Vortex Induction Heater

Due to its economic benefits, induction heating is widely used today. The vortex induction heating device is perfect for rooms up to 60 square meters. m, which must be heated with electricity. Thus, VIN can be used for heating private houses, industrial and warehouse premises, gas stations, car service centers and other free-standing facilities.

The main advantages of using VIN as the “heart” of the heating system include the following:

- Heating occurs almost instantly, because heat occurs directly in the part;

- Over the years, the installation operates with the same power, its productivity does not decrease;

- Compared with conventional electric heating elements, the induction vortex device saves up to 50% of electricity.

That is why today, more and more companies producing household appliances and production machines are using induction heating. An example of such use, in addition to heating boilers, is an induction electric furnace. Ultrasonic induction heater is used in the food industry. For heating metals in industry, an inverter induction apparatus is used, for melting non-ferrous metals - a melting-reduction unit, forging iron and making blanks - an induction electric forge.

Boiler type heater

Materials:

- Container for the boiler body (gas cylinder).

- Nut (32 mm).

- 2 pieces of metal pipe, ½ inch in diameter (about 15 cm).

- Electric heating element and thermostat.

- Tow or special lubricant for insulating the heating element.

- Fastenings for a boiler on the wall.

- Thermal insulating substrate for laminate.

- Plastic pipes for water supply.

- Wires and terminals for electrical wiring.

Tools:

- Welding machine.

- Tool for cutting threads.

- Drill and drill bits for metal.

- Screwdrivers.

- Gas keys.

- Screwdriver tester.

As a container for the boiler tank, a large 50 liter gas cylinder with the valve removed would be an ideal option. It is not recommended to use used cylinders, otherwise water passing through such a boiler, designed independently, will have a persistent smell of gas.

You can get rid of it by cutting the container in half, thoroughly washing and sanding the surface, and then applying a layer of nitro primer to it and welding the structure again. But it is much easier to contact a service that refills and distributes gas cylinders and purchase a new, unused container there. There, by the way, you can buy a cylinder without a tap, and there will be no need to remove it yourself.

Induction heater: diagram and procedure for making it yourself

The uniqueness of man lies in the fact that he constantly invents devices and mechanisms that greatly facilitate work in one or another area of work or life activity.

For this purpose, as a rule, the latest developments in the field of science are used.

Induction heating was no exception. Recently, the principle of induction has been widely used in many areas, which can easily be attributed to:

- in metallurgy, induction heating is used to melt metals;

- in some industries, special rapid heating furnaces are used, the operation of which is based on the principle of induction;

- In the domestic sphere, induction heaters can be used, for example, for cooking, heating water or heating a private home. (You can read about the features of induction heating in this article).

Today there are a great variety of industrial-type induction installations. But this does not mean that the design of such devices is very intricate.

It is quite possible to make a simple induction heater for domestic needs with your own hands. In this article we will talk in detail about an induction heater, as well as various ways to make it yourself.

Do-it-yourself induction heating units are usually divided into two main types:

- vortex inductor heaters (abbreviated as VIN), which are mainly used for heating water and heating homes;

- heaters, the design of which provides for the use of various types of electronic parts and assemblies.

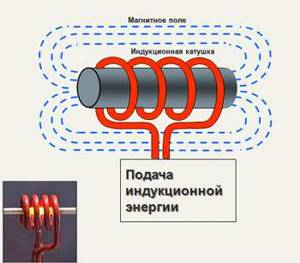

The vortex induction heater (VIN) consists of the following structural components:

- a device that converts ordinary electricity into high-frequency current;

- an inductor, which is a kind of transformer that creates a magnetic field;

- heat exchanger or heating element, which is located inside the inductor.

The operating principle of the VIN consists of the following stages:

- the converter transmits high-frequency current to the inductor, which is presented in the form of a cylinder made of copper wire;

- the inductor generates an electromagnetic field, which provokes the appearance of vortex flows;

- the heat exchanger located inside the inductor heats up under the influence of these vortex flows, and as a result, the coolant also heats up, which then enters the heating system in this form.

Specialist's note: since the induction coil is considered the most important element of a heater of this type, its manufacture must be approached quite scrupulously: the copper wire must be wound in neat turns onto a plastic pipe. The number of turns must be at least 100.

As can be seen from the description, the design of the VIN is not complicated enough, so you can easily make a vortex heater with your own hands.

Tank insulation

To minimize heat loss, the tank must be wrapped in a layer of thermal insulation. For this use:

- isolon;

- construction foam;

- mineral wool;

- foam;

- polyurethane foam.

Some people use foil-based underlay for laminate flooring. In this case, the boiler is wrapped like a thermos. The insulation is fixed using strip ties, glue or wire. We recommend insulating the entire body. This will ensure not only long-term storage of hot water, but will also reduce the duration of heating of the tank, which will reduce coolant consumption.

Without carefully organized thermal insulation, the water in the tank quickly cools down. Most often they resort to the construction of a double tank: a small container is placed inside a large one. The resulting space between them also serves as thermal insulation.

Types of induction boilers

There are the following types of induction heating boilers, designated both by the principle of operation and by the manufacturer’s brand:

- SAV is a type and at the same time a trademark of new generation boilers with a power from 2.5 to 100 kW, produced by the Russian company since 2007;

- VIN - the abbreviation is not only an abbreviation for the name of a type of induction device (vortex induction heaters), but also a patented name for boilers produced by Izhevsk.

Induction heaters SAV

Operation of SAV units does not require the use of an inverter; a current of 50 Hz is supplied to the inductor. The electromagnetic field induced by the primary winding causes the formation of vortex flows in the secondary winding, the role of which in boilers of this type is played by a section of a closed circuit of pipes with coolant. This section of the pipe - the secondary winding - is intensively heated under the influence of Foucault currents and transfers heat to the coolant, which is forced to circulate in the heating system using a circulation pump.

The heating system is constructed using radiators or in a labyrinthine manner, reminiscent of baseboard heating, in order to increase the total area of the outer surface (heat transfer) of the pipes - the heating circuit, at a minimum, should not be minimal in length.

SAV boilers are manufactured for voltages of 220V and 380V. They use water as a coolant (pure or with antifreeze additives), as well as antifreeze. It takes about 5-20 minutes for the unit to reach full operating power (depending on the volume of coolant), the efficiency of the heaters of such devices is at least 98%. For efficient heating of a room up to 30 square meters. An induction device with a power of 2.5 kW is sufficient, the purchase of which, complete with automation and control systems, will cost approximately 30 thousand rubles.

VIN heating units

Boilers of this type are more advanced in operating principle and design, which naturally affects their cost. To operate VIN devices, an inverter is required - a device for increasing the frequency of the incoming current. High frequency current causes the formation of an electromagnetic field of high intensity, which, in turn, causes the occurrence of more powerful eddy currents in the secondary winding. In addition, the heat exchanger and boiler body are made of ferromagnetic alloys that have their own magnetic field. The result of all these processes is a high heating intensity of the heat exchanger and, naturally, the coolant.

A VIN unit with a power of 3 kW is enough to heat a room with an area of 35-40 square meters. (depending on climatic conditions and the quality of thermal insulation of external building structures).

Due to their greater productivity, VIN units can be used not only in residential heating systems, but also for hot water supply. To do this, additional storage tanks equipped with automatic protection are installed into the coolant circuit, the capacity of which is calculated depending on the number of hot water intake points. These containers are provided with hot water by circulating it in a system with direct-flow heating by an induction heater.

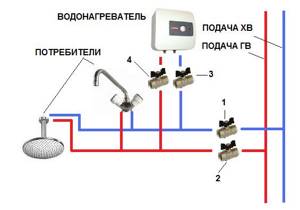

The principle of flow-through water heating

This moment is the most crucial. Installation of electrical wiring and grounding Since water heaters have significant power, separate wiring is installed to connect to the electrical network.

The valve for adjusting the heating is located at the inlet, that is, at the cold water supply. Electrical connection. If the kit does not include a template for transferring marks, then it is better to make one yourself.

Installation of devices is carried out in accordance with the design features. There are wall and floor heaters. The water heater must be installed level both horizontally and vertically. It is strictly forbidden to install a instantaneous water heater and connect it to wiring without grounding.

A second adhesive layer and an outer layer of plastic are applied on top of the foil. In small apartments and bathrooms, water heaters are most often installed in plumbing cabinets, kitchen niches, and sometimes hung from the ceiling in a horizontal position. The boiler is connected from the electrical network using an RCD. Storage devices have undeniable advantages over flow-through devices: The ability to provide several water collection points, to create a full-fledged hot water system in a house or apartment. Installing and connecting a flow-through water heater to the water supply and electrical network Connecting a flow-through water heater to the water supply An electric flow-through water heater can be connected to water in several ways.

Why exactly like this?

The purpose of the safety valve is to protect the storage tank from deformation and damage when pressure or temperature increases. Even a slight misalignment can cause the heating element to fail; the heating element will not be completely covered with water and will burn out over time. And vice versa - when you turn it on, first open the cold water, and then connect the equipment to the network. At the same time, the load on the electrical networks from them is maximum with a power consumption range of 3-27 kW.

Therefore, when purchasing a heater, you must carefully read the installation rules and follow them scrupulously. Power and performance of instantaneous water heaters First of all, you need to determine how much hot water you need. Usually you need to remove the cover, mark the centers of the holes, drill them and insert dowels. But, the larger the volume, the greater the load on the power grid, and, accordingly, the cost of paying bills. It is necessary to conduct a separate circuit with a thick copper wire with a cross-section of about 4 mm2 for powerful devices from 9 kW - 6 mm2.

The water pressure in a centralized cold water system may be too high for the heater. But, before you start familiarizing yourself, you should correctly choose the most suitable device. For example, it is quite popular to install a water heater under a bathroom or kitchen sink. More details about cable selection were written at the beginning of this tip.

To supply a private home, it is not advisable to purchase a large heater, since when heating the water in the tank, a flow-through heating mechanism will be activated, which will create a rather long and high load on the electrical network. Therefore, they consume more power - from 2 to 30 kilowatts. But it is possible to isolate the boiler circuit in a private house into a separate network and heat it at this time at the minimum operating mode of the boiler. The storage one heats the entire volume at once, and it may take up to an hour to heat the water to normal temperature. Technical characteristics also follow from it. Selection and installation of an Electrolux NPX6 Aquatronic Digital instantaneous water heater. Part II.

Induction boiler device

Induction boilers take advantage of the fact that a metal core placed inside an inductor coil is quickly heated to high temperatures due to induced Foucault currents. The heating element of such units is a powerful inductive coil, which is hermetically sealed into a massive metal housing, which is also the core. Water or other coolant, washing the body of the heating element, heats up and then enters the heating system. There are two types of induction heaters, with some differences:

Induction boiler device

- Vortex induction heaters VIN (Vin). Before applying to the primary winding of the inductor, the 50 Hz network current is converted to high frequency. In this way, an increase in magnetic intensity and induced Foucault currents is achieved, and the heating temperature increases. In such boilers, not only the secondary winding, but also the housing is made from ferromagnetic alloys, which increases the heating area and allows the coolant to be heated faster.

- Sav induction heating boiler. Boilers of this type use a secondary winding as a heat exchanger, which is made in the form of a labyrinth with thick walls (to increase the heat transfer area and better heat the coolant). Since the conductor is in an alternating field, the coil additionally generates reactive power.

How to make your own thermostat for a water heater

If the budget is very limited when making a water heater, then you can make a thermostat for the water heater with your own hands. The thermal breaker is installed as follows:

- Remove the thermal relay from a faulty car of any brand that controls the inclusion of forced engine cooling.

- Set the thread type of this part.

- Select a metal tube of suitable diameter and use a tap to cut the internal thread.

- Make a hole in the instantaneous water heater and weld a threaded tube.

- Screw in the thermostat, having first applied high-temperature sealant to the threads.

For the correct functioning of the heating element switching system, you cannot do without using an additional 12 V source and an intermediate relay. The relay installed in the system must be of reverse action, that is, it must open the circuit when low-voltage voltage is applied to the coil. This feature is due to the fact that in a car, the radiator blower is turned on when a certain temperature value is exceeded, while the flow radiator must be turned off at the moment when the temperature value exceeds a critical value.

Depth options

There are 2 definitions of level - low and high. In the first case, the top layer of water is located at a level of 2 meters and below from the surface. At this level, there are no problems with construction and excavation work - the absorption capacity of the soil is high.

If high groundwater is detected, then any work in the soil becomes more complicated. The main problems are the inability to dig a “dry” pit, problems with pouring concrete, laying bricks, and securing wastewater treatment plants.

If the GWL is high

In case of high groundwater levels, the following problems may arise:

- Difficulties with organizing the sewer system.

- Impossibility of creating basements.

- Problems with choosing and installing a foundation.

- Mold in the house.

- Difficulties with laying any underground communications.

- Soil heaving.

Connecting powerful water heating to the entire apartment

Those who want a complete hot water replacement will have to buy something more powerful.

We are talking here about models from 10 kW and above. For example, the popular brands Thermex and Clage. Most often they buy 12-15 kW, and for three phases.

According to factory parameters, such things can withstand a maximum pressure of up to 10 bar (1 MPa) and will easily handle the entire hot water system in the house. The pressure standard for a high-rise building is from 0.3 (minimum) to 6 atmospheres (0.6 MPa).

The flow rate of the device is from 6 to 9 l/min, with an increase in temperature from the initial (delta) by 25C.

Preparatory work again begins with disassembling the water heater.

Unscrew the screws at the bottom of the case and carefully remove the protective cover.

Be careful, there is a cable of wires from the digital display to the control board, do not break it.

This cable is easily disconnected via a plug.

A wall heater often comes with a short piece of standard cable, which can rarely be adapted anywhere.

Description

A typical heating element includes the following components:

- A heating element in the form of a rod or metal tube.

- An inductor is a copper wire that frames a coil in turns. During operation, it acts as a generator.

- Alternator. A separate design where standard current is converted into a high frequency value.

In practice, induction units have been used recently. Theoretical studies are much ahead. This can be explained by one obstacle - obtaining high frequency magnetic fields. The fact is that using low-frequency settings is considered ineffective. As soon as high-frequency current generators appeared, the problem was solved.

HDTV generators have passed their evolutionary period; from lamp ones to modern models based on IGBT. Now they are more efficient, lighter in weight and smaller in size. Their frequency limitation is 100 kHz due to dynamic losses of transistors.

Calculation of the main parameters of the boiler

Before you begin searching for material and directly manufacturing, you will need to calculate the minimum volume of the tank and the working length of the heat exchanger.

Volume and shape of the tank

The volume of the water tank directly depends on the number of residents permanently residing at the place where the equipment is installed. It is believed that a person uses up to 80 liters of water per day. For the calculated value, it is recommended to take 45–50 liters per person. If the norm is exceeded, the water in the tank will stagnate, which will certainly affect its quality.

The shape of the tank is selected taking into account the pressure in the plumbing system. If the pressure is low, then the use of homemade boilers with a square tank is allowed. If the pressure in the system is high, only equipment with a rounded bottom and top can be used.

Boilers with a storage tank of square and rectangular shape can only be used in water supply systems with low operating pressure

The fact is that increased pressure contributes to the occurrence of bending forces on the walls of the tank, so a square or rectangular tank can become deformed. A container with a round bottom is more resistant to deformation due to better streamlining.

Heat exchanger power and length

In vertical indirect heating models, a copper coil is usually used as a heat exchanger, located between the inlet and outlet.

Boiler coil made of copper pipe

For DIY production, it is best to use a copper pipe with a diameter of 10 mm. This product can be easily bent by hand without using any tools. When using a metal-plastic pipe, it should be taken into account that the heating temperature of the coolant should not be more than 90 °C, otherwise the pipe will be deformed and the joints will leak - this will lead to mixing of water in the tank.

The length of the pipe required for the manufacture of the coil is calculated by the formula L = P / (3.14 ∙d ∙∆T), where:

- L—pipe length (m);

- d—pipe cross-section (m);

- ∆Т – temperature difference between heated and cold water (оC);

- P is the power of the heat exchanger for every 10 liters of water (kW).

According to experts, for every 10 liters of water there should be at least 1.5 kW of thermal energy. Taking this into account, you can calculate the length of the pipe for making the coil.

For example, let’s calculate the material for a coil that will be installed in a boiler with a capacity of 200 liters. The temperature of cold water supplied to the container will be 15 oC, and after heating it is necessary to obtain water with a temperature of 80 oC: L = 1.5 ∙20 / (3.14 ∙0.01 ∙65) ≈ 15 m.

Table: length of copper heat exchanger for boilers with a capacity of 50–200 liters

| Storage tank volume, l | Equipment power, kW | Heat exchanger length, m | Boiler tank diameter, m | Coil diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

The number of turns of the coil depends on the method of bending and the distance between the elements. Typically, the coil is positioned so that the distance between the coils and the walls of the tank is at least 10–12 cm. The distance between the coils should not be less than 5 cm. The calculated values for storage tanks of various volumes can be seen in the table above.

If an indirect type boiler needs to be equipped with a tubular electric heater, then the power is calculated based on the fact that to quickly heat 50 liters of water, a heating element with a power of at least 1.5 kW is required. In addition, any combi boiler must be equipped with a thermostat.

Disadvantages and advantages

Let's consider the positive characteristics and advantages of induction equipment:

- Heating is carried out in any environment.

- Possibility of producing ultra-pure alloys.

- Rapid heating and melting of any material that conducts current.

- The elements of the device are mounted externally, there are no inserts. This ensures that there are no leaks.

- The induction water heater does not pollute the environment.

- Convenient when it is necessary to heat a certain area of the surface.

- The contact area of the coolant with the surface of the heater is many times larger than in devices with tubular electric heaters. Due to this, the environment heats up very quickly.

- Compact dimensions of the device.

- The equipment is easily configured to the desired operating mode and is easily adjusted.

- It is possible to manufacture a device of any shape (including independently). This prevents local heating and promotes uniform heat distribution.

A flow-through heater of this type has practically no disadvantages when compared with devices operating on other principles. The only operational difficulty is that it is necessary to match the inductor with the workpiece. Otherwise, the heating will be insufficient and low-power.

Country version of the water heater

At your dacha you can make homemade solar water heaters. The only drawback of such devices is the lack of heating during cloudy weather. The solar water heater is made of the following materials and parts:

- Old refrigerator.

- Water tank.

- Metal-plastic pipe with a diameter of 16 mm.

- Edged boards 200 mm wide.

- Cellular polycarbonate sheet.

- Steel sheet 3 mm thick.

- Black metal paints.

You will also need to purchase consumables for fastening materials and various adapters for connecting pipes. In addition, you will need to buy a low-power circulation pump.

The manufacture of a water heater powered by solar energy can be done in the following sequence:

- The rear radiator is removed from the refrigerator and the copper tubing is cut off where the unit connects to the compressor and freezer. When performing this operation, it is necessary to preserve the original fastening elements of the part.

- A rectangle is cut out of a metal sheet with a grinder, the length and width of which should be 20 cm greater than the parameters of the refrigerator radiator.

- One of the sides of the metal rectangle is cleaned, degreased and painted black. The refrigerator radiator also needs to be painted.

- When the paint has dried, place a copper grid on the painted surface of the metal sheet so that it is equidistant from its corners.

- On the painted surface of a metal sheet, using any sharp object, notches are made under the mounting holes of the copper radiator.

- Then, at the marked points, you need to drill holes, the diameter of which should correspond to the radiator mounting holes.

- It is also necessary to make holes with a diameter of 5 mm along the perimeter of the metal sheet for attaching the side edges of the device. The distance between the holes should be about 100 mm.

- Using a gas soldering iron, adapters for connecting metal-plastic pipes are soldered to the cut ends of copper tubes.

- It is necessary to cut off sections of 200 mm from the board with a hacksaw. 2 segments should be equal to the width of the metal sheet, and the other two should be 50 mm less than its length. After this, the wood must be treated with a protective compound.

- The board sections are installed on an edge along the perimeter of the metal sheet and screwed with wood screws through previously made holes.

- A copper radiator is installed inside the “box”, which is screwed to a metal plate with bolts. The pipes with adapters for connecting the metal-plastic pipe should be brought out through the holes made with a feather drill in one of the side boards.

- Cut a rectangle from a sheet of transparent cellular polycarbonate that will be equal to the size of the metal base.

- Using self-tapping screws and rubber washers, screw the polycarbonate rectangle to the ends of the boards.

- It is necessary to install the freezer removed from the refrigerator into the water tank, and adapters should also be soldered to the copper tubes of it. The freezer should be fixed at the bottom of the tank, and the pipes should be routed to one of the side walls.

A DIY country water heater is installed as follows:

- The device is placed in a sunny area.

- A tee is connected to one of the water heater pipes, to which a metal-plastic pipe and tap are connected. Only a metal-plastic pipe should be connected to the second pipe.

- On the other side, the pipes are connected to the pipes coming out of the water tank.

- It is also necessary to install a circulation pump in the system so that the coolant moves from the water heater to the water tank.

After connecting the pump to electricity, the oil will be heated by solar radiation, which will easily pass through the polycarbonate plate. The device also creates a greenhouse effect, which will allow you to effectively use the device even during partly cloudy weather.

The heated oil will transfer heat to the water in the tank with the freezer installed, so it should be insulated with foam. Hot water intake can be forced using a pump or by gravity, but this will require installing the tank as high as possible. To ensure that the heated oil does not cool down on the way to the heat exchanger, metal-plastic pipes should be covered along the entire length with polyurethane foam.

Making a homemade water heater will not only save money, but also gain invaluable experience in constructing complex devices with your own hands. If you need to make an electrode device yourself, then you should definitely remember about safety precautions when handling devices that run on electricity.

Do-it-yourself induction heater: description of the simplest circuit of a homemade device

Electrical energy is quite expensive today, but heating equipment operating on this resource does not lose popularity.

This is explained by the fact that electric heating is the most convenient way to heat a home.

Of particular interest to users are devices operating on the principle of electromagnetic induction.

Mainly because such a device can easily be assembled yourself. In this article we will talk about the features of these units, study their strengths and weaknesses, and also learn how to make an induction heater with your own hands.

Tips for use

When using such a boiler, it is important to prevent the formation of scale. For this, many homeowners use special liquids.

If this feature is not taken into account, the resulting deposits will negatively affect the heat transfer of the unit. So, half a millimeter of scale reduces thermal output by about 10%. The thicker the deposit layer, the less heat transfer will be.

If you make such a heating device yourself, then the first adapter will need to be attached by welding, and the second one will simply be attached using threads.

If you decide to buy a ready-made device rather than make it yourself, then you need to find out the thickness of its steel core. The thicker the walls, the longer this component will not be subject to rust. In a high-quality induction apparatus, not only water, but also antifreeze, oil and other petroleum-based compounds can act as a heat carrier.

Please note that high-frequency current can be supplied to such a boiler only after turning on the circulation pump and completely filling the unit with coolant. If you want to get the maximum effect from an induction boiler (both homemade and purchased), then you should connect them in a group and operate them in turn or simultaneously.

When choosing a boiler of a specific power, you need to calculate it this way: per 1 sq. m area will require 60 watts. If people do not live permanently in the home where you are going to install the unit, then this figure can be reduced.

Thanks to its compact dimensions, an induction boiler can be installed, for example, in the kitchen. To hide equipment, you should use a regular box or wall cabinet with pre-cut holes for pipes. The induction device can also be installed in the garage. If the building has a small area, then it is permissible to form a small harness. To warm up such rooms, one radiator is quite enough. The entire heating structure can take up less than a square meter.

In the next video you will find yourself making an effective and economical induction heater with your own hands.

How to use a flow heater

It is important to understand not only the procedure for connecting an instantaneous water heater, but also the features of its use. If the heater coil is not sufficiently covered with liquid, it will break and it will become impossible to use the device.

If the heater coil is not sufficiently covered with liquid, it will break and it will become impossible to use the device.

How to use a flow heater

Connection diagram for a water heater in an apartment

Regardless of the option you choose for connecting a flow-through heater, use of such a device is performed in the following order:

- the valve opens;

- cold water is transferred to the heater;

- after some time, cold liquid begins to come out of the heater watering can;

- you turn on the water heater;

- after 30-60 seconds, already heated water comes out of the watering can.

Turning off the device is carried out in a similar manner - you turn off the heater, wait until cold liquid starts flowing from the shower head, and only then turn off the water supply.

DIY instantaneous induction water heater

Before you begin installation, you need to stock up on the necessary parts. So, the best option would be a high-frequency welding inverter with a smoothly varying current range. Such a device will cost the least. A more expensive option would be a three-phase transformer, which is the AC power source for the water heater inductor. In this case, you should use a coil of 50-90 turns, and use copper wire with a diameter of 3 or more millimeters as the material.

As a core, you can use either a metal or polymer pipe together with wire (used as a heating element). In the latter case, the thickness of the walls should not be less than 3 mm in order to easily withstand high temperatures.

To assemble the water heater you will need: wire cutters, screwdrivers, a soldering iron and a welding machine if a metal pipe is used.

Installation of an induction water heater

Wrap the pipe with copper wire, making about 90 turns.

There are many options for assembling the device. We suggest trying to assemble the device according to the following scheme:

- Prepare your workplace, materials and tools.

- Fix a small piece of polymer pipe (remember that the minimum wall thickness should be 3 mm).

- Trim the ends of the core to leave 10 cm of wire left for taps.

- Mount a corner on the lower outlet. In the future, the return from the heating should be connected here (if the heater is used as a boiler).

- Place the chopped wire tightly around the pipe. It is necessary to make at least 90 turns.

- Install a tee on the top pipe through which hot water will flow out.

- Install the protective circuit of the device. It can be made from either polymer or metal.

- Connect copper wire to the water heater terminals, then fill the core with water.

- Check the functionality of the inductor.

Recommendations. It is better to install ball valves on all terminals for convenience and ease of dismantling the water heater in case of breakdown. But it is not necessary to fill the pipe with metal pieces, since this does not give the desired effect. Do not forget to leave a window in the housing for access to the control panel of the welding machine.

Other methods of making a water heater

You can build a water heater powered by the sun. This is a fairly common design, which is distinguished by its efficiency. The device is often found in country houses. Making the device is not particularly difficult, so many can build it with their own hands.

- large capacity tank (100 l or more);

- PVC pipes for filling the container and supplying water to it;

- steel corners measuring 20 mm or square blocks of wood measuring 50 mm for a frame for a container.

It is more advisable to use polyethylene barrels as containers. They are distinguished by their strength. They should be placed in a sunny place where there is no wind. As a rule, the roof of a summer shower is chosen for installation.

In order for the barrel to heat up better, it needs to be painted black. Screens are installed on the leeward side for protection. They are constructed from boards coated with reflective material similar to foil. In this case, the sun's rays are directed towards the tank and increase the temperature of the water. In hot weather, in a container of 200 liters you can get water whose temperature will be 45 ºС.

Advantages and disadvantages

According to manufacturers, the use of induction heating boilers for heating a home is a complete advantage with no disadvantages at all. Let's try to figure out what is the truth and what is a marketing ploy.

1. High efficiency. Efficiency up to 99% is typical for all types of electric boilers.

2. Maximum protection against scale. Since there is no direct contact of the induction winding with the coolant (unlike the heating element), scale can only form inside the pipes. But closed systems are characterized by a consistently low amount of salts. That is, there are no prerequisites for the formation of deposits.

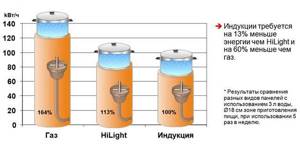

3. Resource savings up to 35%. Before you buy an induction boiler and install it, remember that its main task is to convert energy into heat. To generate 1 kW, according to the law of conservation of energy, you also need to spend 1 kW of electricity. The only difference is the heating speed - the induction unit operates faster by about 20-30%.

4. Complete absence of detachable connections in the design, which eliminates the possibility of leakage. Not entirely true: the boiler includes 4-6 components connected into a unit. The price of the VIN induction heating system includes the boiler itself in a collapsible casing, a control cabinet, a safety group (sensors and relays) and capacitors, pressure relief valves, a set of contacts for connecting external devices.

5. High degree of electrical and fire safety. This is true, but you need to make sure that there is no leakage and that the amount of coolant remains constant. Otherwise, the device will heat up very quickly and there is a risk of explosion.

6. Does not have elements subject to mechanical wear, so the service life is more than 30 years. Firstly, the core is durable, but the varnish insulation on the primary winding (toroidal) is subject to aging. Its service life is 7-10 years. The result of destruction will be an interturn short circuit with corresponding consequences. Secondly, induction boilers are a relatively new product that has not been tested by time; the statement about 30 years of operation is unlikely to be true.

7. Compatible with other systems. You can connect heated floors, gas or wood boilers.

A clever meter that saves electricity. Pays for itself in 2 months! Everyone needs to know this in order to save!

8. They do not require a separate room or ventilation.

9. Does not require preventive maintenance. A boiler is, in any case, equipment with many sensors, relays, and terminals that periodically need to be changed and tightened. Of course, compared to gas boilers, this is insignificant.

Thus, most of the positive qualities are consistent with other types of electrical units. Now let’s analyze the shortcomings identified over several years of operation.

1. Cost. The price of the induction boiler SAV 5 kW is 40,000 rubles. Whereas the heating element Protherm Skat 6 kW is 23,000.

2. Significant weight with small dimensions. Since even the smallest unit weighs from 20 kg, it is recommended to mount them on the floor or hang them on a load-bearing wall using durable brackets.

3. The electromagnetic field generates strong interference in the long, medium wave and VHF ranges. Although manufacturers claim that they do not affect the human body, sanitary and medical officials claim the opposite. It is not for nothing that SNiPs contain standards and rules for the location of devices with high levels of radiation.

4. To operate the heating system in a house with 2-3 floors, a powerful circulation pump is required.

Manufacturing instructions

Blueprints

To make a stove you will need the following materials and tools:

- soldering iron;

- solder;

- textolite board.

- mini drill.

- radioelements.

- thermal paste.

- chemical reagents for etching the board.

Additional materials and their features:

- To make a coil that will emit the alternating magnetic field necessary for heating, it is necessary to prepare a piece of copper tube with a diameter of 8 mm and a length of 800 mm.

- Powerful power transistors are the most expensive part of a homemade induction installation. To install the frequency generator circuit, you need to prepare 2 such elements. Transistors of the following brands are suitable for these purposes: IRFP-150; IRFP-260; IRFP-460. When manufacturing the circuit, 2 identical of the listed field-effect transistors are used.

- To manufacture an oscillating circuit, you will need ceramic capacitors with a capacity of 0.1 mF and an operating voltage of 1600 V. In order for high-power alternating current to form in the coil, 7 such capacitors will be required.

- When operating such an induction device , field-effect transistors will become very hot and if aluminum alloy radiators are not attached to them, then after just a few seconds of operation at maximum power, these elements will fail. Transistors should be placed on heat sinks through a thin layer of thermal paste, otherwise the effectiveness of such cooling will be minimal.

- Diodes used in an induction heater must be ultra-fast. The most suitable diodes for this circuit are: MUR-460; UF-4007; HER – 307.

- Resistors used in circuit 3: 10 kOhm with a power of 0.25 W - 2 pcs. and 440 Ohm power - 2 W. Zener diodes: 2 pcs. with an operating voltage of 15 V. The power of the zener diodes must be at least 2 W. A choke for connecting to the power terminals of the coil is used with induction.

- To power the entire device you will need a power supply with a power of up to 500 W. and voltage 12 - 40 V. This device can be powered from a car battery, but it will not be possible to obtain the highest power readings at this voltage.

The manufacturing process of the electronic generator and coil itself takes a little time and is carried out in the following sequence:

- from a copper pipe . To make a spiral, the copper tube should be screwed onto a rod with a flat surface with a diameter of 4 cm. The spiral should have 7 turns, which should not touch. Fastening rings are soldered to the 2 ends of the tube for connection to the transistor radiators.

- The printed circuit board is made according to the diagram. If it is possible to install polypropylene capacitors, then due to the fact that such elements have minimal losses and stable operation at large amplitudes of voltage fluctuations, the device will operate much more stable. The capacitors in the circuit are installed in parallel to form an oscillating circuit with a copper coil.

- Heating of the metal occurs inside the coil after the circuit is connected to the power supply or battery. When heating the metal, it is necessary to ensure that there is no short circuit in the spring windings. If you touch 2 turns of the coil at the same time with heated metal, the transistors will fail instantly.

Pros and cons of induction water heating devices

The device has a fairly simple design and does not require special documents permitting use and installation. The induction water heater has a high degree of efficiency and optimal reliability for the user. When using it as a heating boiler, you don’t even have to install a pump, since water flows through the pipes due to convection (when heated, the liquid practically turns into steam).

The device also has a number of advantages, which sets it apart from other types of water heaters. So, an induction heater:

- much cheaper than its analogues, such a device can be assembled independently without any problems;

- completely silent (although the coil vibrates during operation, this vibration is not noticeable to humans);

- during operation it vibrates, thanks to which dirt and scale do not stick to its walls, and therefore does not require cleaning;

- has a heat generator that can be easily made sealed due to the operating principle: the coolant is located inside the heating element and the energy is transferred to the heater via an electromagnetic field, no contacts are needed; therefore, there will be no need for rubber seals, seals and other elements that can quickly deteriorate or leak;

- there is simply nothing to break in the heat generator, since the water is heated by an ordinary pipe, which is unable to deteriorate or burn out, unlike a heating element;

Despite the huge number of advantages, an induction water heater also has a number of disadvantages:

- the first and most painful for owners is the electricity bill; the device cannot be called economical, so you will have to shell out a fair amount of money to use it;

- second, the device gets very hot and heats not only itself, but also the surrounding space, so it is better not to touch the body of the heat generator during its operation;

- third, the device has extremely high efficiency and heat transfer, so when using it, be sure to install a temperature sensor, otherwise the system may explode.

Advantages of induction type units

The undoubted advantages of this type of home heating devices include the following characteristics:

- efficiency - the conversion of electrical energy into heat occurs almost completely without significant losses;

- ease of use - constant maintenance of units of this type is not required;

- compact dimensions - induction water heaters are small in size, they can be installed in the heating system in almost any room;

- quiet operation – this equipment operates quite quietly, no noise occurs during its operation;

- long service life - induction units are durable and can operate smoothly for 30 years or more;

- high environmental friendliness - no harmful emissions occur during operation of the device, a chimney installation and a ventilation system are not required.

Many people believe that induction boilers are much more profitable than other home heating options. And compared to equipment equipped with heating elements, the heating time of these units occurs almost twice as fast. Due to the constant circulation and vibration of the liquid, scale does not form in the pipes and inside the device, which greatly facilitates the maintenance and care of the heating system.

But this type of device also has some disadvantages. And the main disadvantage is that induction equipment is quite expensive. But you can try to make such a heater for heating your home yourself.

Operating principle and scope

The generator increases the frequency of the current and transfers its energy to the coil. The inductor converts high-frequency current into an alternating electromagnetic field. Electromagnetic waves change at high frequencies.

Heating occurs due to the heating of eddy currents, which are provoked by alternating eddy vectors of the electromagnetic field. Energy is transmitted with almost no losses with high efficiency and enough energy to heat the coolant and even more.

The battery energy is transferred to the coolant, which is located inside the pipe. The coolant, in turn, is the coolant of the heating element. Due to this, the service life increases.

Industry is the most active consumer of induction heaters, since many designs involve high heat treatment. Their use increases the strength of the product.

High-power devices are installed in high-frequency forges.

Forging and pressing companies, using such units, increase labor productivity and reduce wear of dies, and reduce metal consumption. Installations with through heating can cover a certain number of workpieces at once.

When surface hardening parts, the use of such heating makes it possible to increase wear resistance several times and obtain a significant economic effect.

Design features and operation of the heat generator

To organize individual heating, a transformer consisting of two windings can be used as an induction heater for this system:

- Primary.

- Secondary short-circuited.

Vortex flows here are formed in the internal component. They direct the resulting electric field to the secondary circuit. It is he who performs the simultaneous role of a housing and a heating element for the coolant. With an increase in the density of eddy currents that are aimed at the core, its entire surface initially begins to heat up, and then the entire element.

An example of installing an induction current water heater for heating

For the supply of cold water and the outlet of heated coolant, induction boilers are equipped with two pipes.

For those who want to make such equipment with their own hands, you need to provide that:

- The lower pipe is mounted on the inlet main section;

- The upper one is on the supply section of the pipeline.

How the system works

The heat generated by the boiler is transferred to the coolant circulating in the heating system. Due to hydrostatic pressure, heated water enters directly through the supply pipe into the general heating system and is constantly removed by pumping coolant into it. Therefore, the possibility of equipment overheating is completely excluded here.

Comparison of energy consumption of an induction water heater with others

Constant vibration during operation of the induction system prevents the formation of scale and its hard deposits on the internal walls of the pipeline. Induction heaters do not have standard electric heating elements, so the likelihood of costly breakdowns is reduced to zero. In addition, there are no detachable connections that could threaten unplanned and unpleasant leaks. A positive feature of this boiler is the absence of noise during operation, which allows it to be installed in any residential premises.

Boiler from a gas cylinder

If you decide to make a boiler from a gas cylinder, then it is better to purchase it new and without a valve. If you are using an old container, the hot water may smell like gas.

The cylinder requires preliminary priming. For this purpose, it is cut into two halves. To prevent an explosion, we recommend filling it with water first. The interior of the structure is cleaned and primed. This prevents rusting. After this, the balloon is brewed.

Two holes are cut into the container to drain hot and cold water. At the cold water inlet, the supply pipe is equipped with a check valve. This prevents water from leaking out of the tank.

To obtain an indirect type heater that will operate from the heating system, in addition to outlets for hot and cold water, two more holes are made for installing a heat exchanger. In it, one pipe is adjacent to another.

The coil is installed in the center of the tank or along its walls. Nozzles are welded to its inlet and outlet pipes.

If you want your device to stand, then you should weld supports to it. The attachment will require loops in the form of “ears”.

A 32 mm nut is welded to the place where the heating element will be installed. It must have an internal thread. It is advisable to install a heating element for water with thermoregulation or an alarm sensor. Its power should be 1.2-2 kW.

The result is an indirect heating boiler. In this case, the main structural element is the gas cylinder.