Technology for building a fireplace foundation with your own hands

In the process of creating a foundation for a stove or fireplace in your house, you will need the following materials:

- concrete mixture (water, sand, crushed stone, cement);

- sand;

- brick;

- cement mortar;

- rubble stone;

- gravel.

You should also prepare the following tools:

- concrete mixer;

- tape measure, cord and clothespins;

- formwork;

- hammer;

- Bulgarian;

- shovel;

- level;

- welding machine;

- screwdriver

Before building a foundation for a stove or fireplace with your own hands, you need to dig a foundation pit, the parameters of which may be 12-17 cm larger than the dimensions of the base. Its depth should be approximately 75-110 cm for a two-story house and 65 cm for a one-story house. In non-heaving soils, a straightening sand cushion should be placed at the very bottom of the pit. In heaving soils it is made of gravel and sand - 60% gravel and 40% sand.

Scheme of the foundation for the fireplace.

The height of this pillow must correspond to a similar parameter of the foundation of the building itself. It must be placed with continuous moisture and in layers. Before you organize the cushion, you must smooth and compact the bottom soil of the pit. Compacting must be done manually or automatically. Using a level, you need to control the horizontalness of the base.

All puddles that have formed at the bottom of the pit after rains should be scooped out. If the soil has become fluid-plastic, it is cut back to its original state. If the walls of the excavation pit remain vertical and groundwater does not flow into it, then the foundation for the furnace can be made of either rubble concrete or brick. Here it is necessary to calculate which method is more economical, taking into account such important factors as, for example, the dimensions of the structure, the price of materials and their transportation.

If the foundation for the furnace is placed at a slope, as well as during subsidence and movement of the soil, additional forces may arise that contribute to the destruction of the foundation. This base must be raised to a level that will be 15-16 cm below the floor. In a strictly horizontal position, the surface must be very carefully straightened using a cement composition. The upper part of the base on which the fireplace is installed can only be processed after the above mixture has completely hardened.

The surface is laid out on cement mortar with two rows of bricks. Between them 2 layers of waterproofing material are laid. The best option is the end of the foundation strictly at the level of the finished floor. The base of the fireplace is installed on it, which means the part of the system located below the firebox.

Choosing a location and type of foundation

Before starting construction and after you have decided on the size, purpose and frequency of use of the bathhouse, you need to choose a place to build it. There are nuances here.

If there is a pond on the site, it would be very appropriate to place a bathhouse near it.

However, taste preferences are not enough to choose a place. In addition, the material that will be used during construction also depends on the location.

To build a bathhouse, it is necessary to take into account the level of groundwater, as well as the characteristics of the soil. The choice of foundation type will depend on this.

The simplest and most cost-effective option is a columnar foundation. It is a system of supports made of brick, stone, concrete or pipes. For a very small wooden bathhouse, you can use burnt wooden posts.

A pile-screw foundation is used on swampy soil and at high groundwater levels. For baths, depending on the size, piles from 8-15 cm are used; their installation is carried out using special equipment or manually with the participation of 2-3 people. On soft soil or with a large slope, the piles are connected with a channel or monolithic tiles. After installation, the piles are cut to the required level, filled with concrete and welded.

A pile foundation is chosen if construction is planned on swampy or flooded soil. Steel piles up to 8 m are driven into denser layers of soil. Piles are driven using special hammers or by drilling, with or without the use of special equipment. This type of foundation is considered one of the fastest ways to organize a foundation for a bathhouse.

Strip foundation is considered the most common and reliable. This is the creation of a monolithic base-tape for load-bearing walls. It is suitable for any type of bath, but requires a lot of materials and is considered quite expensive compared to other options. Concrete, rubble concrete, and monolithic concrete are used as materials for strip foundations. Typically the depth of such a foundation is 70 cm, width 25-30 cm if the structure is made of lumber, and a little more for a log structure. You will need 15-20 cm of sand and the same amount of crushed stone, after which the trench is filled with concrete. Sometimes layers of beta and concrete alternate; in some cases, the foundation is reinforced with reinforcement.

Monolithic slab foundations are used on complex and unstable soils. This is an even more expensive and more reliable option.

Craftsmen recommend placing the bathhouse on a hill near a reservoir so that during a flood the structure does not flood and so that flowing wastewater does not cause damage to the structure. If there is no natural reservoir, one can be built. An artificial pool next to the bathhouse will be very useful.

The windows are installed on the western side of the bathhouse - there is more sun there. The entrance door is located on the south side - in winter there will be less snow there.

The bathhouse must be placed at least 10 meters from other buildings, at least 3 meters from the border of the site and about 20 m from the well.

Rules for arranging a fireplace with your own hands

Before assembling the fireplace correctly so that it is as reliable and durable as possible, you need to take into account a number of rules aimed at achieving these goals:

- When installing a brick fireplace, you need to create a separate foundation for it;

- The working part of the firebox can only be made of fireclay bricks, which should not be in contact with ordinary bricks;

- When installing the door and ash pan, you need to lay an asbestos cord and leave a small gap necessary for the thermal expansion of the metal elements;

- The interior of the firebox does not require plaster;

- It is advisable to place the rear wall of the fireboxes at a slight angle.

A separate point is the fire safety rules, compliance with which reduces the risk of fire to a minimum:

- Along the entire length of the smoke exhaust duct, special cuttings must be installed to increase the degree of fire safety;

- When placing a fireplace in close proximity to a wall, it is imperative to lay a layer of refractory material between them with a thickness of at least 20-25 mm;

- When installing a fireplace on a wooden floor, it is necessary to lay a metal sheet or ceramic coating under the structure so that it protrudes beyond the perimeter of the fireplace by at least 30-35 mm;

- At the point where the pipe passes through the interfloor floor or ceiling, a 15-cm layer of heat-insulating, heat-resistant material must be installed;

- A fireplace can only have one of its own chimneys.

The operation of the fireplace is also carried out according to certain rules:

- It is strongly not recommended to heat the fireplace to extreme temperatures;

- For normal operation, the fireplace must be regularly cleaned of soot deposits and ash;

- All flammable objects must be kept at least 70 cm away from the fireplace;

- You can only use the type of fuel in the fireplace for which the design was designed.

Dimensions and varieties

The strip foundation, just like any other, must have sufficient dimensions and exceed in this parameter the dimensions of the heating unit itself on all sides by an average of 500 centimeters or more to one and a half meters.

The depth of the foundation pit is determined in each case individually and depends on the weight and dimensions of the structure. The depth is also affected by the type of soil and the depth of its freezing.

If the house is one-story, the strip foundation will have a minimum depth of 500 centimeters. If the house consists of two floors, a pit with a minimum depth of 1 meter is dug under the strip foundation. The width of the pit depends on the fireplace and must also exceed the dimensions of the heating unit by at least 30 centimeters on each side.

A foundation, the construction of which is carried out according to certain rules for certain categories of heating equipment, may not be built at all. Most often, purchased steel and cast iron fireboxes weighing up to 500 kilograms are installed without a foundation. Due to their light weight, they can be placed even in multi-story buildings. The maximum that is required for their installation is strengthening the floor covering and sealing it.

It is necessary to pour the foundation for furnaces weighing more than 500 kilograms. In order for it to be as reliable, durable as possible, not to sag and not be afraid of moisture, the structure is completed 9-12 centimeters short of the floor level, after which several layers of roofing felt with bitumen are laid on top.

The foundation, the calculation of which is carried out individually, can be either massive, complex and full-fledged, or it can be classified as lightweight.

How to tie to the floor

The first step is to decide what material the foundation will be made of, then decide on the location, then carry out mathematical calculations and start laying the foundation. If the traditional type of concrete is chosen for the construction of the foundation, then temporary formwork is performed and the building mixture is poured.

Within 24 hours, hardening occurs, the base becomes hard and gains strength, which means that such a fireplace can be used for a long time.

It is important to know: for safety reasons, flammable objects should not be installed near the fireplace. It is best to place them at a distance of at least a meter from the fireplace, which will protect your home from fire. Watch the video, which explains the main features of the foundation for the fireplace:

Watch the video, which explains the basic features of the foundation for the fireplace:

Foundation design options

- In the form of a separate structure that is not connected to the main foundation;

- As a single whole with all underground structures.

If to build a house you use a massive reinforced concrete slab, which is installed in accordance with all building codes, there is no need to separate the foundation of the heating device. This base will perform all functions, prevent uneven shrinkage of different structures, and will be a reliable fireproof apron in a wooden country house.

Pouring the foundation for the fireplace stove

When it is not possible to pour a high-quality reinforced concrete slab, it is best to build a separate foundation. It should be placed at a distance of 5-7 cm from the main supporting structures of the building. The free space must be filled with sand. This scheme will allow you to avoid cracks in the above-ground part of the fireplace, which can also form on the walls of the house due to uneven shrinkage.

Rubble concrete, concrete and pile foundation for a stove or fireplace

Diagram of the construction of a rubble concrete foundation for a furnace.

To build a foundation for a fireplace or stove from rubble concrete, you should first make the formwork. Its internal planes are sheathed with glassine, roofing felt, roofing felt or coated with bitumen so that the laitance from the concrete does not leak into the sand. After this, the formwork must be placed on the prepared base and the first layer of large stones must be placed in it. The space between them is filled with rubble. This laid layer must be well impregnated with cement mortar.

Next, you need to make a mixture of cement and sand, which is mixed very thoroughly. To obtain a composition with the consistency of thick sour cream, water should be constantly added to the solution. You should fill 1 row of located rubble at a time. Every other day, it is optimal to form the second and third layers of the mixture. Experts recommend doing the work in one go without interruption.

The concrete foundation for a stove or fireplace is made from a solution of sand, Portland cement and gravel. This construction mixture is poured into a pit with reinforcing mesh. As a rule, concrete is poured in 2 steps. After the first portion, the reinforcement should be covered with a concrete layer and compacted. Next, the rest of the foundation is poured. The concrete sets completely in about 2 days. It should be protected from direct sunlight in the summer, for example, by covering it with a layer of roofing material. To increase the strength of a concrete foundation, it is recommended to water it frequently.

In summer, you can remove the formwork after 6-8 days, and in cold weather - after 9-14 days. If the foundation plane then has defects in the form of small pores and cavities, then it is necessary to carry out additional waterproofing. It is enough to carry out plastering with a composition of clean fine sand and cement if there is no groundwater in the soil. Next, you need to fill the pit with non-heaving soil.

When laying a deep foundation for a furnace, you can use 4 support piles, which are connected on top with a special reinforced concrete screed. They can be made from asbestos-cement pipes, which are reinforced inside with iron rods and filled with concrete mortar. The total bearing area must be calculated for a mass pressure of approximately 7 t. The main cross-section and size of each pile with a soil bearing capacity of 1.5 kg/cm² should be equal to 1600 cm².

When building a foundation for a stove or fireplace of any kind with your own hands, be sure to level its upper platform. It must be checked for horizontalness and smoothed. The maximum level should be 7-8 cm lower than the floor. To waterproof fireplace masonry for any foundation, use 2 layers of roofing material with a bitumen coating.

Why do you need a separate foundation for a fireplace?

In practice, you can find cases when home owners consider it unnecessary to equip a full-fledged foundation for a fireplace. Often people simply limit themselves to supports in the basement, but then over the years they begin to notice that the masonry is gradually deteriorating and the fireplace requires a separate foundation. The most reasonable solution is to lay the fireplace foundation in parallel with the construction of the main foundation of the house. This will save money, time and labor resources. But it is a mistake to believe that it is possible to make these two foundations a single whole, because they are designed for different loads and ultimately give a distinctive subsidence. That is why combining the foundation for a house and a fireplace base is strictly not recommended. There must be a gap of at least 50 mm between the foundations, which is filled with compacted sand.

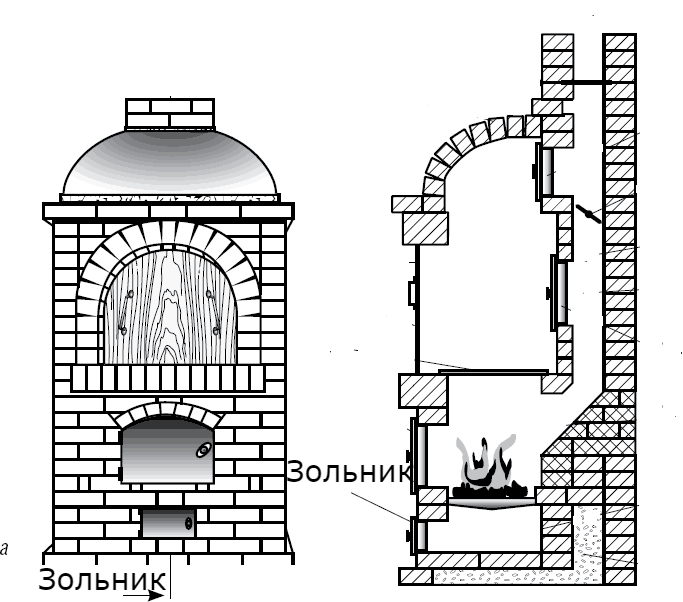

Combustion chamber

There are open and closed combustion chambers. The closed structure must necessarily include additional components - a gate and transparent doors made of fire-resistant glass. The simplest option would be to purchase a ready-made combustion chamber - this will significantly simplify the installation work, and cast-iron closed fireboxes look very good.

Arrangement of the fuel chamber is one of the most problematic and difficult stages of installing a fireplace. The firebox located under the chimney must have a chimney tooth, which is necessary for the efficient operation of the entire structure. To extend the service life of a metal firebox, it is advisable to line its internal walls with fireclay bricks, which will minimize the contact of open fire with the chamber material.

Since the main working process takes place in the firebox, it is worth considering it now:

- The fuel is removed from the fuel basket, which is usually located under the firebox, and placed on a grate located in the chamber;

- The ignited firewood is set on fire, and the intensity of its combustion is regulated using a slide valve, which provides oxygen access to the working area (if the fireplace has an open firebox, the combustion process can only be changed by adding firewood);

- The burned fuel becomes ash and ends up in the ash pan, located directly under the grate (collected ash must be removed periodically, so the best option would be a retractable ash pan);

- The gas released during combustion goes outside through the chimney (for maximum efficiency, it is worth equipping the chimney with a forced draft, which will also allow you to regulate the heat transfer of the fireplace).

The second option is somewhat more difficult to arrange - it involves installing the back wall at an angle of 30 degrees towards the inside of the fireplace. If you make a fireplace with your own hands using such a scheme, the advantage will be increased reflection of thermal energy into the room.

Where should you start building a fireplace?

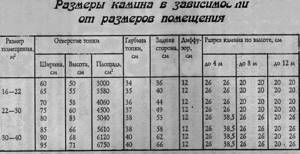

To combine all the necessary properties in a fireplace, both the customer and the architect, when coordinating and developing decisions on the layout of the future home, must calculate the volume of the entire room where the fireplace will be located and select a suitable place for its installation.

Knowing the size of the room is important for accurately calculating the size of the firebox, which will be suitable specifically for this room. It is parameters such as the width, height, depth of the firebox that determine what its heat release will be, the overall dimensions of the fireplace, its scale in relation to the volume of the room. Today, fireplace inserts are made using generally accepted technologies - from refractory bricks and using special concrete.

Metal fireboxes - cast from cast iron or welded from sheet steel - have become widespread. When calculating the size of a brick firebox, you need to pay attention to the size of the brick. When calculating the dimensions of fireboxes made of concrete and metal, only the dimensions of the room are taken into account. In addition to all this, metal and concrete fireboxes are already finished products (or so-called semi-finished products), thanks to this the manufacturability of fireplace work becomes much greater. In most cases, due to better heat transfer, metal fireboxes are preferred.

There are also so-called closed fireboxes, which are made using transparent doors made of heat-resistant quartz glass. Fireplaces based on such fireboxes are in some ways very reminiscent of an ordinary stove. While retaining the visual properties of an open fireplace, they have greater efficiency and are given greater preference in terms of fire safety.

Depending on their location, fireplaces are divided into the following types: frontal, corner and free-standing. Ordinary fireplaces are placed near the wall or in the corner of the room and take up less space. Free-standing fireplaces are an improved version of a home fireplace, which will be located in the very center of the room. This type of fireplace is more efficient in heat transfer.

Choosing a place to place a fireplace is not an easy task, and each person has a special approach to it. In this case, everything will depend on taste preferences and, accordingly, on what the architect generally offers when planning your interior. However, it is worth noting that the fireplace should not fall into the line of air movement throughout the room. A draft can be a problem, as a result of which there will be interruptions in draft and the fireplace may start to smoke. Therefore, you should choose a place for the fireplace that will fully correspond to the location of windows and doors of all types: both external and interior.

The choice of place to build a fireplace is also important when deciding whether to build a foundation for it. If the weight of the fireplace is significantly higher than the load-bearing capacity of the floors, then the construction of a foundation is necessary. The weight of the fireplace to be built is determined by its dimensions, design, material used in the construction of the fireplace, as well as all possible finishing options and chimney design.

How to choose a location and properly install a metal fireplace?

Before you begin installing the fireplace, you must clearly determine the installation location and prepare it properly. For example, if you have a wooden floor that has not been repaired for a long period of time, you should protect yourself from damage resulting from the natural wear and tear of the floorboards. To do this, the wooden elements that will be located directly under the metal structure, as well as at some distance from it, should be replaced. Next, it is necessary to provide insulation by laying a sheet of asbestos or other material with high fireproof properties. Another prerequisite is the presence of an additional hood, which will provide a constant flow of fresh air.

All walls and partitions that are located near the stove without a foundation are covered with insulating material to minimize the risk of fire.

Advantages and disadvantages of a metal fireplace

Any material has both advantages and disadvantages. Metal is no exception, which means it also has negative sides:

- rapid cooling after the fire has gone out;

- the metal surface of the fireplace gets very hot, so accidental contact with it can cause severe burns;

- uneven heat distribution throughout the entire room;

- the need for additional premises or places where firewood will be stored, as well as additional costs for their preparation.

Read also: Use of bacteria in agriculture

You can increase the cooling time and also make the heat distribution more uniform. To do this, it is necessary to line the metal walls of the furnace with bricks, leaving a small air gap. You can make decorative plaster on top of the brick or put decorative or artificial stone, as can be seen in the photo. Along with the negative qualities, metal fireplaces also have undeniable advantages:

- thanks to the air flow that passes through the firebox, there is no fear of mold and dampness;

- Possibility of installation in any room.

Thanks to this finishing, the appearance of the stove will be in maximum harmony with the interior of the room. Among other things, the outer lining will significantly reduce the risk of burns, with the exception of touching the front of the stove.

When building a country house, the design of which includes a fireplace, many people wonder whether a foundation is needed for a fireplace. Some owners do not consider it necessary to install a solid foundation and limit themselves to installing supports, but over time, such a structure will shrink and gradually collapse. There is a technology for performing the work, according to which the foundation of the house should not be connected to the foundation for the furnace structure, since they are designed for different load-bearing loads.

Finishing a false fireplace

Now it’s time for the most creative stage, which consists of giving the frame the desired appearance. There are a great many options for covering a fireplace. In order for the choice to be successful, it is necessary to remember that a real fireplace consists of four main elements - a portal, a lid, a firebox and a back wall. Let's consider ways to finish each element separately.

Decorating the portal

Depending on the style of the room, you can use the following techniques:

- The easiest way is painting. The advantage of this method lies in its low cost, speed of execution and the ability to choose absolutely any shade.

- The most realistic method is cladding with decorative sandstone, gypsum or foam bricks. They are glued to a special mixture. To maintain uniform seams, use plastic crosses for laying tiles. The larger the portal, the wider they should be. After installation, the bricks can be painted in the desired color.

- Wooden panels will also be very appropriate for decorating false fireplaces in a classic style. To protect the surface, it is first opened with varnish.

- Decorative elements made of gypsum or polyurethane stucco look great on plain, smooth portals. They immediately become elegant and presentable.

- You can use decorative mosaics or even small tiles. You can lay out a specific pattern. In principle, any facing materials can be used. Even wallpaper it in the color of the wall and create the feeling that it was squeezed out of the wall. As long as the design style does not contradict the interior of the room.

What to use for lining the lid

Sturdy structures, such as plasterboard or real brick:

- Can be covered with a piece of real wood, opened with varnish or a slab of artificial stone

- You can use a piece of plywood or chipboard as a base and line it with porcelain stoneware.

More fragile structures should not be heavily loaded.

- You can decorate the lid with small pebbles. To do this, apply a thin layer of adhesive mixture to a piece of plywood and drown the pebbles in it. After drying, open with varnish.

- There are remnants of laminate flooring lying around after renovation - great! Feel free to use it for the final element of the design.

- You can use the same material as for constructing a false fireplace. To do this, simply paint the lid in a color or highlight it with a contrasting shade.

What to place in the firebox and how to decorate the back wall

If you decide to use an electric fireplace, then the depth of the niche for it should be at least 40 cm and have an outlet. In all other cases, a depth of 20 cm is sufficient. The following elements can be placed in the firebox:

- Candles that will help create a very warm atmosphere and perfectly imitate the lights of a real flame. For a more harmonious composition, use candles of different heights and diameters.

- Real logs stacked on top of each other will create the feeling that you are about to light a real fire.

- Large river pebbles mixed with multi-colored decorative stones.

- You can place a diode strip with a yellow spectrum of light on the floor, cover it with plexiglass or regular glass, and sprinkle the same pebbles or glass balls on top. The effect of a slight glow will be created, like from hot coals.

- You can not put anything inside at all, but leave this space free by simply placing a decorative wrought-iron grille in front of the fireplace.

- You can even place vases with flowers, various figurines or small pillows.

The back wall can be:

- A continuation of the portal and look the same;

- Lined with decorative bricks, which will give it more realism;

- Have a drawing that depicts fire;

- Covered with mirror panels or a piece of a real mirror. This technique will help visually deepen the niche.

Main functions of fireplaces

For a long time, the fireplace has been assigned the following functions:

Cold protection

It was supposed to protect the room from the cold, and at one time there was no alternative to such heating, but not these days. Today, centralized and individual heating copes with this function much better, although no one is going to give up the fireplace.

Cooking

You can cook food on the fireplace. It is clear that a modern kitchen is crammed with such equipment that there simply cannot be any problems with preparing any dish. But can such food, in terms of aroma alone, compare with that cooked over a fire? And here the fireplace, on which you can bake both meat and vegetables, is simply an irreplaceable thing.

Decor

The fireplace today is a decorative decoration of the entire room; we can say that the fireplace is its soul. Today, a fireplace is comfort, joy and inspiration for all guests and household members.

It is for this reason, most likely, that even if it is impossible to have a real fireplace in a room, you can often see its imitation - with lifeless fire and the fake crackling of fake firewood. But still, even from such a fireplace your soul becomes a little warmer and happier.

What functions does the fireplace have?

The first purpose of any fireplace and stove operating on solid fuel is the heating function. Such devices must heat all rooms in the house efficiently, evenly and quickly enough. However, if you have heating radiators and batteries, you can put the stove in a second place and use it as an additional source of heating.

Also, many devices, in addition to the heating function, are intended for cooking. Such fireboxes can be equipped with a hob for one or more burners, as well as an oven. Such stoves are a full-fledged stove and are quite capable of replacing it in the kitchen of the house.

Also, all modern fireplaces are an integral part of the decor; they have a unique lining of both the portal and the firebox. In addition, if it is impossible to install a wood-burning fireplace in the room, you can create an equally realistic and high-quality imitation, in which a real flame does not burn in the hearth.

We are starting construction - why do we need a foundation?

reliable foundation significant load

In terms of its structure, the foundation for fireplaces is practically no different from the foundations that are laid under other structures. It’s good if there is an opportunity to think about solving this issue even before construction of a house begins. Then it will be possible to build foundations for the house and walls at the same time. Therefore, in the future there will be no need to dismantle various coatings.

But you can’t build the same foundations for walls and fireplaces. After all, they carry different loads, and shrinkage during operation is also different. It is necessary to create a sand-filled gap of 5 centimeters between the foundation of the heating device and any other

There are several features that you need to pay attention to during installation:

- Compared to the size of the fireplace table, the size of the foundation plane under the fireplace should be at least five centimeters larger.

- The minimum depth is 50 centimeters. It all depends on the condition of the soil; sometimes it is necessary to build a foundation at a greater depth.

- Sandy soils are compacted under the pressure of the foundation, so that for a short time it simply sags. Clay soils are unreliable; their characteristics are largely determined by the current humidity. Wet clay is also unable to bear the load.

- Brick, gravel, crushed stone and rubble stone are most often used as foundation materials. Lime-cement or cement mortar serve as binding elements for foundation fillers. A ratio of 1:6 between sand and cement will be sufficient.

Types of materials for manufacturing

A special feature of construction work on the construction of a foundation for a fireplace is the layer-by-layer filling of a pre-prepared recess with concrete mortar of various compositions. The following materials can be used in the work:

- sand – river or quarry sand, free of foreign impurities and debris;

- cement material is the main binding component for concreting. To obtain a high-quality foundation, it is necessary to choose this material correctly - the cement must be homogeneous and loose in consistency, and not have lumps or expired shelf life. Its brand must be no lower than M400;

- crushed stone is a not very large stone of natural origin. The most commonly used is limestone gravel or granite. The first option is not expensive, the second has better frost resistance;

- rubble stone is a natural material, represented by large pieces of rock, the weight of which reaches fifty kilograms.

Rubble stone can be used to make a foundation for a fireplace

Creation Rules

Work begins with digging a pit, the dimensions of which will be 10-15 cm larger than the size of the foundation. The depth of the pit varies between 60 centimeters for a one-story building and 70-100 cm for a two-story building. There should be no irregularities on its bottom. The laying should be carried out in layers: for these purposes, small crushed stone or stone is used. The solution is poured to a depth of 20-25 cm. The distance between large stones should be 3-5 cm. The upper part of the base can be made:

- level with the floor;

- near the floor;

- lower by 15 cm with the goal of subsequently leveling it and making the first layer of brickwork.

The laying is done in two rows along with two layers of waterproofing. If everything was done correctly, the level of the finished foundation and the subfloor should coincide and be at the same height.

Lightweight foundation

The lightweight foundation is laid on a sand cushion. This option is suitable for non-heaving soil rocks. First of all, a pit with a depth of about one meter is dug. The first layer is sand, which is filled with water and compacted. Next, we repeat this procedure until there is a distance of about 300-500 millimeters to the floor level.

To give the foundation strength, crushed stone, broken stone or brick are used as the top and final layer.

Also, a foundation will be needed not only for buildings located inside an enclosed space, but also for outdoor buildings. Such outdoor stoves and fireplaces may have a slightly simplified design, and the chimney may be shorter or simply absent.

Since outdoor structures are exposed to the most adverse conditions all year round, to create the strongest, most stable and long-lasting foundation possible, you will need to invest in foundation blocks. With the help of this material, the surface is perfectly smooth, without much effort.

Technology for building a foundation for a fireplace

In order to build a foundation for a fireplace in a house, it is necessary to clearly define the dimensions of the proposed structure and clarify all the features of construction work, which can be done with your own hands.

In principle, it is best to build the foundation for the fireplace at the same time as the house itself. Then it will be easier for you to decide on the location of the bookmark and it will be more convenient to work. If construction is to take place in an already residential area, you will have to remove the flooring and, quite possibly, partially dismantle the walls. It should be remembered that load-bearing walls are prohibited from being touched.

The foundations for the entire house and the fireplace should not be combined into a common structure, since the load effects on both foundations will be significantly different. It is also recommended to provide a gap between the foundations of at least five centimeters, which should then be filled with sand.

Necessary calculations

In your preliminary calculations, you need to take into account a number of features:

- the fireplace radiation surface should be located opposite the windows;

- all objects in the room should be at a distance of one meter;

- The minimum room area is 11 square meters.

It is believed that the average fireplace is 1 ton. To prevent cracks from appearing in it, it is necessary to build a solid foundation.

As a rule, the dimensions of the foundation should be ten to fifteen centimeters larger than the fireplace itself, if we consider the cross section. The pipe is designed as centrally as possible, because it is this that gives the greatest load. This will make the shrinkage process uniform and make the load symmetrical.

The dimensions of the foundation for the fireplace will be influenced by the following factors:

- type of soil composition and level of its strength;

- freezing depth;

- groundwater.

In any case, the depth is at least sixty centimeters.

Rubble concrete base

In this case, the work is carried out in several stages. First, a formwork structure is installed, lined with glassine on the inside or coated with a bitumen compound to reduce the absorption of cement laitance. A layer of large stones is laid, the remaining space between them is filled with crushed stone. This structure is generously filled with a solution of cement and sand prepared in a ratio of 1 to 3.

The depth of the foundation for the fireplace must be at least 60 cm

The final leveling of the surface is done with a mixture whose consistency resembles sour cream. In this case, cement material and sand are mixed in a ratio of 2 to 1.

There is one peculiarity in this work - everything is done at once, without interruptions. Laying the next layer is done within a day.

Reinforced concrete slab foundation

Let's look at how to properly lay out a reinforced concrete base. This will require sand, gravel, and Portland cement. Four parts of the sand-gravel mixture are poured into the cement portion, and the filling is performed in two stages. After the first layer, a mesh reinforcement frame is installed, concreting is performed, and the surface is compacted and leveled. The concrete will finally set after two days.

In summer, the formwork is removed after five days; in winter, this period is doubled.

Brick foundation

In the case where the pit walls are able to maintain verticality and groundwater does not accumulate below, the foundation can be laid out of moisture-resistant iron ore brick.

The rows are laid using sand-cement mortar, the proportions of which are taken at a ratio of 3 to 1

An important feature is the fact that the soil is likely to freeze, which can cause deformation of the brickwork; for this reason, it is recommended to lay the initial row twenty centimeters below the freezing point. This fact can be ignored if the room is heated around the clock in winter, because in this case freezing is unlikely

Whatever type of base you choose, its surface is checked for horizontal evenness.

The top of the foundation should rise about seven centimeters above the level of the floor covering; to install insulation, two layers of roofing material are laid on its surface.

There is probably no longer any doubt about whether a foundation is needed for a fireplace, and how to make it correctly. All that remains is to choose the most convenient option and get to work. The event is troublesome, but completely doable on your own. As a last resort. You can always use the services of professional craftsmen.

Basic rules for laying a foundation

Whatever option you choose for the foundation for the stove, and whatever size you decide to implement, there are a number of basic rules that you should not ignore:

The foundation for the stove must be made independent, in no way connected with the foundation of the entire house. Why? The fact is that during operation, the house may shrink slightly. When lowering, it should not pull the stove along with it, as this can lead to its deformation, deterioration of draft and disruption of technical properties.

The foundation for the furnace is separated from the general one

In some cases, it is possible to partially combine two bases by connecting them with one wall.

- If both foundations (for the house and for the stove) are located close to each other, you need to fill them with sand 50 mm thick.

- If the foundation for a common house is strip, then the base for the stove should in no case be in contact with this foundation.

- When choosing a place for a stove and, accordingly, a foundation, you should not only rely on wishes, but also on factors such as: the location of doors, windows and roof beams. The location of the chimney should be taken into account so that the pipe does not fall into the ceilings and beams during the construction of the stove.

- When calculating the size and depth of the foundation, be sure to take into account the weight of the floors and the weight of the stove along with the chimney.

The size of the foundation is influenced not only by the dimensions of the furnace, but also by the density of the soil on which it is built. The main load in the furnace is usually created by the chimney, so when designing the furnace, it is necessary to place it closer to the center of the base. This will help avoid asymmetrical loading and premature incorrect shrinkage of the oven.

Sometimes, when designing a very large and massive stove with a stone chimney, stove makers create a separate base for the chimney.

Also, the choice of foundation depends on the material of the furnace. For a metal structure and a stone one, it will be different in depth; the entire mass of a brick oven is at least 400-500 kg, while a metal oven weighs approximately 150 kg.

How to calculate the weight of a stone stove

In principle, for a small metal stove you don’t have to build a separate foundation, especially if it is being built in a house that stands on a tiled monolithic foundation.

The density of the soil and the degree of its freezing play an important role in determining the size of the foundation. The climate in Russia is accompanied by fairly harsh winters throughout almost its entire territory. Therefore, the foundation for the furnace must be laid to the entire depth of soil freezing.

The type of soil is also of great importance.

Types of soil

It comes in three types:

- clay;

- sandy loam;

- loam.

In places where a large number of rivers, reservoirs, and lakes predominate, sedimentary types of soil are usually found. Here, it is better to entrust the construction of the foundation for the stove and the house to professionals, so calculations of the water passage point must be carried out.

In Central Russia, the most common type of soil is loam, which is a mixture of sand and clay. It is clay that predominates in it, so this soil is less plastic.

Loam

Building a foundation on such soil is usually associated with hassle and additional problems, since when dry the loam is crumbly, when frost sets in it begins to “heave”, and when there is a large amount of sediment it becomes viscous.

Clay soil

Therefore, in this case, the depth of laying the foundation for the furnace must be made above the freezing point.

But in forested areas, on the contrary, it is necessary to lay the foundation for the stove below the freezing point of the soil and the foundation must be built on a sand cushion 60-90 cm thick.

One of the most reliable types of soil for building a foundation is gravelly and rocky, but, unfortunately, sometimes you have to build a house and stove on an unstable one. Proper construction of a reliable foundation will help offset this fact.

Basic moments

What to consider when installing a fireplace:

- the hole for the firebox should correspond to 1/50 of the area of the room;

- the height of the portal should be 2 times greater than the depth of the firebox;

- the chimney diameter is made 10-15 cm, it should be 10-15 times smaller than the firebox area;

- the fireplace is not installed in the path of drafts or near steps;

- The length of the chimney pipe is made at least 50 cm.

Foundation layout diagram

The total length of the smoke exhaust system is 3-4 m, sometimes it is increased to 7 m.

The structure must be protected from moisture. To do this, vertical and horizontal waterproofing is carried out using roll or coating materials.

This is interesting: Gas fireplace for a country house (69 photos) - how to install a fireplace without a chimney powered by a gas cylinder

Rubble concrete base

As in the first case, first they make markings and dig a pit of the required size.

Then the formwork is installed, placing its walls strictly level. Coat the wooden form with bitumen mastic or cover it with roofing felt so that concrete milk does not seep into the sand cushion.

Reinforced concrete base

Stones of at least 15 cm in size are not placed tightly on the bottom. The layer thickness should be 150 mm. The gaps between them are filled with crushed stone.

Prepare a cement-sand mortar in a 1:3 ratio and fill it with rubble stones.

If the solution is mixed by hand, lay one row per day. If you have a concrete mixer or construction mixer, you can get the job done much faster.

Preparatory work

Work on arranging a corner fireplace begins with the construction of the base. It is strictly forbidden to connect the foundation of the structure under construction with the base of the main building - this will lead to very unfavorable consequences.

To determine the optimal width of the foundation, add about 50 mm to the width of the front plinth row. Determine the length in accordance with the dimensions of the side row of the plinth. In general, the dimensions of the base should be slightly larger than the dimensions of the future fireplace.

When choosing a place for arranging the foundation and the fireplace itself, make sure that in the future the smoke exhaust pipe does not pass through the elements of the roof rafter system and beams.

The foundation is made extremely simply - a pit of the required size is dug, the bottom of the pit is covered with waterproofing, a layer of a mixture of sand and crushed stone is poured on top, reinforcement is laid and mortar is poured.

Building a foundation for a fireplace

Building a foundation for a fireplace

Allow the foundation to gain strength and cover it with a double layer of roofing felt.

While the foundation hardens, begin preparing building materials for upcoming use. So, the clay must first be soaked in water for a couple of days. Soak the bricks for the same amount of time.

Fireplace foundation laying diagram

Pre-calibrate the bricks you have. Elements with significant deviations from the previously mentioned size cannot be used for masonry.

To prepare the solution, use a standard and proven recipe. Pour the dry sifted sand into the clay pulp, and then mix the resulting mixture thoroughly. Determine the required amount of water individually. The finished mixture should have the consistency of jelly.

Fireplace mortar

Check the finished solution. To do this, roll a sample out of it into a “sausage” about 1.5 cm in diameter. If the sample does not stick to your hands, holds its given shape normally and does not fall apart, everything is fine.

Also check how the solution you prepared behaves directly on the brick. To do this, place the mixture on the building element. It is necessary that the solution does not stick to the trowel, does not fall apart and does not spread over the brick under its weight.

How to build a foundation for a fireplace

Construction of the fireplace begins by preparing the foundation. The furnace cannot be located on the same foundation as the building. The thickness of the foundation should be 5-6 centimeters greater than the thickness of the basement row. The arrangement begins with digging a hole with a depth of 60 centimeters, the width of which is 10 centimeters greater than this parameter at the foundation (more details: “We make a foundation for a fireplace with our own hands”).

To create a base for a fireplace, it is preferable to use bricks or concrete. The choice depends on the financial capabilities of the home owner and his personal preferences. Crushed stone is poured into the bottom of the dug hole, thoroughly compacted and leveled using a level.

Requirements for installing a fireplace

The first thing you need to pay attention to when installing a fireplace in a wooden house is fire safety:

1. You cannot install a fireplace opposite window and door openings. The flow of fresh air may cause a fire to ignite or grow uncontrollably.

2. The fireplace structure should be in the largest room. Installation in a small room threatens oxygen deficiency for household members, since the fire will actively “suck” it from the air.

3. You cannot install the fireplace directly on the floor or logs. In addition to the danger of fire in wooden floors, there is a possibility of their deformation caused by the pressure of a heavy fireplace structure.

4. The flammability of wood requires the installation of a structure located separately from the wall or the laying of a brick sheet.

The feasibility of installing a foundation

Fireplaces are quite bulky structures that require a reliable and durable foundation. Their mass can exceed one ton, and any increase in size will only add additional tens of kilograms to this weight. It follows that a foundation for a fireplace is simply necessary, which will allow the heating device to be used for decades. In addition, the presence of a base will make the operation process completely safe in terms of fire safety.

The optimal solution to the problem is to provide for pouring the foundation for the fireplace in the house at the design stage. In addition, if you build a foundation for a fireplace in a wooden house, you will have to follow all building codes with special care to eliminate the risk of fire.

Chimney installation

If the chimney is not assembled according to all the requirements and rules, then it will be impossible to ensure the operation of even the highest quality fireplace. There are a few simple rules that are best followed in any case:

- First of all, the chimney cannot be built into external walls.

- It is better to place the chimney pipe as close to the ridge as possible. It is better if the section of pipe sticking out on the street is as small as possible.

- Brick is the best material for making chimneys.

- It is better not to place reflectors and umbrellas at the chimney outlet.

- The fireplace will not work if there is no air supply.

- Compared to closed structures, open ones benefit.

By creating the necessary draft, the chimney serves to remove air and gases from any smoke structures and remove combustion products. Among other things, the chimney must be resistant to the effects of an aggressive mixture of condensate and soot, withstand the temperature of the exhaust gases, and comply with operational, fire and building standards.

For each chimney, in principle, processes such as fastening the smoke exhaust structure and its assembly, installation, installation and construction are considered individually. For a brick chimney, the process is as follows:

- Foundation

- Order

- Composition of the solution

- Mopping

- The head and the need for a chimney.

If the chimney is made of ceramics, then the following must be done:

- Foundation and fastening of modular elements

- Audit

- Connection tee.

Most actions are performed for stainless steel chimneys:

- Mounts and brackets

- Pipes “for smoke” or “for condensate”

- The use of bends or elbows to deflect the channel from the vertical

- Passages through floors and roofs

- The head and the need for an umbrella

During the installation process, it is necessary to take into account the thermal expansion that occurs during operation. It is unacceptable to violate the tightness of the installed channel. At the design stage of the fireplace design, the order of installation of the chimney, the correspondence of the component elements, cross-section and height are calculated.

Pit for the foundation

The size of the hole for the foundation, according to experienced builders, should go to a depth of 50-60 cm. Moreover, the size of the pit should be 10-15 cm wider than the finished foundation. In a finished wooden house, doing this with your own hands will not be easy, because the soil under the house may be heavily compacted.

When this labor-intensive part of the work is completed, you can begin laying the “pillow”. This layer consists of 5 cm of sand and 5 cm of crushed stone. After compaction, you can also add reinforced mesh laid on stones or simply parts of reinforcement for strength, as in the photo.

Fireplace base

For effective heating, it is advisable to place the firebox as low as possible. In practice, it can be installed at any height. The dimensions of the fireplace table are not important, the main thing is that the fireplace body fits completely on it along with the trim without overlaps on the sides. Typically, the width of the table is wider than the fireplace portal by one brick on each side. The depth depends on the depth of the firebox. For small fireplaces, the depth of the base is usually 2.5 or 3 bricks.

Depending on the chosen design of the fireplace, an ash collector (ash pan) and an air duct through which air is supplied to the combustion zone can be placed at the base. Sometimes the air duct is led through the foundation into the basement, for example, if it is difficult to supply the volume of air required for combustion through a heated room. In the simplest case, when there is no ash collector and air channels, the thickness of the fireplace base can be only one row of bricks.

Let's consider the structure of a fireplace table measuring 5x2.5 bricks with a drawer for collecting ash. The first row is solid and consists of 25 bricks.

The second row is laid with a bandage to the bricks of the first row, leaving space in the middle for the ash box.

The bricks of the central zone of the third row of the fireplace base form a firebox. Underneath it is laid with fire-resistant fireclay bricks. The fireclay bricks of the front row of the hearth and the adjacent ordinary bricks of the top row of the base are laid with a release of a quarter of the brick. This is made for ease of use; you can place a scoop under them when cleaning the firebox.

The part of the compartment for the ash collector, above which the grate will not be installed, is covered with steel strips 4 mm thick, and the middle bricks of the front row of the firebox are laid on them. In the bricks on which the grate will be installed, holes are made for the protrusions of the grate.

The floor in the considered version is laid out using cut pieces of fireclay bricks. The general rule in this case is that only untouched, factory-fired edges should be facing the fire; brick cuts are less resistant to high temperatures.

The structure of the remaining elements of the fireplace will be discussed in the following articles.

Thank you for your help in preparing the material. carries out a full range of stove work, is engaged in the manufacture, repair, restoration of stoves and fireplaces.

No. 7. Wood fireplace cladding

Probably, this method of cladding may seem impossible to many, because it is no secret that wood is very afraid of fire. However, if you follow certain rules, you can decorate your home with warm and cozy wood - such a fireplace will look great in living rooms designed in a classic style. Wood is an aesthetic, durable and natural material that has a special aroma. To enjoy these benefits, you will have to meet a number of conditions:

- It is necessary to choose rocks that are as resistant to high temperatures as possible and are not very susceptible to deformation due to constant temperature changes. It is clear that all types of wood, without exception, burn, but those that have a denser structure ignite much later. Oak, hornbeam, maple, and cherry are suitable for finishing the fireplace. Larch has average density, but pine, cedar and linden are not worth considering at all;

- impregnation with special means is required to prevent fire. These are fire retardant-based products that penetrate well into the wood structure;

- It is better to place the tree as far as possible from the hearth. Therefore, consider partially finishing the wood or create a niche for installing the cladding 5-10 cm larger than the brick frame. Then the wood will heat up within acceptable limits;

- In any case, it is better to cover the firebox with a protective screen so that sparks do not fall on the wood.

Preparatory work

The first step is to build the foundation, on which the durability and reliability of the fireplace depends. The foundation for the fireplace must be separate - the building shrinks to some extent, so the installed heating unit may become deformed. When creating a foundation in a house that is already in use, it is necessary to take into account all roofing elements that may interfere with the future structure or affect the installation process.

It is much easier to equip the foundation before building the house - all work will be reduced to the following sequence of operations:

- First you need to dig a pit, the depth of which is equal to or greater than the freezing depth of the soil;

- Next, the formwork is installed, and the bottom of the pit is filled with a mixture of crushed stone and sand;

- The next step is laying the selected waterproofing material;

- The foundation is reinforced with metal rods and filled with mortar to a mark located at a height of two bricks below the floor level;

- The poured foundation must be left until it hardens completely (usually this takes about three weeks).

If the foundation is poured from scratch, then there will be no special problems with it. A completely different matter is creating a foundation in an already built house, which will require dismantling part of the floor in the place where the fireplace will be installed.

The work process looks like this: first you need to mark the base of the fireplace on the floor and make indentations of about 20 cm in each direction. Using a grinder, the floor covering is cut along the marked lines. When this operation is completed, you can begin to extract the bare soil and perform the algorithm described above.

When the base of the fireplace is brought to the floor level, the gap between the stone and the floor covering must be decorated. In addition, after each stage of work, it is advisable to carry out cleaning, and immediately before building a fireplace in the house, the room should be covered with plastic film to minimize the amount of contamination of the floor and furniture.

After creating the foundation, you can begin work to ensure fire safety. If we make a fireplace with our own hands, located near the walls, it is necessary to protect each of them from exposure to high temperatures. Asbestos sheets are usually used for these purposes, but ceramic tiles are also a good option.

The last stage of preparatory work is to bring the purchased bricks into working condition. The bricks used need to be collected, sorted by size, and a small number of bricks that will be used in the near future need to be moistened - this way they will not take moisture from the mortar.

Foundation for a free-standing fireplace

This type of work is not at all difficult to do with your own hands if you approach all the calculations correctly.

There is even some savings in the materials from which the fireplace will be made. True, this type of fireplace often requires the dismantling of the floor covering, since it is performed in a ready-made living space. The best option for creating a foundation for this structure would be a columnar type, in which the fireplace would rest on separate pillars, the distance between which should not exceed twice the size of the brick.

Digging holes for support pillars can be done with your own hands, since this work is simple, but painstaking. And only after all the holes for the pillars have been completed, you can begin subsequent work:

- Waterproofing, sealing.

- Laying out the pillow.

- Masonry actions.

- Additional adhesion of materials in the foundation.

- Leveling the outer layer of the fireplace base.

- Covering the foundation with a table.

It is worth checking the depth of the prepared holes so that it does not diverge by a significant amount - this will ensure uniform shrinkage of the entire structure. And the depth itself should exceed the freezing value of the soil by no less than 20 cm . The only exceptions are those foundations where the fireplace will work constantly, preventing the ground from freezing.

Types of fireplaces

Stoves and fireplaces are used not only for heating a room. They create a comfortable, warm atmosphere in the house and are used for cooking. If you look at the flickering flame for 15 minutes, fatigue goes away and your mood improves.

The construction of such a structure must be approached with all responsibility. An obligatory step is the installation of a chimney and the construction of a reliable foundation. The room in which the fireplace is installed must be of sufficient area.

The easiest way to provide for the presence of a fireplace is during the construction phase. You can, of course, build the structure into a previously built house, but this will require additional financial and labor costs.

Types of brick fireplaces and their characteristics are presented in the table:

| № | Fireplace type | Characteristics |

| 1 | Angular | Mounted in one of the corners of the room. The firebox is located diagonally. The smoke chamber is arranged with inclined walls, the chimney is mounted inside a fire-resistant wall. It heats two rooms at once: the one in which it is located and the one located behind the wall, near the fireplace. |

| 2 | Built-in | It is erected only at the stage of building a house. Can be built into a wall, column, non-flammable thick partition. The advantage is that it does not take up much space. Not suitable for use in wooden houses. |

| 3 | Wall-mounted | It is used for large rooms, as it has significant dimensions. Typically the structure occupies the entire wall area. A chimney is installed on the outside of the wall. |

| 4 | Ostrovny | Installed in the center of the room or in any part of it, it has open approaches on all sides. This design takes up a lot of space. Do not install a fireplace near walls made of flammable materials. If the proper distance is maintained, it can be installed even in a wooden house. |

Placement and insulation of foundations

It is unacceptable to build a fireplace on the foundation of a house. Shifts in the foundation of the house will necessarily destroy the structure. The only exception is a monolithic slab for the entire house. But it also has reinforcing ribs for this structure.

It is unacceptable to place the foundation for a fireplace in a zone of freezing soils. This can be near the outer wall if there is no insulation of the foundation of the house. Then the distance from the fireplace to the outer wall should be at least 0.8 meters in order to eliminate the impact of frost heaving from possible freezing of the soil directly under the house. But it’s better to move it to the central part of the house.

If the blind area and the foundation wall of the house are properly insulated (5 cm of extruded polystyrene foam), then the fireplace can be located at a distance of 10 cm from the outer wall, but its foundation must be completely independent, not having a mechanical connection with the supporting structures of the house.

The gap is usually filled with sand. Date: September 25, 2021

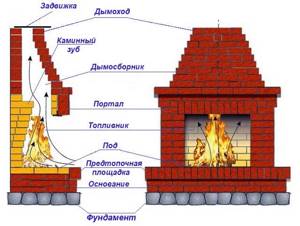

Fireplace elements and their sizes

Below is the basic design of the most common fireplace, which is not exhaustive, it is complemented by various structural elements depending on the needs of the room. But even in this form, the fireplace performs its functions well.

- Foundation

- Base

- Pre-furnace platform (fireplace table)

- Under

- Firebox

- Portal

- Smoke collector

- fireplace tooth

- Chimney damper

All dimensions of the above elements are calculated independently and quite simply, depending on the size of the room.

basic structure of a simple fireplace

In most designs, an ash pit or ash pit is laid between the foundation and the base of the fireplace, closed from the side of the room with a metal door and closed from the side of the firebox with a grate. Its presence makes it easier to remove residual combustion products from the fireplace without creating an open accumulation of ash in the firebox. With a closed portal type, the ash pan performs the function of a ash pan, through which air is drawn into the firebox. For fire safety reasons, it is not recommended to make the ash pit completely open.

ash pan under the fireplace insert

metal ash pan built in with the firebox

One of the main stages is the development of a home fireplace project. The main task when drawing up a project is to correctly calculate the dimensions of the fireplace components. They can be calculated using the table below.

fireplace size calculation table

When drawing up a project yourself, you need to pay special attention to such indicators as:

Fireplace insert size

The dimensions of the fireplace hearth must correspond to the area of the existing room, in the established proportion. If the standard proportions of the hearth are too small for the size of the room, then there may not be enough air draft for smoke outflow and smoke will occur in the room, and vice versa, if the volume of the firebox is too large, the fireplace will draw warm air from the house. If one of the tasks of the fireplace is to heat the room, then a fireplace that is too small will not be able to heat the required volume. It is recommended to make the firebox height at least 30 cm from the floor level for fire safety purposes.

fireplace insert

Fireplace foundation size

Any stone fireplace is a heavy structure that weighs 200 kg or more, and therefore requires a strong and reliable base. To avoid subsidence, distortions with structural damage, and cracks that will make it impossible to use the fireplace, it is imperative to lay a foundation under the fireplace.

A fireplace in a house is an independent structure that must have its own foundation, separate from the main foundation of the house. This need is due to the fact that the distribution of load on the foundation of the house and on the fireplace part of the foundation is different. And if these elements are connected into a single structure, then due to the uneven load, cracks will appear in the base with all the ensuing consequences. The exception is the slab monolithic foundation under the entire house, which can withstand more uneven loads.

cracks in the fireplace masonry as a result of uneven shrinkage of the foundation

The area of the foundation base for the fireplace should protrude beyond the body of the structure itself at a distance of 10 to 15 cm on each side and is filled with the same cake as the foundation for the box of the house, only based on the weight load of its structure. The height of the base for the fireplace should be 3 to 5 cm below the subfloor of the house. The depth of the foundation must be calculated specifically for each fireplace, depending on the properties of the soil and the weight of the structure itself, but it must be at least 50 cm. This can be done in any online calculator for calculating the foundation for a permanent structure. The recommended depth is 20 cm below the freezing layer of the soil under your house.

free-standing foundation for a fireplace

Fireplaces. Construction Tips

The floor in front of the fireplace is recommended to be made of stone, floor tiles or metal.

The location of the chimney inside the outer wall, as well as inside walls located in plan far from the roof ridge, should be considered unsuccessful. A chimney located in the outer wall can create problems in winter, and the chimney away from the ridge will rise greatly above the roof.

If the type and type of future fireplace has not yet been chosen, and the time has come to lay the chimney, you can prepare a brick shaft for the wall (with the size of the channel

26 x 26 cm), or leave openings between the building structures, which will allow the construction of a chimney in the constructed house.

A niche left in advance in a brick wall or an opening in a wooden one, which will subsequently be filled with masonry and will serve as a wall for leaning against the fireplace, can be very useful.

ABOUT HOT AIR

When the fireplace is operating, there is constant air circulation inside it. The air heated in the firebox, rising upward, causes jet thrust. As a result, cold air enters the firebox through special slots and firewood. A cast iron radiator (the outer surface of the firebox that gives off heat) allows you to increase the efficiency of the fireplace. The air, in contact with the radiator, heats up and enters the room through special metal grilles in the fireplace casing. Sometimes these grilles have louvers to regulate the flow of warm air into the room. The higher the radiator temperature, the faster the air flow. The radiator itself is not smooth, but ribbed.

The fins are needed to increase the cooling surface. Some fireboxes have a special damper at the outlet, the position of which can be changed using a drive - a cable. If you close this damper, the hot air stays in the oven longer and more heat will enter the room. In other fireboxes, the flame is regulated only by the lower air intake damper. Typically, the stove is connected to the chimney using steel pipes. Now flexible corrugated pipes made of stainless steel (an alloy with zirconium, which gives special strength to the product) are used for this purpose.

To a large extent determines the performance characteristics of the fireplace. Basic requirements for it:

a) the height of the chimney must be sufficient to create the necessary vacuum or draft in a closed firebox if the fireplace is an open type. The height of the chimney must be at least 5 meters from the fuel combustion surface. When the chimney height is more than 12 meters, special measures must be taken to ensure that the fuel does not burn out in a matter of seconds. After all, an increased vacuum is created in the furnace and it has to be limited. Make sure that the smoke ducts are not lower than the ventilation ducts.

b) the chimney channel must be thermally insulated, made of fireproof, dense materials that ensure its tightness; its main part must pass inside the heated room. In practice, the chimney is made in the form of a brick shaft, inside of which there is a thin-walled stainless steel pipe, or special ceramic chimney sections (blocks) of various sizes are used. It is possible to make a chimney in the form of double-walled metal elements with thermal insulation based on basalt fiber.

The draft in the fireplace depends on it. The section size is selected depending on the size of the firebox. For the smallest stove - at least 180 mm, and for the largest - at least 250 mm. The wider the pipe, the more difficult it is to “start” the fireplace. For good draft, it is desirable that all sections of the chimney are vertical. But if your home already has a ready-made chimney, and design considerations require you to place the fireplace some distance away or to the side of it, this is certainly an option. It is important that the angle of the chimney is not more than 45 degrees for closed fireboxes and more than 30 degrees for open ones.

In the case of a non-flat roof, it is better when the chimney comes out closer to the ridge and is located at least 10 degrees from the horizon in relation to it. Typically, the end of the chimney should be 40 cm higher than the ridge. A special cap made of galvanized steel crowns the pipe. It is made so as not to interfere with the free exit of smoke and at the same time protect it from rain and snow. To isolate the chimney from moisture, where it passes through the roof, foam concrete and a special sealant are used. An “apron” of galvanized iron is made around the pipe, without violating the principle of fish scales, when each overlying layer of roofing is superimposed on the underlying one.

WHY DOES A FIREPLACE HAVE A FOUNDATION?

A fireplace is a house for fire, and any house begins with a foundation. Why can't the fireplace be placed on a wooden floor? - the danger here is not so much in the weakness of the ceiling, but in the fact that cracks and leaks may arise due to the mutual mobility of the floor and the supporting wall. In general, a fireplace is placed directly on the ceiling only if it is a monolithic platform that rests on the foundation of the building. Often, at the initial stage of construction, the model and dimensions of the future fireplace are not yet known. Then they do universal site preparation. The lightweight modular design of the fireplace (350-600kg) will help to avoid building a foundation. Load-bearing cantilever elements built into the wall also help reduce the load on the floor.

The fireplace is the only interior detail built from the foundation to the roof. The foundation for the fireplace must be independent, in no way connected with the foundation of the house. In the case when both foundations are located in close proximity, sand backfill with a thickness of at least 50 mm is made between them. And b) the chimney channel must be thermally insulated, made of fireproof, dense materials that ensure its tightness, the main part of it must pass inside the heated room. In practice, the chimney is made in the form of a brick shaft, inside of which there is a thin-walled stainless steel pipe, or special ceramic chimney sections (blocks) of various sizes are used. It is possible to make a chimney in the form of double-walled metal elements with thermal insulation based on basalt fiber.

The draft in the fireplace depends on it. The section size is selected depending on the size of the firebox. For the smallest stove - at least 180 mm, and for the largest - at least 250 mm. The wider the pipe, the more difficult it is to “start” the fireplace. For good draft, it is desirable that all sections of the chimney are vertical. But if your home already has a ready-made chimney, and design considerations require you to place the fireplace some distance away or to the side of it, this is certainly an option. It is important that the angle of the chimney is not more than 45 degrees for closed fireboxes and more than 30 degrees for open ones.

In the case of a non-flat roof, it is better when the chimney comes out closer to the ridge and is located at least 10 degrees from the horizon in relation to it. Typically, the end of the chimney should be 40 cm higher than the ridge. A special cap made of galvanized steel crowns the pipe. It is made so as not to interfere with the free exit of smoke and at the same time protect it from rain and snow. To isolate the chimney from moisture, where it passes through the roof, foam concrete and a special sealant are used. An “apron” of galvanized iron is made around the pipe, without violating the principle of fish scales, when each overlying layer of roofing is superimposed on the underlying one.

WHY DOES A FIREPLACE HAVE A FOUNDATION?

A fireplace is a house for fire, and any house begins with a foundation. Why can't the fireplace be placed on a wooden floor? – the danger here is not so much in the weakness of the ceiling, but in the fact that cracks and leaks may arise due to the mutual mobility of the floor and the supporting wall. In general, a fireplace is placed directly on the ceiling only if it is a monolithic platform that rests on the foundation of the building. Often, at the initial stage of construction, the model and dimensions of the future fireplace are not yet known. Then they do universal site preparation. The lightweight modular design of the fireplace (350-600kg) will help to avoid building a foundation. Load-bearing cantilever elements built into the wall also help reduce the load on the floor.

The fireplace is the only interior detail built from the foundation to the roof. The foundation for the fireplace must be independent, in no way connected with the foundation of the house. In the case when both foundations are located in close proximity, sand backfill with a thickness of at least 50 mm is made between them.

Features of foundation formation

Before starting work, you must make sure that the foundations of the fireplace and the main building will be located at a distance of at least 5 cm from each other. The resulting gap is filled with ASG or other granular mass, thereby ensuring the independence of the two bases.

The depth of the foundation depends on the level of freezing of the ground, but should be at least 50-60 cm. The perimeter of the hole must be dug 10-15 cm larger than the final structure.

To independently make a trench for the foundation in a finished wooden house, you will have to make a lot of effort, since the soil layer under the building can be significantly compacted.

A layer of sand and crushed stone (5 cm each) is poured into the dug hole, compacted and covered with reinforced mesh and pieces of reinforcement.

Foundation

When choosing a specific type of base for a fireplace, you need to focus on the characteristics of the soil, the weight of the structure and the ease of work.

Rubble concrete or refractory brick

The foundation itself can be made of refractory brick or rubble concrete. The concrete option requires the manufacture of formwork with waterproofing, into which large and small stones are then placed and filled with concrete mortar.

For light fireplace structures, it is recommended to use a block or partially brick foundation. The latest technology involves pouring stone, crushed stone or large pebbles into a trench and laying several rows of bricks.

Brick monolith

Another option for a fireplace foundation is a brick monolith. Its production requires significant financial investments and construction skills. Brickwork is best done with a solution of lime and water (1:3) with the addition of the required amount of sand. All buried parts of the foundation must be protected from exposure to liquids. This can be done using fatty clay, diluted to the consistency of sour cream and applied to the base.

Plate