What is fum tape

FUM tape is a sealant, which is a narrow thin unsintered film made of fluoroplastic. The abbreviation “FUM” stands for: fluoroplastic sealing material.

All manufacturers of this sanitary film offer two types: white (thick) and translucent (thin). Both of these materials have a similar list of characteristics. Namely:

- are characterized by heat resistance;

- elastic;

- resistant to chemicals;

- average tensile strength 1.5 MPa;

- elongation at break not less than 200%;

- thickness 0.075-0.2 mm.

The film is made by rolling a fluoroplastic rope and wound onto polypropylene reels equipped with a lid. The width of the tape can be different: from 10 to 60 mm. To prevent the thin elastic film from sticking together during winding, one side of the tape is coated with lubricant. Most often this is medical Vaseline oil. There are also sealing films without lubricant.

Variety of types of winding: which is better?

Not the best material for packaging. Flax fibers are hygroscopic, and compaction is achieved due to their swelling. If pipeline elements are thin-walled and made of brittle material, they may rupture. In addition, under constant exposure to water, flax fibers quickly decompose, which does not add reliability to such a gasket. The use of flax is not allowed in high-pressure systems, as it will not be able to ensure the tightness of the joints. When used on steel or galvanized pipes, constant moisture in the winding will cause corrosion. Thus, when dismantling is attempted, the corroded connection comes off together with the thread, and new parts must be used for subsequent assembly.

For more reliable flax sealing, paint is used. This type protects the flax fibers from moisture and the soldering joint from rust. However, the use of paint does not provide a complete guarantee of impermeability. Since the fibers are impregnated with paint unevenly, the issue of corrosion formation is a matter of time. At the same time, connections packed with flax and paint are very difficult to dismantle, especially if the pipe diameter is above average. Linen with paint is not recommended in heating systems.

Silicone sealant works best when paired with flax. It impregnates the fibers quite well (with ample coverage), which reduces the hygroscopicity of the material, and, unlike paint, simplifies installation, acting as a lubricant. The disadvantages of this method include low manufacturability and the need for additional components. In general, this method is well suited for sealing under a lock nut, as well as for installing elements that require positioning - taps, eccentrics, etc., since the linen winding does not interfere with adjustment, maintaining the tightness even of a connection that is not fully tightened.

Fluoroplastic sealing material was developed for the needs of the military industry and was not originally used in plumbing. But nowadays not a single plumber can do without FUM tape. Since FUM is very heat-resistant and chemically inert, it is used to seal joints in systems with high temperatures of the working coolant, as well as in systems with explosive and chemical environments, including pure oxygen.

FUM tape prevents the formation of corrosion on threads. Thanks to its surface, it reduces friction, which makes dismantling and installation easier. But this material also has disadvantages. These include poor resistance to mechanical and vibration loads. The connection will not be tight if a reverse threading stroke is used. Thus, this winding for water pipes is screwed into the thread run-out. All this does not allow it to be used for winding fittings that require positioning.

Types of fum tape

There are three types of sanitary fum tape. Each brand is intended for use at sites with different work requirements. The numbers indicate the grade of the product. 1 – first grade, 2 – second grade, etc.

- Brand "FUM-1". Designed to perform plumbing work on utility lines for domestic and industrial purposes. Resistant to aggressive environments, heat-resistant (begins to melt at temperatures from 520°C). Contains lubricant: petroleum jelly.

- Brand "FUM-2". Sealing films of this type are intended for use on objects that interact with oxygen and oxidizing agents. Does not contain lubricant.

- Brand "FUM-3" are narrow strips, which are sections of the edge parts of films of the first two types. It is often used to seal threaded connections when installing domestic lines.

Winding technique

No special preparation of the thread is required before winding (you don’t even have to remove the rust - the connection will not be damaged). The only condition is that the thread must be intact and preferably have a pitch of 14 threads per inch. With a larger pitch (11 threads per inch), there is a real danger of thread breakage due to its small thickness.

"SantekhNit", length 20 m.

The part (pipe, coupling, fitting, etc.) is taken in one hand, and the thread itself is taken in the other to seal the threaded connections. Winding begins from the beginning of the thread and proceeds further along the thread obliquely clockwise. At the beginning of the thread, you should wind a thicker layer, since when tensioned, the thread will “go” deep into the thread. This will ensure uniform distribution of the sealant along the length of the joint.

"SantekhNit", length 20 m.

The number of turns of the universal thread depends on the diameter of the pipe: the larger it is, the thicker the winding should be. Many packages provide recommendations in this regard. If there are none, and there are no practical skills, it is advisable to make several test connections to find the best option. It's better to play it safe and reel in more. “Overkill” is determined by excessively strong tightening force and squeezing the thread outward.

Specifications

FUM tape, the technical characteristics of which meet the requirements for the quality of work at a particular site, will serve flawlessly for at least 10 years. In order to accurately select the most suitable product, it is recommended to familiarize yourself with the characteristics of the 1st and 2nd grade films.

| Characteristics | FUM-1 | FUM-2 |

| Film thickness (mm) | 0,1-0,14 | 0,035-0,2 |

| Film Width (mm) | 10-60 | 5-60 |

| Elongation at break (%) | 100-200 | 100 |

| Availability of lubrication (%) | 20 | 0,3 |

| Maximum tensile stress (kg/cm2) | 40 | 60 |

It is difficult for a beginner in plumbing work to understand all the intricacies of choosing sealing films the first time. Therefore, you can rely on the recommendations of experienced craftsmen and use the same materials in your work.

Questions often arise about which films to use when installing household water pipes. These are the most popular plumbing jobs, during which mistakes made will be noticeable immediately after water is supplied or will be discovered in the near future.

The most suitable fulente for water is as follows:

- for small threaded connections - width 12 mm, thin (0.075-0.1 mm);

- for large threads - width 19 mm, thickness 0.12-0.2 mm.

Advantages and disadvantages of fum tape

PTFE fum tape is sold in any building or household materials store. Therefore, one of the main advantages of sealing film is accessibility. One can also note the low cost of this material. It is cheaper than various types of plumbing threads.

Craftsmen also note such advantages of using films as speed and ease of installation. But to achieve these results, you will need to practice winding the tape on threads of different calibers. After acquiring the skill, working with this material will be easy, simple and pleasant.

The most important advantage of fum films is that connections made using these materials can be quickly and easily disassembled. Including several years after completion of installation work.

Flaws:

- low aesthetics of the joints (the film partially protrudes beyond the outer boundaries of the fittings, which gives the pipeline an untidy appearance);

- when tightening the connections, the tape may “move out” and partially enter the internal cavity of the pipeline;

- high risk of leakage.

Due to the fact that not everyone knows how to properly handle sealing films, it is not recommended to use these materials when installing complex pipelines. However, even in the absence of winding skills, fluoroplastic seals can be safely used on open structures, the distinctive feature of which is free access to joints. These can be garden water supply systems, temporary water supply lines.

Sealing tape: technical properties and application options

Use sealant first when installing each pipeline. The seal is needed to make a wide variety of connections airtight. Such connections are threaded, flanged, and nipple.

Previously, classic tow was used; this material was replaced by a film that is considered fluorine-containing. This sealant is called differently, for example, fum thread, Teflon, and so on. Let's discuss the technical description of this seal, its properties, good qualities and disadvantages, comparison with other materials. We will also understand how to wind it up. Let's consider the question: what to choose: linen or sealing tape?

Designation of fum tape

The full name of the fumlenta is fluoroplastic tape for sealing. This is a product that is used to seal the various connections mentioned above.

Production and varieties

Manufacturing is done using a fluoroplastic rope. The film is rolled out to a specific thickness. As a result, the sealing material is sold in the form of a tape of different sizes. The tape itself is wound on a reel. I use the product during the installation of structures that are under specific pressure. These structures are water supply, gas supply or the main heating system.

The product is considered a deformable filling, and also a thread lubricant - as a result of this, sealing is performed better. This functional product is not used in systems responsible for heating hot water. However, thanks to such sealing, heat is saved.

Let's look at the varieties of this product:

- Fum-1. This type is intended to provide tightness to pipelines. These pipe lines must work simultaneously with an aggressive environment. Contains lubricant. Vaseline oil acts as a lubricant.

- Fum-2. This type is used for structures that have contact with strong oxidizing agents. Therefore, it does not contain lubricant.

- Fum-3. Designed for structures in contact with clean environments. The composition also does not contain lubricant.

Such tape is also divided into types according to a different condition - sizes. Thickness, width and length vary. Thickness can start from 0.075 and can reach up to 0.25 millimeters. The initial width is ten millimeters. The length starts from one hundred centimeters.

You can also find specially prepared gas tape on store shelves, which is yellow in color. The largest thickness of this material is 0.25 millimeters. This tape is intended for gas supply - a system that does not stop working under low pressure. However, for gas supply you can also use an ordinary fum tape.

Properties and characteristics of plumbing tape

Let's talk about the main characteristics and properties of such a product. Thread sealing fluoroplastic tape technical properties:

- Fumlenta has a low level of friction. The tapes are slippery, which makes it easier to seal various joints. Sealing tape provides a better fit and seal.

- Plumbing tape has a high level of thermal stability (resistance to a wide variety of temperatures). This suggests that this material can maintain high temperatures - more than 300 degrees Celsius. But they can be used at a temperature of 250 degrees Celsius and no more. Just like at higher temperatures, dangerous substances appear that can cause harm to the human body. Tapes are also good electrically powered insulators.

- The product has good strength and ductility. The material has a high level of resistance to alkalis and acids. The tape is quite inert to various chemicals. Also, plumbing tape has great resistance to rotting.

- There is inertness to chemical and biological substances. Resistance against alkalis and acids appears.

This product has similar characteristics.

Before this sealing material appeared on the construction services market, tow for plumbing was used for this procedure. Plumbing tow is flax fiber. However, it happened that oil-based paint was additionally used for sealing. Oil-based paint was used for lubrication.

Flax plumbing fibers are also used today in the same way as other products for sealing a wide variety of joints. But instead of oil-based paint, a specialized sealing paste is used, which is applied from the part on top of the winding. Specially designed sealing paste gives the system strength, durability and reliability.

Thanks to this sealing substance, good protection against rotting of the structure is formed. Previously, plumbing tow with the addition of oil-based paint was difficult to dismantle; thanks to the paste, this can be easily done if necessary.

Method of winding sanitary tow

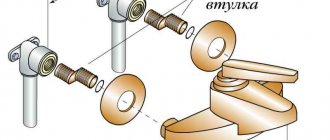

In order to prevent the flax from sliding along the thread, notches are created on it.

If the thread does not have notches, then you should do it yourself. If this is not done, the linen sealing material will slip off.

Before winding, you need to separate a small strand of flax. The designation of length and thickness depends on the diameter of the gas or water pipe. The winding must be tight. The fibers are wound in the direction of the thread. And the end of the plumbing tow, which turns out to be free, needs to be secured with a finger.

Next, you need to insert the turns into a strand, which is considered a guide. Don't forget that the remarkable impermeability is due to the remarkable layer of thickness of the wound material. It is quite difficult to calculate the remarkable thickness of a product on your own; specific experience is required to do this. To wind the product, you also need the help of a specialist.

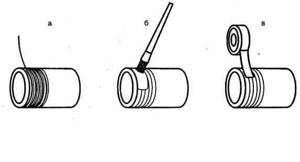

Winding plumbing fluoroplastic tapes

How to wind fum tape correctly? It is necessary to wrap fum tape onto the threads of the outer connecting part of the pipeline (connector). If you are repairing a connection that is considered old, then it is imperative to clean it from corrosion processes. Then you need to degrease the surface. This can be done using a solvent. As soon as the surface is dry, then winding is performed.

Mandatory procedure: the fluoroplastic tape for sealing must be tightly stretched and wound. This is necessary to fill the grooves. How many layers should be applied to the thread with plumbing fluoroplastic tape? This number of revolutions varies. Maybe six, maybe twenty-five. This condition all depends on the dimensions and diameter of the pipe.

Remember that the threads must be completely covered. Compared to plumbing tow, then you will have to spend more fum tape for this procedure. Rewinding must be carried out across the entire width of the product so that it can be pressed into the turns. After twisting has occurred, the fiber must be torn into threads. Thus, the sealing material remains in the middle of the interturn space. This is how sealing works.

It is impossible to make adjustments without losing the tightness. It is not allowed to even slightly unscrew the connecting part of the pipe (connector). Not for gas and water pipes.

Comparison of sanitary tow and fum tape

Which is better linen or fum? Plumbing tow (flax) and sealing tape have their own pros, cons and characteristic parameters. The first material is used to seal a wide variety of connecting parts of steel pipes.

Let's determine what to choose: sealing tape or linen.

Let's consider the important advantages of sanitary tow:

- connection can be controlled. The connecting part of the fitting can be unscrewed by as much as 45 degrees;

- tow ensures reliable sealing. Has the ability to absorb moisture;

- this plumbing material is resistant to mechanical influences;

- If necessary, the plumbing tow can be disassembled.

The main disadvantage is that plumbing tow can rot, since this product has a real composition.

This material is best used on pipes that have a small diameter. It is much better to use fum tape, since you will spend very little time on installation.

So, which is better: fluoroplastic tape for sealing or flax tow? The choice depends on what kind of plumbing work you want to do. In very complex procedures it is better to use fum tape.

Santehgel

Plumbing gel sealant is an innovative tool for sealing pipe threads. Reliability is ensured due to the fact that this material contains polymer materials. Once the substance becomes solid, no shrinkage or expansion occurs.

Sanitary gel has a high level of resistance and can withstand strong temperature changes. Pressure surges are also not a problem for such a product. Sanitary gel can be used in a variety of areas of use: for gas, for water, and so on.

There are only three types of sanitary gel:

- A material that allows for non-heavy demolition. It is sold in a tube, which is green in color;

- Sanitary gel is sold in blue tubes for medium dismantling;

- demolition with heating is typical for material that is sold in red tubes.

Installation using sanitary gel

First of all, you need to shake the tube. Next, a layer of sanitary gel must be applied around the entire circumference of the thread. The layer must first be thick. The sealant gel must be equally divided. This can be done using a brush or a specially designed putty.

At the end, the entire structure is assembled. Polymerization continues for 20 minutes. Don't forget to degrease the surface. Santehgel is better than fum tape. This product is suitable for pipes regardless of what they are intended for.

Working with seals requires specific experience and knowledge. Therefore, it is recommended to entrust the work to real professionals, regardless of what you use: linen threads or fumig material. They know how to wind the fum correctly and will do the winding efficiently. Then the sealing of the connection is ensured. This product is suitable for hot water and gas.

How to seal plumbing threads: flax, fum tape, thread, anaerobic sealant

how to wind fum tape onto a thread

Which is better linen or fum tape for water?

A professional plumber always has different types of seals on hand:

- fum tape;

- flax and sanitary paste;

- threads (type “Tangit”);

- anaerobic sealant.

The craftsmen know that all seals, when installed correctly, perform their task 100%. But to do this you need to know how to use it, what to use and under what circumstances. The abundance of modern sealing materials has displaced flax from its leading position. But not all masters agree with this.

The fact is that in past decades flax was used together with red lead or oil paint. Today – with Unipak plumbing sealing paste. Its main task is to prevent the flax from drying out and rotting. Connections made using these materials can be adjusted (axially shifted) by 45° without loss of tightness.

- inexpensive price;

- suitable for sealing threads of any diameter;

- the connection will be good regardless of whether the base surface is wet or dirty.

The disadvantage is that any connection made with flax subsequently requires additional twisting and tightening. Another “minus” of flax is that it is not very convenient to work with: the fibers delaminate and cling to clothing and the tools and materials used.

Fum tape or plumbing flax - how to seal hot water threads?

If you need to replace outdated pipes, fittings, taps, at the same time the question arises about high-quality sealing of fastening connections in the form of threads. Today's market offers at least 4 types of seals that can cope with the task assigned. Let's talk separately about two of them - fum tape and sanitary linen, compare them and select the ideal option for sealing the hot water line.

Plumbing flax (or tow) was actively used during the years of the Soviet Union, but has not lost its demand even now, despite the wide variety of modern seals. To seal fastening joints in the form of threads, flax strands were used in a configuration with lead on drying oil or specialized oil-based paint. The main working element of the two compositions is lead. It is rarely found in modern analogues, and the sealant itself cannot fight corrosion completely.

Plumbing flax is a classic material for sealing threads

As an alternative, gray sealing pastes are used. Dry winding is strictly prohibited. The paste prevents flax from rotting and drying out, and plays a significant role in water. Without its use on threaded connections with hot water and heating, the flax strand dries, crumbles, and leaks appear. A black coating with traces of corrosion will form on the surface of the pipeline with cold water, and a leak will appear. In direct contact with water temperatures above 90°C, tow shrinks and loses its properties, which is why it is very important to cover it with paste in order to increase the temperature barrier and the working life of the sealant.

Due to the use of paste, there is also the ability to adjust (adjust) the connection and rotate the connector or tap by 45° without losing the seal at the same time, which is especially useful if you have tightened the thread too tightly. This property makes the use of flax its main competitive advantage.

When choosing a quality material for sealing fastener joints in the form of threads, experts advise choosing Unigarn flax and Unipak sealing paste. This seal can be easily removed and replaced if necessary.

Here are the good qualities of using sanitary flax with hot water tap paste:

- 1. Possibility of winding onto pipes of various designs and diameters.

- 2. Winding on dirty, wet and old surfaces.

- 3. Adjustment (control) of connections at 45° and higher.

- 4. Ability to maintain temperatures up to 140°C, used for heating systems.

- 5. Long operational period when implementing the correct winding technique.

- 6. Inexpensive price of the material. The price of 100 g of flax does not exceed 100 rubles, a good paste costs 200–250 rubles. For household use, such a kit is enough for a lot of connections.

Do not also forget that flax is a natural material, it does not have bad impurities, and is suitable for connecting fasteners in the form of threads with clean water.

The material also has its own disadvantages:

- the paste stains your hands and leaves marks on white propylene pipes;

- inconvenient for winding on plastic and very small threads;

- flax fibers get tangled and cause inconvenience during work.

Working with plumbing flax requires skill and knowledge. The main thing is to perfectly attract the tow, hide the ends of the hair, ensure complete closure of the fastening joint in the form of a thread and do not skimp on the sealing paste.

Thread-sealing fluoroplastic tape or fluoroplastic sealant is a thin material of white or transparent color with the addition of fluorine, designed for sealing fastener connections in the form of threads. After purchasing, the tape is absolutely ready for use; there is no need to buy additional sealing cream or paste, as is the case with flax.

Fum tape is sold completely ready for use

Fum tape is suitable for connections of hot and cold water, engineering systems that operate under a pressure of no more than 9.8 MPa. From the outside, the seal looks like a thin plastic plaster wound on a reel. Depending on the diameter of the thread, you can purchase tape from 1 to 10 cm. There are also much thinner options that resemble a sealing thread on the outside.

The material is also distinguished by its content of lubricants:

- 1. Fum tape M1. Used for systems working with aggressive chemical compounds. The tape is impregnated with a lubricant containing up to 20% petroleum jelly.

- 2. Fum tape M2. Not impregnated with lubricant, suitable for engineering systems working with oxidizing agents.

- 3. Fum tape M3. Suitable for clean water lines and other very clean media.

The working life of the finished connection depends on two main components - the quality of the fluoroplastic seal and the correct winding technique. The price does not reflect the characteristics of the tape. To check it, you just need to pull the winding and check for strength. If the seal immediately breaks into fibers, you have a low-quality material that will become rough and break after a couple of months. The tape should stretch slowly and withstand the applied forces to break. The seal must be screwed tightly, deeply deepening it between the turns. As a result of sealing, the threads should be completely covered.

Fum tape has the following advantages:

- 1. Suitable for thin wall connectors, dirty, wet, very small and plastic connections.

- 2. Does not stain your hands and leaves no marks.

- 3. Resistant to chemical and aggressive environments.

The working life of the connection depends on the correct winding technique and the quality of the seal.

However, this is where the advantages of the modern seal end. Despite its high usage, many have a bad attitude towards it. Perhaps everything will be the same as before, when you learn about the disadvantages of the tape:

- 1. After tightening, it will not be possible to adjust (adjust) the connection without losing the tightness. If such a need arises, you will have to unwind the connection and rewind the tape again.

- 2. At the stated temperature of 250°C, the seal will easily withstand 120°C heating. At very high rates, the structure and characteristics of the material are lost. Due to this, it is not practical to use fum tape in a heating system.

- 3. The seal will not withstand vibration loads.

- 4. It is better to use fum tape for fastening connections in the form of threads with a diameter of up to 1 inch; otherwise, you need to take fairly cheap analogues.

Having become familiar with plumbing flax and fum tape, you can sum up which sealant is best to choose for a hot water line. To seal new metal and plastic joints, give preference to fum tape. When working with outdated, rusty Soviet-type threads, use tow with paste. Only with it will you be able to achieve excellent adhesion and the desired tightness. For ferrous metal and brass, flax is used, and for plastic and chrome-plated taps, fum tape is used. Fum tape practically does not tolerate vibration and temperature changes. Therefore, it is necessary to take into account the system pressure and permissible differences.

It is impossible to definitely choose - fum tape or plumbing tow. Professionals say that with proper winding, the two options work 100%. But if you ask clients who have used both grandfather’s flax and modern fum tape, then more positive reviews are given to the first option.

Rules for working with fum tape

The first rule of working with fluoroplastic seals is the correct choice of material. For high-quality connections, only those films that stretch well are suitable. All the rest will eventually begin to crack and turn into crumbs.

In order to avoid installation errors, you need to know how to wind fum tape onto a thread. Masters advise you to remember a few simple rules and adhere to them in your work.

- There are no recommendations for the number of turns to be wound. You need to look at the parameters of the tape: its thickness and width. You also need to pay attention to what kind of thread it is.

- When winding the film, it is slightly stretched. The tape should fit into the grooves of the thread and fit tightly around them.

- If the film breaks during winding and stretching, place the free end on the thread and continue working.

- Winding is carried out until all the threads are hidden under the tape. Its ribbing should look smoothed, but visible through the seal.

Masters claim that the skill of using fum tape comes quickly. It is enough to practice several times and understand the principle of working with this material.

One of the commonly used special tapes is TPL tape (another name is plumbing tape, reinforced tape, TPL tape).

TPL adhesive tape is distinguished by its special composition. This type of tape is made of polyethylene with an additional reinforcing layer of fabric fibers. Plumbing tape has an adhesive base made of rubber.

Modern production technologies make it possible to create a similar tape of different colors, everything will depend on the wishes of the customer. Gray adhesive tape is the most popular, but black and white adhesive tape is also widely used.

How to replace fum tape

It is best to have all types of sealant available - fum tape, flax, thread and anaerobic sealants.

- Linen is the most affordable sealant.

Flax is the cheapest in cost and is rightfully considered the most affordable sealant. It is used together with sealing paste. Without it, flax quickly turns into dust (under the influence of hot water) or into black slush (under the influence of cold water). Only flax connection with paste is reliable and durable.

Linen is used on any surface. Unlike fum tape, sealing with flax does not require preliminary anti-grease treatment of the surface - flax is wound even on damp or dirty threads. When winding flax, special skills and high precision are required when performing “jewelry” work (fine carvings, thin-walled fittings).

One of the challenges when wrapping with flax is determining the correct amount. Both excess and deficiency of flax leads to leakage of the compound. Each flax fiber must be separated, straightened, and they cannot intersect with each other.

- Universal sealing thread.

A sealing thread widely available on the market can be an excellent replacement. The microfibers of the thread are impregnated with a sealing compound. Microfibers maintain tightness under conditions of vibration and severe temperature changes.

- The advantages of the thread include:

- use on any surface, including uncleaned and roughly chopped surfaces;

- aesthetically attractive appearance;

- easy twisting and instant sealing;

- operation at a temperature range from -60 o C to +150 o C.

- Anaerobic adhesive sealant.

On smooth or canonical threads, it is better to prefer a liquid anaerobic sealant. It seals the thread and protects the connection from corrosion. Once in the closed, narrow space between the connecting parts, the polymer hardens, providing a reliable seal.

- The following types of liquid sealants are used:

- low-strength - for connecting joints that are subject to heavy loads;

- medium-strength - for sealing joints during repair work;

- high-strength - the most reliable type of sealants. Dismantling of joints reinforced in this way is impossible.

The main advantage of liquid sealant is its ability to penetrate even the tightest spaces. The sealant is easy to use and does not require serious preparation of parts. But it is difficult to dismantle it. Separating fixed parts will require special tools and high temperatures.

Each of the sealants described is easy to find in any plumbing store and, of course, each should be in a home repair kit. If professional materials are not available, and you need to fix the leak and seal the connection urgently, then you can use the material at hand - an ordinary plastic bag, cut into strips of the required width.

Which is better linen or fum tape

Which is better linen or fum? Plumbing tow (flax) and fum have their pros, cons and distinctive properties. The first material is used to seal various connecting parts of steel pipes.

Let's determine what to choose: fum tape or linen.

- Let's consider the main advantages of sanitary tow:

- the connection can be adjusted. The connecting part of the fitting can be unscrewed by as much as 45 degrees;

- tow ensures reliable sealing. Has the ability to absorb moisture;

- this plumbing material is resistant to mechanical stress;

- If necessary, the plumbing tow can be dismantled.

The main disadvantage is that plumbing tow is susceptible to rotting, because this product has a natural composition.

This material is recommended for use on pipes that have a small diameter. It is much better to use fum tape, because you will spend much less time on installation.

So, which is better: fluoroplastic sealing tape or flax tow? The choice depends on what kind of plumbing work you want to do. In more complex procedures, it is better to use fum tape.

Fum tape or tow, which is better?

Each material has its own advantages and disadvantages. Plumbing flax is used to seal joints of steel pipes (especially rusty and/or large diameter ones).

- Advantages of tow:

- the ability to adjust the connection: unscrewing back by 45 degrees is permissible;

- reliable tightness: absorbs moisture well;

- resistance to mechanical stress;

- easy dismantling of the connection.

The disadvantage is the tendency to rot/decompose, since tow is a natural material.

It is preferable to use plumbing tape on small-diameter pipes, plastic pipes, and in the case of thin-walled fittings. It is easier to work with fum tape and takes less time to install.

There is no clear answer to the question: “Which is better – fum tape or sanitary linen?” It all depends on the specific plumbing job. For example, it is more convenient to connect a kitchen faucet with a flexible hose using fum tape, and it is better to seal a fitting on a water pipe using tow.

Characteristics

Differences between TPL tape and regular adhesive tape:

- The basis of the adhesive tape is polyethylene tape, which is reinforced with fiberglass, which provides increased strength.

- Provides excellent adhesion quality as well as easy peeling without leaving marks thanks to rubber-based adhesive.

- The adhesive tape has high tensile strength. This tape can stretch up to 6 percent of its length;

- High temperature resistance. Up to 80 degrees Celsius, the tape retains its normal shape, as well as adhesive properties;

- Increased resistance to chemicals and moisture;

- Good adaptability to uneven surfaces;

- Adhesiveness parameters. The adhesive applied to the inside of the tape consists of rubber (natural or synthetic). Thanks to this, this tape is characterized by increased quality of adhesiveness, as well as the ability to be dismantled without leaving any traces;

- Strength parameters. The base of the tape is made of a compound of natural fabric fibers and synthetic threads. This ensures high tensile strength of the adhesive tape during longitudinal tension. Reinforced adhesive tape , due to its well-designed fabric, is distinguished by easy transverse tearing, which allows it to be torn without the use of additional devices.

Application

Main applications of TPL tape:

- Due to its excellent sealing properties and complete waterproofness, this tape is widely used in repairing plumbing leaks, as well as for temporarily sealing cracks in pipes. For this reason, this tape is often called plumbing tape. We can say that such a tape will be useful in any home and in any industry;

- In addition, TPL tape is used for sealing and repairing pipes of ventilation systems and air ducts;

- Due to its anti-corrosion properties, this tape is also used to protect metal elements from moisture, which increases their service life;

- Good adhesiveness and high strength have made this tape popular among automotive craftsmen, as well as those involved in laying flooring;

- Also, plumbing tape is useful for packing various goods;

- Scotch tape can be used to seal interpipe joints and as an insulating material used for winding damaged sections of water pipes;

- By gluing tape to the back of mirrors, you can significantly increase their strength and make them safer for others;

- Adhesive tape can be used by auto repairmen to replace car windows for the purpose of temporary fixation;

- The tape is also used by electricians to secure wires;

- In addition, such adhesive tape is also popular among builders and craftsmen involved in interior decoration, as its excellent adhesive properties help in fastening various kinds of structures made of various materials (plastic, wood, metal).

Thus, plumbing adhesive tape is an excellent assistant in work that requires reliable and durable gluing and resistance to adverse conditions and aggressive environments.

Sometimes, during home renovation work involving sealing at the points of contact of the threads, it is necessary to ensure the maximum tightness of the parts. An example of such work would be a routine replacement of a water tap. Tow or FUM tape? Which choice would make the most sense? Of course, due to an old habit, a large number of people still prefer flax. This material is inexpensive and safe to use.

Thread sealing: a - tow, b - mastic, c - FUM sealing tape.

Civilization is developing at a rapid pace. The FUM tape used in practice is used as often as the old, familiar version. Its use is increasingly gaining leading positions among Russian specialists.

Pipe winding, plumbing thread, sealing thread - all these are names for the same material. Thread sealing thread is a stretched polymer fiber that is impregnated with a sealing compound. Each manufacturer has its own. For example, SPRINT thread is impregnated with silicone paste.

Sanitary thread is a modern and very convenient alternative to flax and fum tape. We'll talk about why it's easier to use thread and how to do it correctly in the 4th issue of the Guide. Let us remember that in the first three we talked about FUM, anaerobic sealants and sealing threads with flax.

Why is thread needed?

A reasonable question. Why do you need thread if flax tow and FUM spools are seriously established on the shelves of construction stores? But we know that demand creates supply. The consumer, who is used to doing everything in the house with his own hands, has long been looking for a sealant that would be simple and clear to work with. Without long practice and unpredictable results. And he got it. A sealing thread in a convenient package - which also plays a role, not only the content is important, but also the form - has become an alternative to traditional tools.

Plumbing thread is suitable for both emergency and routine household repairs. If the connection leaks, it can be quickly disassembled and reassembled with the thread. It gives results instantly, i.e. no need to wait for the composition to dry and set. And the winding procedure itself takes about 2 minutes, instead of 5-6 minutes with flax and fum tape.

We have already said that even a home craftsman should have all possible sealants in stock. But first of all, the thread. This is a universal tool for combating leaks and for performing a variety of small household jobs. We’ll talk about the unusual use of thread a little later, but now about its main purpose.

Areas and tactics of application

Plumbing thread is a truly versatile material. Suitable for use in the following systems:

- Water supply - hot and cold

- Drinking water

- Heating

- Gas supply

The following types of work are performed using thread:

- Assembly of internal and external systems

- Replacement of taps and fittings

- Replacing gaskets

- Quickly twist multiple fittings together in preparation for system assembly

Conditions for using sealing thread (using the example of SPRINT thread)

- Operating temperature range from -60 to +120°C.

- Installation temperature - no restrictions

The thread is suitable for sealing all types of threads: thin and thick, new and worn, clean and dirty, dry and wet, plastic and metal. The condition and type of thread are unimportant for several reasons.

Firstly, the thread itself consists of 280 polymer microfilaments. They evenly fill the thread gap, close all cracks and other thread defects and ensure reliable sealing of the seal, regardless of the quality of the parts.

Secondly, the impregnation of the thread contains a water-repellent component, which protects the thread from corrosion and ensures the sealing function even in a humid environment.

However, the tactics for winding the thread depend on the type and condition of the thread.

There are two ways to wind thread, which do not contradict, but complement each other.

The first way is criss-cross. It is relevant if you buy SPRINT plumbing thread. This is the method we, as manufacturers, recommend for assembling metal and plastic connections.

- Fasten the first turn with an overlap at the beginning of the thread.

- Wind the threads crosswise as you go.

- Make as many turns as indicated on the package.

- Twist the connection.

The second method is traditional and is more suitable for worn, thin and heavily soiled threads. We do not recommend this winding method, but many craftsmen use it successfully. Here you no longer need to wind it crosswise, but lay the thread in each turn. At the same time, in the middle of the thread, make the winding thicker than along the edges. As a result, the thread should be completely hidden under the thread, and a tubercle will form in the middle.

Practice or instructions on the package will tell you how many turns to make. If the manufacturer, as in the case of Record thread, indicated the number of turns for different thread diameters, follow these recommendations. You can do 2-3 additional turns to calm down.

Reeling consumption The record for assembling steel pipes looks like this:

– DN 15. Required 5-8 turns (35-55 cm) – DN 20. Required 7-10 turns (60-85 cm) – DN 25. Required 8-12 turns (80-125 cm) – DN 30. Required 9-15 turns (120-200 cm)

Assembling the connection takes about 1 minute. The same amount will be needed to clean the thread if the thread comes out a little when twisting. This is easy to do - you just need to trim the protruding thread and remove traces of paste. By the way, the paste, unlike flax impregnation, can be removed with one movement of a napkin. The connection is neat and clean. As is the workplace around it. No “hair” like flax that flies and settles on all surfaces.

Bottom line: benefits of sealing thread

- Fast twist and instant results.

- Independence - the thread is completely ready for use, you do not have to buy additional materials in the form of impregnation. Saving your money is also obvious here.

- Safety - does not contain toxic substances harmful to the respiratory system, eyesight and skin

- Versatility - suitable for any carving, including smooth ones.

- Convenience - the thread is packaged in a compact box of bright color, which is easy to find among the tools. Inside the box, the thread does not dry out for 5 years, and thanks to the spool, it does not get tangled. There is thread with replaceable spools, for example, Sprint plumbing thread. If the thread is used up - and this always happens at the most inopportune moment - you just need to take a new spool and put it in the same box. Instead of running to the store in the middle of the night. The thread in the box is sold with one replaceable spool, and for further use it is enough to buy a package of replaceable blocks - 3 pieces of 50 meters each.

- Resistance to vibrations, shocks, temperature changes. The connection on the plumbing thread is not afraid of the constant expansions and contractions characteristic of plumbing and heating systems. These deformations are not harmful to the connection.

- Possibility of adjustment. Once the threads are sealed, the connection can be adjusted up to 180° without loss of seal.

Unusual use of thread

As promised, we tell you how unusual, but always useful, to use plumbing thread at home.

- If you have musical instruments, use string to strengthen any flimsy parts. Another option is to repair the straplock of an electric guitar. A resourceful craftsman fixed a loose guitar strap mount.

- For selfie lovers, the thread will be useful if you need to fix your phone holder (aka selfie stick).

- Thread can also be useful outside the home. Here is an interesting experience in assembling a distiller in a chemical laboratory using pipe winding.

- And here is the experience of replacing the rubber gasket during repair of the drain tank.

If you are now looking for a universal seal that can be useful not only in the bathroom and kitchen, but also in any other part of the house for solving small household problems, take thread. It will help you out while you are waiting for a plumber, it will come in handy in your garden, and one day it will help you in the most unexpected situation. So be prepared.

Flax fiber: characteristics

High-quality tow should be without shreds or tears, and have the appearance of a braid.

No one will remove tow from store shelves, because this type of fabric is not capricious, but it is not entirely easy to work with. After all, a situation often arises in which it is not easy to unwind a thread with flax fiber wound on it, and sometimes such ideas remain unrealized. And in the Soviet era, such connections were additionally treated with enamel (red lead), then tightly twisted. Once the paint dried, the joint bonded perfectly. This method was distinguished by its strength and reliability.

As soon as silicone-based sealants appeared on Russian markets, flax compounds were forgotten. Although many experts consider the latter type of material to be a thing of the past, it does not leave its position even today.

Despite the certain complexity of working with tow, its installation is carried out through the following steps. First, the tow is distributed among the fibers, then they are placed in the grooves between the threads. There should be no kinks through the turns. Then you need to apply the sealant. When screwing in flax fiber, remember that there should not be an excess of this fabric. After all, with further operation of the connection, excessive stress appears, as a result of which parts can break.

FUM tape: some features

This raw material is an artificial material with a fluoroplastic base. It is distinguished by noticeable stability regarding the effects of temperature and the influence of mechanical stimuli. It is used in many areas, as its ability to withstand chemical components and hot substrates is maximum.

The main advantages of FUM tape: non-toxic, non-rotting, plastic, resistant to oils and gasoline.

FUM tape is very strong, it is incapable of breaking, does not rot or smolder, does not emit toxic fumes, and is not subject to corrosion.

Material of this kind can be used even under the most severe conditions. This electrical tape does not burn or explode. However, at very high temperatures, over 260 degrees, it can release toxins.

Which is better: FUM tape or tow?

The tow, separated by fiber, without allowing any kinks, is placed in the grooves between the threads, and a sealant is applied.

The use of new materials is dictated by the needs of our time. We will try to clarify many questions regarding materials for threaded connections. After all, not all people are professionals in the construction field, and a large number of craftsmen need to gain the necessary knowledge.

To determine the choice of the necessary raw materials for a threaded connection, you should find out how the thread was made.

To obtain high-quality carvings, several methods are used.

One of them is based on blade plan processing, which results in a very sharp application. Extreme caution should be used with this option, otherwise you can easily get hurt. It is performed by using a variety of cutters, friezes, and marks.

Another method is roller grinding, forming threads with special taps and dies.

The most common method is slicing.

Diagram of thread cutting using dies.

This design is easy to use and allows even an inexperienced craftsman to complete the job with a minimum number of accessories. There is no need to select pipes or rods by size. Thread cutting in industrial production conditions is unprofitable; the productivity level of such structures is noticeably reduced, and there is also the possibility of a significant amount of waste in the form of metal shavings.

Threads produced by rolling are characterized by high quality and good performance. But at the same time, careful calibration of the metal should be done. This method is most often used in industrial settings.

A pipe made by cutting requires a sealing layer of flax, because it helps fill the gaps between the threads and serves as an excellent sealant. If minor leaks occur at the initial stage, it quickly disappears as the tow swells from moisture. Thus, the linen covers all possible cracks and holes.