Extruded polystyrene foam XPS (EPS) is a relatively “young” thermal insulation material that has gained wide recognition due to its unique combination of characteristics. The material does not shrink, does not absorb moisture and does not swell, and it is also chemically resistant and does not rot. Due to the high strength of polystyrene foam, it is possible to obtain a rigid base for the thermal insulation system, which significantly increases its service life. The material has many more advantages, which is what made it so widespread.

What is XPS Extruded Polystyrene Foam

Another name for extruded polystyrene foam XPS (eXtruded PoliStyrene) is extrusion. A similar term is applied to materials that are produced by extrusion - by forcing a viscous melt through a molding hole. First, polystyrene granules are mixed with foaming agents (freons or carbon dioxide-based compounds), then mixed under high pressure, and only then squeezed out of the extruder.

Extruded polystyrene foam has a fine-cell structure

At its core, expanded polystyrene is a plastic with evenly distributed closed cells measuring 0.1-0.2 mm. Externally, the material looks like a smooth plate - transparent or colored. The fine-mesh structure can be easily seen directly on the cut. The edges of the slabs can be straight or in the form of an L-shaped edge, which provides more reliable adhesion of the products during installation. You can explore different types of extruded polystyrene foam by going to the product catalog.

About Penoplex material

Penoplex is a heat-insulating material produced by the company of the same name Penoplex

Penoplex is a Russian-made heat-insulating material, which is slabs of extruded polystyrene foam (polystyrene granules foamed under high pressure, which are then pressed into flat slabs). Thanks to the many small, closed cells, it gives the material excellent thermal insulation characteristics.

The manufacturer offers expanded polystyrene designed for various surfaces, for example, Penoplex Wall is used for insulating external walls and internal partitions, and Penoplex 45, in addition to being used on external walls, is actively used for constructing load-bearing flat roofs and in road construction.

The insulation is produced in different thicknesses, so it can be used for buildings under construction or renovation with different design features.

| Select Penoplex by thickness: | |

|

|

Characteristics of extruded polystyrene foam

The interest of many consumers in extruded polystyrene foam was caused by its high performance. You can easily verify this by considering the main characteristics of the material:

- Thermal conductivity coefficient – λ = 0.029 W/m·K. The lowest rate among all existing insulation materials, even lower than that of the softest mineral wool board.

- Density (specific gravity) – 25-45 kg/m3. Provides lightness of the slabs, ease of installation, as well as low cost of handling and ease of storage.

- Water absorption – 0.2% at full immersion. Since the indicator is very low, sometimes it is even neglected in calculations. Such insignificant moisture absorption is ensured by the closed cell structure. Water cannot penetrate them under any circumstances, only if the integrity is broken when the slab is cut. But even in this case, the absorption of water is negligible.

- Compressive strength at 10% deformation – 15-100 t/m2 (150-1000 kPa). According to this parameter, XPS meets the most stringent requirements for insulation materials.

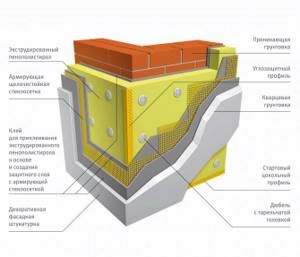

An example of insulating a brick wall using extruded polystyrene foam

Advantages of extruded polystyrene foam

The advantages of XPS expanded polystyrene also stem from its unique characteristics, the list of which is supplemented by:

- High frost resistance – withstands temperatures down to -70 °C without loss of properties. Allows the use of the material at extremely low temperatures, even in the Far North.

- High degree of fire resistance. This is achieved through additives – fire retardants, which are added to the composition of polystyrene foam. This makes the material self-extinguishing, meaning it will only burn when in direct contact with a fire source.

- Chemical resistance. XPS is not affected by acids, oils, alkalis, alcohol, saline solutions, dyes, ammonia and many other substances.

- Safety for humans. It is allowed to use the material in children's and medical institutions.

- Biostability. Eliminates the occurrence of mold and mildew on the material, since it is not a breeding ground for them.

- Durability. XPS has a service life of up to 45 years.

Disadvantages of XPS Expanded Polystyrene

- Insufficient vapor permeability – 0.007-0.008 mg/m·h·Pa.

- Flammability. Even despite its self-extinguishing properties, the material burns when in contact with fire.

- Low sound insulation. Compared to mineral wool and polystyrene foam, polystyrene foam protects less well from external noise.

- Blowability of seams. It occurs due to the rigidity of the material, but this problem can be solved by laying slabs with bandaging. For example, if the calculation requires slabs with a thickness of 100 mm, then you need to buy 50 mm slabs, but 2 times larger.

Strengths of Penoplex

Numerical indicators will allow us to draw a conclusion about the performance properties of Penoplex insulation. The strengths of the material include:

- Low thermal conductivity. The closed cellular structure helps retain heat - the effectiveness of thermal insulation exceeds that of mineral wool and isolon.

- Minimal water absorption. Moisture does not penetrate inside the material. Water can only seep into the outer damaged cells. Minimal water absorption allows Penoplex to be laid without additional waterproofing .

- Resistance to mechanical loads. Thanks to extrusion, the cells inside the porous material are evenly spaced, which significantly increases the strength of the insulation. Under significant loads, dents with a depth of about 1 mm are likely to form.

- Ease of installation. Penoplex slabs are lightweight, which means there are no problems with lifting the material to a height. An additional plus is that there is no weight to the structure .

- Durability of use. a 50-year guarantee for their products . The term is not overestimated - the insulation has passed multiple tests.

Useful: Linen insulation: natural and environmentally friendly

Where is XPS expanded polystyrene used?

Due to low vapor permeability, XPS is not recommended for use in the interior of residential and public buildings. Otherwise, the microclimate inside the facility will not be very favorable.

The use of XPS for interior work is permitted only in buildings that are equipped with a reliable forced-air supply and exhaust ventilation and air conditioning system. This is especially true for multi-storey buildings, where it is impossible to insulate the outside of the building and have to do it from the inside.

In other cases, XPS polystyrene foam is very widespread, especially in Russia, where there are a lot of wet and swampy soils. The unique properties of the material allow it to be used for insulation:

- foundations,

- roofs,

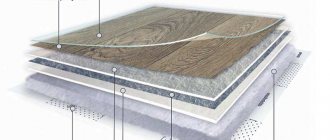

- floors,

- facades.

Work on building insulation with extruded polystyrene foam

Extruded polystyrene foam can be used to insulate various engineering structures, private and industrial construction sites, namely the floors of the first floors, basement and semi-basement basements. In the case of facades, such insulation can be used both in the “wet” method (plaster) and when installing a ventilated frame structure under siding. The scope of application of XPS expanded polystyrene also includes insulation:

- tunnels;

- highways on permafrost and heaving soils;

- airports;

- parking;

- garages;

- runways.

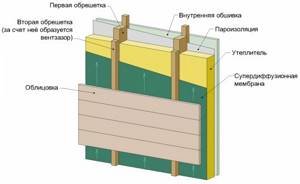

The use of extruded polystyrene foam for insulation under siding

What is important to know about extruded polystyrene foam

- It is important to use slabs only in the recommended temperature ranges. If the range is exceeded, the slabs may become deformed and lose their thermal insulation and mechanical properties.

- Penoplex 35 is characterized by increased chemical resistance to many substances and materials used in construction, as well as bitumen mixtures and mixtures that do not contain solvents. It is important to note that there are certain organic substances that negatively affect the composition of the slabs, as a result of which they can shrink or soften.

- Penoplex boards can be stored outdoors, but provided that they are carefully packed in the original packaging. It is important to note that the top layer of the slab, which will be exposed to direct sunlight, may fade, so it is recommended to cover it with a tarpaulin or other material.

- Penoplex 35 is resistant to biological degradation and does not pose a danger to the environment or human health. This fact is further confirmed by certificates and other documentary evidence.

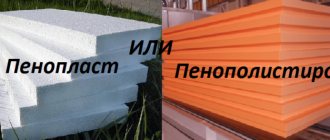

Differences between XPS and EPS polystyrene foam

There are 2 types of expanded polystyrene: extruded (XPS, eXtruded PoliStyrene) and foamed (EPS, Expanded PolyStyrene). In terms of chemical properties and thermal conductivity, the materials are very similar to each other, but some of their properties are fundamentally different:

- Compressive strength.

It is higher for XPS, but this is not important in all cases. Engineers determine the required strength. For most projects, EPS is sufficient, which allows you to save money on the budget, but for work with the foundation, XPS is still recommended, since it requires high-performance thermal insulation.

- Moisture retention.

Another argument in favor of using XPS for insulating the foundation and the soil around it (to prevent freezing), since this material does not absorb water. It is recommended to exclude the use of EPS in such cases. It has low water absorption (2%), but in the case of insulation of the foundation this can be critical. Soil in direct contact can cause the EPS to deteriorate over time.

- Insulating ability.

EPS has exactly the same vapor permeability as wood, and wooden houses are considered the most favorable in terms of microclimate. The XPS cannot boast of such properties. When insulating the walls in the house with it, the humidity slightly increases and the air exchange decreases. In this regard, when carrying out interior work, XPS is most popular in cases where it is necessary to reclaim square meters, for example, on a loggia. Here, the use of XPS will eliminate dampness of the walls and provide the required degree of thermal insulation without increasing its layer.

Penoplex and expanded polystyrene: comparison of materials

Expanded polystyrene insulation means ordinary polystyrene foam. Like Penoplex, it is produced in slabs, the maximum thickness of the heat insulator is 500 mm. For wall insulation, sheets of 50 mm or more are used, and for the ceiling a lower value is acceptable.

Polystyrene foam is also made by foaming using polystyrene foam granules. However, there is no extrusion with compression stage. As a result, large cells are formed in the structure. This affects the strength of the insulation - polystyrene foam is less rigid than Penoplex .

Expanded polystyrene is also inferior in terms of thermal efficiency, density and water absorption. The vapor permeability level of polystyrene foam and Penoplex is comparable.

Knowing the purpose, upcoming loads and operating conditions of extruded polystyrene foam, it is easy to choose the optimal type of Penoplex. It is possible to install the insulation yourself , except for facade work at height - in this case you will need the help of construction climbers.

Popular manufacturers of extruded polystyrene foam

The number of companies producing XPS foam is growing steadily, but a few manufacturers still remain in the lead. Among them there are both domestic and foreign companies. The most popular of them are presented in the table.

| Name | Logo | A country | Product Features |

| Eryap | Türkiye | The company produces Bonuspan expanded polystyrene panels. The capillarity of the material is practically zero. | |

| IZOCAM | Türkiye | In the production of XPS boards, the company uses developments from American companies. The latest technologies allow the manufacturer to use lightweight but durable material. | |

| "Elite-Plast" | Ukraine | The large-area production complex allows the production of extruded polystyrene foam on an unlimited scale. The products comply with the Kyoto Protocol, therefore eliminating environmental pollution. The products are produced under the Penoboard brand, predominantly blue in color. | |

| "TechnoNIKOL" | Russia | The company produces its own types of XPS expanded polystyrene - "TechnoNIKOL" and "TECHNOPLEX" for insulating loggias, floors, balconies, foundations and walls in basements. | |

| "PENOPLEX" | Russia | Another large Russian manufacturer of EPS. In line extruded polystyrene foam XPS "PENOPLEX" bright orange slabs are presented:

| |

| Fibran | Greece | Fibran Eco XPS boards are environmentally friendly because they do not use freon in their production, which makes the material absolutely harmless. The production of the material is organized in Bulgaria. The slabs have a bright turquoise color. | |

| Ursa | Germany | One of the well-known European companies that produce insulating materials. The XPS URSA expanded polystyrene line includes predominantly white slabs with a thickness of 30-100 mm and a density of 30-50 kg/m3 in several varieties:

|

The widest range of extruded polystyrene foam from

The assortment of popular domestic products includes variations of insulation for a variety of areas of construction. The most common versions of the material:

- Extruded polystyrene foam "TechnoNIKOL" XPS Carbon Eco . Contains carbon particles that increase strength, reduce thermal conductivity and give the material a lightened tone with a silvery tint.

- "TechnoNIKOL" Carbon Prof. Professional building material. It has high strength and the lowest thermal conductivity coefficient. Suitable for almost all types of foundations. The line also includes slabs for creating a slope on a flat roof (Prof Slope).

- "TechnoNIKOL" Carbon Eco Drain. Designed for lining wall drainage, for which it is equipped with drainage channels or ribbing. By using this material on flat roofs, you can get rid of stagnant water.

- "TechnoNIKOL" Carbon Eso Fas. This type of slab is distinguished by a characteristic milling, which ensures particularly high adhesion to the base. The use of the material is relevant for plinths and plaster facades.

- "TechnoNIKOL" Carbon Sand Mon. Special slabs for thermal insulation of monolithic buildings. Used as an insulation layer for sandwich panels. There are also analogues of these boards: Sand PVC for PVC sandwich panels and Sand VAN, designed for thermal insulation of isothermal cars.

Extruded polystyrene foam XPS "TechnoNIKOL"

XPS line of extruded polystyrene foam also includes:

- “TECHNOPLEX 30 250” (λ = 0.027 W/m K).

- “TECHNOPLEX 35 250” (λ = 0.028 W/m K).

- “TECHNOPLEX 45 500” (λ = 0.030 W/m K).

"TECHNOPLEX" was developed mainly for private and country houses. The material is distinguished by the use of nanographite in the production, which increases strength. Due to the addition of graphite particles, the plates acquire a light silver color, thanks to which they can be easily distinguished from ordinary ones.

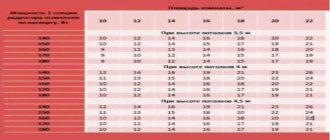

How to calculate the amount of extruded polystyrene foam

One of the simplest methods for calculating the amount of thermal insulation material is based on the surface area that needs to be insulated. To do this you need:

- Take plans, facades or wall layouts - it all depends on what you are going to insulate.

- Having determined the length and width of the insulated surface, calculate its area - S, m2. For example, let's take a value of 10 m2.

- Take the area of one expanded polystyrene slab - P, m2. For example, extruded polystyrene foam “TechnoNIKOL CARBON ECO 1180x580x30 mm” has an area of the largest side of 1.18 · 0.58 = 0.6844 m2.

- Next, divide the area of the entire insulated surface by the area of one slab and multiply by 1.05-1.1 (for reserve for scraps) - S / P · 1.05 = 10 / 0.6844 · 1.05 = 15.34 pcs. When rounded to the nearest whole number you get 16 pieces. – this is the number of slabs required to insulate a surface of 10 m2.

How to properly insulate a house

The tactics for performing the work are determined by the scope of use of the extruded heat insulator. Fixation on vertical surfaces is often carried out with insulation glue; on horizontal surfaces, sheets are secured with dowels.

Useful: Advantages of a frame house with a pitched roof and stages of roof construction

Wall thermal insulation technology

The entire process of insulating walls on the first floor can be done independently . For high-altitude work, it is better to involve professionals with special equipment.

Be sure to use insurance during installation. It is better to enlist the help of an assistant who will supply the slab material.

Sequencing:

- Preparation. Clean the walls from dirt, remove any remaining finishing materials, and remove dust from the surface. Remove visible defects and unevenness - level with plaster.

- Gluing. Apply the adhesive in an even layer on the slab and press the insulation against the wall. Installation is carried out from the bottom row, using the base profile as a support.

- Consolidation. Fixation is carried out after 3 days - after the glue has completely dried. Dowels are attached at the rate of 4 pcs. per 1 sq. m, near windows and doorways - 6-7 pcs. per 1 sq. m.

Finally, foam the joints between the sheets. If two-layer insulation is necessary, the slabs are laid out in a checkerboard pattern . The final stage is installation of reinforcing mesh and plastering.

An interesting option for insulation with siding is double-sided slabs. The inner side is extruded polystyrene foam, and the outer side is decorated with decorative finishing. This material greatly simplifies the work. In one pass it is possible to thermally insulate and cover the walls.

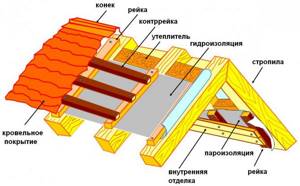

Roofing

The roofing pie is formed in the following sequence:

- Internal lining.

- Lathing.

- Moisture-resistant, vapor-permeable membrane.

- Penoplex.

- Rafter system.

- Windproof membrane.

- Roofing covering.

Installation of insulation is carried out when the rafters are assembled and the sheathing is nailed.

Stages of work:

- Install a starting rail at the bottom of the rafters.

- Lay out the slabs in a checkerboard pattern .

- Secure the material with self-tapping screws and seal the seams with tape.

- Stuff bars on top - the slats will provide a ventilation gap.

- Fill the sheathing for installation of the roof covering.