Here you will learn:

- General characteristics of the device

- Device and principle of operation

- Types of inverters for heating boilers

- Advantages and disadvantages of equipment

- Basic rules for choosing a module

- How to calculate inverter power

- Review of inverter models

- Summary table of models with prices

- How to connect an inverter to a boiler

The equipment used to heat water and distill it through a pipeline is energy-dependent, that is, the efficiency of operation is directly determined by the quality of the voltage of the electrical networks. In such conditions, it is recommended to use an inverter for the heating boiler. As a result, in case of any unforeseen situation, be it a power outage, power surges or an accident, the equipment will be protected from breakdown.

As a consequence of such a situation, the entire system may fail if, due to a power outage, there is a long-term downtime of equipment during the winter months. An electric inverter for a heating boiler is used to protect any type of device: gas, liquid and solid fuel.

Operating principle and design of the UPS

The name itself shows the purpose of the device - to provide uninterrupted power supply from a reserve when the main source is turned off.

The first uninterruptible power supplies appeared after the creation of computers and were intended to maintain high-quality power supply and short-term continuation of work after the main power was turned off. The UPS filters the incoming voltage, and if it does not meet the required parameters or disappears, it automatically supplies power to the consumer. The UPS consists of the following main components:

- power switching system (bypass);

- Charger;

- DC to AC converter;

- governing body;

- battery.

Internal Components

A switch is needed to switch the voltage source. The working element can be a power relay (in cheap models), thyristors, and recently IGBT transistors have begun to be used. The response time ranges from 6–10 ms. The ability to switch a current of a certain power affects the power of the entire device. In interactive circuits, the commutator is also used to switch the terminals of the autotransformer windings.

The charger unit converts the input AC voltage into a rectified voltage of the required value to charge the battery. This device will determine which batteries can be charged.

The conversion of the battery's direct current into alternating voltage is carried out by an inverter. It is he who is responsible for the voltage quality and power of the UPS. The battery is the source of energy for such a conversion, and its capacity will determine how long the uninterruptible power supply can provide energy to consumers.

Schematic diagram

Electrical components, buttons, and switches act as the control body. LCD screens can be used for visual control. According to the principle of operation of UPS for heating there are:

- reserve;

- interactive;

- double conversion.

To understand what is their difference, it is worth analyzing each circuit; in the future, this will help solve the question of how to choose a UPS?

Reserve

The simplest circuit uses a simple filter at the input that can delay high-voltage and electromagnetic pulses; it is made in the form of a capacitor (C) or a coil and capacitor (LC). The load is connected directly to the network. If the power quality deteriorates significantly or if it disappears, the supply voltage is supplied from the UPS. Used in simple and cheap models. Often used to power computers, it has a high efficiency of about 99%.

Appearance of a computer UPS

The disadvantage is the complete lack of ability to change the voltage amplitude and frequency of the mains current. The inverter circuit is simplified as much as possible, which leads to distortions in the shape of the sine wave. Instead of a sinusoid, as a rule, there are rectangular signals. They are not dangerous for the computer, since the current is immediately rectified.

For lighting and heating devices, the signal shape does not matter.

Linear interactive

This circuit is more suitable for an uninterruptible power supply for all heating system pumps. The main difference from the previous circuit is the ability to change the input voltage. To do this, a transformer is installed in the input circuit, the primary winding of which has several terminals; it acts as a stabilizer.

At rated voltage, no adjustment is made, and if the balance is disturbed, additional turns are automatically connected or disconnected. This stepwise switching allows the battery to be used less, which significantly extends its life.

Interactive UPS diagram

The inverters used produce rectangular, trapezoidal, step or sinusoidal voltage, it all depends on the complexity of the device. Naturally, this affects the cost.

Inverter

The inverter or double conversion circuit is very different from the previous two. There is no direct connection of the load to the network, but the connection occurs according to the following scheme: the network voltage passes through a surge filter, a rectifier, after which part of the energy, if necessary, goes to charge the battery, and the rest goes to the inverter, is converted into alternating current and goes to the consumer.

Appearance of the inverter UPS

A fully automated system capable of controlling amplitude and frequency, the output signal shape is as close as possible to a sine wave. When the mains power is turned off, the UPS continues to operate from the battery, which has virtually no effect on the output signal.

Hybrid solar inverter: disadvantages

An alternative to receiving energy from the sun and converting it into electrical current is solar power plants. The system can convert solar energy into alternating current only if it has a high-quality inverter. Hybrid inverters combine two types of inverters: grid-connected and stand-alone.

The biggest advantage is that the hybrid inverter can use direct and alternating current for its operation.

It is important to note that the amount of sunlight and energy that is converted does not increase. But the inverter works many times safer. Disadvantages of a hybrid inverter:

Disadvantages of a hybrid inverter:

- Impossibility of functioning without mains voltage.

- The energy converter runs on a battery, and if it runs out, the inverter will stop working.

This problem can be solved. To do this, just in case, you should always have additional elements that will work through the controller. Using a hybrid inverter is an excellent option for economical and smart use of solar energy. The expense of purchasing an inverter and installing it quickly pays off.

What to follow

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we will highlight several types of boilers.

Gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive and is available to a wide range of consumers. What types of gas heating boilers are there? They differ from each other depending on what type of burner is atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products escape through a special pipe using a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall-mounted gas boiler

As for the method of placing boilers, the choice of heating boiler involves the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to supply hot water, then you can install modern wall-mounted heating boilers. This way you won’t need to install a boiler to heat the water, and this will save money. Also, in the case of wall-mounted models, combustion products can be discharged directly onto the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall-mounted models is their dependence on electrical energy.

Electric boilers

Next, we will consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. These types of heating boilers are small in size, so they can be used in small houses, as well as in cottages with an area of 100 sq.m. All combustion products will be harmless from an environmental point of view. And installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and its prices are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as backup heating devices.

Solid fuel boilers

Now it’s time to consider what solid fuel heating boilers are available. Such boilers are considered the most ancient; such a system has been used for heating premises for a long time. And the reason for this is simple - fuel for such devices is available, its quality can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to operate in autonomous mode.

Gas generating solid fuel boiler

A modification of such boilers is gas generator devices. This boiler differs in that it is possible to control the combustion process, and the productivity is regulated within the range of 30-100 percent. When you are thinking about how to choose a heating boiler, you should know that the fuel that such boilers use is wood, and their humidity should not be less than 30%. Gas fired boilers depend on the supply of electrical energy. But they also have advantages over solid fuel ones. They have high efficiency, which is two times higher than solid fuel devices. And from the point of view of environmental pollution, they are environmentally friendly, since combustion products will not enter the chimney, but will serve to generate gas.

The rating of heating boilers shows that single-circuit gas generator boilers cannot be used for heating water. And if we consider automation, it is great. You can often find programmers on such devices - they regulate the temperature of the coolant and give signals if there is an emergency.

Gas generator boilers in a private home are an expensive pleasure. After all, the cost of a heating boiler is high.

Liquid fuel boilers

Now let's look at liquid fuel boilers. Such devices use diesel fuel as a working resource. To operate such boilers, you will need additional components - fuel containers and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this purpose, replaceable burners or special burners are used that can operate on two types of fuel.

Liquid fuel boiler

Pellet boilers for home

Due to the design features of pellet boilers, they are classified as a separate class. The fuel for such devices is sawdust compressed into granules. As a rule, a special shed or bunker is allocated for storing pellets near the boiler. The length of independent operation of the equipment depends on the size of such a bunker. Typically, about two buckets of pellets are required per day of work.

A special burner is installed in a pellet boiler, which allows you to burn fuel almost completely. If the granules are of high quality, then about 3-5% of ash is formed as a result of combustion. Therefore, cleaning the firebox is required only once a week or even several weeks. Thanks to the automation of the equipment, it can work autonomously for several weeks.

Among the disadvantages of modern pellet boilers are the high price and sensitivity to fuel quality. Pellets must be durable, not crumble or break, have low ash content and good calorific value.

Pros and cons of inverter boilers

The assessment of any equipment is carried out on the basis of a comparison of advantages and disadvantages, so it is worth considering all the factors characterizing the operation of an inverter boiler.

Let's start with the advantages:

- Small overall dimensions. At its core, an inverter boiler is a closed cylinder of a relatively small diameter. Thanks to this, such a unit can be installed in an ordinary kitchen; it does not require large rooms, a chimney, and there are no requirements for ceiling heights or other conditions that must be observed when using gas equipment.

- The high thermal power and minimal inertia of the equipment allows the coolant to heat up very quickly, so there are no problems with creating a comfortable atmosphere in the room.

- The fire safety of equipment of this type is in many ways superior to that of gas and solid fuel equipment.

- Possibility to use various coolants. The unit is capable of working with both water and oil heating systems.

- Very high efficiency, for many models it reaches 97-98%.

- The cost-effectiveness of the equipment allows you to significantly reduce the cost of paying bills (compared to conventional electric boilers).

- The simple design guarantees the durability and reliability of the boiler.

Now let's look at the existing disadvantages:

- The most important thing is the high cost of this type of equipment; such boilers cannot be classified as budget models.

- Can only be used in closed heating systems.

- The use of an inductance coil leads to a significant increase in the mass of the unit; it can only be mounted on solid walls.

That's basically all the main disadvantages. That is why the use of inverter boilers is considered advisable if it is impossible to operate equipment on natural gas. In addition, you can assemble an inverter boiler yourself; it is enough to have certain skills in working with metals and electrical equipment.

Selection of technological gas boilers

At the moment, on the heating equipment market, manufacturers offer modern technological equipment with a wide range of different functions, but these functions may not always be useful. There are modern technologies that are very popular in Russia and Europe.

Condensing gas boilers

Let's start the Vyborg gas boiler with condensing technology. The wall-mounted condensing boiler is more modern and more economical. Everyone knows that when a burner operates, energy is generated. The high-temperature flue gas releases its energy through a heat exchanger. At the same time, the energy that is hidden in water vapor, in conventional boilers, it simply flies out into the chimney. Thanks to this type of technology, the condensing boiler operates efficiently and economically.

If we compare a condensing boiler with a traditional one, condensing boilers use burners with a very large modulation range, that is, these boilers can operate at a minimum power of 10% of the rated power of a given boiler. When compared with traditional boilers, their minimum output is only up to 30%. If the boiler is incorrectly selected in terms of power, it begins to operate in clock mode, that is, it often turns on and off. And this is excessive gas consumption, excessive electricity consumption and wear and tear of the boiler.

The condensing boiler also has a full modulation pump, that is, a frequency pump that allows you to adapt to different heating systems. If in traditional boilers either a single-speed or a three-speed pump is installed, and it operates at a constant speed, and the heating systems are different, including they may be jammed (illiterate installation), then the pump will overheat and the boiler will constantly turn off. This will cause the equipment to fail.

Another advantage of condensing boilers is the main heat exchanger. Heat exchangers are made of different materials, either an aluminum-silicon alloy, the so-called silumin alloy, or stainless steel. Silumin is not bad either, because aluminum has good corrosion resistance compared to copper, which is used in the main heat exchangers of traditional boilers.

One of the main problems when operating gas equipment is unprepared coolant and because of this, the heat exchanger will quickly fail. This problem is solved by increasing the passage of the main section of the heat exchangers. That is, the design of the heat exchanger is made of stainless steel pipes with an increased flow area, which allows the coolant not to linger in this type of heat exchanger. This extends the service life of this equipment.

Weather-compensated automation

If you want to have a more comfortable room temperature, you should pay attention to the presence of weather-compensating automation in this type of equipment. This is possible by connecting an outdoor sensor to the boiler. As soon as this type of equipment is connected to the boiler, the boiler heats the coolant based on the outside temperature

As soon as this type of equipment is connected to the boiler, the boiler heats the coolant based on the temperature outside.

Many consumers are wondering whether they should connect a remote control for the boiler. There are a lot of examples from life, because this thing helps the consumer not only get information about what is happening at home with this boiler, but also if your old parents cannot figure out the equipment themselves, then using a mobile application you can see what happened with model of this boiler and you can reconfigure or reboot the boiler. And having a boiler with a remote control, the consumer can enter into an agreement with a service center that will monitor your boiler around the clock.

Uninterruptible power supply for the boiler depending on the situation

So, let's begin to understand each situation described above separately.

When the networks are worn out and short-term surges in consumption (a powerful welding machine, connecting a powerful heating device) can leave a block or village without electricity for a short period of time, it is worth thinking about backing up the boiler power using an uninterruptible power supply (UPS) with a rechargeable battery (AB).

The most ordinary computer UPS, unfortunately, cannot help in this situation. Its battery is enough to power the boiler for 3-5 minutes. In addition, at the output it does not produce a pure sine wave, which is necessary to power boiler equipment and a circulation pump, but an approximation of a sinusoid or meander. This is a form of output voltage that can cause damage to your boiler equipment.

Therefore, you will need a UPS that has a pure sine wave output and is capable of working with connected batteries.

If the emergency power outage period increases to 6 hours, you should consider using a 100 A*h battery as a power source for the boiler and circulation pump. This capacity will allow the boiler burner and boiler automation to operate for up to 8 hours without recharging the battery.

Even a day, that is, 24 hours, will not be an obstacle to powering the boiler from the battery, you just need to calculate the battery capacity for this period. A battery with a capacity of up to 200 Ah is suitable.

But a power outage for more than a day should make you think about purchasing a gasoline generator in addition to the UPS and capacious batteries.

It is best to buy an inverter generator, because only an inverter generator has a pure sine wave output, which is so necessary for modern boiler equipment.

Accidents lasting more than 3 days leave you no choice - only a generator. No UPS power system with a reasonable number of batteries will withstand such a period and will not be able to provide autonomous power to the boiler. Unless you are ready to install 5 batteries with a capacity of 100 Ah in your boiler room. And then, they will have to be charged with the same generator, since the total capacity of 500 Ah is not enough to power the boiler equipment for 72 hours.

The power source for the boiler thus appears as follows:

- For short-term outages up to 24 hours - a UPS with a battery.

- For outages from 1 to 3 days - a UPS with a battery and recharging from a gasoline generator.

- For outages of more than 3 days - only a gasoline inverter generator or a generator with a separate inverter.

The criteria by which you should choose a power source for a heating boiler are very simple:

- Pure sine output.

- Possibility of connecting external batteries.

- Possibility of connecting a large capacity battery (ideally up to 600 A*h in total).

- Reliability and ease of execution.

- Developed service support in your locality.

The last point is important, because in the event of an accident, a faulty UPS is actually a “dead” boiler, and, as a result, the heating system of your home freezes.

All of the above criteria are applicable to all modern heating boilers - gas, diesel, solid fuel, pellet. You can back up an electric boiler in case of an emergency either with a boiler using a different type of fuel, or with a generator if the boiler power does not exceed 5-8 kilowatts. Otherwise, you will have to buy a gasoline generator that is too powerful.

List of popular models and manufacturers

There are many domestic and foreign companies, firms and organizations operating in the electrical engineering market segment. Some of them produce products under license, others develop their own technologies and offer customers unique, innovative and competitive products at a very reasonable price.

Device

Inverter Energy PN-500 is an inexpensive, practical device that provides uninterrupted power supply for modern low-power boilers. Manufactured at the production facilities of ETK Energia, one of the leaders in the domestic electrical market.

ETK Energia inverters fully comply with all GOST standards and requirements for household electrical equipment. The environmental safety and quality of products are confirmed by international certification certificates issued to the company.

Connecting one basic battery to the device ensures full autonomous operation of the fuel boiler for 6-7 hours. If you connect a second battery, the operating time will double.

The unit produces a pure sine wave at the output, which helps preserve the expensive electronic “filling” of modern heating boilers. When the operation of the central electrical system returns to normal, the inverter automatically switches to voltage stabilization mode and protects the boiler from sudden power surges.

Device "Elim-Ukraine"

has been operating in the electrical equipment market for more than 10 years and is respected by customers.

Devices produced under this brand have a switching power supply, eye-pleasing LED display and demonstrate an extremely high level of efficiency (up to 98%). Produces a pure sine wave signal without distortion or surge levels.

Inverters are also convenient because they work correctly with both gel and car batteries

Equipped with protection against overheating, general overload and deep battery discharge. One of the expansion options allows you to connect an additional battery of any capacity to the equipment to maintain autonomous operation of the heating system even in the absence of voltage in the central main networks for a day or more.

Unit Rucelf UPI-400-12-EL

The Rucelf UPI-400-12-EL device belongs to the category of linear-interactive energy sources. It has a built-in stabilizer, which, even if there is a minimum mains voltage, equalizes the current flow without using the battery. This makes it possible to economically use the battery life without overloading and extending their service life.

Important advantages of Rucelf UPI are completely silent operation and efficient provision of devices with the necessary power supply during a power outage

Reasonable cost is another characteristic feature of the products of the Russian company Rucelf.

Thanks to this, customers can create a full-fledged autonomous infrastructure to recharge heating systems during emergency power outages or power surges.

Installation

The device may only be installed in individual premises. The induction heating boiler is attached vertically, the return pipe is connected to the tube located below, and the coolant supply is screwed in at the top. The boiler must be mounted on the wall using fasteners designed to support the equipment’s own weight and the liquid being filled into it. When attaching, you need to focus on the bottom and top - 70cm, and on the sides 25cm. A shorter distance is not allowed.

The device must be grounded. Metal-plastic pipes are attached to the pipes coming out of the boiler. For safety, it is necessary to install a pressure gauge and spirotop.

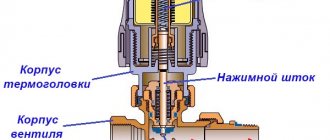

Induction heating

Types of modern UPS

Automation and control units of gas equipment require high-quality electricity, so the choice of emergency power supply must be approached very responsibly. An uninterruptible power supply for a gas boiler includes a battery and a system for switching to emergency power.

When the main voltage parameters are turned off or there is a large change in the parameters, there is an immediate transition to battery power. Power supply units that ensure the operation of equipment from a battery may have different designs and operating principles.

Typically, the following power supplies are used for heating systems:

- Backup sources (Off-line);

- Line-Interactive;

- Double conversion UPS (On-line).

Backup UPS (Off-line)

Backup power supplies are a large group of inexpensive devices that provide only a transition to a battery without equalizing the mains voltage parameters. They consist of a rectifier, converter, battery and switching device. In fail-safe mode, the electronic control unit of the heating equipment and the pump receive power directly from the network. When the main power is turned off, the switch connects backup power through the inverter-converter.

A UPS of this design has low performance parameters:

- No mains voltage stabilization;

- Long switching time;

- The voltage shape corresponds to the network.

This group of devices is low cost, but the least reliable.

Linear interactive

A linear-interactive uninterruptible power supply for a heating boiler differs from a backup UPS by the presence of a built-in stabilizer. If in the Off-line power system the transition to the battery is carried out even with small voltage surges at the input, then the interactive source, due to the stabilizer, can operate with sufficiently large voltage fluctuations, so its reliability is higher.

Main parameters:

- The network voltage is equalized by a stabilizer;

- Long transition time to reserve;

- Long period of work;

- The output signal shape can be stepped.

Double conversion power supplies (On-line)

The emergency power supply with a double conversion system (On-line) has fundamental design differences from the two previous devices.

This device converts AC to DC and secondary converts DC to AC. In this case, the reduced constant voltage charges the battery, which is connected to the input of the second inverter. In the event of a power outage, no time is required to connect the battery, since it is constantly on-line.

The characteristics of this device are much higher than those of a backup and line-interactive UPS.

Main characteristics:

- Almost ideal sine wave at the output;

- Instant activation of reserve;

- Voltage and frequency stabilization;

- High price.

Double conversion UPS is the only device that produces a pure sine wave instead of an approximated (stepped) curve and maintains a stable frequency

For some electronic devices (for example, a gas boiler) this can be very important

How to calculate inverter power

- To understand how many times the starting power of the pump is greater than the consumed power, find the energy efficiency class in the passport. It is designated by letters - from A to G. Experts recommend multiplying the power consumption by 5 for all energy efficiency classes except A: for it the power is multiplied by 1.3.

- We add up the power consumption of the boiler and the starting power of the pump. We multiply the amount by 1.2 - this is the safety factor.

For example, a boiler consumes 200 W, and a pump in energy efficiency class C consumes 40 W. The total power consumption will be: 200+40x5=400 W. Taking into account the safety factor, we get 400x1.2=480 W. This is the minimum power rating of your UPS.

Self-production

A significant amount will be spent on purchasing components, and only a professional can install it.

As the experience of specialists shows, it is easier to purchase an industrially manufactured product and modernize it to suit your needs. Typically, modernization consists of increasing the power supplied by the inverter to consumers and powering them from a more powerful battery.

To do this, it is enough to purchase a UPS to power the computer, connect the built-in car battery in place and equip the case with forced ventilation.

To do this, you need to purchase or ask your friends for a computer uninterruptible power supply (possibly with a damaged battery) with a power of 300.0...400.0 Watts, a car battery with a capacity of 50.0...55.0 ampere-hours and two fans to cool the computer case.

The sequence of operations is as follows:

- The built-in battery is removed.

- A car battery is connected to the UPS terminals

- The fans are installed on the ventilation grille of the uninterruptible power supply.

The main advantage of the modernization is not in increasing the power of the inverter, but in providing the ability to charge the car battery from the integrated charging unit.

Design and principle of operation

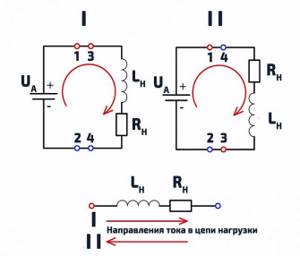

The principle of operation of the inverter as a separate element is quite simple. To provide power to a consumer (boiler) operating on alternating voltage, by connecting a direct current source (battery), you must first connect the source with one polarity, then disconnect and connect it with the reverse polarity. Accordingly, in order to obtain the required frequency of 50 Hz, it is necessary to carry out the switching algorithm 50 times per second, which is what modern inverters do.

The switching functions are performed by an electronic board with a set of transistors or tristors operating in switching mode. Converters with a power of over 300 Watt emit a large amount of thermal energy during such operation, therefore they are additionally equipped with a cooling system.

A diagram showing the operating principle of a voltage inverter.

Let's look at the principle of operation of the inverter using the example of the schematic diagram above. On the left is a UA battery with terminals 1-2 and an RHLH1 active-inductive boiler with terminals 3-4. At time I, the boiler is connected with terminals 3-4 to terminals 1-2 UA, and the current direction is from UA to LHRH1. At the next moment of time II, terminals 3-4 change their position and the direction of the current changes to the opposite relative to the boiler - the consumer of electrical energy.

Advantages and disadvantages of equipment

The inverter is convenient because it is not tied to a specific type of DC voltage source. The unit can be powered using a regular car battery, a generator set with a simple signal rectification principle, or from UPS batteries.

If the module does not have a built-in charger, the owners will have to personally control the capacity level and the degree of discharge of the device.

Among the main advantages of the device:

- a wide range of models and the ability to select a product with an almost ideal output sinusoid;

- correct operation with all sources of rated voltage and direct current;

- reasonable cost compared to other similar units of similar power;

- no restrictions on increasing battery capacity and duration of autonomous operation.

Disadvantages include criteria such as:

- lack of control over the battery charging/discharging level;

- the response threshold setting is not subject to additional correction;

- the need to arrange an external communication circuit for automatic activation in the event of a power outage in a residential area;

- high cost of “sophisticated” modules with a wide range of capabilities.

The final choice of a suitable device is strictly individual. It all depends on how much the voltage “jumps” in the network, how often consumers are cut off from the supply of resources by the central electrical system, and how long they have to sit without electricity.

Uninterruptible power supply units for heating pump

Externally, the device resembles a large system unit. Often the front panel has a display with a clock and a panel with buttons. Intuitive controls - all basic data is displayed on the screen: input and output voltage, battery charge level, current strength and others.

The essence of its work is to accumulate energy in batteries and then release it when necessary.

Connecting an uninterruptible power supply to the heating system

The UPS consists of:

- uninterruptible power supply unit;

- 12 V battery(s).

The voltage of 220 V is converted to 12 V and supplied to the charger. At the same time, energy feeds the boiler from the network. When the battery(s) are fully charged, the current supply is automatically stopped, i.e. it continues to arrive, but in transit.

If the network is turned off, the UPS begins the reverse conversion - constant from 12 V batteries to alternating 220 V.

Operating principle of an uninterruptible power supply

The automation will automatically turn on the backup power supply, and when the power supply is restored, it will switch to operation from the network. No human intervention is required to charge the batteries. It works silently.

Most often, batteries made using AGM technology or with gel electrolyte are used. Connect them in series. All end bends and jumper cables are included.

Do not place batteries too far from the inverter. This reduces the current readings.

There is one caveat - the UPS takes longer to charge than it discharges. Therefore, an uninterruptible power supply for a circulation pump will not be able to completely replace the power plant for a long time.

The need for a UPS

In addition to the situations already listed (power outages and power surges), a UPS is also useful when the energy source is an air-cooled generator - diesel or gasoline.

The voltage produced from it has a sawtooth output when a pure sine wave is required. A double conversion UPS installed between the boiler and the generator solves the problem.

So, here is a list of requirements for a UPS:

- voltage stabilization;

- possibility of long-term operation without external power supply;

- voltage supply in the form of a smooth sinusoid;

- frequency accuracy;

- smooth and instant transition to batteries;

- reliability.

No. Computer UPSs have output voltage in the form of teeth - rectangles. They overheat the circulation pumps.

But car batteries have completely different charge and discharge cycles. They are determined by the thickness of the internal plates.

The result of connecting a computer uninterruptible power supply to a circulation pump

A car battery has thinner electrodes. In addition, you will see that he always “thinks” that he is not fully charged. Battery life will be reduced and resistance will be low. All this will lead to boiling of the electrolyte and will greatly deteriorate the condition of the device.

Car batteries can only be used in well-ventilated areas (the hood of a car is ideal).

Explosive hydrogen accumulates in a confined space.

The service life of special batteries for UPS, with proper use, is 12 years. If, contrary to the warnings, you use a car one, it will fail much earlier. Therefore, the savings in this case are questionable.

Varieties

There are two types of UPS for the circulation pump (based on switching time):

- Line-interactive.

- On-line.

Linear interactive:

- The time it takes for such a UPS to switch to battery operation is 4-10ms.

- They use one or two batteries with a capacity from 38 to 100 A/h.

- Lower voltage.

- Stabilizer required.

- They cost less.

Uninterruptible power supply classification

On-Line:

- switching time to battery – 0 s.;

- protects against voltage surges by double conversion;

- can work autonomously longer;

- use at least three batteries with a capacity from 45 to 100 A/h;

- filter functions;

- are more expensive.

Which inverter to choose

Russian inverters are, of course, cheaper than American ones, but in them you cannot change how the batteries will be connected: with what charging algorithm, the threshold for starting work, how third-party sources will be controlled.

Setting these parameters helps to use the battery more safely, smoothly switch to the mode, and allows the use of inverters in parallel. American systems are more reliable, they last longer, and they will last longer for the benefit of your home.

There are two types of inverters: online and offline. In online inverters, a discharged battery begins to simultaneously work and be recharged from an external power source (for example, a similar operating principle is characteristic of a car battery).

However, such a compound mode actually has a very bad effect on the batteries, causing them to wear out and quickly expire. An offline inverter is much safer for batteries - here the battery is either charged or discharged at the same time. This is a more gentle operating mode.

Offline inverter

Therefore, when making calculations in order to identify a more reliable option, turn your attention to offline inverters. Don't forget to also consider the voltage quality

Imported models produce a voltage of 230 V. Typically, one battery has a voltage of 12 V. Their distortion coefficient is quite low - from two to three percent. To achieve this, such models use a special algorithm that generates a sinusoidal voltage output, high-quality transformers and matched filters

Don't forget to also consider the quality of the voltage. Imported models produce a voltage of 230 V. Typically, one battery has a voltage of 12 V. Their distortion coefficient is quite low - from two to three percent. To achieve this, such models use a special algorithm that generates a sinusoidal voltage output, high-quality transformers and matched filters.

Types of inverter heating boilers

There are different types of industrial and household equipment:

- Industrial boilers. These are large units with an enlarged heat exchanger. The systems use a complex current conversion system; the power rating of the boilers is much higher than that of household appliances.

- Household. Compact units designed for use in private homes. A toroidal coil is integrated into the circuit, which can receive current from the network or batteries.

You should know that inverters can also be installed in gas boilers, since the system has a built-in circulation pump that runs on electrical energy, and besides, all boiler control is based on electricity.

When choosing an inverter for a gas boiler, it is necessary to correctly calculate the power of the connected energy carrier so as to take into account the value of the starting current for the pump. It is recommended to increase the pump power by 3 times and multiply by a factor of 1.2-1.3. The result is the required power of the unit.

UPS rating for boilers

The TOP boilers include devices with the best, according to experts, characteristics. They have different types of designs.

Helior Sigma 1 KSL-12V

The UPS is equipped with one external battery. The device is adapted to Russian electrical networks. Weight 5 kg. Operating voltage 230 W. According to the type of design, the model belongs to On-Line devices. On the front panel of the Helior Sigma 1 KSL-12V there is a Russian-language LCD display that displays network indicators. Input voltage range from 130 to 300 W. Power 800 W. The average cost of an uninterruptible power supply is 19,300 rubles.

Advantages:

- A special mode of operation with generators is provided.

- Compactness.

- Reliability, long service life.

- Quiet operation.

- Availability of self-test function.

- Low power consumption.

- Does not overheat during long-term operation.

- Long battery life.

- Possibility of self-installation.

- Affordable price.

Flaws:

- The input voltage has a narrow range of acceptable values.

- Small battery capacity.

Eltena (Intelt) Monolith E 1000LT-12v

Product from Chinese manufacturers. Applies to On-Line devices. Fully adapted to work with Russian electrical networks. Input voltage range from 110 to 300 V. Power 800 W. Voltage power selection occurs automatically. Weight 4.5 kg. There is a Russified LCD display. The average cost of the model is 21,500 rubles.

Advantages:

- The relevance of the charging current for connecting to a battery with a capacity of 250 Ah.

- Optimal input voltage range.

The disadvantage is the high price.

Stark Country 1000 online 16A

The device is manufactured in Taiwan. The model was updated in 2018. Power 900 W. The UPS is designed to operate with two external circuits. The uninterruptible power supply provides complete protection of the boiler in case of an emergency power outage. Weight 6.6 kg. The average cost of the device is 22,800 rubles.

Advantages:

- Automatic selection of operating power.

- Ability to work offline 24 hours.

- Battery protection from deep discharge.

- Wide input voltage range.

- Possibility of self-installation and ease of operation.

Flaws:

- Short wire.

- Average noise level.

- High price.

HIDEN UDC9101H

Country of origin: China. The UPS is adapted to work with Russian electrical networks. It is considered the quietest uninterruptible power supply in its class. It has an automatic system for adjusting the operation of the cooling system, so it never overheats during long-term operation. Power 900 W. Weight 4 kg. The average cost is 18,200 rubles.

Advantages:

- Long service life.

- Reliability in operation.

- Wide input voltage range.

- Intelligent control system.

- Compactness.

The disadvantage is the need for initial setup.

Lanches L900Pro-H 1kVA

Country of origin: China. Power 900 W. The uninterruptible power supply is characterized by high efficiency. The model is adapted to the loads of Russian electrical networks and has an LCD display. It displays the parameters of the input voltage of the network and other indicators of operating modes, including the battery charge level. The package includes software. Weight 6 kg. The average selling price is 16,600 rubles.

Advantages:

- Resistance to power surges.

- Affordable price.

- Reliability of operation.

- Easy to use.

- Long battery life.

The main disadvantage is the low charge current.

Energy PN-500

The domestic model has the function of a voltage stabilizer. Available in wall and floor versions. Operating modes have sound indication. A special fuse is installed to protect against short circuits. The graphic display is multifunctional. The average cost is 16,600 rubles.

Advantages:

- Input voltage stabilization.

- Overheat protection.

- Reliability of the design.

- Long service life.

Disadvantage: high noise level.

SKAT-UPS 1000

The device is characterized by increased operational reliability. Power 1000 W. Has the function of input voltage stabilizer. Input voltage range from 160 to 290 V. Average sales cost 33,200 rubles.

Advantages:

- High precision of work.

- Automatic switching of operating modes.

- Reliability in operation.

- Long service life.

The disadvantage is the high price.

Operating principle of an induction boiler

The basis of the principle of operation of the boiler is the creation of thermal energy from electrical energy. The action of electromagnetic induction is as follows: we pass current through a coil wound with wire, and an electromagnetic field appears around this winding. A metal core placed in a coil (which tends to be attracted by a magnet) will begin to heat up quickly.

Heat Generator Mechanism: It is an electrical inductor consisting of a primary winding, a secondary winding and a core. By converting electricity into eddy currents, the primary winding directs the electric field to the secondary winding, which in turn transfers energy to the carrier. Under the influence of the electromagnetic field, eddy currents are formed in the body and core. They heat up the metal. The water takes heat from the core and distributes it throughout the building.

The operation of an induction cooker is based on the same principle. Such tiles are much more economical compared to conventional electric stoves. This is achieved by the absence of heat loss when transferring heat from the heater to the cookware. Marketers today refer to induction heating boilers as advanced developments created on a new principle. But in reality, this is not entirely true. Inductive principles have been used since the last century for smelting furnaces. Also, no new materials are used to make the boilers.

Induction options are safer compared to other heating boilers and require virtually no maintenance. They do not contain dynamic parts and, as a result, have no mechanical wear. With sufficient cooling, the service life of the coil is unlimited. Such boilers do not require a separate room. Compared to gas boilers, they practically do not require maintenance work.

Advantages of an induction boiler:

- Constant coolant circulation;

- Lack of heating elements;

- Silence.

An inductive electric boiler can heat not only the area of a small private house, but also industrial premises, without requiring large installation and maintenance costs. Induction heating boilers on the market are not cheap. The reason is in the system sensors. The inverter used in the control system increases the cost of the heating boiler.

Review of inverter models

The limited scope of the article will allow us to include only the most common inverter models in the review.

Let's start the review with the Helior Sigma 1 KSL model, we suggest you watch the video first

| brand, model | Characteristics | Short description | Price |

| Helior Sigma 1 KSL | Type: online Battery: external, charging current 6A Power: 800 W Input voltage range: 138-300 V at 60% load | A floor-standing UPS capable of operating without switching to power backup over a wide voltage range. Can use lead-acid car batteries. Owner reviews describe this device as quite reliable and effective at an affordable price. Can be used without a battery as a voltage stabilizer (for example, in the summer). | 17600 rub. |

| Lanches (East) EA910 II RT LCDH | Type: online Battery: external, charging current 6A Power: 900 W Input voltage range: 145-295 V at 100% load | Requires the use of two series-connected batteries (operating voltage 24V). The inverter output already has a clear neutral, which is necessary for phase-dependent boilers. | 22680 rub. |

| Eaton Powerware 9130 700 | Type: online Battery: built-in Power: 630 W Input voltage range: 160-276 V at 100% load | Due to the use of a built-in battery, this inverter is only suitable for use during short-term power outages: the operating time from a fully charged battery at 50% load is no more than 19 minutes. | 27760 rub. |

| INELT Intelligent 500LT2 | Type: line-interactive Battery: external, charging current 8A Power: 300 W Input voltage range: 165-270 V | This inverter is one of the cheapest devices of the linear-interactive class. Although its low power output does not allow it to be used in heating systems with a large number of powerful pumps, it is an excellent choice for small buildings due to its support for batteries with a capacity of up to 250 Ah. At the same time, the package already includes a battery that allows you to operate at 100% load for up to 43 minutes. | 16650 rub. |

| N-Power Smart-Vision S1000N LT | Type: line-interactive Battery: external, charging current 12A Power: 600 W Input voltage range: 165-280 V | Another representative of the class of linear-interactive devices. A 24V battery is required for operation - when two 12V batteries with a capacity of 50 A*h are connected in series at maximum load, the device will operate for almost 2 hours. Batteries are not included. | 14600 rub. |

| Powerman Online 1000 Plus | Type: online Battery: external, charging current 6A Power: 800 W Input voltage range: 115-295 V | An affordable, online-class UPS with a wide operating range of a built-in stabilizer. Requires two series-connected lead-acid batteries for operation; there is built-in protection against deep battery discharge. | 16130 rub. |

| SVEN Reserve Home 1000 | Type: line-interactive Battery: external, charging current 10A Power: 600 W Input voltage range: 150-275 V | Although the operating voltage range of this UPS is smaller than most of the devices reviewed, it is worth noting the powerful charger and operating voltage of 12 V, unlike most other devices that require the purchase of two batteries to obtain 24 V. | 11280 rub. |

A Question of Choice

Uninterruptible power supplies are single-phase and three-phase. Three-phase installations are usually not used in everyday life - they are intended rather for industrial purposes. For a heating system, single-phase models are more suitable, of which there are a sufficient number on the market.

The power of the installation will have to be calculated based on the total power of the equipment that will be connected to it. At the same time, it is imperative to take into account that when starting up any equipment, the peak load is the highest. In particular, if you open the passport of the circulation pump. then there will be an entry called “Inrush Current”.

When choosing an uninterruptible power supply of a certain power, this indicator will need to be taken as a basis. If you neglect this advice, this installation will fail immediately. However, this will not happen if the system has a pump with a soft start function.

battery for UPS

The operating voltage range is calculated taking as a basis the voltage drops that occur in a particular electrical network. If such fluctuations are within +-9%, then it is advisable to purchase an uninterruptible power supply with an operating range of plus or minus 10%.

If you do not take this indicator into account when choosing such equipment, then with each voltage surge the pump will go into autonomous operation, and connecting batteries too often will lead to the uninterruptible power supply simply failing.

It is also worth noting that the UPS can be equipped with a whole range of additional functions:

- Cold start - thanks to this feature, it will be possible to turn on the equipment even when the electricity is turned off.

- Indicators. showing the condition of the device.

- Display.

- Control via microprocessor.

- Self-diagnosis of the device every time you turn it on.

- Indicator with sound signal. indicating discharging batteries.

You can even find floor-standing models on sale that are more similar in size to a computer system unit. There are also wall-mounted UPSs, but they are much less common.

The power consumption of the pump is also taken into account. If you install too weak equipment during a power outage, the battery power will not be enough to keep the system running

Battery capacity also plays an important role.

In general, it is recommended to take equipment whose batteries are connected externally. Due to this, you can select the required number of batteries, as well as obtain the required battery life of the pump.

Uninterruptible power supplies with batteries inside are used quite rarely today, since they are not able to maintain autonomous operation for a long period of time.

There are 2 lines of stabilizers designed specifically for circulation pumps of the heating system - Teplom and Slope:

Teplokom STT 222/500

It was created for heating systems where boilers with an open or closed combustion chamber are installed. It has a microprocessor control system, as well as technology that allows you to start the device immediately after the power supply is restored. It has wall mounts and can also be installed on the floor.

The price of such equipment does not exceed 3 thousand rubles.

On sale you can find a model that can be installed outdoors thanks to a housing that does not allow moisture to penetrate inside. The cost of such equipment will be slightly higher and reaches 4.5 thousand rubles.

Skat ST 1515

It is a UPS equipped with a voltage stabilizer. It is designed for certain voltage fluctuations in the network - up to 10% in each direction.

Its cost can reach 6 thousand rubles.

How to choose a generator for a gas boiler

Minimum required power

The first thing you should pay attention to, having decided on the type of fuel used and the presence of an inverter, is the power of the generator. Calculating the power of an electric generator is simple: it is equal to the total starting and operating power of all connected devices

It is also recommended to have a reserve of 20-30%.

The required power to ensure the operation of a gas boiler is indicated in its operating instructions as electricity consumption or power consumption (section of technical characteristics). Usually these are small values of the order of 120-180 W. Approximately the same amount (on average 150 W) is consumed by the circulation pump, if available, and approximately the same amount is consumed by the turbine in turbocharged boiler models.

Total, if only a gas boiler is connected to the generator, the minimum required power = 120-180 + 150 + 150 + 20-30% = 504-624 W or 0.5-0.62 kW.

Synchronous or asynchronous

| Synchronous | Asynchronous |

| The voltage value and its frequency are maintained stably and with high accuracy | Voltage magnitude and frequency vary over a relatively large range |

| Vulnerable to electrical overloads at start-up and in set mode | Resistant to electrical overloads at start-up and in set mode |

| More expensive, have a more complex design and higher maintenance requirements | Cheaper, simpler and more reliable, low maintenance |

Synchronous generators are an excellent solution if ultra-precise current characteristics are required, and serious voltage drops often occur in the network. In the case of a limited budget, a conventional asynchronous generator is sufficient; you can protect the operation of the heating system from voltage surges in the domestic power supply network using a stabilizer (or an inverter type generator, where it is already installed) and a UPS (uninterruptible power supply).

Voltage

Voltage fluctuations can affect the boiler electronics. For expensive models of gas boilers with multifunctional automation, it is better to take care of the quality of the voltage coming out of the generator.

Frequency

As a rule, volatile gas boilers are designed for a frequency of 50 Hz, which is indicated in the operating instructions for the model. Almost all generator models (with the exception of more powerful industrial ones) are designed for a frequency of 50 Hz. If the frequency differs, the boiler controller will fail.

Availability of through neutral

There are phase-dependent and phase-independent gas boilers, as indicated in the instructions.

If phase-independent boiler models do not cause any difficulties, then for normal operation of phase-dependent boilers it is necessary to have a through neutral or a virtual zero. Most generator models do not have a pronounced phase. In this case, it is necessary to either select a generator with a clear phase and zero, or connect the generator through a transformer. There is also experience in taking a terminal with a high grounding potential as a phase.

Other criteria

Having decided on the main technical criteria, you can pay attention to:

- Continuous operation time – conventional household generators cannot operate continuously 24/7, since the engine requires cooling breaks. If larger models can often work for 12-16 hours or more, then compact gasoline models weighing up to 10 kg are limited to 3-5 hours of continuous operation;

- starting method - there are models with manual and automatic starting. The latter are more convenient, capable of ensuring absolute autonomy of the heating system, but autostart is used mainly on more expensive and powerful models;

- noise level - depends on the operating speed of the engine, the ability to adjust power and the presence of sound insulation. Typically, compact, low-power gas generators have a soundproof casing.

What does the cost depend on?

Prices for electric boilers, whether they are double-circuit or not, directly depend on several main factors. Of course, the first thing that influences is the brand. The more famous it is, the more expensive the unit will cost. If we talk about foreign companies whose electric heating boilers are used all over the world, they offer equipment from 500 to 1000 euros. Such prices can be called considerable, but at the same time tolerable, when compared with gas installations.

When choosing a floor-mounted or wall-mounted electrical unit, you must first find out the main points for yourself:

- power;

- one or two circuits;

- installation option;

- equipment.

If the buyer has limited financial capabilities, he can choose a cheap foreign electric double-circuit boiler or a domestic one. Manufacturers of the latter often claim that they use only high-quality imported components in their production.

This allows them to offer well-built equipment for relatively little money. Thus, there are models on the market today whose cost starts from 150 euros. It is worth agreeing that such a price tag is more acceptable. But before purchasing, you should still check the complete set of internal components, because you still need to understand what kind of device you are purchasing.

An electric double-circuit floor or wall-mounted boiler is perfect for installation in private homes that do not have a gas main. Such units make it possible in a short time not only to heat water for household needs, but also to heat the room. In this case, all control is carried out using automation. The main thing that needs to be assessed is the cost of operating expenses during the heating season.

Complete set of inverter energy sources

In the modern market of household related equipment, inverters are presented in several versions. Some brands produce extremely simple units that work only as voltage converters.

The rechargeable battery is not initially included in the package of such modules, but its connection is allowed by the design, and the user can purchase this element separately in the future.

You need to purchase inverter equipment only from the regional official representative office of the manufacturer. There, in addition to the product, the buyer will be given a warranty card for service and, in case of problems identified in the first working days, the product will be replaced with a working one

Some types of inverters have a built-in battery of a certain, usually small capacity, but increasing its volume using external additional batteries is not possible.

Devices of this type keep the heating equipment operating for a short time and mostly serve to enable the owner to correctly disconnect the system from the power supply in an emergency.

A basic battery is built into universal units. Expanding the capacity of the device is carried out by adding external batteries. In this way, the operating time of the device is increased from several hours to several days.

What is an inverter

One of the legacies of Tesla (and his business partner George Westinghouse, boss of the Westinghouse Electrical Company) is that most of the appliances we have in our homes are specifically designed to run on AC power.

Appliances that require DC current but draw power from an AC outlet require an additional piece of equipment called a rectifier, typically made of electronic components called diodes, to convert AC to DC. An inverter does the opposite job, and it's pretty easy to understand. Let's say you have a battery in a flashlight and the switch is closed, so the DC flows through the circuit always in the same direction as the race car around the track. Now, if you take the battery out and turn it around, assuming it's the other way, it will almost certainly still produce light and you won't notice any difference in the light you get - but the electrical current will flow in the opposite way.

Let's say you had lightning-fast hands and they were dexterous enough to turn the battery over 50-60 times per second. Then you would become a kind of mechanical inverter, turning the battery's DC power into AC power at a frequency of 50-60 Hz.

Of course, that's not how the inverters you buy at electrical stores work, although some are truly mechanical: they use electromagnetic switches that quickly switch to the current direction. Inverters like this often produce what's called a square-wave output: current either flows one way or the other way around, or it switches instantly between the two states.

Such sudden changes in direction are dangerous for some types of electrical equipment. At normal AC power, it gradually changes from one side to the other in the form of a sine wave.

Electronic inverters can be used to create this kind of smoothly varying AC output from a DC input. They use electronic components called inductors and capacitors to increase and decrease the output current than the sharp, square wave on/off output you get with a basic inverter.

Inverters can also be used with transformers to change a certain DC input voltage to a completely different AC output voltage (higher or lower), but the output power must always be less than the input power. The law of conservation of energy implies that an inverter and transformer cannot supply more energy than they consume, and some energy must be lost as heat as electricity flows through various electrical and electronic components. In practice, inverter efficiency often exceeds 90 percent, although basic physics tells us that some energy - whatever it is - is always lost somewhere.

Simple and accessible information about the types of voltage converters

The type of inverter is the main criterion when choosing, which you need to decide on first. Each type has certain properties, operating algorithm and characteristics.

Off-line

Off-line inverters are also called backup inverters; they have the simplest design and operating algorithm:

- At normal voltage in the electrical network, the inverter is inactive, and the boiler operates in normal mode, exclusively from the electrical network.

- As soon as the voltage in the electrical network drops below a critical level (usually 175-190 V) or disappears altogether, the inverter instantly switches the power to the boiler to the battery connected to the converter. The switching occurs imperceptibly, in modern models it takes 4-8 ms, which is enough for the uninterrupted operation of the boiler unit.

- As soon as the voltage in the electrical network is restored, the inverter switches power to the main network and goes into standby mode.

Also, most devices are designed for overvoltage; they usually operate at values above 260-300 V. Off-line inverters are the simplest and most inexpensive, their prices start from 4 thousand rubles.

Line-interactive

Line-interactive voltage converters are the most optimal and universal for a modern heating boiler. In addition to the converter and switching relay, as in Off-line devices, linear-interactive models use a voltage stabilizer.

In standard mode, the boiler still consumes electricity from the main network, but the voltage is equalized by a built-in stabilizer; some more technologically advanced models are equipped with additional filters that smooth out noise, eliminate interference in the network, etc. With this type of operation, the battery is used less frequently and the energy efficiency (efficiency) is much higher.

Linear-interactive models often have a built-in battery that can ensure the boiler operates for 20-120 minutes, while it is also possible to connect external additional batteries that can extend autonomy to several days.

On-line

The most technologically advanced and expensive double conversion inverters. A simplified operating algorithm looks like this:

- At the input, the inverter converts the alternating voltage of the electrical network into a constant voltage of 12 V.

- At the output, the inverter converts 12 V to 220 V with a perfectly pure sine wave with a frequency of 50 Hz.

The batteries in such a device act as a buffer capacity necessary to equalize the current parameters. The advantage of the technology is that the boiler does not contact the electrical network directly and, at any current parameters in the network, receives an ideal, pure sine wave produced by the inverter. However, due to double conversion, the efficiency of such equipment is lower, up to 90%.

Equipment Features

An inverter boiler, like every type of heating device, has its advantages. Thanks to this, the equipment is quite popular among consumers and is gradually being used more and more often. At the same time, of course, one cannot do without disadvantages, although for such boilers they are not very significant.

Advantages and disadvantages of inverter heating

Inverters, in a broad sense, are devices that convert direct current into alternating current, and their operating principle is based on the phenomenon of electromagnetic induction. How does inverter heating differ from other types of heating systems? The list of differences is quite impressive:

- The design of inverter boilers has no moving parts or mechanisms, so the wear resistance of such devices is higher. Thus, the service life of inverter boilers is significantly higher than similar devices of other types and is usually at least 10 years.

- Inverter boilers have a fairly simple design, and if necessary, you can assemble it yourself.

- The coolant in inverter boilers heats up much faster than in any other heating system. The reason is simple: inverter devices do not have the usual heat exchanger, so all the thermal energy is used to heat the coolant.

- Almost every inverter boiler can work with any type of coolant, since the working elements of the boiler do not come into direct contact with the coolant. The coolant can only affect the characteristics and performance of the heating system, but the boiler will operate normally.

- Inverter boilers are quite expensive: when compared with conventional household appliances, an inverter boiler will cost at least 2-3 times more.

- Household inverter boilers are heavy, but the dimensions of such devices compensate for this disadvantage. In addition, the successful shape allows you to place such a structure almost anywhere.

- The boiler is adjusted using complex electronic systems that will ensure continuous operation and control of the boiler parameters. Thus, despite the simplicity of assembling the boiler itself, to independently create control elements you will have to study electronics. Installation of electronic systems is mandatory, otherwise the equipment may be damaged and fail.

- Inverter heating devices do not create noise and are fire-safe devices: no fuel is used during operation, which can cause ignition, and there are no moving elements.

- Such systems are environmentally friendly: since no fuel is used, there are no emissions into the environment, because there are no combustion products.

We recommend: Adjustable throttle washer - an effective solution for high-quality adjustment of the heating network

Heating system installation

Before you begin installing an inverter heating system in a building, you need to determine what equipment will be needed for this. The power of the product is selected depending on the area of the heated premises, taking into account heat loss and a small reserve.

It is approximately believed that 1 kW of heating equipment performance is sufficient to ensure normal microclimatic conditions in an area of 8–10 square meters. m.

For rooms with non-standard heights, for example, production workshops, a kilowatt is enough to heat 2 cubic meters of air.

Features depending on the type of equipment

Based on the calculated power of the boiler, the type of electrical network required to connect it is selected, which can be single- or three-phase. The first is suitable for equipment with a power of up to 10–12 kW, most often used for heating dachas or small private houses. Three-phase is designed for inverter devices with a capacity above 6 kW.

At the same time, boilers with a power of 6 to 12 kW can be connected to a network with a voltage of both 220 and 380 Volts. Such equipment can be used without creating an additional circuit.

In addition, when choosing an inverter boiler for large industrial premises, they prefer industrial equipment with increased dimensions, large heat exchangers and a complex current conversion system. While for home use you will need a household model, relatively compact and cheap.

What to consider during installation?

The use of inverter-type boilers is allowed in both gravity and pressure heating systems. Taking into account the fact that the rate of heating of the coolant is high, it is recommended to install a device in the system for dosing the water supply from the device to the common pipe system. This reduces the need for new heated fluid and increases the efficiency of the device.

Before starting installation, it is worth finding out whether the parameters of the existing electrical wiring will be sufficient for the operation of the new equipment. If necessary, the wires are replaced with others with a larger cross-section. If a three-phase network is required, additional cables are laid separately from the general power supply network. In addition, the equipment requires a special protective unit that automatically turns off the power in the event of sudden changes in voltage in the network.

When arranging inverter heating, you should not forget:

- provide for the installation of a special air release valve in the system;

- about installing an expansion tank necessary to compensate for the thermal expansion of the liquid, as well as a circulation pump (unless, of course, the system is free-flow);

- about the location of the boiler at a certain distance from furniture and other things;

- ground the equipment.

It is also recommended to equip the boiler with a remote control device such as an electronic programmer or even a GSM module. With their help, you can provide fairly comfortable heating, for example, of a country house that is not visited daily, but only on weekends.