When designing sewer lines, a number of mandatory requirements are observed for their normal functioning. One of the main conditions is the presence of hydraulic valves in the connected plumbing fixtures. It is useful for any owner who lays a pipeline for drainage with his own hands to know what a water seal for sewerage is - this will allow him to avoid installation errors and ensure reliable operation of the system.

Typically, a water seal is provided by plumbing siphons, sold in a wide range in the retail chain; they differ in design and dimensional parameters, some products have built-in additional elements. To choose the right device correctly, if it is not supplied complete with sanitary equipment, take into account the scope of application, design features of siphons, and their installation technology.

Rice. 1 Siphons under plumbing fixtures

Purpose of a water seal for sewerage

The sewer water seal performs the following functions in the system:

- Prevents unpleasant odors from sewer pipes from entering the room.

- Reduces noise when draining waste water streams.

- Blocks the entry into the home of explosive gases (ammonia and methane), which are formed during the decay of organic waste.

- During a fire, it cuts off the siphon units of plumbing fixtures from the general sewer line.

- Performs the functions of a garbage collector, accumulating various types of waste at the bottom of siphon devices.

- Prevents bacteria, various types of microorganisms, and insects from entering the premises through sewer pipes.

Rice. 2 The operating principle of water seals in toilets and siphons

General information

The water seal performs several functions:

- Eliminates sewer odor

- Protects drainage from water hammer

- Reduces the risk of blockages in the central system

- Reduces stress on pipes

For your information. If you do not use plumbing fixtures for a long time, the water will gradually evaporate from the “lock” and an unpleasant odor may appear. After the first flush, the amount of water will be restored and the smell will be eliminated.

If you assemble a sewer system without siphons, then the bathtub, toilet, and sink will lose their water barrier, the liquid will go directly into the sewer system, and an odor will come from the pipes.

Features of the device and principle of operation

A hydraulic valve is a structural element of a pipeline that constantly contains water. A water plug separates the drain openings of sewer appliances from the pipes - as a result, foreign odors from the sewer do not penetrate into the room.

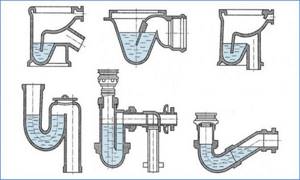

To install a water seal, two main methods are used.

In the first case, the pipeline is bent or a separate element is installed, giving it a U-shape - here the water seal is the water collecting in the lower part of the bend. In another method, the drain pipe of plumbing fixtures is lowered into a deep glass that has a side branch - in this case, the water seal is a water column collected in the lower part of the glass body.

When draining water from plumbing fixtures, the water plug is always renewed - thus, there is no long-term stagnation of water in the water seal, which leads to the appearance of moldy odors.

Advantages and disadvantages: user reviews

Modern hydraulic valves, operating on the principle of communicating vessels, not only protect the room from the penetration of sewer odors, but also balance the load of wastewater on the system in the process of blocking the water hammer. When choosing a plumbing fixture, you should take into account not only the design features of such a product, but also focus on their advantages and disadvantages.

| Advantages | Flaws |

|

|

Types of sewer water seals

On the plumbing equipment market you can purchase both a ready-made water seal for the sewerage system and various elements from which it is easy to assemble it yourself. The consumer usually uses two or three types of hydraulic locking units, the remaining modifications are intended for use in specific conditions.

Rice. 3 Knee siphons

Knees for bath

In appearance, knee models of hydraulic valves resemble the letter U; the unit is characterized by a simple design and high strength. The main installation locations for U-shaped elbows are under the bathtub; in the toilet, a similar water seal is built into the structure.

There are several types of elbow siphons, some models are designed for rigid and durable installation in the pipeline and have a design in the form of one elbow with union nuts, others consist of several parts that allow precise adjustment to the inlet and outlet pipes.

Knee siphons can be made small in height, unlike bottle siphons - this expands their scope of application from sinks to installation under bathtubs that have a low drain pipe. The disadvantages of the devices include inconvenience in maintenance - in order to remove dirt and debris that has settled to the bottom, you have to completely dismantle the device.

Rice. 4 Construction of bottle siphons

Bottles for sinks

Structurally, they are made in the form of a cylindrical settling body with an upper and side outlet, which has a screw-on lid at the bottom. During operation, water enters through the inlet pipe into the volumetric flask, and after filling it, it pours out through the side outlet - the water seal provides the liquid remaining in the flask of the device. The design allows you to collect all the dirt from the sinks at the bottom of the flask and periodically remove debris by unscrewing the lower cap; if heavy objects have fallen into the sink, it is easiest to get them out of the bottle body.

Due to ease of maintenance, bottle siphons are installed under kitchen sinks and washstands in bathrooms, where there is enough space under the sinks to accommodate their rather voluminous and vertically elongated body. The disadvantages of siphons of this design include the impossibility of cleaning the sewer pipeline with a plumbing cable through their body - the device must be dismantled, freeing the pipeline, after which the necessary work is carried out.

Rice. 5 Types of siphon corrugations

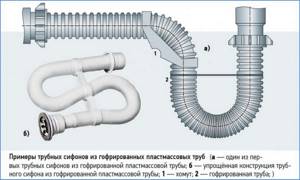

Corrugated S-shaped

One of the simplest and most universal options for organizing a water seal is to use a piece of flexible corrugated pipe, which is bent in the shape of a U, like an elbow. When the outlet pipe of the corrugation is lowered down, an S-shape appears.

The corrugation is good for its versatility - the bend can be made in any convenient place, it is easy to connect to the drain hole and sewer pipe at any relative location and distance due to the ability of the corrugated shell to stretch and easily change its direction. A plastic holder is included to keep the shape unchanged.

The main disadvantage of a corrugated water seal is the high hydraulic resistance to water flow and the ribbed inner shell, in the grooves of which dirt accumulates intensively.

Rice. 6 Overflow siphons for shower bowls - design

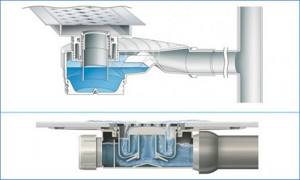

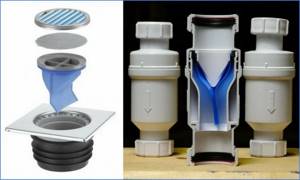

Overflow for shower cabins

A distinctive feature of all shower cabins is the rather small distance of the specially designed drain hole from the floor - this imposes certain requirements on the siphon unit. Structurally, many siphons for shower cabins are made in the form of a low cylindrical body into which a removable glass is lowered. Water enters the glass through a pipe with a lid lowered into it, and after filling it pours through its walls, which have side holes or the height of the upper edge below the siphon body.

If any debris or small valuable items get into the shower tray, they can be easily removed by removing the cover along with the inlet pipe and pulling the glass containing the items out of the siphon assembly. The designs of overflow shower siphons are quite varied; they are all united by a round chrome-plated lid, which provides a side drain and is comfortable to stand on, as well as a low body.

Rice. 7 Parts of the shower overflow siphon

Bath drains

In bathhouses, steam rooms and saunas with a shower, in places where stormwater accumulates, water collects from a large area, so to bring it to the drainage point, the floor is made with a slope, and a drain is placed in the center. The standard device is a small-volume chamber into which water enters through the upper grill and pipe, after which it overflows through its edges or upper outlets and then follows the pipe.

The design is in many ways similar to bottle-type siphons, but does not have a lower removable lid for removing debris, since the body of the device is placed (walled up) in a screed. Dirt usually collects in the inner cup, which is easily removed from the device body.

Rice. 8 Operating principle of drain valves

Types of hydraulic valves depending on design

Depending on the design features, there are 6 types of water seals: cranked, bottle, double-turn, corrugated, dry and with an overflow system.

An elbowed siphon with a water seal is easy to recognize by its appearance. Its design resembles the Latin letter U. The siphon is made of plastic or metal. The first option is represented by products made of polypropylene, which are characterized by reliability, simplicity and ease of installation. For the manufacture of metal siphons, cast iron or bronze is used. Today, such models are less common, which is due to their high cost.

Plastic devices can be produced in a disposable design; they do not have the ability to adjust the position of the element. In case of failure, the product is completely dismantled. Other models consist of components that can move and rotate to adjust the position of the nozzle. The parts are fixed using overhead plastic nuts and clamps.

The elbow has two bends: inlet and outlet. The lower position of the second element is 5-6 cm below the first. More reliable and durable options are represented by the S-shaped design. Cleaning the product is carried out using a special flexible cable with a brush at the end or manually after disassembling the product.

The elbow water seal for sewerage has a U- or S-shaped design

This sewer water seal is characterized by durability, which ensures free and easy installation of the system without fear of damage. Elbowed siphons are mainly installed on sinks, bathtubs and toilets. There are models equipped with an additional outlet, which makes it possible to simultaneously use the water seal for the washing machine.

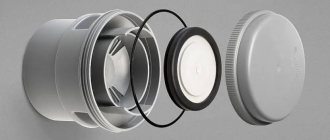

Dry water seals

The need for dry water seals is caused by one of the disadvantages of wet ones - they constantly contain water, and if it is not changed, it begins to smell bad, microorganisms, mold, and algae can appear in it. Therefore, the installation of dry water seals is relevant in places where water is used at long intervals - baths, saunas, shower rooms and similar rooms.

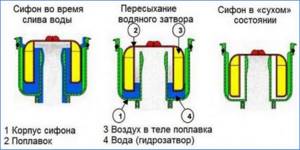

There are several types of dry water seals, differing in their operating principles, the main ones being:

Float A sewer drain with a float-type water seal is one of the most popular models. The typical design is an inverted lightweight glass, the edges of which are immersed in water located between the drain body and its central drain pipe. Water enters the interior of the body through a cover that protects the inverted float; after using the shower, it gradually dries out, the float sinks to the bottom and blocks the drain hole with its body.

In other designs, instead of a float, a light ball is used, which, after the water leaves, is lowered into the outer seat and hermetically closes the drain hole.

Rice. 9 Operating principle of the float siphon

With check valve . The operating principle of the design is based on the fact that the drain channel is closed by a valve on curtains (pendulum design) or in the form of a spring-loaded nipple. When using water, it opens the valve under pressure and pours into the pipes; as soon as the water is turned off, its pressure on the locking element drops, and it mechanically closes the drain channel.

Membrane . One of the latest developments is a dry water seal for sewage with a silicone insert. Its difference from analogues is that it is detached from drains, sanitary equipment and other elements of devices due to the possibility of use anywhere in the pipeline.

This is achieved by a design that is a short piece of pipe, inside of which a silicone membrane is placed in the form of a short sleeve. Its direction is indicated on the body of the device by an arrow; when turned on directly, water passes freely through the hose under its own pressure; in the absence of direct water flow, the walls of the hose are compressed and do not allow the liquid to flow back into the channel. Similar products are supplied to the domestic market by foreign manufacturers in standard sizes 32, 40 and 50 mm. The advantages of the devices are that they can be located vertically or horizontally in the pipeline.

There are other models of membrane valves that are mounted directly into the drain in a vertical position; they operate on the principle of a check valve, opening under water pressure and closing the channel after it leaves.

Rice. 10 Types of dry membrane hoses

Reasons for shutter failure

When the drain starts to smell, there is most likely a problem with the water seal. It’s easy to check, you just need to look into the sink, bathtub, toilet - if there is no water in the drain, then there really is no water plug.

Failure of the water seal occurs for the following reasons:

- Pressure drops within the sewer system. As a result, the plug is drawn into the water intake, which leads to the appearance of odors.

- Creating a vacuum in pipes. This is only possible when a large amount of water passes into the system from the water intake. The pipe lumen is blocked.

The latter situation is likely if pipe installation standards are violated. Namely:

- The installed pipes have a smaller diameter than required and simply cannot cope with water flows.

- After the repair, the horizontal lines fail.

- The lumen of the pipe narrows due to icing or blockages, in particular fatty deposits.

If a water seal with a siphon and corrugated pipes is installed, then using a mesh on the sink or bathtub will help prevent breakdowns. It will stop large particles from entering the sewer. Failure of the water seal due to improper installation can only be corrected by reworking the entire system.

Reasons for failure

The water seal of the sewerage system is a structurally simple product that does not contain complex elements, so its failure occurs quite rarely. The following situations arise most often:

- A water seal failure in a sewer occurs when the pipe in an apartment in a multi-storey building, a cottage, or in a country house along the riser above is closed or clogged. In this case, when large volumes of water are drained, the vacuum formed in the riser pipe carries water from the water seal with it, and it opens. This problem can be eliminated by cleaning the riser pipe or installing a vacuum valve at its end.

- Blockages are the most common cause of failure of water seals; dry operating devices are especially susceptible to this disease. If debris gets under the lowering float or into the closing sleeve of the membrane, they cannot close and foreign odors enter the room.

- Improper installation is another reason why water seals malfunction. Failure to observe slopes in pipes, spontaneous straightening of corrugations, and violation of the assembly sequence of complex systems leads to incorrect operation of locking devices.

- Leaks can also cause water seals to fail. A situation that often arises is that water flows out of the bottle elbow through a poorly screwed sump lid at the bottom.

Rice. 11 Types and cost of siphons for sinks and bathtubs

Tips and tricks for use

For sinks, do not use a corrugated siphon, despite the fact that these pipes are flexible and compactly laid. The downside is that debris is deposited in the bends of the corrugation, and the diameter of the pipe decreases. It is advisable to use it for a bath.

It is undesirable to expose the water seal to boiling water or hot oil - this will lead to cracks in the pipe and, as a result, leakage.

For rarely used plumbing fixtures, only dry water seals are required. If there is a cold effect on the sewer, you should not use a combined float design. Modern siphons are made of polymer materials, they do not rot, are easy to install, and serve for a long time. Metal products are chrome plated to resist corrosion.

The reason for the appearance of an odor in a room with properly installed hydraulic equipment can be depressurization of drain pipes, a long-term operated sewer system in which bacteria multiply on the vessel wall, or a broken water plug. To check the tightness of the equipment, you need to bring a lit candle to the opening of the sink or toilet. If the flame does not fluctuate, there is no depressurization and it is enough to pour a disinfectant into the sewer.

Plug failure occurs if the diameter of the sewer pipes is small and the volume of drained water is significant. A pressure difference is created in the pipes and the liquid moves in the opposite direction. In this case, it is enough to open the tap for 2-3 minutes so that the water restores the seal in the siphon. This will solve the odor problem.

Blockage

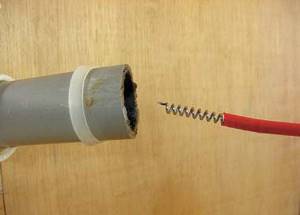

If using a plunger or unscrewing the siphon does not help get rid of the blockage, then it is advisable to use a plumbing cable.

Unscrewing the upper nut and lower fasteners at the junction of the siphon with the sewer system, after which the entire siphon part is removed.

Immersion of the plumbing cable into the drain pipe until the resistance level. Clear the blockage using a rotating motion.

At the final stage, the siphon with a hydraulic seal is screwed on.

Prevention

To avoid significant accumulations of scale or any other deposits in the drain system, it is necessary to flush the inside of the siphon monthly with hot water with the addition of citric acid.

Also, special chemicals such as “Phlox” and “Ruff” can be used for this purpose.

Every six months it is strongly recommended to replace rubber gaskets that have lost elasticity and become thin. The use of protective grilles and meshes prevents large particles of debris from entering the pipe.

To prevent clogging of the bathroom drain, periodically clean the water seal of hair and other debris.

After the water supply is shut off, the siphon “up to the knee” is disassembled and cleaned. After assembling the structure, the joints must be treated with a special waterproof sealant. It should be remembered that siphons with any chips or visible cracks cannot be repaired and must be completely replaced.

The sewerage system in urban and suburban conditions provides comfortable living for people, and for the full functioning of sewage networks, it is necessary to correctly select and install a water seal. Despite the apparent simplicity of such a device, improper installation and use of the wrong type of hydraulic valve can be one of the reasons for the failure of the sewer system or plumbing fixture.

Features of choosing a water seal

The most important thing when choosing is to purchase and install a water seal that matches the purpose of the device. That is, bottle-type appliances are installed in the kitchen, U-shaped appliances are installed under the bathtub, appropriate low-height products are installed in shower cabins, and drains specially designed for these purposes are installed in floor screeds.

When choosing a suitable model, we are additionally guided by the following considerations:

- In no situation should you install a corrugated water seal in the kitchen, despite the ease of connection - dirt will always accumulate on its walls, preventing drainage. This will lead to the need for frequent sewer cleanings, spending financial resources on the purchase of various chemicals or plumbing cable for cleaning work, the price of which is much higher than the difference in cost between a cheap corrugation and a conventional siphon.

- Before purchasing siphons for a bathtub, you should be especially careful - not every model is suitable for installation under a bowl due to its vertical dimensions. Therefore, you should first measure the distance from the drain to the floor, and then select the desired modification. This also applies to the choice of shower siphons, if they are not included in the package.

- When the water seal in the system often breaks (the situation can arise in an apartment building or private building if the sewer riser is clogged at the top), purchase a kitchen siphon with a built-in vacuum valve.

Rice. 12 Siphons for shower cabins and drains - prices

What to consider when choosing a device?

When independently choosing a siphon device corresponding to a plumbing fixture, you need to take into account a number of the most important factors, presented:

- dimensions of the assembled device;

- typical features of a siphon;

- the material from which the pipe system and fasteners are made;

- number of drains;

- availability of additional connections;

- level of protection against congestion and blockages;

- diameter of inlet and outlet openings;

- the presence or absence of overflow.

For installation in a kitchen sink, the most suitable option would be to purchase a regular bottle model that effectively traps food particles.

The use of a knee device would also be an acceptable option. Sinks and bathtubs are most often equipped with models with an overflow that prevents flooding. The recommended material is polypropylene, but the external parts can be finished with chrome parts.

If the project includes a sink or washbasin in the form of two sinks, devices with a pair of drain points are purchased.

Before purchasing, it is mandatory to measure the amount of space allocated for the production of the installation. The siphon must be placed in the designated area.

If the hydraulic valve from the siphon is supposed to be pulled into the sewer network, then it is advisable to modernize the system by installing a vacuum valve.

A standard vacuum valve allows you to effectively normalize the operation of the sewer system. The models produced today are suitable for installation on a vent riser and installation on an outlet from a plumbing fixture.

How to install

Any siphon purchased in a retail chain has an instruction manual, which details the order of its assembly according to the drawn diagram, so a detailed description of the process of connecting various parts does not make sense. Installing a standard siphon (Fig. 13) in a bathtub consists of the following steps:

- On the floor, according to the instructions, connect the elements of the U-shaped sump, screw in the inspection cover and the pipe, which is attached to the bottom of the bath.

Important: The most important thing in this case, as in assembling the entire siphon, is the correct installation of the cone-shaped ring gaskets. The sharp end should fit into the joint of the parts being connected, and the wide end should be pressed with a union nut.

- Next, place a gasket in the drain hole of the bathtub, place the assembled unit underneath and screw it with a screw inserted into a metal cup with holes on the other side. However, do not apply too much force when rotating to avoid stripping the thread.

- Insert a pipe with a cup and a rubber gasket from the outside into the overflow hole at the top of the bathtub, screw it on the other side with a screw through a metal round grille.

- Next, connect the outlet pipes of the overflow bowl and the lower unit of the siphon with a double-sided corrugation; to do this, place cone-shaped rings on its ends and screw the corrugation with union nuts, pressing the wide edge of the gaskets.

- Insert a corrugation with a cone-shaped ring into the outlet hole of the siphon unit and press it with a union nut. The second end of the corrugation is inserted into the sewer pipe.

13 Bath siphon - assembly diagram Seals in the sewer system are the main way to get rid of unpleasant odors from pipes. For their installation, various types of siphons are sold in the retail chain. Each product is intended for use in a specific type of plumbing fixture, so the consumer only has to purchase the item for its intended purpose, assemble and install it according to the attached instructions.

Distinctive features of siphons

Naturally, there are characteristic design differences . For toilets, internal siphons with a rear drain outlet are used, and in today's variations there is a system of two products with different levels of location.

The system under the sink differs in the way it is executed, since the liquid plug is formed by means of a pipe passing through the inner glass of the siphon. A settling tank is designed to discharge solid fractions and requires systematic cleaning. The advantage of modern types is the ability to adjust the level of the plug relative to the displacement of the pipe. This device is most suitable for the “tulip” set.

The bathroom plumbing is connected using

a knee-type water seal with any outlet location.

The two-turn system has an “appendix” with a relief valve, which greatly facilitates its maintenance. Often such structures have outlets for the overflow pipe, which are necessary for connecting household appliances. Siphons with an automatic function have integrated drain grates , so when water reaches the boundaries of the hole, the connecting cable reacts by opening the plug on the drain pipe.

Regarding outlets of perpendicular direction, water seals with storage are also used. When choosing such a mechanism, the parameters of coincidence of pipe diameters and daily waste volumes are implied. To draw an analogy, the design of a water seal resembles two glasses inserted into one another. As an example, CENTER AQUAPA products for plastic pipes with a diameter of 55 and 110 mm.