pipeline, so it is not necessary to lay the system underground, below the freezing level of the soil.

How to lay a water pipe underground

The main problem when transferring liquid, especially hot liquid, is heat loss during movement. Because of this, underground installation is recommended: losses in the air will be much higher, while the soil conducts heat worse. In practice, this, of course, is not enough and the pipe must be laid in the ground with insulation.

Quite familiar materials are used for this - basalt wool, foamed polyethylene, expanded polystyrene. The thickness of the thermal insulation layer is calculated taking into account the weather. In some cases, even the use of a heating cable is allowed.

The second mandatory requirement is determining the depth. The pipeline must be located below the soil freezing level. Otherwise, there is a high risk of water freezing and, accordingly, damage to the system. For middle regions, the freezing level is about 1.4 m. The optimal depth for a water supply system is considered to be 1.6 m. Greater depths are not recommended, since the product may not withstand soil pressure, especially when it comes to HDPE water pipelines.

The pipeline is placed in the ground in a ready-made form - assembled and insulated, so all welding work must be completed before installation.

The technology for assembling the water supply system itself is simple, if the diagram is correctly calculated.

- In accordance with the plan, they dig a trench to the required depth. The width is small: for one HDPE water pipeline. for example, 40–50 cm is enough.

- Most often, in private construction, an inlet valve is installed in a well. Sometimes a water meter is installed there. A hole equal to the size of the water pipeline is made in the wall of such a well, and the assembled and thermally insulated pipeline is lowered into the well.

- If the meter is placed in a well, then it would be correct to immediately bring the gander up. The meter itself is mounted in front of all taps.

- The water supply enters the house at the same depth as it is placed in the trench. Upward installation is only permitted inside the building.

- The trench is filled with sand until a layer of sand 5–10 cm thick is formed above the water conduit. Then the trench is filled with soil.

You can learn in detail how to lay a water pipe underground in the video.

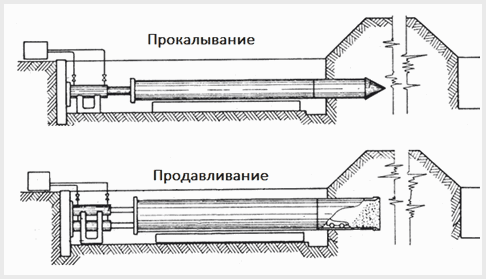

In cases where some kind of obstacle arises in front of the well - a road, for example, which is not uncommon in a summer cottage where more than one person uses the well, the question arises of how to lay a pipe underground without digging. Such technology exists, but in fact, in most cases it is cheaper to lay a trench.

To lay a pipeline without digging, you need to bring a regular trench to the obstacle. Then a recess is made at the bottom of the trench and a timber support platform is secured. The soil in the desired area is pierced with a 3-meter solid rod. The bar rests on the jack, the latter rests on the platform. This way you can puncture the area under the road without digging.

Laying the heating system

You can lay a heating pipe underground in the same way as a water pipe. But in addition to the above requirements, several more are added:

- It is allowed to place heating pipes above the freezing level. But in this case, the thermal insulation should be much better and protection against water freezing should be provided. Laying the system below the freezing level is always cheaper in the end;

- The return pipe should in no case be higher than or at the same level as the supply pipe;

- It would be correct to provide additional protection from ground pressure, especially if there is a danger of movement or high groundwater.

Thermal insulation materials for heating water pipes are the same. The photo shows a heating system in a “shell” made of polystyrene foam.

How to insulate a water supply with your own hands

Application of thermal insulation materials

The best materials for underground insulation are polystyrene foam or basalt casing. Their installation is carried out as follows:

- The two halves of the casing are placed on the pipe with an offset of 10-20 cm relative to each other.

- To insulate corners and various components of the system, fragments of the desired shape are produced.

- To secure them, they are wrapped with tape or plastic tape.

- You can wrap it with a layer of waterproofing, for example, foil or penofol.

- The waterproofing joints are also covered with tape.

Particular attention should be paid to the places where the water supply passes through the walls.

Using a heating cable

Cable layout options:

Internal installation is more difficult to do, and the cable must have high insulation characteristics.

The use of cable increases energy costs, so that they do not become unaffordable, there are several subtleties:

- You can lay the wire only in the most vulnerable places, at the rise of the system from the ground and at the entrance to the house.

- Turn heating on and off manually, depending on weather conditions.

- Equip the water supply with a sensor (there are modern systems) that will automatically turn on the heating if the temperature drops below 5 °C.

Installation of a self-regulating heating cable inside the pipe

- The water pipe is glued in a spiral (or lengthwise) with foil tape.

- The wire is wound in a spiral or along the conduit.

- The cable is secured with another layer of tape.

- A layer of insulation is put on.

- The resulting cake is tightly wrapped with a layer of plumbing tape.

- The cable is connected to the network.

- The trench is filled up.

If a spiral is used to wrap a pipe, you can find out from the instructions for a particular product how many turns are permissible to make and in what increments.

When using a metal casing, it is wrapped with metal wire.

Rules for laying heating pipes

During the design process of the system, it is necessary to take into account the rules for laying heating pipelines. They describe in detail the characteristics of transport lines, both intra-house and for centralized heating.

The main regulatory document currently is SNiP for laying heating pipelines. It is best to use the current edition, and in particular SNiP 41-01-2003. In addition to the requirements for organizing centralized heat supply, it provides recommendations for laying autonomous heating pipelines.

Regardless of whether heating pipes are laid in a wooden house or one built of brick, the following rules must be observed:

- The coolant temperature should not exceed 95°C, and the nominal pressure should not exceed 1 MPa;

- It is impossible to lay pipes in unheated attics, cellars and undergrounds if the design temperature in winter is below -40°C;

- Maintaining the optimal speed of coolant movement, depending on the noise level. The average for autonomous systems is 0.5-0.7 m/s. It directly depends on the diameter of the pipeline, the power of the circulation pump and the heating boiler;

- Hidden installation of heating pipes in baseboards or wall grooves is carried out taking into account the properties of building materials. The temperature effect from the surface of the line should not change the appearance or affect safety;

- Pipe material: metal, plastic or metal-plastic. In this case, only steel pipes must be installed at the boiler outlet and inlet. Their length must be at least 0.5 m.

These are general recommendations, the observance of which is mandatory for any method of organizing transport heat mains. But it is important for the consumer to know the intricacies of the technology used to lay heating pipes in the floor or walls.

In a gravity heating system, the slope of the pipes must be observed. It must be at least 0.3 cm per 1 lm. The same applies to the return line leading to the boiler.

Trenchless pipeline installation options

There are technologies for laying a pipeline in the ground without constructing ditches.

These methods aim to:

- do less work with the land - saving time and costs;

- minimize damage to infrastructure - less costs for the renewal of decorative and road surfaces, unexpected damage to highways;

- lay pipes in a straight line, without going around obstacles of minor difficulty;

- reduce damage from work with the earth to the external environment.

Today the following trenchless methods are used in industry:

Rehabilitation is the replacement of outdated pipes with new ones, which, for its part, is carried out in two ways: relining and the renovation method.

Relining is built on pulling a new polypropylene pipe with a smaller diameter in the middle of the working pipeline, saving the old one as a protective shell.

Renovation is the installation of a new pipe instead of an old one that has worn out and collapsed, the fragments of which will also protect the new pipeline from external damage.

Piercing (punching) is the connection of two pits dug to the required depth by a puncture made at a certain height of the wall.

Of these methods, we will only perform the relining method for everyday tasks and purposes. A cable is inserted into one end of the old pipe and pushed until it comes out of the other end. Then a new lash is attached to the cable and pulled back. The possibility of using this method depends on several points:

- the condition of the lumen of the old pipeline;

- diameter of the new pipe;

- flexibility of the new whip;

- length of the repaired area;

- ratio of the diameters of the old and new pipeline.

With a favorable combination of these factors, the technical implementation of the installation process of a new pipe is not difficult. However, all this applies to drawing a new line without thermal insulation, and the condition of the material for insulating the old pipe is unlikely to be good. Since it is not possible to make the heating pipes in the middle of the old line warmer, the method loses its attractiveness regarding heating.

Due to this, when installing heat supply pipes going deep into the soil in private housing, it is hardly possible to do without digging a ditch or, at a minimum, alternatively laying the pipe on the ground with backfill.

Underground heating pipes

In a private house, you may need to lay heating pipes underground. This scheme is used for a separate boiler room or for supplying a heat main to other buildings - a garage, outbuildings, etc.

To correctly lay heating pipes underground, the following rules must be taken into account:

- The main line may be located above the soil freezing level, but then protection against the formation of ice plugs should be provided. At the same time, heat losses will increase;

- The coolant supply cannot be at the same level or below the return pipe;

- Protection from possible soil pressure. If it is not provided for, there is a possibility of deformation or destruction of the pipeline.

The correct heating pipe for installation in the ground is first selected. It must have external frost protection. Depending on the soil temperature in winter, this can be passive or active insulation.

To improve the thermal insulation qualities, you can fill the installation trench with expanded clay on top of the sand layer.

Passive protection of heating pipes

It is a protective cocoon (shell) leveled over the highway. It is best to purchase ready-made heating pipes for installation in the ground. A multi-layer “pie” is installed on top of the plastic line. It not only protects against the effects of negative temperatures, but also shifts the “dew point”. This reduces the likelihood of condensation appearing on the pipeline.

Taking into account the rules for laying pipelines for heating systems, the following types of thermal insulation materials can be distinguished:

- Basalt wool . In addition to good thermal insulation qualities, it is hygroscopic, i.e. moisture from the surface of the pipe will be removed through the wool fibers;

- Foamed polyethylene . Recommended for use in combination with mineral wool. It forms the primary thermal insulation layer, and the basalt insulation protects the pipeline from exposure to low temperatures;

- Shell made of expanded polystyrene foam . The best option for laying heating pipes to a shallow depth. Sealing is ensured using special locks, which are insulated with tape after installation.

However, unlike laying heating pipelines in the floor, it is necessary to constantly ensure a high temperature of the coolant. Even the best passive protection with insulation will not be able to prevent the formation of ice plugs.

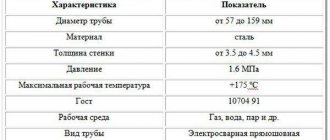

For regions with extremely low temperatures, a special Uponor Ecoflex Thermo Twin pipe can be used for external installation of heating mains. In addition to reliable thermal insulation, it is equipped with a heating cable.

Heating cable for heating

According to SNiP, the possibility of using external heat sources is not provided for the external installation of heating pipelines. But in practice, in autonomous systems with an external pipeline, this is one of the best ways to protect the pipeline from freezing.

The principle of operation of a heating cable is simple - a resistive interaction occurs between two wires, as a result of which electrical energy is transformed into thermal energy. This scheme can also be used for laying heating pipes in a wooden cottage in technical rooms where the thermal insulation of the walls is low.

It is best to use self-regulating models. Between the conductors there is a polymer filler with a varying electrical resistance. As the temperature decreases, the electrical resistance decreases, causing the cable temperature to increase. In this way, the surface of the heating pipe installed in the ground is heated.

What else needs to be taken into account when laying heating system pipes: in a private house, in the floor, in the ground? If there is a possibility of exposure to negative temperatures, you can use special antifreeze instead of water. Its crystallization temperature is below 0°C and depends on the concentration. For propylene glycol compositions, the lower limit may be at -60°C.

The video describes the pipes that are recommended to be installed for collector heating under the floor:

How to properly insulate

Thermal insulation of heating pipelines in a private home is not very difficult; it can be done with your own hands. It is enough just to follow simple conditions. All the details of the pipe insulation process can be seen in the video.

On the street

When installing thermal insulation in an open space, it is important to ensure that the pipeline is reliably sealed from precipitation and to isolate the insulation from sunlight. Previously, mineral wool was often used for thermal insulation and wrapped in roofing felt; now shells made of PPS or polyurethane foam with an outer layer of galvanized steel, reinforced foil, fiberglass or fiberglass are usually used. The heating main on the street experiences constant wind loads, so it is necessary to select a durable material for thermal insulation - polyurethane foam, extruded polystyrene foam. For large-diameter heating mains, galvanized steel shells are used.

Underground

When installing thermal insulation underground, it is necessary to especially carefully seal the insulation of steel heating pipes. It is necessary to carefully glue the joints of the shells and seal difficult areas with polyurethane foam foam. The quality of installation of the heating pipeline and thermal insulation depends on the preparation of the trench - the slope must be maintained, the pipeline with thermal insulation must be covered with sand. Underground, it is best to use ready-made shells with an outer shell made of fiberglass, fiberglass, or kraft paper for thermal insulation.

Indoors

Inside dry rooms, attics, and basements, mineral wool is often used for thermal insulation of heating pipes - rolled or in the form of shells. On top it is wrapped in penofol, fiberglass, roofing felt, and fixed with wire or tape. You can also use foam shells or penofol.

Heating pipes for installation in the ground

Special pipes, made by installation in the ground, are necessary for the heating system in a private house. Installation of pipes for the heating system by professionals from the company.

The range of choice of material and method of installing pipes for the heating system is quite wide. To install equipment, it is necessary to determine the nature of the work and pricing policy. Next, you should pay attention to the technical characteristics of the pipe for a private house for installation in the heating system.

An alternative to choosing pipes for a heating system

In the service market, many companies now present to the attention of potential clients their equipment made for installing a heating system. The alternative choice is quite large and multifaceted. There are quality equipment and durable materials that need to be properly selected and evaluated. There are different steel pipes used in the heating system in a private home.

Heating Water LLC company presents to customers a huge selection of materials for installing a heating system, performing installation and commissioning work. The craftsmen working in the company have a professional approach to the issue of performing various types of work and individually install pipes for a private house in a centralized heating system , connecting the heating system to the general system.

What affects the quality of the heating system

Among the many factors, there are especially important ones that influence the choice of quality equipment. The wide demand for equipment makes it possible to choose flexible pipes. The customer always requires high-quality installation of heating mains and selection of the best pipes, but it is worth considering:

- – pricing policy in the market of goods and services;

- – be able to correctly evaluate decent work;

- – choose a specific type of pipe;

- – correct installation of the necessary equipment in the heating system of the boiler room .

Thus, the quality of correctly performed installation is influenced by certain factors on which the startup of the heating system depends. In a private home, heating is an integral part of communications. Together with other systems such as water supply, gas supply, the heating system plays an important role in the settlement process.

Ordering services from a company

It’s easy to fill out an application for work by calling + 8 (495) 211-17-01 to the company “Heating Water” LLC. If it is necessary to carry out work on installation and adjustment of equipment for the heating system, then qualified specialists will be able to:

- – competently advise on technical issues;

- - draw up an estimate correctly;

- – work out the pipe laying scheme;

- – organize work on installation of the heating system.

The order of services is carried out by the client by telephone by appointment. The pipes needed for the heating system can be selected by specialists in this industry. It is important to consider that they will be in the ground, so it is important to respect the service life depending on the conditions. If there is a developed pipe distribution scheme, the craftsmen will definitely take into account all the client’s wishes.

Installation of a heating system in the ground

To connect the heating system, you must first fulfill all the requirements. This is a complex technological process. In this case, you should lay pipes in the ground with an individual approach to each client.

The following conditions are required for installation:

- – it is necessary to open an order to perform work;

- – prepare a project;

- – draw up an agreement with the technical supervision service;

- – study of the work area;

- – measuring the depth and width of the ditch for laying pipes;

- – carrying out direct installation work;

- – testing and commissioning.

The listed conditions are necessary for the correct execution of documents of the established form in the relevant authorities. This must always be done first, before providing services for installing pipes for the heating system in the ground.

Why do you need to insulate communications?

Perhaps someone may wonder why insulate something that is already hot. Indeed, the heating circuit is always warm, since heated coolant circulates in it. Do not forget that all insulation for heating pipes has excellent thermal insulation properties.

The essence of insulating heating pipes is to ensure that the coolant maintains its temperature for as long as possible.

It is especially important to use insulation for heating pipes if the heating main runs through the air or underground from the place where the water is heated to the heated room. Let’s assume that the pipe is not insulated; this is extremely negative for heating. In this case, the boiler, or a set of heaters, raises the temperature of the water in the system and directs the working fluid to the place where it should give up its heat. Such places are heated residential and non-residential areas. The coolant interacts with the walls of the circuit and heats them. And they, in turn, interact with the environment. As a result, the water in the system becomes colder and, accordingly, the temperature in the heated room will also be lower.

It turns out that a certain amount of fuel was spent to heat the water. And since significant heat loss occurs from the place where the coolant is heated to the destination point, the efficiency of the heater becomes lower. A lot of fuel was burned, and the temperature in the heated rooms was low. Therefore, to reduce fuel consumption and increase efficiency, the pipe must be insulated. Various materials are used for heating in private homes and for large highways.

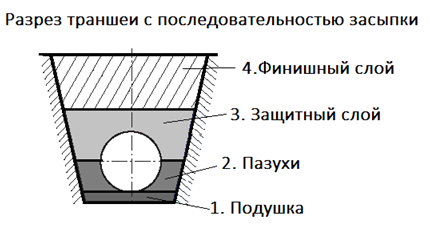

Backfilling the trench

Backfilling of the trench begins after checking the heating system in operation - if pressure testing of the circuit reveals defects in its tightness, it will be necessary to eliminate them.

Backfilling a trench is a critical stage of work, the correct execution of which determines the uniform distribution of loads and the durability of the pipeline section in the ground.

Backfilling of the trench begins with laying soft plastic soil on the sides of the pipe (in the grooves). This is done evenly along the entire length of the pipeline, preventing it from moving to the sides. The soil laid on the sides is thoroughly compacted, after which the pipeline is backfilled from the same material with a protective layer of at least 15 cm along the entire width and length of the trench in accordance with the requirements of SNiP. Compaction of this layer is carried out to a lesser extent - this is a necessary condition for the formation of a strong protective arch of soil over the pipe, resting largely on the sinuses on the sides of the pipe.

After compaction of the protective layer is completed, the trench is completely filled with soil removed during digging, removing large stones from it. Backfilling must be carried out evenly along the entire length of the trench, avoiding the formation of pipe sections with a large difference in the vertical load from the soil.

The evenly growing load from the backfill will be taken up to a greater extent by the protective soil arch above the pipe, and the residual compressive force for the pipe is not terrible - it is designed for it.

If the trench is filled in separate sections, then the difference in the vertical load on the buried and open segments of the pipeline will lead to tensile forces, which the pipe resists less well.

Types of heat insulators

Below are the main materials for thermal insulation of communications:

Thorough insulation of heating pipes

To insulate outdoor heating pipes, special mineral wool is used. Mineral wool for heating pipes comes in several types:

- Basalt – made from rock with a high basalt content. A special feature of this insulation is its high resistance to heat; the operating temperature reaches 650 degrees Celsius. Basalt wool does not react with chemical compounds and does not emit toxic substances when heated.

- Fiberglass - the main component is quartz sand. It is used not only in its pure form. Glass is made from sand, which is also part of this insulation. This material can only be used for insulating external pipes, since their operating temperature is less than two hundred degrees, about 180.

The disadvantage of such insulation of heating pipes is the tendency of the material to absorb moisture, which negates all its thermal insulation characteristics. How to insulate outdoor heating pipes to avoid mineral wool getting wet? It is for this purpose that waterproofing is used in tandem with basalt or glass wool.

Indoor insulation

Of course, insulating heating pipes in a house where the coolant must give up its heat is not necessary. But when it comes to unheated rooms, then insulating heating pipes with your own hands is very important. These spaces include basements and attics. There is no water in the basement and there shouldn't be. The insulation layer can only be threatened by increased humidity, which is not significant for materials such as basalt wool, polystyrene foam and polyurethane. Any of the above materials is suitable for insulating heating pipes in the basement, even without the use of additional waterproofing.

Most often, for domestic purposes, covers made of expanded polystyrene foam, popularly called “gray skin,” are used. But due to their high cost, they are often inferior to a cheaper type of insulation - mineral wool. In private houses with open-type heating, some elements of the circuit are located above the ceiling of the heated room. It is very important to provide insulation for the pipes and heating tank in the attic. The location of the latter is explained by the need to place it at the peak point of the contour.

Before insulating heating pipes in the attic, thoroughly familiarize yourself with the characteristics of the material. It must be resistant to heat. In the tank, the temperature of the coolant sometimes reaches the boiling point.

Price

Prices for insulation for underground water pipes are based on diameters and thickness.

Approximate cost per linear meter:

- Basalt cylinder – 33-220 rub.

- Expanded polystyrene. A meter of polystyrene foam shell will cost 120-700 rubles.

- Foamed polyethylene (Energoflex, Thermoflex, etc.) - from 10 to 500 rubles.

Glass wool is sold in rolls. Price for 1 m2 is approximately 100-130 rubles.

A meter of Folgizol waterproofing costs about 25 rubles.

The heating cable is sold in a package, from 2 meters (the longer, the cheaper):

- Constant power from 95 to 714 rubles.

- Self-regulating – 500-1660 rub.

An emergency with a water supply can happen due to a small leak, so along with high-quality insulation, all seams and pipe joints must be done conscientiously. Changing the system in winter is extremely problematic. To avoid having to sit without water while waiting for spring, it is better to immediately apply effort and resources and insulate the pipeline according to all the rules.

Not everyone decides to install a water-heated floor in their home, because this is associated with considerable inconvenience, especially due to the need to install a concrete screed. This takes time, and the work itself is dirty. However, not everyone knows that there is a good alternative - polystyrene foam for heated floors. Let's look at the main characteristics and styling features.

Read about the rules for installing stove heating with a water circuit in this topic.

Insulation underground

Such pipes are laid underground

Heating pipes are also laid underground. Important points when insulating heating pipes in the ground:

- bury communications below the freezing level. This indicator is individual for each region;

- prevent moisture from getting into the insulation;

- prevent deformation of the insulating layer under the weight of the earth.

Laying communications underground has always been expensive, as special attention to insulation is required.

The most common method is the use of insulation in conjunction with rigid casings. It could be:

- Communications wrapped in insulation, which are placed in plastic sewer pipes with a diameter of 110 or 160 mm. Mineral wool, foam materials or polystyrene can be used as insulation for heating pipes in the ground.

- Factory multilayer pipes.

The latter come in various configurations. The main thing they have in common is a pipe (plastic or metal), a layer of insulation and a rigid frame. The high cost of such products often becomes the reason for insulating underground heating pipes using the first method.

What are the purposes of pipe insulation?

Currently, insulation of external water supply pipes is carried out with a removable shell made of foamed polyurethane or polyethylene foam. If it is not possible to purchase factory-made insulation for a water supply pipe, it is permissible to wrap the communications with mineral wool and cover them with a protective layer of polyethylene film.

Insulating the water supply system will not only solve the problem of water freezing in pipes laid in the ground and in an open way, but also protects the internal water supply network from the appearance of unwanted condensed moisture deposits on the surface of the pipes. Condensation creates the preconditions for the start of destructive metal corrosion processes and increases its electrical conductivity. In addition, during repair or maintenance work on frost-covered utility lines, it is easy to slip and get injured.

Insulation on the street

To insulate heating pipes outdoors, the possibility of contact with moisture must be taken into account. It could be rain or snow. Therefore, waterproofing must be provided. The standard method of insulating heating pipes on the street:

- a layer of mineral wool;

- winding with silk threads;

- layer of roofing material;

- winding made of metal wire, resistant to corrosion (galvanized or aluminum).

Do heating pipes need to be insulated? You have probably seen more than once the deplorable state of the insulating layer of heating mains in your city. This directly affects the temperature in apartments. For example, there is a temperature level of the supplied coolant determined by government regulations. Based on this value, the average temperature in residential premises and the cost of utilities are calculated.

Calculations are made taking into account the serviceability of all elements of the heating system, including the insulating layer of heating pipes passing from boiler rooms to houses. If there is insufficient thermal insulation in apartments, the temperature will be lower. It turns out that according to the documents everything is fine, but in fact, the standard is not met and, as always, there is no one to blame. And people have to pay in full, even though their home is far from Tashkent.