Ways to soundproof an apartment

Today, there are three main methods of soundproofing walls, which are used for apartments and private houses:

- Frame;

- Frameless;

- Floating.

The frame version of sound insulation is perfect for finishing an apartment with high ceilings and a large area. A frame made of plasterboard profile or timber is installed at the base of the wall, and shimproofing material is installed in the resulting cells. The advantage of this method is its effectiveness in reducing noise levels, but there are also disadvantages. If we talk about the disadvantages of frame sound insulation, then the cost of work and materials will be quite expensive for the owner and plus the total space of the room will decrease.

A frameless method of installing walls is to soundproof the walls in an apartment with your own hands, cheaply and without drywall. It is the simplest and most affordable. Insulation is provided by special panels that are attached to the wall with plastic dowels “fungi” or special glue. The main advantage of this method is that the area in the room is reduced literally a little, while the technique is quite effective and reliable, provided it is installed correctly. Another important advantage is that you can carry out frameless sound insulation of walls with your own hands.

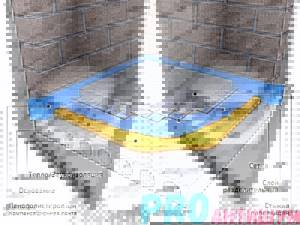

The floating method of sound insulation is considered new, and it is used mainly for floors. This is perhaps the cheapest sound insulation, but it is used for certain surfaces. The principle of operation of this method is that the insulating material is spread on the surface of the floors, then waterproofing, reinforced screed and floor covering. The main advantage of such insulation is the complete absence of rigid fastening, and, consequently, the minimization of vibration noise.

Floating sound insulation structure

You can make high-quality and reliable noise insulation of a room using various methods. The most acceptable option for soundproofing walls, in terms of price and quality, is frameless sound insulation, which you can do yourself. Cheap sound insulation of walls will not entail significant investment and can be done independently.

Stone or mineral wool - is there a difference?

Many people confuse and substitute the concepts of stone and mineral wool. Some people think that this is one and the same thing, while others by mineral wool mean glass wool. In general, complete chaos and confusion. Let's dot all the i's together.

- Mineral wool is the general name for thermal insulating fibrous materials that are obtained from molten rocks, glass or slag.

- Mineral wool is divided into several types:

- stone or basalt - made from rock that is crushed, heated very much, and subsequently melted, after which it can be used to create slabs, mats and rolls. Since basalt is a hard rock, essentially a stone, the second name for basalt wool is stone;

- glass wool - produced from waste from the glass industry;

- slag wool - made from waste from the metallurgical industry (blast furnace slag).

- Comparing mineral wool and stone wool is like comparing trees and birch.

Glass wool absorbs moisture, as a result of which it loses its positive qualities. This does not happen with stone wool. The material has low hygroscopicity, and its noise-absorbing properties are not lost over many years. Slag wool and ecowool are also used, but in terms of performance they are inferior to basalt wool.

Please note that we are talking specifically about sound-absorbing properties - stone wool is not a sound-proofing material. But due to noise absorption, the room becomes quieter.

Algorithm of actions when using various materials

For different finishing materials, the procedure for installing sound insulation will vary.

Plasterboard construction

To install sound insulation in a plasterboard structure you will need:

- Drywall;

- Wood slats;

- Profile for plasterboard structures;

- Hardware to attach the entire structure to the wall and ceiling;

- Sound-absorbing material.

The first step is always and everywhere considered surface preparation. Markings are made on the prepared wall and a frame is mounted to which the drywall will eventually be attached. The profile cannot be attached directly to the wall, as there must be an anti-vibration substrate. As a rule, the substrate is rubber or cork material, which suppresses vibrations. After installing the frame, insulating material is placed in the openings. It is important to know that soft materials absorb sound and vibration much more effectively. Also, as an alternative, you can use sound-absorbing boards with a semi-rigid base. Upon completion of installation of sound insulation, sheets of plasterboard are attached to the profile. The joints between the sheets must be coated with soundproofing sealant or reinforced strip and putty. At the final stage, the surface is prepared for wallpapering or other finishing methods. Budget sound insulation guarantees a high level of protection at an affordable price.

Decorative panel

Currently, it is quite popular to use decorative panels as wall decoration. Manufacturers provide consumers with a huge range of products that differ in their properties and external parameters. Using decorative soundproofing panels, you can hide uneven surfaces of the wall. The slabs are attached to the prepared sheathing or to each other using special grooves. The thickness of the decorative slabs is relatively small, which in turn allows minimizing the loss of the total area of the room. With perfectly smooth walls, the material can be attached using an adhesive solution directly to the surface. The main advantage of such sound insulation is that after installation is completed, the wall does not need to be prepared, but can be immediately painted in any color. Budget soundproofing of walls in an apartment can save money and provide high efficiency. It is also worth noting that decorative slabs have a relatively low weight, which in turn allows you to independently install sound insulation in an apartment without calling a specialist.

Roll sound insulation

Protecting a room using rolled material is quite simple and does not require any special knowledge and skills from the specialist. In addition, soundproofing walls with your own hands is a budget option and is considered the most economical and affordable. The insulating material is glued to the wall surface using special glue. According to the principle of pasting, the process is similar to wallpapering. This soundproofing option is perfect for those who rent an apartment and do not want to spend a lot of money and effort. The only disadvantage of such sound insulation is its effectiveness, which is much lower than with other materials.

In order for budget sound insulation of walls to be effective and reliable, sound insulation of walls must be taken care of in advance about choosing the appropriate material, since today the variety of products is so great that there is something to choose from. Thanks to the ease of installation, you can do all the work yourself.

What is the difference between ecowool and glass wool?

Now let’s talk about the differences between ecowool and glass wool. The best sound insulation is the one that lasts longer. In this sense, ecowool will give a hundred points head start. After a short period of time, perhaps 7 years, glass wool will begin to release various harmful substances into the environment. First of all, these are phenols and formaldehydes. As a result, living indoors will become difficult. This is not the only point. The instructions are different.

Glass wool in rolls

Glass wool is sold in sheets of various thicknesses. According to science, you need to evaluate the resistance to the passage of sound vibrations of this material, and then select products of the required sizes. No one actually does this. But that's not the point. Glass wool sheets affect the size of the sheathing. It is manufactured in such a way that insulation fits into the cells without any modification. Ecowool is installed using a completely different principle.

It is essentially what is called liquid insulation of walls in an apartment. Supplied in plastic bags or other sealed containers. Before use, dilute in the required volume. And then it is downloaded to where it is needed. Some people do this using spray guns. The equipment settings must be such that sufficiently large ecowool fractions pass through the channel. The procedure for carrying out soundproofing work in this case is fundamentally different. First, the cladding is done. Then several holes are cut in it. They are divided into two groups:

- Pouring.

- Tests.

Soundproofing the work area

In this case, the soundproofing of the wall in the apartment will depend on how correctly the sheathing is divided into sections. Filling with ecowool is done from bottom to top. It will not be possible to process the entire sheathing at once. The material spreads quite poorly. Then, in any case, the sheathing will need to be divided into several sections. To control the filling of each, the corresponding holes are used.

Sound level and transmission paths

A distinction is made between airborne noise, transmitted by air vibrations, and shock noise, transmitted by vibration of the structure.

Building structures always dampen noise to some extent, convert it into thermal energy, and act as sound insulators.

The level of sound insulation of structures is characterized by the sound insulation level index. This index is used for both airborne noise and impact noise.

Moreover, only floors in buildings are characterized by the impact noise insulation index. All enclosing structures are characterized by the airborne noise insulation index.

Types of noise

Noises are divided into 2 main types:

- Airborne is sound that travels through the air. This noise includes people talking, cars moving outside the window, dogs barking, etc. This noise enters the room through windows, cracks and crevices in walls and ceilings.

- Impact (vibration) - occurs upon contact with building structures and has a high level of distribution. Such noise can be heard when furniture is moved, various objects fall on the floor, or repair work.

There is also structural noise that spreads as a result of vibration during the operation of a drill, hammer drill or other equipment. It is considered a special case of shock.

Materials for absorbing noise in the home

There are many means for soundproofing walls in a residential building. Let's look at the characteristics of some of them and options for their use.

Cork sound insulators

Outside, you can use thick cotton fillers, but if you need to sheathe the walls inside, then the smallest thickness of the material is important so as not to take up a lot of room space. Porous cork wallpaper or cork panels will do the job perfectly.

Modular plug does not allow a certain range of noise to pass through

Cork not only does not allow noise to pass through, but also, like any wood, retains heat and is also used as a finishing material. Corridors, hallways, and children's rooms are often decorated with such wallpaper.

Loaded vinyl (or sound block)

If the square meters are especially small, then it is impossible to do without vinyl film. Its thickness is no more than 3 mm, but the film is very heavy - 5 kg per square meter. This is what provides a high noise absorption coefficient.

Loaded vinyl (sound block) - high-quality, dense, but expensive membrane

Vinyl film is elastic, resistant to moisture, and the mineral dust that is added to it absorbs sound. One layer of material is capable of blocking sound at 25 dB, two layers - more.

ZIPS

ZIPS panels, glued under wallpaper.

Soundproof panel system ZIPS-Module for walls

They are a two-layer “sandwich” consisting of panels, inside of which there is basalt fiber with a solid gypsum fiber sheet.

Soundproofing panel ZIPS-Module floor

Such panels are up to 7 cm thick and absorb up to 10 dB.

Substrates

Soundproofing adhesives and wallpaper underlays.

Wallpaper backing

This thin material can easily be glued to the wall and is not expensive at all, but the effect of such sound insulation will not be great.

Fiberglass

Fiberglass slabs act as the middle layer in sound-absorbing partitions.

They are placed inside interior partitions or between the floor slab and the suspended ceiling. To prevent the fiberglass from fraying during installation, it is wrapped in a special non-woven fabric.

Drywall

It also has the ability to block sound, of course, in combination with other materials, for example, a “sandwich” of fiberboard, chipboard and plasterboard.

Mineral wool

Mineral wool, ecowool, basalt wool.

Minvata

These are fibrous materials that absorb noise well, but are thick, making them impossible to use in a small room.

Foamed polystyrene

The material is environmentally friendly and durable. It has low thermal conductivity, therefore it is used for thermal insulation. It is thinner than mineral wool and is resistant to moisture and mechanical stress. Capable of blocking sound at 4 dB. Often used as an insulating material in combination with others.

Expanded polystyrene

In general, it should be remembered that any type of noise-absorbing structure alone will not give the desired result. The more materials are combined to protect a home from extraneous sounds, the better the effect will be.

Cork

Cork materials are divided into groups that have their own functions.

- A pressed sheet created from crumbs. Does not rot. Has a service life of 40 years. Prevents the spread of mold. Sheet thickness 2-4 mm. Can be produced in rolls. Impact noise reduction index 12 dB.

- Substrate. It is created by mixing cork granules and synthetic rubber. Reduces impact noise. Used as a substrate for various finishing materials. To install the substrate, waterproofing is required.

- The base is kraft paper, bitumen impregnation, cork crumbs. Waterproofing is not required during installation. But, with strong moisture, the crumb peels off from the base and begins to rot.

Density

Depending on the density indicators, the following types of wool are distinguished:

Lightweight

Density indicators – up to 90 kg/m³. Serves for heat and sound insulation, mounted in places not subject to loads. An example of this type of material is soundproofing mineral wool P-75 with a density of 75 kg/m³. It is suitable for thermal insulation and sound insulation of attics and roofs, heating network pipelines, gas pipelines.

Tough

It is characterized by a density of more than 90 kg/m³; during use it may be subject to some load (its degree is determined by the density of the wool). Hard wool includes P-125 wool, used for insulating walls and ceilings of buildings and internal partitions of premises.

Technical

It is used for insulating industrial equipment and can withstand significant loads. For example, PPZh-200 mineral wool is used for insulating engineering structures and serves to increase the fire resistance of structures.

A little about what kind of noise there is?

Everyone knows that in Khrushchev buildings you can hear the conversation of neighbors living several floors above. But this also happens in modern houses. In monolithic buildings, sound is transmitted through vibration of walls and ceilings, cracks, crevices and gaps in the structure. Therefore, it is advisable to think about sound insulation even before you start repairs.

Sounds enter our homes in a variety of ways. There are several types of noise:

- a drill drilling into a wall, falling objects, steps coming from above, moving furniture - this is a manifestation of impact noise ;

- a dog barking, a child crying, neighbors playing music, loud conversations – this is airborne noise.

Sounds of the first category penetrate through the vibration of house structures, while sounds of the second category are heard through cracks and cracks. Before choosing a soundproofing material, you need to decide which noise you will eliminate. In both cases, stone wool slabs are the best choice.

Release form

Depending on the form of release, mineral wool products are of the following types.

Mats

Convenient for use over a large area for installation in suspended ceilings and partitions. For ease of transportation and storage, the material is produced in compressed form , and after opening the packaging it acquires the declared parameters. The disadvantage is the difficulty of cutting into small pieces.

Plates

Tile products have good sound insulation properties (especially when absorbing “airborne” noise) and are easy to install. It is used to insulate roof slopes, walls, and ceilings. Density indicators usually do not exceed 30 kg/m³

Rigid slabs

This material in slabs is recommended for absorbing “impact” noise. They are easy to install and easy to cut. An important requirement is to lay a vapor barrier layer between the insulating material and the ceiling.

Rolls

Material of small and medium hardness is usually rolled into rolls. Thanks to this shape, it is convenient and easy to transport; the user has the opportunity to cut layers of material to the desired length. The width of the material is standard and is usually 1 m.

Finally, there is acoustic wool that has a foil layer on one side. Sound insulation using foil material is effective, but is suitable for external parts of buildings or with careful insulation of the material with film.

Material with foil does not require additional waterproofing; in addition, its thermal insulation properties are increased due to the ability to reflect thermal radiation.

Soft insulation

Soft sound insulation includes materials made from different types of fibers sold in rolls:

- Soundproofing membranes - there are self-adhesive and regular ones, made from synthetic and natural fibers. Used for walls, ceilings and floors. Separately, for floor insulation, membranes are produced from bitumen polymers with a layer of polyester felt.

- Needle-punched fiberglass material – Used for finishing walls and ceilings. Insulation is well suited for frame structures.

- Backing made of polyester fabric - made specifically for “floating” floors, excellent as a backing for laminate flooring.

- Mineral wool is a simple and affordable heat and sound insulation material used in frame insulation.

MaxForte SoundPro

A new generation material, created taking into account theoretical developments in the field of building acoustics and practical experience in installation work. With a minimum thickness of 12 mm, the material provides maximum protection against airborne and impact noise and is indispensable in small apartments, where every centimeter counts! Completely environmentally friendly: does not contain adhesives or other chemicals. MaxForte-SoundPRO - ideal for any premises: apartments, kindergartens, schools. The material also acts as fire protection (completely non-flammable) and thermal insulation!

MaxForte EcoPlate 60

The material MaxForte-ECOslab is made of 100% volcanic rock (without impurities, slag and blast furnace waste). MaxForte-ECOslab has excellent acoustic properties, which allows this product to be successfully used for soundproofing the most acoustically complex objects: multiplex cinemas, recording studios, listening rooms, home theaters, etc.

MaxForte EcoAcoustic

Made from 100% polyester (polyester fibers) without the addition of adhesives. To give shape, innovative thermal bonding technology is used (melting the polyester fibers themselves). The material is produced on modern equipment from SIMA (Italy); exclusively primary raw materials are used in production. EcoAcoustic is completely safe for human health: the slabs do not emit or contain harmful substances!

Sealant MaxForte

MaxForte sealant is intended for sealing seams, joints, holes in soundproofing walls and ceilings, as well as in the construction of “floating” floors and floors on joists. Due to its low modulus of elasticity, the sealant has excellent vibroacoustic properties and provides a significant reduction in the vibration load between building structures, acting as a damping layer.

VibroStop Pro

Vibration-isolating mount designed to combat impact noise penetrating floor slabs and walls. The use of VibroStop PRO can significantly reduce the vibration load on the profile and provide additional sound insulation of the ceiling and walls at a level of 21 dB.

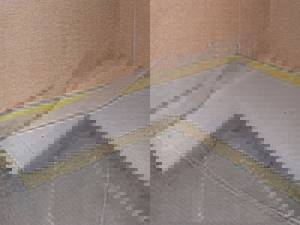

MaxForte Shumoizol

The rolls are spread with the soft side on the floor, the edges are placed on the walls. After work, all excess can be easily cut off. The joints between the rolls are coated with MaxForte Hydrostop liquid rubber.

Advantages:

- Impact noise level reduction 27 dB.

- The material does not tear or crack during installation, due to the addition of imported plasticizers to the composition.

- Can be used as waterproofing, the material is waterproof.

- Belongs to sound absorption class “A” out of five possible.

- The material can be used for dry screed and under laminate.

MaxForte SoundPro

Installation is carried out by analogy with Shumoizol, the edges are placed on the walls, the rolls themselves are overlapped by 5 cm, and the joints between them are coated with MaxForte Hydrostop liquid rubber. Next, a construction film is laid, this is done so that the screed solution does not penetrate into the sound insulation layer.

Advantages:

- Impact noise level reduction 34 dB.

- Reduction of airborne noise level 10 dB.

- Rolls are resistant to moisture. Not subject to rotting.

- Belongs to sound absorption class “A” out of five possible.

- The material does not attract rodents.

MaxForte EcoPlate 110 kg/m3

To begin with, MaxForte tape is laid around the perimeter in two layers. The slabs are placed on the floor close to each other and covered with construction film.

Advantages:

- Belongs to sound absorption class “A” out of five possible.

- Completely non-flammable material.

- Does not contain phenol resins.

- Due to the optimally selected density of 110 kg/m3, the screed does not spring and will not burst over time.

- Sound insulation at 36-38 dB.

If it turns out that the apartment already has a screed, or it is an old housing stock where the ceiling simply cannot withstand the heavy weight of the screed, an effective option is a floor on joists.

Noise insulation

When performing repair or construction work, insulating the premises is a prerequisite for subsequent comfortable living. The choice of high quality insulating material is the key to comfort and coziness in the room, it is a guarantee of maintaining optimal temperature and microclimate.

It should also be noted that high-quality noise insulation of the room is no less important for a comfortable stay.

Poor sound insulation of an apartment , as a rule, is a problem for most panel apartments. Residents of such apartments constantly have to listen to sounds that they do not want to hear. Moreover, this could be the noise of the elevator, a working TV, the constant barking of a dog, the screams of neighbors and much more. All this not only has a bad effect on our mood, but also on our health. WE become more irritable, tired. How to find a way out of this situation, that is, improve sound insulation, and, therefore, make living in an apartment more comfortable?

You can solve this problem on your own; currently, a huge selection of various building soundproofing materials is offered, and modern technologies are also used.

You yourself may be the culprit for reducing the sound insulation in the apartment even at the stage of finishing work, when you carry out redevelopment, knock out niches, demolish walls, etc.

|

|

Many experts first advise sealing voids in walls, ceilings and floors, as well as interpanel seams, with special soundproofing insulation. Such voids are air “sound bridges,” that is, it is through them that “air noise” penetrates into your home. And the ideal option for filling such voids would be a specially designed sound-absorbing material, for example, the insulation materials we offer.

That is, you will not only get rid of unwanted sounds in the apartment forever, but also qualitatively insulate your living space.

Soundproofing insulation can be purchased at any construction market; we also offer this product. This material is able to densely fill voids.

Main types of insulation

There are the following types of insulation:

1. Glass wool, or fiberglass 2. Basalt mineral wool 3. Polystyrene foam, or expanded polystyrene 4. Extruded polystyrene 5. Penoizol 6. Polyurethane foam

The price of sound insulation depends on the manufacturer, type, quality characteristics and other parameters.

Insulation materials with noise-insulating properties usually include expanded polystyrene, that is, polystyrene foam, glass wool, that is, fiberglass, and penoizol.

Polystyrene foam is a synthetic product from the plastics category. Thanks to the inner surface, consisting of voids filled with air, high thermal insulation qualities are achieved. The material is widely used to protect walls and floors, roofs and ceilings.

Glass wool has fibers formed by drawing in - wide and long. The material perfectly withstands vibration and is durable and elastic. Between the glass wool fibers there are many voids filled with air, which ensures excellent sound insulation and heat retention.

Penoizol is characterized by high noise and heat insulation properties, high vapor permeability and fire safety, which prevents the appearance of condensation indoors.

|

|

To achieve optimal sound insulation, our experts recommend that you use only high quality insulation materials that allow you to create effective thin sound insulation systems, which is the most important thing for achieving excellent sound insulation and at the same time preserving the usable area of the room. You can find a detailed description of all categories and types of soundproofing insulation on the pages of our website.

It should be noted that in soundproofing systems, as a rule, various types of insulation are used, the main of which are:

1. Insulation made of basalt (mineral) wool. 2. Insulation made from extruded polystyrene. 3. Fiberglass insulation.

They are represented by various brands, namely:

1. ROCKWOOL, 2. Penoplex, 3. ISOVER, 4. Teplex, 5. Styrofoam, 6. Ursa Foam and others.

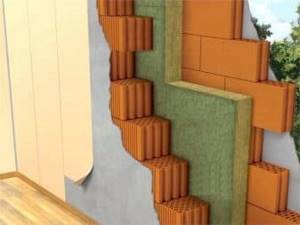

Recommended areas of use:

- Walls with external insulation along the frame and facing with siding.

- Frame walls with a metal or wooden frame.

- Frame cladding of partitions and walls.

- Acoustic ceilings.

- Frame and sheathing soundproof partitions.

- Partitions made of blocks and stones, insulation in the middle layer and in other cases.

Acceptable areas of use:

- Thermal insulation of a loggia or balcony using mineral insulation

- Attic ceilings on beams

- Pitched roofs with thermal insulation installed under and between the rafters

- Insulation of various industrial equipment

- Reinforced concrete floors, joist floors

- Duct Insulation

- Thermal insulation of walls of saunas and baths

- Railway transport

- Thermal insulation of sauna and bathhouse floors

- Water transport

- Modular cabins

- Road transport and in other cases.

If you want to buy sound insulation , then contact our online store. We offer a huge range of different high quality insulation materials. And the prices will pleasantly surprise you!

The benefits of soundproofing walls with your own hands

Self-soundproofing is preferable for several reasons:

- The owner of the apartment knows best in which areas extraneous sounds are heard more often and more strongly.

- Involved specialists work when it is convenient for them. Self-soundproofing can be done at any time convenient for the apartment owner and his family members.

- The work does not require high qualifications. The main condition will be accuracy and thoroughness.

If you plan to install an insulator with your own hands, you need to carefully study the installation method of the selected material, clarify for yourself its features and specifics. This will allow you to do the work correctly and eliminate errors and omissions.