What is a thermal accumulator

A thermal accumulator is a device designed to accumulate thermal energy for the purpose of its use in homes, buildings, and industrial production.

A thermal accumulator or, as it is sometimes called, a buffer tank, is nothing more than an ordinary barrel (round or square). But this barrel is not simple, but magical.

It can save your money and create a comfortable temperature in your home. The simplest modification of a heat accumulator has two outputs at the top and two at the bottom. What else could be simpler? Many people have heard about the heat accumulator, but not everyone knows when and how to use it, while saving on heating costs.

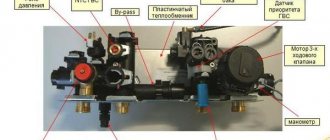

Functions performed by electronics in heating boilers

Society has already become accustomed to the fact that in the modern world, most processes related to life support are controlled using electronics. The same applies to hot water supply and heating systems in the house.

Why do we need electronics in this case? For example, to constantly maintain the desired indoor temperature. This can be achieved if the coolant is always hot. A smart electronic system, which is built into the heat accumulator, controls the water temperature level. If necessary, the circulation pump is turned on to supply coolant water to the heating system. The electronics will open the heating dampers in time. If necessary, it will close the pipeline valves so that the coolant flows into the radiators directly from the boiler.

The capabilities of the system allow you to transfer hot water from the boiler to the hot water supply pipeline.

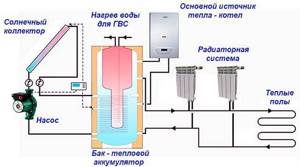

Moreover, the electrical system will help control the operation of a solid fuel boiler. An additional pipe for connecting a solar collector can be installed in the battery. And this is another significant saving in energy resources. True, the cost of such a device will be higher.

When is it beneficial to install a heat accumulator:

— you have a solid fuel boiler;

— you are heated with electricity;

— solar collectors have been added to help with heating;

— it is possible to recover heat from units and machines.

The most common case of using a heat accumulator is when a solid fuel boiler is used as a heat source. Anyone who has used a solid fuel boiler to heat their home knows what comfort can be achieved using such a heating system. Flooded - undressed, burned out - got dressed. In the mornings in a house with such a heat source, you don’t want to get out from under the blanket. It is very difficult to regulate the combustion process in a solid fuel boiler. You need to heat it at both +10C and -40C. The combustion and the amount of heat generated will be the same, but this same heat is needed in completely different ways. What to do? What kind of efficiency can we talk about when at above-zero temperatures you have to open the windows. There can be no talk of any comfort.

The installation diagram of a solid fuel boiler with a heat accumulator is an ideal solution for a private home when you want both comfort and savings. With this arrangement, you heat a solid fuel boiler, heat water in a heat accumulator and get as much heat as you need. In this case, the boiler will operate at maximum power and with the highest efficiency. The amount of heat that wood or coal provides is the amount you will store.

Second option. Installation of a heat accumulator with an electric boiler. This solution will work if you have a two-tariff electricity meter. We store heat at night rates and use it both day and night. If you decide to use such a heating system, it is better to look for a heat accumulator with the ability to install an electric heater directly into the barrel. An electric heater is cheaper than an electric boiler, and no material is required for piping the boiler. Minus the work of installing an electric boiler. Can you imagine how much you can save?

The third option is when there is a solar collector. All excess heat can be dumped into a heat accumulator. In the mid-season, you get great savings.

Connection methods

Connecting a heat accumulator to a solid fuel boiler is carried out in various ways.

But in any case, there are a number of rules that must be observed.

:

- all connections in the system must be threaded or flanged;

- It is recommended to install shut-off valves on the TA main;

- equipment of instrumentation and control equipment inputs and outputs;

- installation of cleaning filters at the entrances;

- installation of a pressure gauge and safety valve on the TA;

- provide for the installation of an air vent valve.

Plan for connecting a heat accumulator to a solid fuel boiler

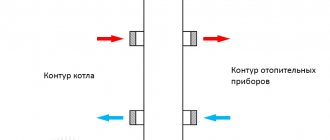

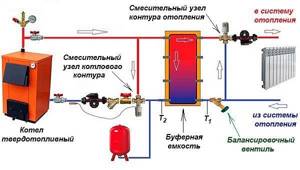

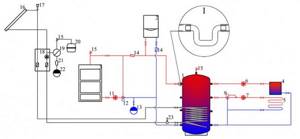

Compliance with these requirements ensures the functionality and safety of the entire heating system. Connecting a solid fuel boiler to a heat accumulator is carried out according to various schemes. The photo shows one of them. At its core, it is a simplified basic model of a heating system. Having understood the principle of its operation, you can begin installation yourself.

Watch the video to see how the strapping is done:

The boiler circuit mixing unit prevents cold water from entering the boiler. At the same time, a similar heating circuit unit, if necessary, supplies part of the hot coolant to the system to maintain the set temperature in it.

The balancing valve allows you to ensure equal heating of all heating devices, no matter how far from the boiler they are located. In the presence of additional coils and a solar collector on the roof, the TA turns into a thermal accumulator for a certain time. This allows you to reduce fuel consumption for the boiler. The connection diagram of the heat accumulator to the solid fuel boiler remains virtually unchanged.

Connection diagram of a heat accumulator to a solid fuel boiler

For your information. A heat accumulator for heating boilers can not only be connected, but also made with your own hands, which has already been tested by many.

The heat accumulator for a solid fuel boiler allows you to burn fuel with maximum efficiency and increases the time between adding firewood. Along with noticeable fuel savings and a comfortable temperature in heated rooms, this device is becoming in demand in every heating system. Connecting a heat accumulator to a solid fuel boiler on your own does not create any great difficulties.

The use of solid fuel allows you to efficiently heat your home at low costs. By installing a heat accumulator for a solid fuel boiler, you can make its operation more rational. This reduces fuel consumption and increases the service life of heating equipment.

The ability to accumulate heat allows you to load fuel less frequently and use the boiler for hot water supply in the summer. To choose the right heat accumulator, it is necessary to calculate its volume based on the power of the boiler and its operating conditions.

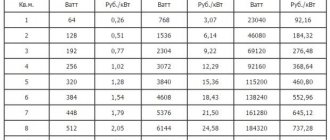

Heat accumulator calculation

The calculation formula is very simple:

Q = mc(T2-T1), where:

Q—accumulated heat;

m is the mass of water in the tank;

c is the specific heat capacity of the coolant in J/(kg*K), for water equal to 4200;

T2 and T1 are the initial and final temperatures of the coolant.

Let's say we have a radiator heating system. The radiators are selected for the temperature range of 70/50/20. Those. When the temperature in the battery tank drops below 70C, we will begin to experience a lack of heat, that is, simply freeze. Let's calculate when this will happen.

90 is our T1

70 is T2

20 – room temperature. We won't need it in our calculations.

Let's say we have a heat accumulator with a capacity of 1000 liters (1m3)

We calculate the heat reserve.

Q=1000*4200*(90-70)=84,000,000 J or 84,000 kJ

1 kWh = 3600 kJ

84000/3600=23.3 kW heat

If the heat loss at home is 5 kW on a cold five-day period, then the stored heat will be enough for us for almost 5 hours. Accordingly, if the temperature is higher than the calculated one for a cold five-day period, then the heat accumulator will be sufficient for a longer time.

Selecting the volume of a heat accumulator depends on your tasks. If you need to smooth out the temperature, set a small volume. If you need to accumulate heat in the evening in order to wake up in a warm house in the morning, you need a large unit. Let there be a second task. From 2300 to 0700 – there should be a supply of heat.

Let's assume that heat loss is 6 kW, and the temperature regime of the heating system is 40/30/20. The coolant in the heat accumulator can heat up to 90C

Reserve time 8 hours. 6*8=48 kW

M=Q/4200*(T2-T1)

48*3600=172800 kJ

V=172800/4200*50=0.822 m3

A heat accumulator from 800 to 1000 liters will satisfy our requirements.

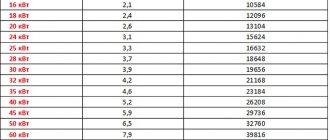

Calculation of the volume of the boiler buffer tank

The most optimal solution to this task would be to entrust its implementation to heating engineers. Calculating the volume of a heat accumulator for the entire heating system of a private house requires taking into account various factors known only to them. Despite this, you can make preliminary calculations yourself. To do this, in addition to general knowledge of physics and mathematics, you will need a calculator and a blank sheet of paper.

We find the following data

:

- boiler power, kW;

- time of active fuel combustion;

- thermal power of heating the house, kW;

- boiler efficiency;

- temperatures in the supply and return pipes.

Let's look at an example of a preliminary calculation. Heated area - 200 m2, active burning time of the boiler - 8 hours, coolant temperature during heating - 90° C, in the return circuit - 40° C. The estimated thermal power of the heated rooms is 10 kW. With such initial data, the thermal device will receive 80 kW (10×8) of energy.

We calculate the buffer capacity of a solid fuel boiler based on the heat capacity of water

:

m=Q/1.163×∆t where: m – mass of water in the container (kg); Q – amount of heat (W); ∆t – difference in water temperature in the supply and return pipes (°C); 1.163 – specific heat capacity of water (W/kg °C).

Calculation of the buffer capacity of a solid fuel boiler

Substituting the numbers into the formula, we get 1375 kg of water or 1.4 m3 (80000/1.163×50). Thus, for the heating system of a house with an area of 200 m2, it is necessary to install a heating unit with a capacity of 1.4 m3. Knowing this figure, you can safely go to the store and see which heat accumulator is acceptable.

Dimensions, price, equipment, manufacturer are already easily determined. By comparing known factors, it is not difficult to make a preliminary choice of a heat accumulator for your home. This calculation is relevant when the house is built and the heating system is already installed. The result of the calculation will show whether it is necessary to disassemble the doorways due to the dimensions of the TA. Having assessed the possibility of installing it in a permanent place, the final calculation of the heat accumulator for the solid fuel boiler installed in the system is made.

Having collected data on the heating system, we perform calculations using the formula

:

W = m×c×∆t (1) where: W – the amount of heat required to heat the coolant; m – mass of water; c – heat capacity; ∆t – water heating temperature;

In addition, you will need the value k - boiler efficiency.

From formula (1) we find the mass: m = W/(c×∆t) (2)

Since the efficiency of the boiler is known, we refine formula (1) and obtain W = m×c×∆t×k (3) from where we find the adjusted mass of water m = W/(c×∆t×k) (4)

Let's look at how to calculate a heat accumulator for a home. The heating system is equipped with a 20 kW boiler (indicated in the passport data). The fuel fill burns out in 2.5 hours. To heat a house you need 8.5 kW/1 hour of energy. This means that during the burning time of one bookmark, 20 × 2.5 = 50 kW will be obtained

8.5 × 2.5 = 21.5 kW will be spent on space heating

The excess heat produced 50 – 21.5 = 28.5 kW is stored in the heat exchanger.

The temperature at which the coolant is heated is 35° C. (The difference in temperature in the supply and return pipes. Determined by measurements during operation of the heating system). Substituting the required values into formula (4) we obtain 28500/(0.8×1.163×35) = 874.5 kg

This figure means that to preserve the heat generated by the boiler, you need to have 875 kg of coolant. To do this, you will need a buffer tank for the entire system with a volume of 0.875 m3. Such simplified calculations make it easy to select a heat accumulator for heating boilers.

Advice. For a more accurate calculation of the volume of the buffer tank, it is better to contact specialists.