There are several materials available for high-quality and tight connections of threaded plumbing parts. This review discusses a method for sealing threads with flax and paste. Note that this is not the simplest solution; to some it may seem outdated. But, with the minimum required skills and low price of materials, flax is a worthy alternative to expensive ribbons and threads.

What sealants does the building materials market offer?

There are several types of sealing materials that differ in cost, ease of use and reliability of use:

- FUM tape (fluoroplastic sealing material)

- Sealing thread

- Linen thread

Among all the FUM proposals, tape is quite difficult to use, sealing thread has good qualities, but is too expensive, and only flax is an impeccable product that has proven itself over many decades.

How to properly wind flax on a thread?

To ensure a strong and tight connection, the threaded areas must be cleaned of rust using fine-grained sandpaper

At this stage it is important not to damage the threads. Then you should check whether there are notches on the thread - with them, the laid flax threads are fixed and do not move when connecting the parts

If there are no notches, they can be applied with a file or a plumbing wrench.

Proper winding of flax consists of several steps:

Check the tightness of the connection with a clean, flax-free thread to understand how thick the winding should be. Take a bunch of flax and separate a strand of sufficient thickness from it to obtain a tight connection. The flax hairs should be the same length, without lumps, straw or debris. Twist the strand into a loose rope of such thickness that it can fill one thread groove. Holding the end of the flax rope at the edge of the thread, wind it in the direction opposite to how the nut is tightened. Each subsequent turn should fit tightly to the previous one

Here it is important not to overdo it with the number of layers, there should be no more than two, otherwise the connection may burst when tightened or from hot water during operation. If the bundle turns out to be short, winding should be continued with the next bundle. Inspect the reverse side of the winding and make sure there are no bald spots. Apply a layer of special paste or silicone on top of the flax and tighten the connection until the paste hardens

The use of a sealing composition contributes to the durability of the connection, prevents rotting of the flax, and makes it easy to disassemble the structure in the future. Sealant should not be used as a sealant; such a connection is difficult to disassemble.

Using a sealant when threading pipe systems is easy. This approach does not require the use of expensive equipment, and can be easily performed by both a professional and a home plumber.

1. Purpose of tow and how it works.2. Types of sealing materials.3. Method of sealing pipe threads with tow.

In plumbing work, tow is used to seal pipes and transitions connected by threads. It is made mainly from flax waste and is a coarse fiber of small size. If you wind the tow correctly, protection against leaks will be provided throughout the life of the pipeline. Answering the question of how to wind tow on a thread, it should be said that the quality of workmanship prevents the risk of a leak in the plumbing system. There is a gap between the threaded connections through which water freely flows out of the pipeline. If it contains properly laid plumbing tow, then the gap becomes smaller, and as water penetrates into such a connection, the flax swells and the leakage stops.

For reference

Quite often, home craftsmen have to decide how to wind flax onto the tap thread. If you want to hermetically connect the elements of the water supply and pipes, then perform work called packing. If it is necessary to pack two pipes at right angles using a coupling, it is best to cut threads at their ends. The coupling will have internal threads and external threads. Twisting them will not be enough; for a proper connection, the threads must be sealed.

The procedure for winding plumbing tow

How to wind tow on a thread? Before winding tow, it is necessary to carry out preliminary preparation of the thread. Since the surface of the thread is most often flat, the winding will begin to slip and bunch up. And it is not possible to seal it. The threads must have serrations that allow the fibers to engage on the threaded surface. The winding will not slip and will provide high-quality sealing.

You can make such notches or notches using a file or needle file. If you don't have these tools, you can use pliers. Using them you need to squeeze the thread in a circle. But it is better to purchase threads on which the manufacturers have already made notches.

Then you need to separate a strand of fiber from the braid. Choose a strand that will suit the thickness. The material should not be too thick, but not too thin. The fiber strand should not have any lumps. If there are lumps, they must be eliminated. The winding process can occur in different ways.

Many specialists twist the product before winding, others braid thin braids, and some wind it loose. It depends on the person himself. The overall result will be the same.

How to wind tow correctly? In any chosen option, the winding of turns is carried out in the direction of the thread. Beyond the thread boundaries, the end of the fiber strand must be clamped with a finger. The first turn is applied in the form of a “lock”. Be sure to twist the strands tightly, leaving no gaps. Once the winding is completed, a strand of fibers must be glued to the accompanying product closer to the outermost part of the thread. Winding of tow on the thread is done crosswise.

These are the most common and popular methods for sealing threaded connections. All of them are great, but you need to follow certain rules and nuances.

Review of sanitary flax

Linen is a popular material for winding.

The outdated name is tow. Linen is an environmentally friendly material that does not pose any harm to human health. The product does not require certification, therefore, it is possible to seal drinking water pipes. The additional material that is also needed for impregnating sanitary tow is environmentally friendly. Thanks to impregnation, this material will last for a fairly long period of time. Linen is a publicly available product. The product is sold in absolutely any plumbing store, so finding it will not be difficult.

Let's consider the advantages and disadvantages of this material in detail.

Benefits of flax

Pros of this product:

- Low cost. Tow has the smallest price tag in comparison with other windings. Therefore, when purchasing, it is better to pay attention to the quality of sanitary tow. If flax is sold in the form of a braid, then it is a quality material. If it is in the form of a tight coil, then this indicates low quality.

- Versatility in use. Can be used for any type of connection if winding is carried out correctly.

- During swelling, the volume of the winding becomes larger. This means that if the connection starts to leak, the material will immediately close everything. Small leaks will be closed.

- Resistance to mechanical stress. Only flax allows you to orient plumbing fixtures more accurately. You can make one revolution back without losing the tightness.

Disadvantages of flax

There are also disadvantages:

- In addition to tow, it is necessary to use other means, for example, grease, sealing paste, silicone and other products. If flax is an organic material, then it can rot due to the influence of water and air. Air gets in during repairs or maintenance, which must be carried out every year. And the listed products can interfere with this process.

- It is necessary to carry out preliminary preparation of the thread. Most manufacturers who produce fittings make already prepared threads for plumbing tow. It has notches. If they are missing, then they must be created. This can be done using pliers, a file or a hacksaw. They are necessary so that the plumbing material cannot slide along the coils.

- If the connections are made of brass or bronze, then during winding it is necessary to carry out the work carefully and carefully. If you apply a thick layer of winding to such connections, defects will appear on the threads. It may even happen that the thread breaks.

- Strict rules must be followed when winding this organic material. In addition to the thread, you need to first prepare the plumbing material itself. It is necessary to impregnate it with some substance to prevent future rotting. Winding must be carried out observing the direction. Winds against twisting. The ends of the flax must be brought beyond the boundaries of the thread, then they should be tightened. Hold with your finger and twist.

- It is also worth noting that the additional materials indicated above do not prevent the destruction of the connection. If you use silicone to glue different connection elements, then it will be extremely difficult and even impossible to separate them later. If flax is used without the use of additional materials, then rust appears on the winding, which will transfer to the steel.

Sealing involves sealing the water pipe. If it is necessary to seal cold water pipes, then in this case flax and tape are equally suitable. You just need to wind it correctly. But if it is necessary to seal pipes made of plastic or metal-plastic, then it is better to choose FUM tape.

The main advantage is that using tape the work will go much faster, since installation is quite easy. Also, the threads of the fittings are smooth, so the use of plumbing tape will be much more effective.

We suggest you familiarize yourself with How to lubricate the oil seal of a washing machine

The hot water pipeline sets its own conditions. The product must not only seal perfectly, but also have good resistance to high temperatures. PTFE sealing material (fum tape) in this situation is not the best option.

During winding, the FUM tape splits into fibers, which fill all the voids, thereby preventing the penetration of water. High water temperatures can affect the fibers so that they begin to shrink, eventually leading to leaks. Tow has a high level of resistance to hot water.

Also, do not forget about the low price of tow even with the use of additional materials. Plumbing tape is an expensive rewind. If you need to carry out large volumes of work, then you will feel a significant difference in cost. But installation is much easier and faster using fum tape.

Mounting a linen product requires certain skills from a person. Even a beginner can install fluoroplastic sealing material.

How to reel

everything is very simple. The main thing is not to be afraid and not to overdo it. The bottom line is this: If you wind too much, the connection may burst; if you wind too little, it may leak. How to use Unipack? The manufacturer recommends spreading the paste onto the cleaned threads, then wrapping flax and adding another layer of uniatka on top. We smear only on top, and sometimes I just smear the entire strand with unipak and then wrap it around the thread.

The most important thing is that you need to wind the flax so that when twisting it does not unwind. On a regular thread, wind it clockwise

When twisting the product, the linen will not unravel. And so, here we go:

Did you reel it in and apply a unipak? Now let's twist it.

The most important thing is not to wrap too much so that the fitting does not crack. This connection must be carefully tightened with two keys. And we can end here. Let's move on to the next connection.

To seal connections you need to use your choice:

1. Linen + sanitary paste.

Linen is not suitable for temperatures above 90 degrees; over time, it boils, burns, and loses its properties.

2. TANGIT Uni-Lock or equivalent.

Tangit Uniloka is more expensive than its analogues, 20 meters of Tangit Uniloka (packaging on a blister on which it is written that it is enough for 50 connections for a 1/2-inch thread) costs 130 rubles, and the analogue - “Plumbing” 50 meters costs the same 130 rubles ( in Leroy-Merlin, St. Petersburg).

3. Polyamide thread + silicone lubricant.

On the packaging of Tangit Unilock and its analogues the composition is written: polyamide thread + silicone. If we want to save money, we conclude: you can buy regular thick polyamide thread at a hardware store or a sewing store and buy thick or liquid silicone grease from auto parts or the same plumbing paste.

4. Linen rope + plumbing paste.

Construction and hardware stores sell household linen, jute and similar ropes made from plant materials. They cost about 50 rubles. for 50 meters.

Silicone sealant is not suitable because it polymerizes/hardens and if you need to position the connection, say, after a few hours, it will be torn inside the thread. Therefore, it is necessary to use a non-hardening and non-washable sealing filler. Additionally, vinegar-based silicone sealants can be corrosive to metals.

In general, in order to understand what is better, you just need to experiment.

How to wind? Crosswise, as indicated in the instructions for Tangit unilok, either with or against the thread - it’s all a matter of habit. The main thing is to wind it tightly so that the thread is covered with the material used. I can wind it this way and that way, and nothing will come out of the thread or leak. But still, thread or flax wound against the thread will be cut faster when tightening the nut, this is obvious.

Winding different materials for 1/2" thread:

1.

We take flax, smooth it, cut off a strand one, or maximum two, matches thick. We smooth the separated strand again, holding it between our fingers, and throw away the small fibers. If desired, you can twist the strand into a lace. We wind it very tightly along the thread, starting from the edge so that the thread groove is completely closed. Then we take the plumbing paste and spread a small amount with rotational movements onto the wound flax. If your hands grow from the right place, then everything should work out very neatly. Then we tighten the connection, twisting should occur with a certain force, but not with all the dope! If the nut tightens easily, it means there is not enough flax, or there is too much gap between the internal and external threads. You need to unwind the flax and wind more new one. If everything is done correctly, then the linen should not come out from under the thread and it will be dry :)

2.

We wind the Tangit unilock thread along the thread or crosswise 6-8 turns and connect it. And that's it.

3.

Homemade option. We also wind the polyamide thread and coat it with plumbing paste or thick silicone grease. Or first soak the entire skein of thread with liquid silicone lubricant. We wind on the connection. Let's connect. That's all. If you soak or soak a skein of thread in liquid lubricant, then you need to put it in some small plastic box or bottle so that dirt does not stick to the thread and it does not stain anything.

4.

We separate the linen rope into two laces from which it is twisted. We cut off 40-50 cm. We wind it onto the thread. Lubricate with plumbing paste and tighten the connection.

Synthetic thread - Tangit Unilock or an analogue - is the most versatile!

True knowledge will come only with experience!

Additional benefits

Before you wrap flax on threads, you should know that it swells as it absorbs moisture. This allows you to increase the tightness, because the leakage has no paths. The mechanical stability of the material is quite high; it is this characteristic that makes it possible to adjust plumbing fixtures without losing the hermetic properties; connections can be unscrewed a full turn or half a turn.

Varieties, alternatives and selection rules

Flax is good for laying almost all metal pipes, including cast iron, stainless steel, non-ferrous metals, including copper, and their alloys, such as brass. The only exceptions are aluminum and metal-plastic products, as well as those made from polymer compositions. For them, professionals recommend using fum tape.

Fibers of various qualities are available on sale. All of them are produced on the same equipment - a carding machine. They are distinguished by numbers, which contain a description on the label. They vary in the range from 8 to 24. In this case, fibers with a higher number will have fewer impurities and vice versa. They are also characterized by a degree of flexibility, which is less important in their work.

Fibers are packaged in coils, as well as braids of fixed weight and size. Their color can vary from white to light gray, as well as beige due to the use of natural raw materials.

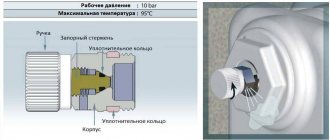

Sealing paste

Plumbing paste is a necessary component for sealing threaded connections with flax. It performs the following functions:

- Maintains fibers in normal condition.

- Protects threads from corrosion.

- Provides adjustment (adjustment) of the connection.

- Makes it easier to dismantle the connection in the future.

According to the scope of application, pastes are divided into:

- For low pressure water supply. Such pastes remain sealed at temperatures up to +140°C and pressures up to 8 bar. The connection can be adjusted within 1 ⁄ 8 thread turns (45° angle).

- For drinking water systems, natural, domestic and bottled gas. Pastes of this type can withstand pressures of up to 16 atmospheres and a maximum temperature of +130 °C. They are also resistant to minor vibrations.

The paste application process includes the following steps:

- Cleaning the thread.

- Wrap tightly with a strand of flax along the thread.

- Applying and evenly distributing the paste onto the wound flax.

- Removing excess.

There are many toothpastes available from different manufacturers. For example, let's look at the most common products.

Unipak is suitable for sealing threaded connections in water supply and heating systems at a maximum pressure of 8 bar and a temperature of no more than +140°C. The paste does not affect the quality of water in pipelines, protects the flax in the connection from decomposition and burnout, prevents its oxidation, thereby protecting the connection from corrosion. Even after prolonged use, easy dismantling of the connection is guaranteed.

Multipak is suitable for sealing threaded connections in pipeline systems with gas (maximum pressure 5 bar, maximum temperature +70°C), hot and cold water (maximum pressure 16 bar, maximum temperature +85°C). Also, this paste is recommended for use in heating systems with coolant, including ethylene glycol and propylene glycol. Multipak does not affect the quality of water in pipelines. Connections made with its help are resistant to vibrations and provide complete tightness and flexibility in adjustment.

How to wind flax on a thread

Hello dear homemade people.

Until now, the best winding for thread is linen. First, I will justify this statement, and then we will analyze the execution process piece by piece.

The first alternative to flax is fum tape. There are at least three reasons why it should be abandoned.

1. It is unknown who made it, despite what is indicated on the label, which means there are no guarantees of quality.

2. It takes a long time to wind it.

3. When tightening the thread, especially when installing valves, it is impossible to correct its position, that is, you can only tighten it forward. If you push it back a little, the connection on the gun will leak.

The second alternative is a Tangit unilock pipe with a lock. I won’t argue about the lock - it’s dead, but as for the key: consider that they screwed it up and threw the key away, so you can’t find it.

You can't unscrew it, you can only cut it.

Linen is a completely different matter.

How hard to tighten

It is impossible to give any numbers here, because tightening is done by hand. On the one hand, the stronger the better, but you should remember the fragility of the parts being connected. Modern plumbing components are rather weak compared to Soviet ones. Often, when over-tightened, a part with an internal thread breaks. Even if everything worked out well and the parts are intact, strong stress can manifest itself later in the form of a crack on the tee and a leak.

By eye, the optimal tightening can be considered a little tighter than if the parts were tightened with bare hands. In general, you need to learn to feel the material.

After twisting, the paste that has come out is removed with your finger. The result is a neat connection, without flax fibers sticking out in all directions. That's all science!

Disadvantages, negative points

Despite the large number of advantages, natural sealant is not without its disadvantages. They are especially obvious when installation and repair technology is violated. After short-term use, rust may form at the joints, making it difficult to dismantle structures during subsequent repairs. In view of this, it is recommended to regularly inspect connections for leaks and take measures to eliminate damage.

The material is very sensitive to the quality of work, so it is recommended to use it only by experienced craftsmen.

Attractive physical properties are compensated by the low chemical sensitivity of the material. Thus, flax fibers will be destroyed under the influence of antifreeze if they are part of the mixture passing through connected communications.

Disadvantages of using flax

If you are thinking about how to wind flax on a thread, you should first become familiar with all the disadvantages of this material. The base material is organic, so it can rot when exposed to air and moisture. They can get inside during routine examinations. For this, tow is accompanied by additional material that can prevent rotting processes. This can be oil paint, sealing paste, lithol or solid oil.

In some cases, it is necessary to prepare the threads before winding, and if the material is laid in too thick a layer, this can cause damage to the connections, which is especially true for brass and bronze. If you are faced with the question of how to wind flax on a thread, you must remember that the seal being described requires the master to know the rules for winding. Related materials in combination with flax can significantly complicate disassembly, this applies to silicone or oil paint. Sometimes such additions make the installation process impossible. Flax is not suitable for use where temperatures can reach 90 °C. In such places, the material is welded and loses its sealing qualities. If you work with steel, you should definitely follow the winding technology. Otherwise, the threads may be subject to corrosion.

Flax tow: features

Plumbing tow is a fibrous material that is used to seal threads. This is a completely natural product obtained from the primary processing of homogeneous, thin, long-fiber flax, which is extracted from the stem of the plant.

The scope of application of tow is very wide. Depending on the production technology, it can be tape, construction, jute and sanitary. Construction tow is a reliable way to insulate almost any connection. For its production, fully combed short flax fibers are used, and it is supplied in bales. This material is intended for construction work on sealing seams, laying and insulating log houses. Being natural, flax is especially valued among those who build wooden houses. If construction tow is supplied in rolls of a certain width, then it is called strip tow. Linen tape tow is a material for caulking up to 1 cm thick. It is used for sealing seams and voids in log houses and laying crowns.

What is used for reeling? The classic option is good old flax (also called tow or hemp), fum tape, anaerobic sealants and Tangit polyamide thread.

There have been debates about what is best to use for many years, but no clear answer has been found. The fact is that the material is selected depending on the type of work and can be interchangeable and complementary.

Let's talk about the advantages of flax for plumbing work:

- the main “plus” of flax tow is its price – cheaper than any other material;

- it is used sparingly;

- its thin fibers are very durable;

- with proper winding, it is suitable for any type of work with any connections, including sealing cast iron and ceramic pipes;

- flax can swell, absorbing possible moisture, thereby hermetically blocking the path to leakage;

- the high mechanical stability of the material allows you to adjust the plumbing fixtures: without losing the hermetic properties, you can unscrew the connection half a turn or a full turn.

Precautionary measures

- It is not recommended to wind the seal using two or more pieces - this will compromise the tightness and strength of the connection.

- The tape on the thread should not be partially unwound, since if it is applied again, the connection will lose reliability. If winding is unsuccessful, the material should be removed completely and the process repeated.

- If, when connecting the elements, too much tension is created, which can lead to breakage, the tape will not be loosened. In this case, you also need to apply the seal again, removing the old section.

We suggest you familiarize yourself with how long you can store fish in the freezer. FUM tape is a material that is sufficiently reliable when sealing threaded connections. Its correct use will ensure the tightness of any pipeline even for a person who does not have extensive experience in plumbing work.

What is the best way to moisten tow?

I removed the plug from the battery (bleeding air), there was tow on it. Now I want to screw it in again, but I don’t know what is the best way to moisten the tow so that it holds well?

It is best to “wet” with Winpak, (UNIPAK),

The plug for the battery fits perfectly.

The second option is tow and fum, it is tow and fum that I most often use for these connections.

Guarantee for correct “forging” of connections is 100%.

It is important (you are writing about an old unscrewed plug) to properly prepare the thread and wind the tow correctly in the right amount.

The thread must be cleaned of old tow, rust and paint (previously they used paint).

We fluff the tow and wind it between the turns of the thread.

At the beginning of the “daddy” there is less tow, towards the end a little more, ideally, the correct winding looks like a cone.

We applied a couple of tows on top, along the diameter of the fum, then tighten the plug.

When tightening, feel the thread; the knot should tighten tightly, but without too much effort.

When winding tow, the tow can be moistened even with ordinary water, the tow will lie better.

Wind the tow with constant tension.

We wind the tow clockwise in the case of a right-hand thread.

Source

Sealing of threaded connections of gas pipes. Linen

Linen strands or flax complete with lead lead on drying oil in our country is the most famous and popular method of sealing pipe joints.

With the help of flax strands, both gas and water pipes are installed in most apartments and houses. Largely due to the fact that this is spelled out in SNiP. Sometimes, instead of lead lead, its iron counterpart is used, but it has a clear drawback - the lack of protection against rust. In some cases, the red lead is completely neglected and the connection is established without it. This significantly increases the likelihood of corrosion developing in threaded connections.

Sealing pipe joints with flax has a number of undeniable advantages:

- Availability and low cost.

- High level of adhesion after drying oil has dried.

- Strong fixation due to high forces when tightening the connection.

However, this outdated sealing method has many disadvantages:

- To install pipes correctly, you need to have professional knowledge.

- Using too much thread tightening force may damage the part.

- Over time, gas or heating systems may begin to leak due to the destruction of the flax structure, so repairs to the system must be carried out on time.

- Difficult dismantling. It is often necessary to heat up the compounds until the flax burns out.

Thus, using flax for sealing is fraught with some problems, but with good reliability it will allow you to save on purchases.

What is fum tape and what is it used for?

FUM tape, or fluoroplastic sealing material, is a thin synthetic sealant produced in the form of a tape, usually having a translucent or matte white tint. Due to the fluorine content, fum tape has quite high mechanical and thermal stability. It does not age, does not tear when stretched and does not lose its properties under the influence of an aggressive chemical environment or high temperature. FUM 1: Used for sealing general industrial pipelines or for systems operating in aggressive chemical environments. It contains up to 20% petroleum jelly as a lubricant;

Expert recommendations

Around the wound flax it is necessary to apply plumbing paste or any other sealing material, the movements must be rotational. The work should be as neat as possible. The second end should be glued closer to the edge of the thread, and before tightening, you need to check whether the pipe hole is filled with sealing material. Now you know how to wind flax on a thread; you can see photos of these works in the article. However, from them you will not be able to understand that it is necessary to tighten the elements with moderate force. If the nut goes easily, then little flax was put in. The winding will be correct if the material does not come out and the surfaces around the joint remain clean. It is not recommended to use organic tow for gas connections, this is due to the fact that under the influence of gas it and the silicone, which is used additionally, are destroyed. Here it is most appropriate to use fum tape.