Types of boilers for heating a private house

At the heating system design stage, the homeowner may be faced with a seeming variety of boilers. Selecting the right unit will simplify the availability of energy resources. Manufacturers produce 4 types of heaters: electric, gas, solid and liquid fuel boilers. The latter modification is rarely used due to the high price of fuel (mainly diesel).

The most common boilers are those using natural gas. They operate in manual or automatic mode and do not require constant monitoring. Even budget models are able to independently maintain the temperature at a given level. A significant limitation in using a gas boiler is the availability of fuel. If there is no gas pipeline connected to the house, the owner will have to look for another source of heat.

Electric boilers can become an alternative to gas ones. However, the cost of electricity is higher compared to blue fuel. The heaters also operate automatically, they are silent and take up little space, which eliminates the need for a separate room for installation of equipment. In addition, they do not require the construction of a chimney.

In the absence of access to a gas pipe and unwillingness to pay electricity bills, homeowners install boilers that burn solid fuel. You can burn wood, coal, and pellets in them. However, such heaters require constant supervision: as the fuel burns out, it must be periodically added and the ash must be removed. In addition, solid fuel boilers are installed in a separate room so that soot does not settle in living rooms.

For your information!

Some manufacturers produce automatic solid fuel boilers with ultra-long burning. They independently regulate the temperature of the coolant, and fuel enters them from the bunker, which ensures continuous operation of the unit.

Is it possible or not?

- Is it allowed to place a boiler room in the basement?

Yes. SNiP 2-35-76, which is still in force today, directly states that it is permissible to design built-in boiler rooms in residential buildings, provided that they heat water to a temperature not higher than 115°C.

- Is it possible to place gas boilers in the basement?

In the case of a single-family home, yes. It does not contradict the above excerpt from SNiP: the temperature of the coolant at the boiler outlet is usually kept within 70-80 degrees.

A nuance: according to the text of the same SNiP, in the basement you cannot use heating equipment using gas or liquid fuel with a flash point (the minimum temperature at which vapors of a substance can ignite in the air upon contact with an ignition source) below +45 degrees. Natural gas has a flash point of -187.8°C. However, this restriction does not apply to basement floors.

Definition of flash point

Please note that we are talking only and exclusively about private homes. Another SNiP - number 42-01-2002 - directly prohibits the placement of gas-using equipment in the basements and ground floors of buildings, with the exception of blocked (low-rise adjacent to each other) and single-apartment buildings.

Requirements for boiler installation

The norms and rules that ensure trouble-free operation of boilers vary for each type of heater. The most stringent requirements are imposed on units operating on gaseous fuel. This is associated with the risk of depressurization and subsequent explosion of the gas-air mixture. When installing heating in a private home, the homeowner should be guided by several documents:

- SNiP 41-01-2003 “Heating, ventilation and air conditioning”;

- SNiP 21-01-97 “Fire safety of buildings and structures”;

- SNiP 2.04.01-85 “Internal water supply and sewerage of buildings.”

To approve the project, the homeowner submits an application to the local utility service, which specifies the type of equipment to be installed. After considering the request, the regulatory authority agrees on the technical conditions that must be fully implemented when installing the boiler and heating system. The next stage is drawing up and agreeing on the project. The processing time for the latter depends on the complexity and can range from several weeks to 3 months. If the project has not received approval, then the applicant is given a list of actions that need to be performed to obtain a positive conclusion.

How to choose a solid fuel boiler for heated floors

The choice of boiler depends on the size of the house, the permanent residence in it and the volume of the room where the heating equipment is located. You can use any solid fuel boiler for underfloor heating, which was installed for heating through a radiator system.

It is enough to install additional equipment that ensures safe operation, taking into account the characteristics of solid fuel combustion.

Requirements for a boiler room in a separate building

Boilers and related equipment may be installed in a separate building - a boiler room. The dimensions of the latter, as well as the building materials from which it is made, are regulated by the relevant SNiPs. More stringent requirements are established for a gas boiler room, since during its operation an explosion and fire of the gas-air mixture is possible. Such a project must be approved by the supervisory authorities.

For your information!

The latest change in legislation regulates the installation of a gas alarm, which automatically stops the gas supply to the boiler room when a leak is detected. This standard applies to boiler units with a capacity of more than 60 kW.

For boiler rooms that are designed for equipment running on electricity or solid fuel, less stringent requirements are put forward, since the unit in this case is not classified as explosive. Therefore, design and construction work can be done independently. When constructing a building, non-flammable or low-combustible materials are used to prevent the spread of fire in the event of a fire.

Selecting a Heat Source

Now let's figure out how to organize heating of a residential basement. We have to compare heating equipment according to two parameters - efficiency and autonomy.

Economical

- Which boiler provides the cheapest heating (see Boiler in the basement: install it yourself)?

Here is the rating of heating equipment for this parameter in 2021 prices:

| Thermal energy source | Price per kilowatt-hour of heat, rubles |

| Main gas | 0,7 |

| Dry firewood | 1,2-1,4 |

| Coal | 1,5-1,7 |

| Pellets | 1,6-1,8 |

| Diesel fuel | 3,4-4,0 |

| Electricity | 4,0-5,5 |

The conclusions are obvious: gas boiler rooms in the basement are the most profitable; Electric heating equipment, on the contrary, will provide you with the most expensive heat.

However, there are a couple of solutions that can significantly reduce costs when using expensive electricity for heating needs.

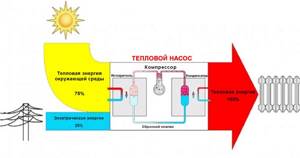

A heat pump uses electricity not for direct heating, but to operate a compressor that circulates coolant between two heat exchangers - an internal one, which transfers heat to the heating system, and an external one, located in the ground, under water or in the air. The highlight of the heat pump design is that it is able to extract thermal energy from a relatively cold environment to heat a hotter one.

Monoblock air heat pump

Moreover, the amount of heat transported into the house from a low-potential source is 3-6 times greater than the amount of electrical energy consumed to operate the compressor. This feature allows electric heating using heat pumps to successfully compete with solid fuel boilers.

You get most of the thermal energy for free

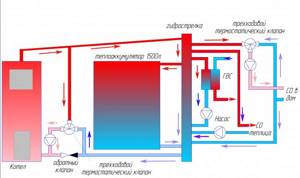

Another solution to reduce the cost of heating the basement with electricity is the use of a heat accumulator (a thermally insulated large-capacity water tank). When combined with a dual-zone meter, it can reduce the cost of a kilowatt-hour of heat to 1.5-2 rubles.

Heat accumulator in the basement

How does this scheme work:

- At night, the electric boiler operates at rated power, maintaining heating operation and heating the water supply in the accumulator;

- Night electricity consumption is paid at a lower night tariff;

Meter with separate accounting of day and night energy consumption

- During the day, the boiler turns off, and the water continues to circulate between the heat accumulator and the heating devices, gradually releasing heat to them.

Heating circuit with heat accumulator

Autonomy

- Which basement heating requires less attention from the owner?

- All types of electric heating installations (boilers, electric radiators, heat pumps, etc.) and gas boilers. They work autonomously for an unlimited time, do not require periodic maintenance and are able to automatically maintain the set temperature in the room.

Electric boiler: turn it on and forget it

- An honorable second place goes to diesel boilers. Their autonomy is limited only by the size of the fuel tank.

- Third place goes to pellet and coal boilers with automatic fuel supply. The bunker lasts for 7-10 days of battery life.

Solid fuel boilers and stoves - classic, pyrolysis and top combustion - trail sadly behind. The record for autonomous operation in this class belongs to the Stropuva top combustion boiler and is only 31 hours. A typical inexpensive basement stove requires maintenance (lighting and ash pan cleaning) every 6-12 hours.

Conclusion: a floor-mounted or wall-mounted gas boiler in the basement is an ideal solution in all respects. It does not require the owner's attention and provides the cheapest heat.

Wall-mounted double-circuit gas boiler

How to install a heating boiler in a private house with your own hands

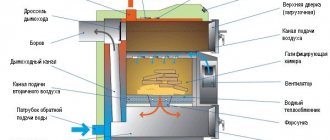

Most models have built-in circulation pumps and expansion tanks. The simplest and most common piping scheme involves the location of a supercharger with a bypass line and a sump on the return line. An expansion tank is also installed there, which is necessary to compensate for the temperature increase in the volume of the coolant. A pressure gauge is used to monitor pressure, and air is removed from the boiler circuit through an automatic air vent.

A solid fuel heater must be equipped with an external circulation pump, an expansion tank and a safety group. Additionally, a cooling circuit is installed, designed to lower the temperature of the coolant in case of overheating. To protect the internal surfaces of the boiler from condensation, the system is equipped with a three-way valve that regulates water heating.

Heating of private housing construction can be implemented independently. The owner must carefully comply with the requirements of regulatory documents, follow the recommendations of manufacturers and the advice of specialists. The successful completion of installation is facilitated by watching videos that show the step-by-step execution of the work.

Peculiarities

The combustion process of solid fuel can be controlled by supplying the amount of air. It is enough to close the damper on the hood or the blower door, and the intensity of oxidation and heat generation will decrease. But you can’t quickly “turn it off.” In electric and gas equipment, heating stops within a few seconds. It is impossible to extinguish firewood and coal instantly, even by filling it with water. This creates problems when operating the equipment. It is difficult to regulate the temperature of the water supply to the pipe system located in the floor.

When the electricity is turned off, and along with it the pump, the water stops circulating and begins to boil. Steam can rupture heating pipes, the storage tank and the boiler itself. To avoid this situation, you should install switches and accumulate or intensively expend excess heat.

Installation of a wall-mounted boiler

There are wall-mounted and floor-mounted gas boilers for the basement of a house. Both have their advantages and disadvantages. Wall-mounted boilers are most often used, although they require a lot of labor to install.

The main condition for mounting the boiler is reliable fixation. A space of at least 20 cm must be left between the boiler and other equipment. A space of 2-3 cm must be made between the wall and the installation. The boiler can also be mounted above other existing equipment.

You should begin installing a wall-mounted boiler by collecting all the necessary elements: instructions, brackets, fasteners, pliers, screwdrivers and other tools. Boiler manufacturers are required to place a rating plate on the equipment. They should be compared with those written in the instructions.

If the wall to which the boiler is mounted is made of wood or other material that is easily flammable, then it is necessary to use thermal insulation material. Its thickness must be at least 3 mm.

The next stage is the installation of brackets. It is imperative to use dowels here. The instructions contain a diagram according to which all actions should be performed. Next you need to secure the strips to the boiler. Various manufacturers offer their own methods. You must act according to the instructions. In most cases, screws with self-tapping screws are used.

Before hanging the boiler on the brackets, you should wash the pipes of the unit. A stream of cold water is used for this. This eliminates particles that enter the system when equipment is being built or transported.

The boiler is hung on brackets using a special strip. This point is also stated in the instructions. After installing the equipment in place, you must make sure that it is in a horizontal position, without distortions.

To prevent the boiler from clogging during operation, it is necessary to find the pipe leading to the heat exchanger and connect a filter element to it. There are ball valves on both sides of this filter element that allow you to shut off the water.

The most important thing is that only licensed company employees are allowed to put such equipment into operation. Therefore, even if the installation can be done independently, the connection must be carried out by a specialist.

Provide heating for your private home and basement

Drafting

How to draw up a heating project correctly? There is no difficulty in this.

We present to your attention the key points that should be completed first:

- Draw a plan diagram.

- Divide the house into zones, determine the desired temperature in each room.

- Calculate heat loss.

- Determine where, how many and what kind of radiators will be installed.

- Select a heating scheme.

- Calculate the power and required amount of material.

Dividing the house into zones

Dividing into zones will help optimize heating costs and make it pleasant to stay in each room. Don’t forget that everyone has their own feeling of comfort, some like the heat, others like the cool.

- The ideal temperature is 21 - 24 C.

- For good sleep, a higher temperature is recommended - from 22 to 25 C.

- In the living room, shower and bathrooms it can be reduced to 21 C.

- In the room for cooking and eating, as well as in the work area, the most acceptable temperature is from 18 to 20 C.

- In the vestibule, corridors, hallway and garage, 12 C heat is sufficient.

Diagrams by type of coolant supply

The radiator will work effectively if the coolant is evenly distributed across all sections.

Warm and cold water have different densities. The heated coolant always tends upward. In the system it is replaced by cold, denser water. This feature is taken into account when supplying coolant to the batteries.

Coolant supply diagram

Upper eyeliner

Each radiator has vertical channels connecting the horizontal upper and lower manifold. The presence of these elements allows the coolant to circulate in the device.

With the top connection, mainly only the top of the battery heats up. To prevent such an effect, a jumper is installed after the first rib in the direction of flow of the coolant. Therefore, the heated water first falls into the lower collector.

Then it passes through all sections of the radiator and enters the return pipeline. As a result, the top connection turns into a diagonal way to connect the battery.

If there is no jumper in the radiator, the supply pipe is connected at the top, and the return pipe at the bottom from the opposite end of the battery. This option is called diagonal strapping.

Bottom eyeliner

This is the easiest way to tie. The scheme involves installing the boiler in the basement or on the ground floor. From the heat generating unit, the main pipeline is led to the attic, where the expansion tank is installed. A starting line is laid from the tank, but not lower than 1.5 m to the first radiator.

The supply and return are connected to the batteries at the lowest points on opposite sides. All radiators in the system are connected to pipelines in the same way and installed in series.

When installing a heating circuit with natural circulation, the pipes are laid at an angle. The last battery must be located above the boiler. The height difference between the final radiator and the heat generating unit should not exceed 3 m.

Connection in progress:

- circulation pump;

- bypasses;

- shut-off valves;

- Mayevsky cranes.

Pumping equipment runs on electricity.

When it is turned off, circulation of the coolant is possible only in a natural way. Therefore, it is better to lay pipelines at a slope. Date: September 25, 2021

What does it mean to heat with air?

This kind of heating method has been known to ordinary people for a long time. Previously, ordinary houses were warmed by heated air, which from the stoves that were heated went through channels specially made for these purposes. And these days, many owners of country houses are thinking about how to make air heating for their homes with their own hands, since this heating method has many advantages over others.

To heat rooms, both internal and external air masses are used. If air is taken only from the street, then this kind of system will be called a supply air system. For this purpose, supply-type fans are used; they drive air directly to the heating unit.

The complete recirculation scheme looks like this: the internal air is in motion all the time, moving from a hot state to a cold state, after which it goes to the heating device, where it heats up again and moves into the room to release heat and a new cooling stage.

Air heating is a type of heating that you need to pay attention to if the choice is made first in order to save money. The most economical method is designed for the air to be heated in a heater or heat exchanger and distributed throughout the rooms through special channels

In each room, several holes can be placed near the floor, through which the air will fill the room with heat.

The most economical method is designed for the air to be heated in a heater or heat exchanger and distributed to rooms through special channels. In each room, several holes can be placed near the floor, through which the air will fill the room with heat.

Description of heating type

First, you need to stock up on three main ingredients.

- Heat generator. For this purpose, a heating boiler or furnace is most often chosen. The boiler will operate on any known type of fuel or be powered from the home electrical network.

- A network of air ducts that are usually made of galvanized steel. They may look unsightly, but are often decorated with all sorts of finishing materials to match the design of the room.

- Supply fan.

This heating design, equipped with your own hands, will heat any room well and fairly quickly. Climate control devices can be built into such a system, which in the summer will serve as air conditioning and air purification. The location of air conditioning devices is carried out both at the top of the room and at the bottom - this depends on the selected air heating scheme.

The supply fan forces warm air into the ducts. It is installed immediately under the combustion chamber of the boiler and, using a filter, cleans the air from all kinds of impurities and dust in order to supply it to the heating site - the heat exchanger. After it passes through the duct network, the cooled air is returned to the heat exchanger.

Is it possible to install a gas boiler yourself?

If the installation rules are violated, the boiler will be marked as arbitrarily connected and registration will be denied. If the installer is confident in his abilities and has read the current SNiPs, then why not try to save money?