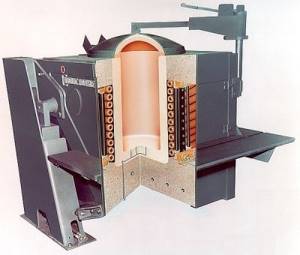

Boiler design VIN

Vortex induction heaters (VIN) are not produced in the city of Izhevsk. These devices became known and popular in the CIS countries. Apparently, due to its simplicity of design and reliable operation.

The boiler consists of:

• Metal body.

• Induction coil, it is located in the inner chamber of a hollow cylinder. A metal pipe is inserted into the hole of the cylinder, acting as a core.

• Two pipes for cold water inlet and hot water outlet.

• Quartz sand.

• Control cabinet.

• Temperature sensor.

• Safety system.

Advantages

- Economical. Compared to similar models, operating costs are 20% less. The efficiency of the induction unit is more than 97%, which is higher than that of classical models (due to the fact that heat loss for heating the induction coil is minimal). Electricity costs for heat production are significantly less than when burning coal or gas.

- Fast heating of the coolant.

- Durability. Subject to operating rules and regular technical inspections, induction boilers can last up to 40 years. Due to the absence of moving joints, there is no wear of parts. The use of copper increases the service life of the winding. In modern models, the core is made of reinforced materials that can operate in aggressive environments for several decades.

It is important to know! The service life depends on the quality of the transistors. Well-known brands offer a trouble-free operation guarantee of up to 10 years.

- No scale. Due to constant vibration, deposits cannot linger on the surface of devices even if the coolant is oversaturated with lime. There are always water bubbles on the core that repel scale particles.

- Compactness. The dimensions of induction boilers allow them to be installed in limited spaces. They do not require constant maintenance, a separate room and the construction of a chimney.

- Silence. Induction models do not create acoustic vibrations (circulation pumps make noise). Important! There are many circulation pumps whose operation does not create additional noise.

- Safety. To ensure correct operation and avoid emergency situations, RCDs and automatic circuit breakers are used, and special automatic shutdown devices are installed on boiler bodies.

- Fire safety. Unlike gas and solid fuel boilers, there is no open fire when operating induction boilers.

- Easy to install. With minimal skills in working with electrical appliances and handling, you can install the boiler yourself.

Boiler marking

The plant produced several modifications of boilers that use electromagnetic induction for their operation. They all have different powers.

The numbers after the abbreviation indicate the boiler power. A boiler with a minimum power of 3 kW is capable of heating an area of 40 square meters, a device consuming 80 kW will create heat in a building of 900 m2.

Review of manufacturers and models of induction boilers

For you, we have prepared a review of manufacturers of induction heating boilers, as well as some of its models.

VIN

It has many models and thus provides a huge choice for the consumer. The power of VIN heating boilers is from 3 kW, the heating area is from 30 m², the starting price is from 32,000 rubles.

The VIN company's models are called vortex models. Their difference is in the power supply: the first winding, which is already converted and high-frequency, is supplied with electromagnetic field strength that is enhanced due to Foucault currents. The specifics of manufacturing the boiler body and heat exchanger are also taken into account. Ferromagnetic alloys are used for their manufacture.

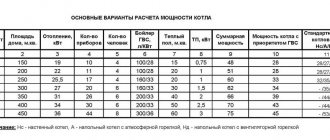

Let's look at the features of boiler models from this manufacturer in the table.

| Model | Heating area, m² | Network voltage, V | Average cost, rub |

| VIN-3 | 30-40m2 | 220 | 32000 |

| VIN-5 | 50-60 | 220 | 33000 |

| VIN-7 | 70-90 | 220 | 37000 |

| VIN-7 | 70-90 | 380 | 46000 |

| VIN-10 | 100-120 | 380 | 50000 |

| VIN-15 | 150-170 | 380 | 46000 |

| VIN-20 | 200-230 | 380 | 60000 |

SAV

The characteristics of the SAV heating boiler are ease of use and installation, environmental friendliness, automatic operation, and durability. There is practically no possibility of scale formation, and there are no parts that move and are subject to wear.

Models from SAV have their own operating characteristics. The first winding of the induction heater is supplied with an industrial voltage of 220/50 from the boiler power supply. The second winding occurs in a closed loop. Liquid moves through it. It is part of the heat exchanger in which the heating fluid is heated. In addition to water, antifreeze may also be suitable.

Since the current quickly increases the temperature of the circuit, the efficiency of all boilers is very high.

| Model | Power, W | Network voltage, V | Average cost, rub |

| 2,5 | 2100 | 220 | 32 950 |

| 3,5 | 2950 | 220 | 35 100 |

| 5 | 4235 | 220 | 37 000 |

| 5/2 | 4235 | 220 | 42 500 |

| 7/2 | 5970 | 220 | 45 000 |

| 7/3 | 5970 | 220/380 | 52 000 |

| 10 | 8750 | 220/380 | 55 000 |

| 15 | 12670 | 220/380 | 65 000 |

The disadvantages of the SAV induction boiler include its high cost. The price of models of such a boiler ranges from 32,950 to 65,000 rubles. Two more disadvantages are dependence on electricity and the difficult process of adjusting power.

Geyser

There are many models from this manufacturer. They are distinguished by high productivity. The power range is from 4.5 to 250 kW, and the efficiency reaches 98%.

The "Geyser - 5" model requires a mains voltage of 220 V, the other main models (10, 15, 20, 25, 50, 100, 250) - 380 V.

The uniqueness of this model is its reliability, as evidenced by reviews. These boilers are stable and have a second class in electrical safety. They do not require special maintenance, and due to the absence of combustion products, there is no possibility of harm to health. Geyser boilers are small in size, so the unit can be installed in a small space. The model operates quite quietly, so owners do not have to use soundproofing materials.

As a minus, we can note the complex installation and connection of the Geyser boiler. All models of induction heating boiler require 380/3ph. Only boilers with low power of 220/50 can operate from the network.

Edison

This brand is used for heating residential premises, as well as industrial, administrative buildings, etc. Its models are different (4.7; 13; 22; 50; 100; 250; 500). This induction boiler is used in closed heat supply systems. As a rule, it uses water as a coolant. The heater operates “automatically”, but if desired, you can change the operation of the heater either according to the temperature of the coolant or the air temperature in the building.

Edison boiler

The Edison boiler has more positive characteristics than negative ones. Its advantages include a long service life, high electrical and fire safety, as well as an efficiency factor that does not change during operation. In addition, when purchasing this boiler, you will not need to constantly monitor it and constantly maintain it.

Some more characteristics of the Edison heating boiler:

- current frequency 50 Hz;

- maximum coolant temperature in degrees – 115;

- the weight of the equipment ranges from 40 kg (Edison 4.7) to 1500 kg (Edison 500).

- use (with the consent of the manufacturer) of various coolants such as oil, water, antifreeze.

Miratron

The model range of these boilers has a power ranging from 6 to 30 kW and is also suitable for heating industrial and residential premises (up to 350 m2).

Boiler Miratron

Here are some more characteristics:

- efficiency factor of the Miratron heating boiler is 90%;

- excellent protection against scale;

- proper use of energy and saving the user’s budget;

- connection to any type of electrical network;

- works very quietly and does not require constant supervision;

- work only with closed heating systems;

- the use of an inverter starter in control and, as a consequence, the high cost of equipment;

- large weight and dimensions of the boiler.

The cost of the Miratron heating boiler varies. For example, the “Miratron A006” model with a power of 6 kW, a heated area of 70 m² and a weight of 50 kg has a price of 45,000 rubles. “Miratron A006” with a power of 15 kW, a room heating area of 170 m² and a weight of 80 kg - 65,000 rubles.

Comparison of popular models

Let's compare some models from different manufacturers of induction heating boilers with similar characteristics.

| Name | Power, W | Cost, rub. | Country of Origin | Heating area, m² |

| VIN-5 | 4250 | 27 000 | Russia | 60 — 150 |

| Edison-5 | 5000 | 35 000 | Russia | 100 — 120 |

| INERA SAV | 4500 | 30 000 | Russia | 50 — 80 |

Also on the market are new heating elements and electrode electric boilers.

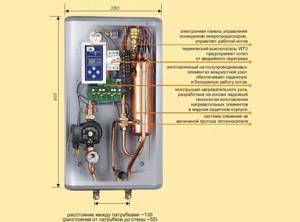

Vortex induction boiler VIN – 5

The boiler is used to heat private houses. Consumes 5,000 W. The body is metal, the thickness of the core walls is 10 mm, the coil is made of copper. Operates on 220 volts.

The boiler easily heats a room of 60 meters. The pipes have a diameter of 25 millimeters. Weight is 27 kilograms. Dimensions 675 x 133. The first number is the height, the second is the diameter.

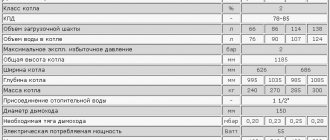

Specifications

All commercially available models of induction heating devices differ in a number of characteristics:

- Power - varies widely from 5 to 30 kW. The specific value depends on the heated area.

- Current consumption - most models with a power of 10 kW or more require a three-phase current of 380 V. Less powerful ones operate from a standard network.

- Weight - affects how the boiler is mounted. There are options for both wall and floor mounting.

- Dimensions - the convenience of placing the device in a living space depends on them.

- Coil type - with one or two circuits. In the second case, there is a constant reversal of magnetization of the core and faster heating of the coolant.

Advice! When choosing a specific boiler model, you need to be guided by a simple relationship - for every ten square meters of area of the heated room, you need to count one kilowatt of power. For example, if the area is 80 sq. meters, then to heat it you need a boiler with a capacity of at least 8 kW. It’s better to have a little more (+ 2 kW) in case of inevitable heat losses. In total, a 10 kW boiler is needed.

Truth and myths

In specialized stores you can often hear amazing characteristics that are attributed to this heating equipment. Unfortunately, not all of them are true. In order to increase sales, department managers sometimes lie. It's time to consider the main theses with which they operate.

Novelty

Claim: Advanced innovation based on physical principles.

Realities:

- Michael Faraday discovered the phenomenon of electromagnetic induction in 1831.

- In industry, since the second half of the twentieth century, induction furnaces have been successfully used to melt steel.

No innovations, much less innovative technologies, have been implemented since then. This is a well-known principle that has found a new application and has helped manufacturers fill a hitherto vacant niche.

Economical

Vortex induction heaters

Claim: Induction boilers use 20-30% less energy than other electric counterparts.

Realities:

- Any heating device converts 100% of the energy used into heat, provided that it does not perform mechanical work. The efficiency may be less. It all depends on the heat dissipation around the heating device.

- The time it takes to reach the required coolant temperature directly depends on the efficiency of the heating element. Any statements that induction models consume less electricity are nothing more than gimmicks. The law of conservation of energy is unshakable. To obtain one kilowatt of heat, it is necessary to spend at least 1 kW of electricity.

- Some of the heat will inevitably be wasted. For example, the coil itself heats up, since the resistance of the conductor is not zero. However, the losses in any case remain in the house, and do not fly away through the chimney ducts.

The conclusions are quite obvious - the manager who makes such statements is engaged in outright deception, or is himself misled.

Durability

Statement: the equipment works flawlessly for at least a quarter of a century. Its reliability is not comparable to other electrical analogues.

Realities:

- Mechanical wear and tear on boilers of this type is impossible in principle, since they have no moving parts.

- Copper winding has a decent margin of safety. Provided it is properly cooled, it can last indefinitely. Insulation breakdowns are also not a problem for her. The fact is that the turns are not wound end-to-end, but at small intervals.

- The core will gradually deteriorate in any case. It can be affected by aggressive impurities, and the constant heating-cooling cycle does not impart strength. However, this process is so extended in time that more than a dozen years may pass before its completion.

- The control circuit includes several transistors. It is they who determine the failure-free operation period of all equipment. Component manufacturers, as a rule, declare a ten-year warranty. However, there are often cases when they worked without problems for 30 or more years - it all depends on the technological process.

Thus, induction boilers will in any case work much longer than their heating element counterparts. The heating elements of the latter may require replacement after just a few years.

Indispensability of characteristics

New generation induction boilers

Claim: Appliances with traditional heating elements lose power through scale formation. Here this process is absent, and technical parameters have not changed for decades.

Realities:

- The influence of scale is somewhat exaggerated. Firstly, the lime layer itself is not characterized by high heat-insulating qualities. Secondly, in a closed whirlpool the formation of a large amount of lime deposits is unlikely.

- Regarding the core of the induction boiler, the content of the thesis is true. It is impossible for scale to form on it, even if the coolant is oversaturated with lime inclusions.

Deposits simply cannot adhere to a surface that is constantly vibrating under the influence of an electromagnetic field. In addition, water bubbles regularly form on the core, which destroy any scale. Obviously, this statement is true for induction boilers, but not true for other electric heating devices.

Silence

Claim: There is absolutely no noise when operating induction equipment. This sets it apart from other electric analogues. Vortex induction boiler

Realities:

- Any electric boiler does not make noise when heating water, because there are simply no acoustic vibrations.

- Only circulation pumps can create noise. However, if the operation of the heating system is based on the use of convection currents, then this noise will be eliminated.

- If hydraulic resistance forces you to resort to forced circulation, then there are many silent pumps for heating systems on the market today. So the sellers' statements in this case are quite fair.

Compactness

Statement: the dimensions of induction boilers are small, which allows them to be installed in any room.

Reality: this is actually true. The devices are a piece of pipe that does not require a separate space. The thesis does not distort reality at all.

Safety

Statement: the boiler is absolutely safe.

Realities: in the event of a coolant leak, the electromagnetic field will not automatically disappear. Heating of the core will continue, and if the power supply is not interrupted, the mount and housing will melt in a few seconds.

Therefore, during installation it is necessary to provide for automatic shutdown of the boiler in such a situation. So the safety of the boiler is at the same level as in heating equipment.

What do you need to know about installation?

The delivery set of electrical devices includes a technical passport with a detailed description of the characteristics and instructions that indicate the rules of installation and operation. The installation of boilers must be carried out in accordance with the attached manual.

If there are any shortcomings, for example, if the system does not have a pump for forced circulation, the boiler may be removed from warranty service. Therefore, manufacturers recommend engaging experienced plumbers or trained employees of the organization that sold the electrical equipment for installation.

An induction boiler can be built into an existing heating system as either the main one or a backup one when connected in parallel. As for the installation location, you should definitely adhere to the rules that are standard for all electric heating devices.

The heater must be located at least 80 cm from the ceiling and floor. The gap with the wall must be at least 30 cm. Like any powerful power equipment, the induction boiler must be grounded in accordance with GOST 12.2.007.0.

We recommend: Do-it-yourself insulation of the ceiling in a bathhouse - several affordable methods

The cross-section of the cable used to connect the induction boiler is calculated based on the power of the equipment. Electrical wiring is laid in cable ducts or in corrugation

DIY induction electric boiler

The simplicity of the design allows home craftsmen to make an induction heating boiler themselves. When manufacturing the simplest version of such a heater, you will need to purchase a high-frequency welding inverter .

It is desirable that it be equipped with a device for smoothly adjusting the current. The power of the structure depends on the value of the welding current (at least 15 amperes).

You should also prepare the following materials:

- thick-walled plastic pipe, the internal diameter of which is slightly less than 5 cm;

- stainless steel wire 7 mm;

- adapters for connecting to the heating system;

- enameled copper wire;

- fine metal mesh.

The wire is cut into pieces of about 5 cm . Then a plastic pipe is taken, a metal mesh is fixed at the bottom, and then an adapter is attached to the base. This pipe will perform two functions simultaneously - it will become a section of the heating system pipeline and the basis of the induction coil.

The inside of the pipe is completely filled with wire scraps . They will serve as a material heated by an electromagnetic field, and a fixed metal mesh will prevent them from falling into the pipeline. Then an adapter is also installed on the top of the plastic pipe.

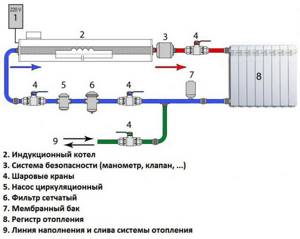

Induction boiler diagram

The next stage of work will be the manufacture of the coil . Around a base of plastic pipe filled with wire scraps, 90 turns of prepared copper wire are carefully wound. The wire should be located in the middle part of the pipe.

The finished device is installed using adapters into a gap in the heating system pipeline . Installation is carried out strictly vertically.

After installation, the coil should be connected to a high-frequency inverter, and the heating system should be filled with coolant. The heating device must be connected to ground. Now you can start using the heating device you made yourself.

To prevent heat loss and have a more aesthetically pleasing appearance, a thermally insulating casing should be made.

Also watch a video on how to make induction heating with your own hands:

If you calculate the funds spent on purchasing components for the manufacture of a homemade VIN boiler, then it is obvious that its cost will be much less than the finished product purchased in a store.

A study of consumer demand in the boiler equipment market shows that the majority of buyers who use electricity for heating their homes prefer modern factory-made induction boilers, equipped with various safety systems, powerful and economical. This new generation of heating equipment is becoming more popular every year.

Who invented the induction heating unit

The marketing argument about the innovation of the induction boiler does not stand up to criticism. The principle of induction was discovered back in the first third of the 19th century by Michael Faraday , a researcher known to us from a school physics course.

And induction melting furnace for the metallurgical industry was released into the world in Sweden

Of course, engineers and scientists were still considering induction for heating boilers in everyday life. But, having studied the pros and cons, we considered this option irrational.

Induction heaters for home and everyday use began to be used throughout the CIS in the mid-90s . Before this, high-power induction boilers were used in the USSR only in heavy industry for metal smelting.

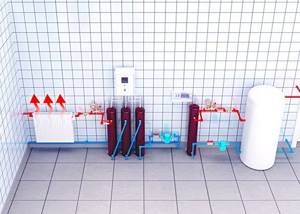

Do-it-yourself installation of induction boilers

The simplicity, high reliability and safety of the design allow you to install the purchased induction boiler yourself. This will require only basic skills in electrical installation, working with pipes and auxiliary tools.

Before starting work, you should familiarize yourself with an approximate drawing illustrating the placement of all elements of the system.

After this, you need to draw up your own drawing with the placement of elements relative to the existing room. Having done this, you can roughly calculate the amount of materials needed. In general, in addition to pipes and fittings, you need to purchase:

- Pressure gauge and safety valve (to control and relieve excess pressure).

- Circulation pump and system fullness sensor (will not allow idling and protect against overheating).

- Mesh filter (there is no scale in the system, but this does not mean the absence of other contaminants that can damage the equipment).

- Expansion tank (closed type, membrane).

- Heating radiators (how many depends on the room).

- Automatic fuse (which one depends on the power of the heater).

We recommend: Water pump for heating - selection, installation and nuances of application for a finished system (125 photos)

Important! An induction boiler requires a separate power supply line. Its parameters must correspond to the power of the device and an automatic safety device is required at the input.

Advice! When using plastic pipes to install the system, you must not forget about elements to compensate for their expansion and fasten them without rigid fixation. If pipes are laid in grooves, then they must have a significant gap to prevent thermal deformation.