How to properly wind flax on a thread

The tightness of threaded connections depends entirely on the packaging. And although only at first glance, winding flax on a thread does not represent anything complicated, as in any other matter, there are also subtleties and secrets here.

For example, it often happens that the tow is cut off by the thread or, on the contrary, comes out. In this case, it is necessary to scrape the thread, making small notches on it.

So, how to properly wind flax on a thread and the best way to lubricate tow in the process of sealing the thread will be discussed below.

What is sanitary flax made from?

Plumbing flax is a fiber obtained from the stem of flax, hemp , and other bast crops. The plants from which the seal is made only affect the color of the tow, but not the quality. Color can vary from pale gray to various shades of brown. Despite the different plants for the production of tow, the name of the material does not change; it is still plumbing flax. At its core, it is waste from the primary processing of these crops.

Advantages of sanitary flax

- Low price .

- Equally effective for any diameter .

- Equally effective for connections made of almost any material (aluminum fittings and fittings for metal-plastic require increased care due to the fragility of the materials).

- Can be used when installing heating systems .

- It is possible to adjust (loosen the connection) by 180° without the risk of leakage.

- It is environmentally friendly product.

- Plumbing linen is able to expand upon contact with water, filling more tightly the space between the parts.

- Vibration resistant.

- Resistant to temperature changes.

- Can be used for hot and cold, for indoor and outdoor water supply, drinking water supply is no exception.

- Used for sealing gas pipelines.

Disadvantages of sanitary flax

- Working with plumbing flax requires a certain skill.

- Useless without plumbing paste.

- During work, your hands and surfaces get dirty with plumbing paste.

- Prone to rotting.

How to properly apply linen seal

Preparing the seal

This is the first operation in the entire process, on which the further quality of work depends. From the purchased flax “braid” you should separate a small amount of sealant, sufficient for several threaded connections, and set aside the rest. Do this so as not to spoil the entire “braid” by tearing off the flax for each connection separately. This can tangle the fibers and, as a result, ruin the entire material.

From the separated piece of sealant, take the required amount as needed until completely used, and then proceed again as described above.

The selected strand should be smoothed, inspected and, if necessary, cleaned of debris and small fibers.

Twist the seal into a bundle of size that will allow it to fit into the thread groove.

Thread preparation

For high-quality sealing of the connection, it is desirable (but not necessary) to have notches on the edge of the external thread. They are necessary so that when winding the flax, it is fixed in place and does not scroll.

On pipes with cut threads, the diameter of the pipe part is always slightly larger than the outer diameter of the thread. When winding and tightening the nut, even if the flax moves along the thread, it will rest against the increased diameter of the pipe part and the connection will not lose quality.

But, there are designs (for example, modern tees, crosses or angles) where, on the contrary, the diameter of the pipe part is less than the outer diameter of the thread. Here, when twisting, if the flax moves, it can almost completely go beyond the place where it is applied, since there is no stop. It is better to have notches for such cases.

Many of these structures already have them. But, if they are not there, then it is not difficult to do it yourself. A simple and quite sufficient way is to use a conventional technically sound pipe wrench. It has sharp teeth on the working part. If the diameter of the thread allows, then simply press the outer surface of the thread with this key several times, using medium force.

If the diameter of the thread is such that the wrench spread is not enough, then you can use a regular file or a hacksaw for metal, working with them across the protrusions of the thread.

How much sealant is needed per thread?

It depends on the size of the thread itself. Naturally, the larger the size, the greater the amount of sealant needed. It should be borne in mind that both a small and an excessive amount of flax will negatively affect the quality of the seal of the threaded connection.

Therefore, if there are any recommendations, the main advice remains - try it yourself. Try it several times until you understand and feel it. There is no other way. There is no exact answer in centimeters, meters, width and thickness of the sealing strip.

As a guide, we can recommend that the thickness of the prepared flax strand should be commensurate with the thickness of one or two matches.

Application of sealing paste

A prerequisite for high-quality thread connections using flax is the use of additional sealing material in the form of a paste, for example, “Unipak” or “Multipak”.

It is needed in order to:

- simplify the assembly and disassembly of the threaded unit after long-term use;

- protect the threaded connection from corrosion;

- eliminate chemical decomposition and burning of flax in heating systems;

- if necessary, perform an important regulatory operation. If, when fully tightening the threaded connection, it was not possible to precisely reach the required angle, then you can unscrew it in the opposite direction up to 45° without losing the tightness of the connection.

Characteristics of sanitary flax

- Use temperature up to 140 °C.

- A good quality seal has no rotten smell.

- Humidity should be no more than 12% (it should feel dry to the touch).

- Available in the form of braids, coils or bobbins.

- Under certain conditions, withstands pressure up to 16 atm ( see below Insoluble sanitary paste).

Plumbing flax differs from each other in the content of the flax , it is combed and torn flax (the flax is the waste that remains after primary processing, essentially garbage). The amount of fire content in the compactor is indicated by numbers from 8 to 24. The higher the numerical value, the lower the fire content in the material.

Combed sanitary flax

These are purified, thin and long fibers intended for sealing gas and water pipes. Thin and long fibers tightly fill the threads, thereby making the connection reliable. Well suited for gas lines and thin threads.

Frayed sanitary linen

Torn flax is the raw material for the production of combed flax. For torn flax, a large amount of fire is the norm. For this reason, torn flax is best used for large diameter cast iron joints.

How to choose the right linen

Flax for sealing threaded connections is sold in various quantities of 100, 200 and 500 grams and looks like a “braid”, rolled several times.

When choosing this material, you should pay attention to the following:

- flax must be combed, that is, the fibers must not have knots;

- elasticity and fine fibers are signs of a high-quality linen seal;

- There should be no foreign inclusions among the fibers in the form of remnants of the flax base (this looks like pieces of dried grass).

How to properly wind plumbing linen

This is what the finished thread should look like.

- The first step is to determine the direction of the thread , left or right thread. The right one is the one that twists clockwise.

- If there are no notches on the threads , carefully, so as not to damage the threads, make notches using a needle file , an adjustable wrench, or any metal object. This is necessary so that when screwing the thread, the tow does not rotate with the fitting, but holds on to the notches.

- Apply a thin layer ; many plumbers do not do this, but this procedure will not be superfluous.

- From the total volume of the seal, it is necessary to separate an even , non-tangled strand , about 30-35 cm long for threads with a diameter of up to one inch. The excess can then be cut off with a knife.

- Plumbing linen must be wound in one single strand .

- The flax strand must be straightened to form something like a ribbon 2-3 mm wide.

- Press one end of the strand at the base of the thread with your finger

- Wind in the direction of the thread , i.e. clockwise for right-hand threads.

- The linen strand should be laid tightly , turn to turn.

- If necessary, go over the entire thread surface one more time.

- The thread must be completely covered with plumbing linen.

- At the end of winding, the entire surface of the thread should be rolled between your fingers to tighten the flax.

- Treat with a thin layer of plumbing paste.

How to wind plumbing flax (video)

Preparatory stage

Before winding flax or tow on the thread, you need to prepare the joint surface and determine the required amount of tow. Screw the fitting onto the thread as is, without wrapping anything. This will help determine how much tow you will need to take.

If the thread is smooth and even (in the case of factory threading, most likely this will be the case), it is recommended to apply notches on the threads for better adhesion. For this, a water wrench, a triangular socket or regular pliers are suitable; all you need to do is apply notches across the thread, without being too zealous. This is done in order to prevent the tow from sliding along the threads.

The notches should not be too deep; you do not need to literally pierce the metal (watch the video). The reliability of the connection in the future will depend on how the tow is wound correctly. If you put too little and rarely, it will leak, but too much can be much more dangerous - a wound area that is wrapped too tightly can burst when the temperature rises (as you know, metal expands when heated).

How can you lubricate plumbing linen?

Before the advent of plumbing paste, red lead paint mixed with drying oil, oil paint, and silicone were used. Many people still use this method of compaction to this day. However, these methods have significant drawbacks.

Plumbing linen and paint

Advantage:

- The connection is sealed efficiently.

- Protects threads from corrosion.

Flaws:

- After the paint has dried, it is extremely difficult to disassemble such a connection.

- Very dirty work and not neat appearance of the connection.

Plumbing linen and silicone

Advantage

- Available material.

- High-quality seals the connection.

- Allows you to adjust the connection.

Flaws

- Due to the presence of acetic acid in its composition (a strong smell of vinegar appears during operation), it is not permissible to use it on metal pipes, since acetic acid causes metal corrosion.

General information

Since every home craftsman has at least once encountered the problem of winding flax onto a tap thread, you should learn how to do this. If you want to hermetically connect each element of the water supply and pipes, then you should perform packing. To do this, two pipes must be packed at an angle of 90 degrees using a coupling, and there must be a thread at the end of each pipe. The coupling will have internal threads as well as external threads. Twisting alone is not enough, so for the best connection, sealing should be done.

Description of flax (tow)

Before you start winding flax onto pipes, you should become more familiar with what flax tow is. This is a fibrous type material that is used to seal threads. The product is natural, it is made from the primary processing of homogeneous, thin and long-fiber flax. The scope of application of the material is wide. Depending on the manufacturing method, the material can be tape, jute, plumbing or construction. In our case, we will talk about insulation, which makes it possible to reliably seal each connection.

To make this material, combed fibers are used, which are brought in bales. They are used for construction work when sealing seams, insulating a log house and laying wood elements. The material is natural, and this is especially valuable among those people who are building a wooden house. If rolled material was used to connect pipes with flax, then it can be called tape. This material is also used to caulk seams in log houses and lay crowns. The advantage of using flax is the cost, since the material for plumbing work is several times cheaper than other analogues. In addition, it is economically consumed, and the fibers, although thin, are very strong. If they are wound correctly, they can be used for various types of work where any type of connection will be used. Can be used for cast iron and ceramic pipes.

Advantages

Before you start wrapping flax on the thread, you should know that it begins to swell and absorb moisture, which allows you to increase the level of tightness, since there will be no way for leakage. In addition, the material has high mechanical stability, and it is this characteristic that makes it possible to adjust plumbing fixtures, and the hermetic properties will not be lost; connections can be unscrewed by half a turn or a full turn.

Disadvantages of use

If you are thinking about how to wind flax on a thread, you should first become familiar with all the shortcomings of the material. So, the material is based on a substance of organic origin, and therefore it can begin to rot when exposed to moisture and air. Also, it sometimes gets inside even during a routine examination. To do this, when using tow, you should also use another material, additional, which will help prevent the rotting process. This can be sealing paste, oil paints, solid oil or lithol.

Sometimes, before winding, you should first prepare the thread, since if you lay the material in a large layer, then there is a possibility of damage to the joints, and this is especially true for bronze and brass. If you are faced with the question of how to wind tow on a threaded connection, then you should remember that such a seal requires knowledge of the rules of winding.

Additional materials in combination with tow will make further disassembly difficult, and this applies to oil paint and silicone. Sometimes such additions make the installation process completely unbearable. It is not suitable to use flax when the temperature reaches +90 degrees. In such places, the material begins to weld, and then completely loses its sealing properties. If you are dealing with steel, then you should definitely follow the winding technology, as otherwise the thread may be subject to corrosion.

Plumbing paste for flax

Plumbing flax is practically ineffective without sanitary paste . The paste can be water-soluble or insoluble, gray or dark green in color.

- Protects threaded connections from corrosion.

- Extends the service life of sanitary tow.

- Due to its lubricating properties, it ensures tighter screwing of fittings.

- Over time, the connection does not stick, which makes it possible to easily dismantle the plumbing unit.

- Has a long shelf life.

Insoluble sanitary paste

Insoluble paste can be used even with low system pressure, in cases where it is not possible to completely shut off the water supply. In other words, a threaded connection can be inspected using a wet thread under low pressure.

- Operating temperature depending on the manufacturer from - 20°C to + 130°C

- Pressure withstands: For natural gas in gas supply systems and household bottled gas—up to 5 atm, at temperatures from -20°C to +70°C. For heating - up to 5 atm at +130°C. For drinking water -16 atm at temperatures up to 85°C.

- Melting point 180°C

- Ignition temperature 350°C

Soluble sanitary paste

The soluble paste has the following characteristics:

- Temperature maximum 140 °C.

- To work with soluble paste, the working surface of the thread must be dry.

- Operating pressure, depending on the manufacturer, is within 16 atm.

The composition of sanitary paste includes only those components that are not prohibited for use in the food industry, so they can be used, including for drinking water supply.

Paste composition:

- Water.

- Fatty acid.

- Paraffin oils.

- Natural natural minerals and various components.

- Graphite.

- Chalk.

- Talc.

The composition may vary slightly between different manufacturers.

Technical paste for flax

On the market you can find various pastes and mastics for sealing the threads of pipelines transporting oil, gasoline, diesel fuel, and various petroleum products.

All technical characteristics and recommendations for use are indicated on the packaging.

Plumbing flax: cheap and cheerful

Linen is a classic winding. Sometimes it is called tow in the old fashioned way.

Advantages of flax for plumbing work:

Low price. Cheaper than any other winder

When purchasing, you need to pay attention to quality. Good flax is sold in a braid or loose coil, has no lumps, is clean (light in appearance)

Versatility. Suitable for any type of connection. Of course, with proper winding.

The ability to increase volume during swelling. That is, if immediately after the connection there is a small leak, it very soon “closes” itself. Flax fibers get wet and, swelling, cover small leaks.

Mechanical resistance. The only material that allows you to more accurately orient plumbing fixtures. You can, if necessary, make a half-turn back without losing the tightness.

But there are also disadvantages:

It is mandatory to use accompanying materials with it (lithol, grease, fum-let, sealing paste, silicone, oil paint). Linen is of organic origin. And like any organic matter, it has a tendency to rot, especially under the combined influence of water and air. And air enters the water supply or heating systems during repairs or preventive inspections, which must be carried out annually. The accompanying material is designed to prevent rotting.

Requires special thread preparation. Many manufacturers of fittings make their threads already prepared for winding with flax. The threads have notches. If they are not there, then they need to be applied to plumbers (with a file, pliers, or less often with a hacksaw). They are needed so that the flax, during the joining process, does not slip along the turns of the thread and does not come together in a bundle.

Requires caution in brass and bronze connections. Too thick a layer may break the thread and cracks will appear.

Plumbing linen is the only material that is very demanding in terms of compliance with winding rules. In addition to the already mentioned preparation of the thread, you need to prepare the flax itself: soak it with the accompanying material to prevent rotting. Then wind, observing the direction of the thread turns, that is, against the winding. Bring the ends of the fibers outside the thread area, pull them and, holding them with your finger, screw the connection onto the thread and tighten.

Disadvantages include the fact that the accompanying materials (not all) prevent the dismantling of connections (for example, to replace part of the system, connect new elements, or in the event of a leak). Silicone and paint glue the parts of the connection to each other in such a way that the process of separation can be quite difficult, sometimes simply impossible. The same problems arise when separating steel elements, when incorrectly wound flax (or without accompanying material) as a result of rotting allows rust to occur in the threaded connection.

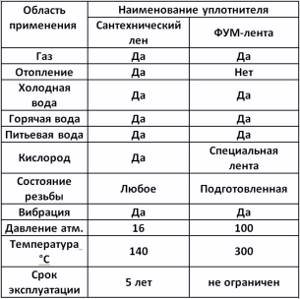

Plumbing flax or FUM tape

The table shows comparative characteristics of sanitary flax and FUM tape .

Comparative characteristics of sanitary flax and FUM tape.

Advantages and benefits

The material has an easily dosed fibrous structure and high tensile strength, which is maintained even when the reinforcement is twisted. Provided that appropriate accompanying materials are used, the maximum temperature can reach 140-150 degrees.

Compared to other materials, flax sanitary fibers have the lowest cost among similar sealants, which allows them to be purchased in kilograms. This is facilitated by the widespread availability of the material.

Environmental safety due to the use of natural raw materials allows the material to be used in the construction of water pipelines. But, despite the content of natural components, fibers do not cause allergic reactions.

An additional advantage is the service life, which, if installation rules are followed using sanitary flax, will be 5 years.

Might be interesting

Waterproofing

Foundation waterproofing: optimal choice of technology

Waterproofing

Clean water is the key to health, waterproofing concrete…

Waterproofing

Instructions for waterproofing a swimming pool

Waterproofing

Selection of materials, methods of waterproofing work...

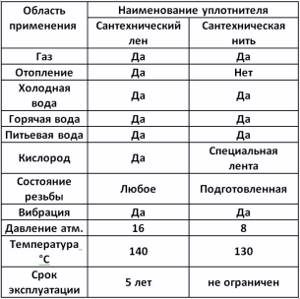

Plumbing flax or plumbing thread

The table presents comparative characteristics of sanitary flax and sanitary thread.

Comparative characteristics of plumbing flax and sanitary thread.

Plumbing flax or anaerobic sealant

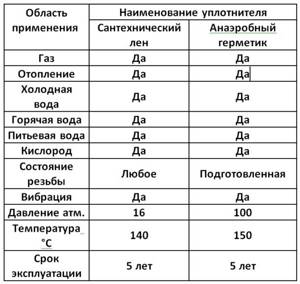

The table shows the comparative characteristics of sanitary flax and anaerobic sealant.

Comparative characteristics of sanitary flax and anaerobic sealant.

Manufacturers of sanitary flax

Russia

- MasterProf. Ordinary sanitary linen made in Russia.

- Remsan. The Russian company produces not only seals, but also heating systems and components for them.

- Uniflax. It has been producing linen products, including sanitary linen, since 2001.

Europe

- Unipak. A very popular and high-quality manufacturer of thread seals from Denmark.

- Unigarn. In principle, the same as Unipak, from the same manufacturer.

- UNI-FITT. Italian sanitary tow, like Unipak, is in great demand.

China

- No name. Chinese sanitary ware at a very affordable price.

Use Cases

As the name implies, plumbing flax is mainly used for connecting elements of water supply and sewerage systems. This applies to pipes, fittings, taps, and other components. However, according to the technical documentation, including GOST and SNiP, it can be used for other purposes. Thus, it is recommended to be used when laying engineering systems, such as gas pipelines, as well as when assembling steam and water heating systems.

The special properties of the material are used by folk craftsmen. They call it tow flax and use it as an environmentally friendly insulation for caulking bathhouses and log houses. It does not allow moisture to pass through, but allows air to pass through. It is also used as sound insulation.

The principle of operation of such a sealant is based on the use of hygroscopic properties. It consists in the fact that the plumbing fixtures will allow moisture to pass through at the threaded connection and, under its influence, the flax fibers used for winding will physically expand, minimizing the gaps, thereby preventing the further spread of moisture, leaks and, as a result, the formation of rust.

Simple winding is facilitated by high flexibility, the length of the fibers can be varied by cutting.