In modern construction, clay plaster has given way to professional finishing materials. But as before, it remains in demand among people living on their land. In this article we will tell you in what proportions a clay solution is prepared, and how to plaster the walls and ceiling with this affordable and environmentally friendly material.

Where is clay plaster used?

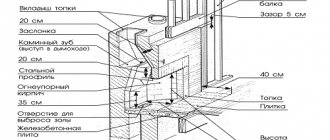

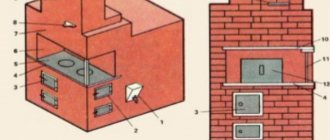

For many years, clay plaster was used, perhaps, only for laying partitions indoors, as well as for finishing and laying stoves and fireplaces.

But, if you look at old buildings plastered with clay compounds, you can be sure that it is still in good use. Red brick partitions are also very durable, in the masonry of which cement-clay mixtures are often used. Moreover, unlike fragile drywall, you can hang heavy racks on them without fear of them falling.

Clay-sand mortar is most often used to plaster wooden and clay (adobe) walls not only outside, but also inside the house. In principle, any surface can be plastered with clay. The main thing is to prepare them correctly, as well as select the fat content of the clay and maintain the proportions with additives (sand, sawdust, straw) in the solution.

This environmentally friendly material is able to absorb excess moisture and release it as needed. Clay plaster with the inclusion of flax or straw fibers looks original, so designers and craftsmen are increasingly using it as a decorative finish.

Mortar of clay and sand for plaster. How to choose the type of solution

As the main criteria for choosing the formulation of the created material, important factors such as the required thermal conductivity and surface characteristics should be taken into account:

- A clay composition with felt is the most durable and warm option. This composition is suitable for rough processing of external walls;

Roughing

- Add sand to the clay-felt mixture, and its plasticity and thermal conductivity parameters will decrease. This mixture is suitable for treating wooden surfaces in which thermal insulation is already at the highest level, due to the properties of wood;

Clay-sand material

- A mixture of clay and sand is more suitable for finishing surfaces, outside or inside a building.

You should also know that any clay solution is suitable for application to various types of materials. Plastering wooden, brick, concrete or other substrates does not require changes in application technology.

Advantages and disadvantages

Plastering walls with clay has many advantages:

- Environmental friendliness; clay does not contain harmful impurities.

- Fire resistance: it is absolutely not afraid of fire.

- This material easily sticks not only to concrete or brick, but even to wood. In the latter case, shingles are used to secure it.

- Even a non-professional can work with plastic clay mortar.

- It is able to “breathe,” that is, absorb moisture from the air and release it when the relative humidity changes, which is very important for creating a comfortable microclimate.

- Adsorption. It has been noticed that allergy sufferers feel more comfortable in rooms decorated with clay plaster. After all, clay can absorb odors and bind harmful substances.

- It costs absolutely nothing: you can dig it up with your own hands in the nearest quarry or in your garden.

- Good sound insulation and heat conservation.

Despite the obvious advantages, clay plaster also has disadvantages:

- Duration of surface drying - a layer only 1 cm thick will dry for 5 days. Thicker 5-10 cm layers dry in 2-3 weeks.

- Moisture capacity. Due to their ability to absorb water, clay surfaces require additional protection.

- Low strength. Of course, it cannot be compared with cement mortar. Clay is easily scratched and chipped.

Paving stones and paving slabs

The use of clay as an additive in mixed cement mortars along with diatomaceous earths and the commonly used lime. As a first approximation, we can assume that the clay content by weight in relation to cement should not exceed 1:1 - 1.25:1. With a larger clay addition, the quality of solutions in terms of their frost resistance and softening coefficient can significantly decrease, why is it currently It is still impossible to judge the suitability of such mortars for brickwork. A large number of tests carried out did not reveal any negative properties of cement-clay mortars that could affect the judgment about the possibility of their use. On the contrary, tests have proven, to a certain extent, the valuable qualities of cement-clay mortars, not to mention the fact that in most cases their cost is lower than similar solutions with other additives. However, the quality of the clay used apparently still plays a significant role, since different clays gave quite different results in our experiments. In particular, clays with a high content of organic matter produced solutions with the worst performance. The best results in different test cases and according to different characteristics were shown by different clays. However, in most cases these best indicators related to cases of introducing brick clays into mortars. Despite the significant difference in the chemical composition of the clays we use, it has not been possible to establish any specific relationship between the quality of the resulting solutions and the chemical composition of the clays. This should, apparently, be the subject of further research in this area.

However, it is now possible to outline some ways to assess the quality of clays and the compounds found in them that can have a negative impact on the properties of cement-clay mortars. Clays, generally speaking, are so diverse in their mineralogical and chemical composition; this circumstance gives some researchers the opportunity to claim “the presence of as many varieties of clay as there are deposits being examined” (G. Zalmang). In addition, the layered nature of a significant part of the deposits makes the composition of the clay very varied even in the same deposit. Therefore, the selection and use of clays in mixed solutions should be treated with great care. Possible impurities in clay that can have a certain effect on the strength and durability of the mixed solution over time include those often found in them: a) sulfides - pyrite and marcasite; b) organic substances (plant tissues, bituminous substances, carbon, humic substances, in particular humic acids; c) some easily soluble salts in the form of iron sulfates (melanterite), calcium (gypsum), magnesium (epsomite), potassium and sodium, sodium and magnesium chloride, soluble silicates of alkali and alkaline earth metals, alkali metal chlorides.

Effect of pyrite

Pyrite in clay is usually found in the form of yellow grains with a metallic luster, cubes and flat rosettes visible to the naked eye. However, in the so-called alum clays, pyrite is also contained in a finely distributed state, and in this case it cannot be removed from the clay even by elutriation. According to Rice, pyrite can be found in almost every deposit, but in clays lying near the surface of the earth, it can rarely be found in a stable form, since in the open air it quickly turns into iron sulfate, and then into limonite (2Fe2Q3 3H2O), which is for mixed solutions, according to all available data, apparently harmless. However, the decomposition of pyrite and marcasite releases sulfuric acid, which forms sulfates with calcium, magnesium or iron carbonates contained in the clay. It should be noted that usually clays containing pyrite or marcasite are discarded during the production of ceramic products and go to waste. In any case, the clay should be examined for pyrite content before it is used. Humic acids are part of humic substances that are soluble in alkalis. According to Sven-Oden, one can generally distinguish:

a) humic acid, insoluble in water, black-brown in color; b) peat, insoluble in water, yellow-brown in color, c) fulvic acid, soluble in water, light yellow in color.

Humic substances, in turn, are divided into humic acids, humins, which dissolve in strong alkalis only with long boiling, and humic charcoal, which is completely insoluble in alkalis. When heated, humic acids also become insoluble in alkalis. The chemical structure of humic acids remains generally unclear, but the presence of a COOH group in them is considered proven. The presence of humic acids can be assessed by the concentration of hydrogen ions. According to Prof. Shvetsov, we can generally assume that acids containing only the carboxyl group COOH do not have a particularly harmful effect on cement mortars when added to the mixing water. However, due to the insufficient understanding of the chemical structure of humic substances and acids, the question of the nature and extent of their possible influence should still be the subject of systematic research.

The absence of a decrease in strength when mixing Portland cement with swamp water containing humic substances and, in particular, humic acid, was observed by a number of researchers. In 1924, D. Abrams published the results of experiments on studying the strength of Portland cement mortars (over a period of 90 days to 2 1/2 years), based on which it can be established that there is no significant decrease in the strength of mortars mixed with swamp water. Engineer Speransky, through a series of experiments with natural and artificial waters containing humic substances, also showed the possibility of using them for mixing cement mortars. In these experiments, the studied peat waters ranged from 4.6 to 6.3, while the oxidability ranged from 11 to 50 mg of oxygen per liter of water. In clays, according to Zalmang, the content of humic substances is usually in the range of 0-0.5% at pH from 7.1 to 4.8; only in particularly contaminated clays, which are mostly dark gray or brown-black in color, the content of humic substances reaches 2-2.5% at a pH value of 6 to 7. In the above experiments, Eng. Speransky observed (for up to 90 days) even a slight increase in the compressive strength of samples mixed in contaminated water compared to samples mixed in distilled water (when all samples were stored in ordinary clean water). The absence of a serious influence of humic substances introduced during mixing of Portland cement on the strength of solutions can be explained by the presence of an overwhelming mass of cement compared to the amount of reagents introduced and neutralized by cement.

Some observed increase in strength, in relation to the general data of prof. B.G. Skramgaeva and G.K. Dementyev, can be explained by some increase in the efficiency of hydration from the action of acids. Thus, it can be assumed that humic substances and acids, if they are present in the mixing water, are unlikely to have a serious negative effect on the strength of mortars for masonry. Nevertheless, in the experiments, clays with organic impurities showed the worst results and a tendency to some decrease in strength in the long term of hardening. However, for clays with a high content of organic matter, Mache's experiments below make it possible to find measures that can help reduce or eliminate the danger from the introduction of clays containing humus.

In his experiments, Mache investigated the effect of introducing chernozem containing humus on the strength of plastic cement mortars. The humus content in the chernozem, determined using the M. Pietre method, was 11.7%.

Considering from this point of view the influence of the presence of humus, it is possible to think that solutions with clays containing organic substances can be protected from the influence of the latter by introducing additional alkali, in particular lime. Hence it should be assumed that the three-component solutions proposed by prof. V.P. Nekrasov (cement-lime-tripoli or cement-lime-clay), in some cases (the introduction of small amounts of lime when using raw clay and raw tripoli) from this point of view can give higher strength indicators than two-component cement-mixed mortars.

Along with humic substances, organic substances can also be found in clay in other forms: a) in the form of plant tissues (leaves, stems, roots, pieces of tree trunks), which can easily be removed from the clay during its preparation; b) in the form of organic substances of a bituminous nature, the effect of which on the quality of the cement mortar can be considered harmful only in rare cases (for example, in the very harmful form of brown coal) cases; c) in the form of solid carbon in modifications similar to anthracite, which should not be considered harmful.

Since a significant content of this kind of organic substances is characterized by a grayish, bluish-gray and black color of the clay, and sometimes even visible inclusions, it is necessary to refrain from using such clays for mortars. It would be advisable to test clays of a different color for the content of organic substances in them and establish the degree of acidity by determining the pH indicator (pending the development and testing of simpler research techniques).

It should be noted that by calcining clay at a red-hot temperature or prolonged heating at a temperature of about 250° (for example, when drying before grinding), you can get rid of a significant part of organic substances. In this regard, it should be noted that, apparently, the use of clays activated by calcination, as proposed by the above-mentioned instructions by V.P. Nekrasov (1933), may be appropriate and beneficial in a number of cases. The most dangerous impurities in clay for cement-clay mortars can be, in addition to organic substances, easily soluble salts. Organic substances can directly cause a slight decrease in the strength of the solution, while the presence of soluble salts can appear over time and lead to subsequent weathering of the solution due to salt migration phenomena. Weathering of building materials usually means their loss of strength and partial or complete destruction under the influence of atmospheric and other factors. The phenomena of weathering of building mortars in general, to one degree or another, occur relatively often, and the main reasons for such weathering can be divided into two most important categories:

1) Poor mixing of the mortar, leading to (the presence of weakened areas that are weathered mainly by the action of frost; with poor mixing of the mortar, reliable and complete adhesion of masonry elements cannot be achieved. In the absence of proper adhesion, cracks and damage easily occur in the brick wall even from slight precipitation of the foundation.These cracks are the centers for the spread of weathering phenomena under the influence of the subsequent entry of water into such cracks and their freezing.

2) Weathering due to chemical and physical influences occurs, in particular, when the components contain solutions of sulfates, carbonates and chlorides. Of the above possible soluble salts with regard to the weathering phenomenon, the most harmless is calcium carbonate, followed by calcium sulfate and potassium sulfate. The most dangerous salts (in this regard are sodium sulfates, for example, Glauber's salt (Na2SQ4 . 10H2O), and magnesium sulfates. The latter salt is especially dangerous in combination with potassium sulfate, since the resulting triple salt (K2S04 . MgS04 . 6H2O) contains significant amount of water and crystallizes with a significant increase in volume, even greater than during the crystallization of sodium sulfates.

Gypsum is most often found in sulfate clay, according to Dawit and a number of other researchers. the content of sulfuric acid salts in clays varies greatly and can be quite significant. For example, according to Nirsch. the SO3 content in clay from the same deposit ranged from 0.016 to 0.271%. It should be noted, however, that often the SO3 content in fired brick reaches 0.2-0.3%, which is explained by the sometimes use of coal with a significant content of sulfur compounds for firing. Particularly often, a high SO3 content occurs in relatively lightly fired brick varieties. Thus, weathering of masonry under the influence of sulfates can also occur due to their presence in piece elements of the masonry. Along with this, it should be noted that the hardened cement used for masonry may also contain a number of compounds that contribute to the appearance of efflorescence. The destruction of mortar in masonry joints due to fading phenomena generally occurs as follows: moisture introduced into the wall along with the mortar dissolves the available soluble salts. As the masonry dries from the surface, soluble salts move towards the outer surfaces of the wall. Subsequently, soluble salts approach the wall surface, where they crystallize in the pores of the solution and on the surface. Since this crystallization occurs for a significant part of the soluble salts with a large increase in volume, such crystallization leads to the gradual destruction of the seam from the surface, to the falling off of the plaster, partial chipping of the brick, the appearance of clearly visible deposits, etc.

The phenomena of weathering are especially intensified with inevitable fluctuations in humidity, since when the humidity of the environment changes, most of the above salts either lose or re-add crystallization water, thereby changing the volume and causing serious internal stresses in the body of the solution. The simplest examination of clay for the content of compounds capable of producing efflorescence on the masonry can be done in the following way: take a glass cylinder (or, better yet, a flask with a narrow neck) and fill it with distilled water; ground brick is tightly placed on the upper hole of the cylinder or flask ; after this, the cylinder is turned over so that the distilled water penetrates into the brick. Subsequently, the brick is dried, and if there are soluble salts in it, they appear in the form of a whitish coating. For the purpose of testing clay, a brick that does not have such a coating must first be selected. Next, the tested clay is dried, crushed and mixed with a large amount of distilled water. The resulting liquid clay milk is poured into a brick, a preliminary test of which has shown the absence of soluble salts in it. If there are soluble salts in the clay, they penetrate into the brick and after drying they will appear on its surface in the form of a whitish coating. The presence of soluble salts in clay can also be assessed by evaporating the residue from water filtered from the clay. The presence of sediment will indicate the presence of soluble salts. Of the other impurities found in clay, in addition to the above, most can even be considered useful. Such impurities include: quartz in the form of fine particles and grains of ordinary sand, silica in the amophoric state (usually found in clay only in very small quantities), hydrates of silica, mica, hydromica. The influence of mica was assessed by Professor Ponomarev, who, in his research cement-mica system noted that small additions of crushed mica (in an amount of 2 - 3%) do not have a significant effect on the strength of the solution, but rather sharply increase the cohesiveness of the resulting mass.

More significant additions of mica quite seriously reduced the values of tensile and bending resistance of the tested samples. There is no reason to expect any harmful chemical effect of mica on the astringent part of the solution, if we take into account the extremely high degree of chemical inertness of micas in general. The most dangerous effect of a significant amount of mica can be, as research by G. Kathrein shows, a decrease in the frost resistance of the solution.

Since the mica content of clays in the vast majority of cases is very low, there is no reason to expect a harmful effect of clay on mixed cement-clay mortars in this regard. Hydrates of alumina, silica and iron oxide, sometimes present in clays in small quantities, can, according to Rodt, have a very beneficial effect on the properties of the solution and, in particular, on its strength during long periods of hardening associated with drying.

Research carried out by Michaelis on gelled hydrates of calcium oxide, alumina, silica and iron oxide hydrate, subjected to drying for the purpose of partial dehydration, showed the possibility of obtaining aggregates of very high strength, especially from gels of silica and iron oxide hydrates. The influence of iron oxide, which is constantly found in clays, can also be assessed from Grün’s experiments. According to these experiments, the introduction of 30% ground iron oxide (based on the weight of cement) into cement-sand mortars 1: 3 even gives a slight increase in the tensile strength of the mortars with very minor changes in the compressive strength (10%). Thus, the influence of this component of clay cannot be considered harmful.

According to the same Grün tests, as well as a number of other studies, the fine dust and fine sand contained in clays also have a more positive than negative effect on the density and strength of cement mortars, especially during long hardening periods. However, it should be noted that this will take place, of course, not with any quantity of the introduced additive, but only in those cases when the granulometric composition of the mortar is within certain limits. (In addition, it should be emphasized that according to the above studies by Feret, the addition of fine sand particles incomparably increases the tensile strength of mortars and the amount of adhesion than compression resistance. This indicates that in general the addition of fine particles can have a fairly beneficial effect on the quality of the mortar in masonry, but that the assignment of the tire additive value should be made with full consideration of the resulting granulometric composition of the mortar.Hydromicas, which are always present in clays (iron hydroxide, calcite, dolomite, glauconite, and feldspars present in some clays, are apparently harmless depleting impurities.

In general, when using clays in mixed mortars, most of these impurities have to be taken into account as (coarse-grained impurities, partially replacing sand in mortars. With this approach, highly sandy clays must be “injected into mortars with mandatory consideration of the content in them coarse-grained inclusions, i.e. with a corresponding increase in the dosage of such sandy clay and with a decrease in the amount of introduced sand.

As can be seen from the above cursory list, the greatest attention when choosing clays should apparently be paid to the content of soluble salts and, in particular, sulfates. Experiments carried out at the Industrial Academy named after comrade. Stalin on the use of highly saline loess showed that the presence of a significant amount of soluble salts in the mortar leads to the appearance of extremely developed efflorescence on the surface of the samples, accompanied by softening and loosening of their outer crust. In this regard, the sulfate salts of sodium, magnesium and potassium turned out to be especially unpleasant. Since soluble salts can easily have a harmful effect on the mortar and masonry (the phenomenon of efflorescence - the appearance of efflorescence), clay containing a significant amount of such salts can be used only after long-term aging, which promotes the leaching of sulfates, or after treating it with barium compounds.

However, both methods can be effective only in the case of a relatively low content of soluble salts in the clay and, in addition, only in relation to some of them. The danger of the direct influence of sulfates on Portland cement in a mixed mortar appears to be somewhat reduced, both due to the supposed action of clay, similar to the action of weak pydraulic additives, and especially in cases of using mortars for masonry exposed to air conditions. Since pyrite, as well as gypsum and other sulfates are undesirable impurities in clay and in the production of bricks from it, then any brick secret is usually assessed from the point of view of the presence or absence of such harmful mineral impurities in it, which is why data from similar tests can be used when choosing clays for mortars.

Specifications

In terms of thermal conductivity, clay-sawdust coating ranks second after gypsum-perlite mortar - its thermal conductivity is 29 W/m ×°C. In its pure form, the thermal conductivity of clay is 69 W/m × °C, that is, almost 1.5 times lower than that of a cement-sand mixture.

Another important indicator for plaster is vapor permeability . After all, moisture must be removed from the premises to avoid condensation. Vapor permeability coefficient for clay = 0.11-0.15 mg/(m*hour*Pa). This is more than that of log walls. Therefore, clay is excellent for plastering wooden houses.

The density (ratio of mass to volume) of clay is 1700 kg/cubic meter. m. Brick has a similar density.

The consumption of clay plaster with a layer thickness of 1 cm is 15 kg per 1 sq. m.

Fireclay clay – a synthesis of natural and human

Chamotte is a word borrowed from the French language, which has recently been heard with renewed vigor. Tired of unnatural delights and plastic gloss, people are striving for natural materials, among which fireclay occupies a prominent place. However, it is not possible to obtain such a material without human intervention - special white kaolin clay must be fired in rotating kilns at a temperature of about one and a half thousand degrees Celsius, since it is in such extreme conditions that it completely loses its plasticity and loses all the water associated with its molecules .

Thanks to this, fireclay acquires properties close to those of stone. The resulting pieces of fireclay are crushed in special mills and already in this form go on sale in the form of dry construction masses or are used for the production of fireclay bricks. It should be noted that not only builders, but also designers are partial to fireclay. Fireclay clay has some inexplicable restrained beauty, a special texture, a natural spirit, thanks to which things made from this material can decorate even the most sophisticated interior, so this method of use is not at all uncommon. In a creative environment, ceramic dishes, tiles, and figurines are made from fireclay clay.

Builders, in turn, are trying to use textured fireclay not only for cladding surfaces exposed to high temperatures (the same fireplaces and stoves), but even for the facades of houses!

Fireclay clay is also found in construction stores under the name kaolin - the essence does not change. The color of this material ranges from white with cream shades to gray-brown. Fireclay is actively used both for creating mortar for laying bricks, for mixing brick mortars, and for carrying out plastering work. When purchasing, make sure that the clay has not been sitting on the shelves for a long time - otherwise it could lose its properties, because stores do not always maintain the conditions it needs. Prolonged exposure to humid air can completely ruin fireclay, just like what happens with cement. Using such material is more expensive.

What clay is suitable for plaster?

The ratio of clay and sand in the composition directly depends on the fat content of the clay.

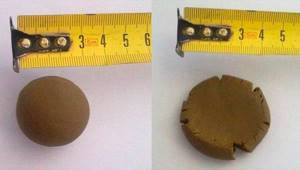

Very oily clay requires much more sand. Proportions can vary 1:5 (clay-sand); 1:4, 1:3 (for clay of medium fat content) and even 1:2. If the clay is very thin, then sand may not be added at all. Please note that you need to measure components not by weight, but by volume. To do this, it is more convenient to use a bucket or large jar. To select the proportions of the clay solution, you need to determine the fat content of the clay . This is done as follows.

Prepare 4 types of the indicated solutions with different sand contents and try to roll a small ball of 3-4 cm in size from each of them. Now throw each of them from a height of about 1 m.

The “correct” ball, when dropped on a hard surface, should not change its shape much or be damaged. If it is flattened, the solution is too greasy. It will crack as it dries. If it crumbles, then the clay is thin, and you need to increase its ratio in the mixture, otherwise the plaster will be fragile.

Also, to check the readiness of the solution, you can place a clay ball on a hard surface and flatten it, reducing its height by half. Ideally, small cracks should appear along the edges of the sample. If they don’t appear at all, then more sand is needed. If the cracks are deep, then, on the contrary, clay is added.

You can try to roll out the prepared solutions into a long rope 20-30 cm long with a cross-section of a couple of centimeters. By experimenting and selecting the ratio of sand and clay, it is necessary to ensure that such a flagellum does not crack after bending.

Advice! If you want your clay plaster to last as long as possible, protect it from moisture with a thin layer of cement (ironizing) or paint.

Lime composition

Lime and gypsum mortar

When constructing stoves, more complex solutions using lime are also allowed. They are used mainly for plastering.

First of all, the lime is slaked with water and kept in a special container or pit for about 7 days. The result is “milk”.

There are several options for the mixture for preparing the solution:

- Clay plus asbestos. Proportions: 1 part clay, one lime paste, 2 sand and 0.1 asbestos. First, a dry mixture is prepared, to which thick “milk” is added from clay and lime, mixed in a separate container. After this, the solution is thoroughly mixed.

- Plaster with asbestos. Proportions: sand one, gypsum one, lime - 2 parts, asbestos 0.2. Preparation technology: dry ingredients are mixed without water and lime is poured in. After this, the finished composition is brought to a homogeneous mass and applied to the surface.

There is a limitation for such a solution - it must be used within 7 minutes. The culprit is gypsum, it hardens very quickly.

How to make mortar for plaster

You can prepare mortar for plaster without any complicated tools.

We take an old large container - for example, a trough or bathtub. Even if a large volume is required, you should not soak more than 10-15 buckets - mixing the clay with sand will be difficult. Clean clay, free of soil and plant roots, must be soaked at least 24 hours and stirred periodically. In this case, it will be easier to work with - it will be easy to knead it with your hands. Drain off excess water. We remove all large lumps that are poorly moistened with water and plant debris. Since we have already determined the quality of the clay and know the required proportions, we prepare the solution by adding sand in the required amount.

Add liquid gradually so as not to overdo it. Continue kneading until the solution reaches the desired consistency.

If you have a mixer or at least an electric drill, the cooking process can be significantly speeded up. Large quantities require a concrete mixer. By the way, to ensure that the clay in it breaks perfectly, throw a couple of stones or pieces of brick into the water. They will help break the clay and mix the solution.

Cement clay mortar for plaster. Cement based

Plastering walls with cement mortar is the most common type of finishing work. A cement-based mixture is somewhat similar in consistency to masonry mortar, but differs from it in density, as well as the possibility of adding additional components and various plasticizers to it.

Please note that the addition of plasticizers should only occur after consultation with a specialist about the required proportions. Otherwise, there is a risk of spoiling the composition.

What is most surprising is that to prepare a high-quality mixture based on cement, the main component, the quality of which you will have to personally monitor, is not cement, but sand.

Yes, yes, don't be surprised! And the quality of the entire composition depends on how clean the sand filler is. To achieve this, I advise you to carefully sift the sand through a large mesh before mixing all the components. There should be no stones or clay in it, not to mention any debris that might get caught.

After sifting, you can begin mixing the composition. First, you need to mix sand and cement in the required proportions in dry form. For exterior finishing, I recommend mixing “M500” cement with sand in a ratio of 1:5. That is, one part cement to five parts sand.

For interior wall decoration, use M400 cement and mix it with the sand component in a ratio of 1:4. One part cement to four parts sand. The resulting mixture must be mixed until smooth, after which you can add water and stir until thick. You can mix both in a trough and in a construction mixer.

Additives in the clay mixture

For plastering fireplaces and stoves, asbestos, lime or gypsum is often added to the mortar to increase the strength of the future plaster. Very little of them is required - 1/10 of them. For example, if the ratio of clay and sand is 1:2, then 0.1 part of asbestos and 1 part of lime are added to the mixture.

Advice! Please remember that cement, which breaks down under the influence of very high temperatures, is not used for laying the stove. Only clay (preferably fireclay) and sand in a ratio of 1:3. For a small fireplace, you can use a 1:2 ratio.

Fireclay (white fired) clay is often used for plastering stoves. After exposure to high temperatures, it acquires the properties of stone and becomes fireproof. It is crushed and used in solutions in proportions 1:3:1 (clay, sand, cement M400-500).

For oily clay, the amount of sand can be increased. Remember that the amount of cement is calculated based on sand. That is, the more sand, the more cement.

In the event that it was not possible to obtain high-quality clay without chernozem impurities (and in some areas it has to be obtained from great depths), it is better not to take risks and purchase ready-made mixtures for plaster and especially for laying bricks for stoves and fireplaces. After all, stoves built on an unsuccessful solution may begin to smoke when it cracks.

Clay mortar with the addition of sawdust is an ideal option for insulating a building. The lumber in the composition not only improves the heat conservation of the building, but also acts as reinforcement for the plaster layer. However, this mixture is not very elastic, and it is not easy to smooth it out. Therefore, the mud hut is often left without leveling. But after drying, the plaster with sawdust is not afraid of cracks and does not crumble.

Advice! If the solution turns out to be too liquid, leave it alone for a while, and then simply drain off the excess water.

What are plasters made of?

The main elements of any batch are: fillers, binders, and liquid.

Let's look at what they are.

Filler

Purified river quartz sand can be packaged in containers and delivered to end consumers

The most common is quartz river sand. Preference should be given to the middle fraction, since large particles are difficult to work with and provide poor adhesion of the constituent elements of the plaster, while small particles are more suitable for finishing thin-layer finishing.

Before use, it must be sifted through a 3*4 mm mesh to remove debris, stones and soil impurities. You can use an inclined sieve and throw sand onto it with a shovel. Only a pure component will allow you to obtain a homogeneous mass and will not spoil the coating during application.

Binders

They carry the function of combining the components into a homogeneous mass. With the addition of any of these elements: cement, building gypsum (alabaster), lime or clay, the plaster composition becomes viscous and lies easily and reliably on the base.

Appearance of cement in dry matter

This element gives strength to the surface. For this type of work, choose the grade of cement M400 or M500 without slag (D0). The mixture with its addition begins to set after fifteen minutes and dries completely after 12 hours.

“When purchasing it, pay attention to the production time. Expired and stale goods lose their durability every month and this can affect the quality of the work performed.”

Construction gypsum

Does not shrink in solutions, makes it viscous and dries quickly. Added without additional processing.

For the industrial production of building mixtures, tared lime comes in bags.

For plastering walls, only slaked lime is used. Lime “boils” when combined with water. Therefore, you should prepare lime milk a day before the planned work.

The recipe for lime milk was discussed earlier in the article “A simple method for making decorative plaster at home.”

This binder component gives viscosity and plasticity to the solution.

Clay

Appearance of clay soaked in water, ready for use in solution

This element is introduced as a plasticizer for plastering complex surfaces (wood or old red brick), as well as for coatings exposed to high temperatures (furnaces).

Liquid

We take ordinary tap water. The main condition is clean.

Preparing walls before plastering

Clay mortar, due to the lack of chemical bonds with the plastered surface, does not adhere well to a smooth base. Therefore, when facing bricks, the joints must be jointed before plastering.

To reinforce wooden surfaces finished with clay plaster, shingles are used . The use of plaster mesh in this case is not very convenient. Since clay is not as flexible as gypsum, it will not bond well to the mesh.

Shingles are narrow boards 3-5 mm thick, which are nailed onto the wall. The wooden planks are positioned at an angle of 45°. Moreover, the nails should not go into the wall completely, but only halfway. The rest of them are bent and recessed into the wall. In this case, the shingles will hold up better.

Is it possible to add cement to clay when laying a stove?

Gas heating is common throughout our country. However, the popularity of conventional stoves still remains high, because they are installed not only in residential premises, but also in bathhouses.

The construction of the stove takes place from the simplest materials - bricks and clay. However, the use of cement in laying causes a lot of controversy. Many believe that it cannot be used in construction, while others are of the opinion that this will only make the stove stronger.

But in reality, with constant use and heating of the stove above 250 degrees, Portland cement begins to deteriorate, which negatively affects its strength.

In addition, cement has a different degree of expansion than clay, and it is from it that bricks used for masonry are made. The difference in the expansion of materials leads to the appearance of cracks and its disintegration. As a result, clay and cement begin to peel off, which causes defects. Therefore, you should not use cement to add to the solution, because over time it will cause cracks to appear.

However, there are some exceptions. For example, a concrete-sand mortar without adding clay can be prepared for the construction of complexes and fireplaces that will not act as a heater for the room. Only the firebox itself is made from fireclay bricks and basalt cardboard is necessarily used. But you need to keep in mind that fireplaces rarely heat up more than 50 degrees. You can also use cement in areas where the oven does not heat up much - in decorative elements, arches.

Plastering with clay

The principle of working with a clay mixture is essentially no different from working with conventional plaster:

- Beacon profiles are also placed for alignment.

- To obtain a durable surface without cracking, the thickness of each layer should not be more than 10-15 mm.

- In case of strong slopes and the need to apply a solution of greater thickness, clay-straw or sawdust mixtures are used, which can be applied to shingle-reinforced walls in a large layer.

- If necessary, a new layer is added on top of the first only after the surface has dried.

- After finishing with shingles, the walls are dust-free and moistened with water.

- The surface is moistened abundantly so that it does not take liquid from the solution and weaken the plaster.

- The solution is applied with force to ensure better adhesion.

- To reduce the formation of cracks, it is advisable to add fiber additives to the solution.

The video below shows how to plaster a wall made of clay or wood.

Is it possible to add cement to clay when laying a stove?

Hi all. In this short article I want to talk about working with clay mortar to which cement is added.

Many stove makers argue both in life and on forums. Some people always use cement in laying the furnace, while others are categorically against it. Therefore, I decided to look into it and write my opinion on this matter.

The most frequently asked question is: “ Why can’t the stove be placed on cement? He's strong."

Customers almost always ask me about this.

I quote from the Wikipedia site:

»

Under conditions of prolonged exposure to high temperatures, ordinary Portland cement concrete is not suitable for use at temperatures above 250°.

It has been established that when ordinary concrete is heated above 250-300°, a decrease in strength occurs with the decomposition of calcium oxide hydrate and destruction of the structure of the cement stone

."

But this is not the most important point. Cement has a completely different degree of expansion

compared to the clay from which bricks are made.

Therefore, the oven, due to the difference in the expansion of materials, will begin to crack and crumble. The materials will begin to peel away

from each other.

Therefore, cement cannot be added to the clay solution (some fractions of a percent can of course be allowed

, but I don’t see any point in this).

But there are exceptions

in which you can add cement, and even completely build the oven on a cement-sand mortar (without clay).

And this can be done in barbecue complexes

and

fireplaces

, where there is no need to heat the room with the mass of the stove.

The firebox itself in such furnaces is lined with fireclay bricks, with the obligatory laying of basalt cardboard. In this case, the main masonry does not heat up more than 50

degrees.

Cement can also be used in places where the stove remains cold (woodshed arches, decorative elements, etc.)

Warmth and comfort to you

If the article was useful,

please like it, this is the best gratitude.

Be sure to write your

opinion in the comments, it’s important to me.

Source

Use for plastering

In this case, the solution is prepared a little differently. Its composition should be like this:

- Portland cement - 1 hour;

- fireclay clay - 2 hours;

- quarry sand - 7 hours.

Water is added in such an amount that the finished solution acquires the consistency of sour cream. Since baked clay has much less plasticity than ordinary clay, the plaster layer of it must be strengthened using a special metal mesh. The solution is applied in the usual way - using a spatula.

How to repair a hole in a clay wall. HOW TO SEAL HOLES IN A BRICK OR CONCRETE WALL

The extent of repair work to the surface of a brick or concrete wall will depend on the extent of the damage. If these are holes left when old nails, screws or dowels were removed, then it is enough to cover them with putty or a special repair mixture.

Let's take a step-by-step look at how this can be done:

- To do this, take a long nail or screwdriver and widen the hole. This must be done so that the putty penetrates as deeply as possible inside.

- Then use a dry brush or vacuum cleaner to remove any accumulated dust and crumbs.

- Now moisten the resulting hole with water. For this purpose, you can again use a brush or a spray bottle, or a piece of foam rubber. This should be done so that moisture from the repair mixture or putty does not quickly absorb into the wall.

- After a few minutes, putty the damaged area, carefully rubbing the mixture into the hole.

- Once completely dry, sand the surface with fine-grained sandpaper.

- Now the area can be painted over or wallpapered.

If the hole in the wall is large and deep enough, for example, it was left after replacing pipes or dismantling an electrical outlet, then putty alone will not be enough. You will need either cement, gypsum, or a ready-made concrete repair mixture, which can be purchased at a hardware store.

What to do in this case:

- Before you fix a hole in the wall, prepare the hole by clearing away any debris and moistening it with water.

- Then fill the void with pieces of stone or brick mixed with cement mortar. This will save putty and strengthen the area being restored. Cement mortar for this purpose is prepared from one part cement and three parts sand. In such a case, you can also use building gypsum or concrete repair mixture.

- When this cement (or plaster) “patch” has dried, putty it, carefully filling and leveling the remaining voids and cracks that have formed.

- The area treated in this way should dry well. This will take at least 12 hours.

- When everything is fairly dry, smooth the surface with fine-grit sandpaper. To prevent this place from showing off as an ugly bump, it should be leveled with the rest of the wall surface.

- The wall is leveled, and now it can be painted or wallpapered.

If, during the shrinkage of the building in the room, the interpanel seams have come apart or a deep crack has formed, then there is no need to rack your brains about how to repair such a hole in the wall. In this case, use polyurethane foam, which is sold in aerosol cans at any hardware store. It perfectly fills voids, easily penetrating even hard-to-reach places.

Polyurethane foam adheres perfectly to various surfaces and quickly hardens in air. So you are guaranteed a good result in the process of eliminating deep cracks and holes.

- Before you start work, prepare the place - clean it of dirt, dust and other debris. Wet the wall surface.

- Before applying the foam, you need to shake the can well so that its contents turn into a homogeneous mass. This will take you at least a minute.

- During operation, hold the container upside down, since the gas contained in it, which displaces the polyurethane foam, is lighter than it.

- Vertical cracks should be filled from bottom to top.

- If the hole is too deep, apply the contents of the can in layers, applying a new layer after the previous one has dried.

- After filling the hole, do not touch the damp polyurethane foam with your hands, this can change the structure of the material and slow down the process of its hardening. Wait until it dries.

- Remove excess dried foam with a knife and putty the surface.

- When the putty is dry, smooth the area with fine-grit sandpaper.

Now you can see for yourself that it is simple and easy to repair any hole in a concrete or brick surface, no matter what size, without outside help.

The main thing is to correctly assess the scale of the repair work and carry it out in accordance with the rules for using the material that you will use when restoring your wall.

How to repair a crack in a clay wall. Repair of adobe walls

In towns and rural areas, buildings are still used in which mortars containing clay were used as building materials. It was used to make adobe blocks and was used as a finishing material to cover walls and ceilings. This was due to its availability and good astringent properties.

For various reasons, we have such a house, for example, someone inherited it. Sooner or later the need for repairs arises. Modern craftsmen are very reluctant to undertake repairs in these rooms; they suggest removing the clay and re-plastering the walls. Is it worth doing? Clay walls have excellent performance - low thermal conductivity, high sound insulation properties. But it remains possible to carry out repairs on your own.

I have such a need. The outbuilding needed repairs; the interior decoration was done with clay mortar. The task is to repair the coating and bring it to a state that allows wallpapering. Here's what it was originally:

I have done similar work before, so the method is time-tested. I'll tell you about it:

The first part of the work is cleaning the surface - removing old whitewash and paint. To quickly remove whitewash, it must be moistened with warm water using a brush or roller, after which it can be easily cleaned off with a spatula, without forming dust. The coating is cleaned down to the base, leaving a clean clay surface. There is no point in washing off the whitewash; some of it will still remain and will not allow you to do the job properly.

The next step is to repair the surface - large potholes, cracks, and so on. This work must be done using clay mortar. To prepare, we will need clay, which can be obtained directly on the site, and sand. Before use, the clay must first be soaked for about a day. If it is necessary to apply a thick layer, a reinforcing additive – straw or sawdust – is added to the solution.

We prepare a solution from one part clay and four parts sand, the solution should be thick and at the same time easily come off the trowel. We use the resulting solution to carry out the necessary work; we first moisten the surface generously; you can apply the solution by hand or using a trowel. It is necessary to sketch, not spread. When applied, the solution adheres better to the surface. We remove the excess using a wide spatula or a rule, depending on the size of the patch. And leave until completely dry. When performing this work, you should not use cement-based solutions; their properties differ from the recommended composition.

{module ads4|none}When drying, cracks and peeling may form. We use a rule in our work: to repair coatings, it is necessary to use the same material as the material from which the coating is composed. If the walls are plastered with cement plaster, then we use cement-based compounds for repairs, gypsum walls are repaired with gypsum compounds, and so on.

The surface has been repaired. Now you need to treat all the walls with a primer solution; for this it is better to use a deep penetration primer with antifungal properties. Apply the primer two or three times until completely absorbed. After the primer has completely dried, we obtain a surface similar in strength to cement plaster. The surface does not crumble or smear. You can move on to the next step.

We apply a layer of gypsum-based plaster mixture over the entire area; if it is necessary to level the walls, we carry out the work according to the installed beacons. Using a spatula, if beacons are used - rules. Level the resulting surface using putty, and after complete drying, clean it with an abrasive mesh. Or sandpaper.

The resulting finished surface allows the necessary finishing work to be completed. Pasting with wallpaper, decorative tiles, applying decorative plaster, painting, and so on.

Ceilings can also be repaired in a similar way, only when applying the plaster composition, it is necessary to reinforce the surface with a painting mesh.

Types of fireclay clay

Currently, two main types of this material can be purchased in construction stores. Regular fired clay is made from kaolin. The second type is made from discarded fireclay bricks. It is simply broken into pieces and then ground into powder of different grain sizes. It is not too difficult to distinguish the first variety from the second. The package containing brick clay must be marked with the letter “U”, which means “disposal”. This material cannot be used in critical work. Fireclay clay can also vary in grain size and moisture content.

Source