What is the service life of polystyrene foam as insulation?

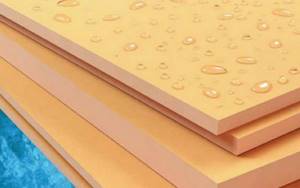

One of the universal thermal insulation materials can be called polystyrene foam, which is used for various types of work.

Some people mistakenly consider it short-lived and harmful, but in reality everything turns out to be completely wrong. The service life of polystyrene foam is influenced by various parameters, but their impact is not nearly as detrimental as is commonly believed. Foam boards have the necessary rigidity, resistance to moisture, temperature, and corrosion. They are not susceptible to rotting, which is so important when insulating wooden surfaces. The only downside that should be noted is the fragility of the material. During operation, care should be taken not to damage the slabs. This circumstance cannot prove the fact that the service life of foam plastic is short. Insulating walls with foam plastic will protect them from moisture, cold and corrosion for a long time.

Styrofoam storage rules

Expanded polystyrene, manufactured in compliance with quality standards, does not require any difficult storage conditions.

The material is not afraid of climatic temperature fluctuations and practically does not absorb water. Polystyrene foam can even be stored outdoors if there is no free space. The main thing is to have a canopy that protects from UV rays. For small amounts of foam, it is convenient to use an opaque fabric. We found out that there is no need to be afraid of the fragility of polystyrene foam. It is durable, you just need to take a little consideration of its properties. The warmth that you give to your home today will keep your descendants warm.

Types of foam and performance data

For work, foam-based insulation is used, not all of them are slab. Their service life and conditions are different. The following types of heat insulators are known:

Table of characteristics of various brands of polystyrene foam.

- PSB-S-15 is a low-density material that can be used for insulating roofs between rafters, where high mechanical strength is not required.

- PSB-S-25 is a universal foam plastic that is most often used for work. It is resistant to moisture, it is used for insulation of facades, floors, interior walls, attics, balconies, i.e. The scope of application is wide. The service life of this material is long, and the operating conditions are not so demanding.

- PSB-S-35 is a durable material that is used for waterproofing and insulation of foundations when it is necessary to prevent soil heaving. It is used under the most unfavorable conditions, the service life is significant, as is the stability.

- PSB-S-50 has high mechanical strength, the resistance of the insulation to various types of influences is the best. Aging rate is low.

Polystyrene foam is available in the following types:

Comparison table of polystyrene foam and polystyrene foam.

- Polystyrene, i.e. unpressed and pressed material, which has high performance characteristics. Available in the form of slabs, convenient for work. Polyurethane material in the form of foam rubber allows you to perform thermal protection work, which is necessary for internal walls, for cladding structures where rigidity does not matter.

- Polyethylene is an elastic material that is a film with air bubbles. It is used only for packaging; it is almost never used in construction, since its service life is short.

- Polyvinyl chloride products are similar to extrusion materials, the elasticity is greater, but the service life and conditions of use are sufficient for wall insulation.

- Polyurethane foam is the highest quality and most durable among foams. It is applied only in liquid form by spraying, hardens quickly, after which it forms a very strong film that can withstand almost any impact. The quality of this material is high and its service life is long.

Return to contents

Advantages of polystyrene foam

One of the thinnest insulation materials

Among all insulation materials, ordinary polystyrene foam, also known as expanded polystyrene, has almost the lowest thermal conductivity coefficient. What does it mean? This means that its thickness as insulation will be the smallest compared to other materials. Here is a list of these materials in increasing order of their ability to conduct heat:

- Penoizol (50 mm).

- Foam insulation (75 mm).

- Mineral wool (125 mm).

- Wood (340 mm).

- Brick wall (900 mm).

- Concrete (2132 mm).

- the thickness of the materials at which their equality as heat insulators is achieved is indicated in brackets;

- penoizol is a liquid material that consists of several components. When they are mixed, it swells and hardens. At the same time, it acquires a porous light structure similar to hardened polyurethane foam. Its main disadvantage is toxicity. Therefore, it can only be used for insulation of non-residential premises. Usually, it is poured into a specially prepared cavity inside the wall.

The lightest insulation

Finding out the weight of polystyrene foam boards is very simple. All manufacturers indicate the density of the material on the packaging:

- 15 kg/m 3;

- 25 kg/m3;

- 35 kg/m3.

And the density of one cube is its weight. That is, one cube weighs 15, 25 and 35 kg, respectively. By the way, this is how you can check the quality of the material you buy. If the package says 25 kg/m3, and the tested package of sheets weighs less, don’t hesitate. You were a little misled.

Sometimes the manufacturer bypasses this point. For example, a package with a declared density of 25 kg/m 3 will contain sheets with a actually lower density. But this packaging will have its own beautiful name. And a pack of sheets with a real declared density will be called differently: “Warm House”, “Standard” or “What else”. But, in any case, the lighter the pack, the lower the density of the insulation. Remember this.

For work, you can use foam of any density. The main thing is to understand that the lower it is, the more fragile and fragile the sheet will be in your hands. But the use of such sheets, for example, on the first floor of a building is not recommended - the facade can easily be damaged by an impact. Therefore, the denser the sheet, the better.

One of the most inexpensive insulation materials

This is truly the most inexpensive industrial insulation material. At the same time, two types are used in construction practice:

- sheet foam;

- foam chips or balls.

Today, the selling price for both of these species is approximately equal. Most likely, this is due to an increase in demand for balls. Most often they are used for roof insulation. The cement-sand mixture is mixed with balls and poured onto the ceiling. It turns out warm, durable and inexpensive.

Polystyrene foam is a very multifunctional insulation material.

Here are its main areas of application:

- wall insulation;

- roof insulation;

- floor insulation;

- insulation of the basement of the house.

Insulating walls with foam sheets has become a classic today. The result is very warm, relatively inexpensive, quite durable and reliable. In terms of service life, polystyrene foam covered with a layer of plaster can last for a very long time. Manufacturers guarantee the service life of facades made of polystyrene foam boards without major repairs for 30 years. They say that in Germany, houses insulated with foam plastic are insured for longer periods. Up to 100 years.

When insulating a roof, polystyrene foam chips or balls in a cement-sand mixture are most often used.

Extruded polystyrene foam is used for the floor and base. It differs from conventional foam in its manufacturing technology, being more dense and durable. But its price is much higher.

A little more positive about polystyrene foam

Polystyrene foam is the most convenient and pliable building material to work with.

It can be cut with a knife or hacksaw. You can easily make any hole or recess in it. This property is very much used by builders when designing shaped elements of a building facade. Cornices, ledges, window frames and other architectural elements are very easy to make from such a convenient material. Due to its lightness, the foam element can be glued to the facade anywhere. Well, after the glue has dried, it can easily be further processed, for example, with a drywall plane.

These were the strengths of foam insulation. But, like any other material, it also has its weaknesses. What are the disadvantages of polystyrene foam and why can’t it be used to insulate a basement or ventilated facade?

Rotting and shrinkage

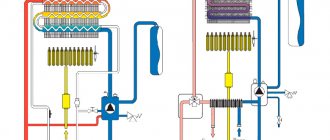

Diagram of thermal conductivity and thickness of materials.

For insulation, it is recommended to use polystyrene foam, since it is not subject to rotting. It is not afraid of mold, fungi, etc.; insects cannot damage the surface of the insulation. Even with prolonged exposure to water, polystyrene foam does not absorb it, damp spots do not form on it, which means that there will be no mold. All this is important for insulating a house, since the service life of insulators is greatly increased, which means that repairs will not be required.

Any building material is susceptible to so-called shrinkage over time; even metal is not immune from this. This happens under the influence of periodically or constantly repeated various loads, due to which the insulation or other material begins to sag and lose shape.

Wöhler's special tests show that foam insulation is less susceptible to shrinkage than other materials. It does not lose its shape, does not cake, or sag. This is important to consider, since cavities and other defects open the way for heat loss. For example, mineral wool cakes over time, air cavities appear, which negatively affects the thermal insulation characteristics.

Return to contents

Limit parameters

Characteristics of thermal insulation materials.

Service life largely depends on what conditions the material can withstand during use. Such indicators are determined by physical properties, chemical properties, and resistance to mechanical loads. It should be noted that polystyrene foam is completely unaffected by the aggressive environment of concrete, plaster, gypsum, lime and other building mortars that are used during work. And the mechanical strength is usually enhanced by special cladding; the service life is increased by protecting such slabs with plywood and chipboard. The material is enclosed in a shell, where it can perfectly perform its properties without being subject to negative loads at all. This is important because impact loads can be critical for foam. Not every type of it is susceptible to them, but ordinary slab materials can collapse.

Return to contents

Polystyrene foam

There is pressed and non-pressed foam; it is not too difficult to distinguish them, even if you are not a professional. If you have ever looked at the structure of a material, you have most likely noticed that it consists of small balls that are interconnected, like a honeycomb in a beehive.

Pressless foam can be seen in boxes with household appliances, as it is actively used for packaging.

In terms of thermal insulation properties and appearance, the pressed one is practically no different from the second one; its granules adhere to each other somewhat more firmly, due to which it does not crumble. At the same time, pressed foam is more difficult to produce, which means it is more expensive, which is why it is less widespread.

Wear resistance

It is necessary to pay attention to how much the material resists wear. Typically, manufacturers independently conduct the necessary research, which includes tests for resistance to certain types of loads. This wear can be associated with various parameters. The most common causes are temperature, moisture and aggressive substances. The results obtained make it possible to conclude that during the entire service life and even longer, signs of wear do not appear on the foam plates. These periods are 20-50 years depending on the type and type of material. Such conditions are quite sufficient to perform high-quality cladding of the external and internal walls of the house, roof, attic and foundation, where polystyrene foam can be used as waterproofing.

Return to contents

Comparative characteristics of the service life of insulation materials

To choose the most durable material, you must first compare the service life that distinguishes polystyrene foam and other types of popular thermal insulators. This can be done using the example of insulating the façade of a building.

Characteristics of mineral wool insulation.

- The condition of the layer of plaster applied on top is destroyed after approximately 400 cycles.

- Decrease in thermal protection indicators after 700 cycles. After this period of time, the plaster completely crumbles, there is no protective layer.

- The condition of the layer of plaster applied on top is destroyed after approximately 700 cycles, delamination is observed, and the mesh rots.

- Decrease in thermal protection indicators after 700 cycles.

- The service life before major surface repairs is about 20 years.

How to protect foam from destruction

To protect polystyrene foam you need:

- close the sheets from direct rays of the sun in time;

- prevent contact with solvents;

- install a starting profile that protects you from rodents.

If you have attached polystyrene foam to the facade, try to quickly cover it with a layer of plaster. It should be intended specifically for exterior decoration.

If you feel that you will not have time to install the protective layer before the onset of winter, put the foam away for storage. But do not fix it to the outside wall.

Service life of insulation: table, characteristics, description of advantages and disadvantages

Today in this article we will look at the current issue in our time about the service life of insulation in the table. As a rule, houses, buildings and other structures are insulated for a long time, so materials are needed as reliable and of the highest quality as possible . Many people believe that various types of insulation do not last more than 30 years. Taking into account the fact that the wall that is being insulated lasts about 100 years, we come to the conclusion that during this time the procedure must be done 2-3 times. If you calculate the cost of such an update, it may not please you.

What affects the service life of insulation?

As with everything, it is believed that the service life of insulation depends on its cost and quality. Manufacturers of the inexpensive substance claim that it can last at least 50 years. In practice, this figure is not confirmed by anything, so in the footnotes they write that today there is no standard operating time for insulation materials.

In addition, what the material is made of is important. Experts confirm that man-made fibers cannot provide a warranty of more than 35 years. During this time they dry out and collapse. But the most important thing is that they lose half of their heat-saving properties. While natural fibers do not lose their original qualities and can last for a longer period.

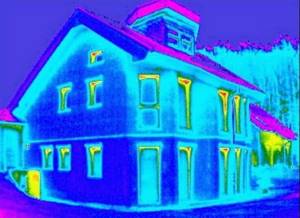

According to regulatory guidelines, every home must undergo an energy audit upon completion. Such checks should be carried out every 25 years so that the current level of heat-saving properties can be assessed. But since we are unable to find out the exact numbers due to verification, we use data that comes to us from Europe.

Comparative characteristics of the service life of insulation materials table

There are many types of insulation, but today we will take a closer look at the most budget-friendly and reliable options. These include:

- Mineral wool.

- Basal wool.

- Styrofoam.

| Name | Life time |

| Mineral wool | 25-40 years |

| Basal wool | 40-50 years |

| Expanded polystyrene | 30-50 years |

| Polyurethane foam | 20-50 years |

| Foam glass | 80-100 years |

The first type is called stone . It has a fairly high level of quality, as it is made from basalt stone. Its cost is much higher, but both the quality and the period of suitability meet expectations. According to statistics, mineral wool is used most often in construction. Duration of operation is about 50 years. But this figure is still disputed, and it has several nuances. At the moment there are two types of mineral wool.

The second is slag . This means that water practically cannot penetrate into it, and the material itself is quite dense. Accordingly, it is made from slag from the metallurgical industry. It is significantly inferior to the previous one in price, quality, and service life. In addition, it is not resistant to sudden temperature changes and may become deformed after a certain time. But despite this, it is often used as the best option if the construction is temporary or less significant.

It is worth noting that this substance has two important advantages:

- Non-flammability . You don’t have to worry that the material is not susceptible to fire from metal tiles, which can heat up to high levels in extreme heat. And also other effects of high temperatures will not pose a threat to the insulation, and therefore to you.

- Vapor permeability . Izover has the ability to “breathe,” which is also important. The material easily passes all vapors through itself, but at the same time they do not accumulate inside. This property makes mineral wool environmentally friendly, and in combination with thermal insulation it is a huge plus. In addition, no additional treatment is required for condensate.

Basal cotton wool is not inferior in the duration of the action of the previous substance. Manufacturers provide a warranty of over 50 years. A very long time ago, construction began to use insulation made from fibrous material. But the peak of its exploitation has occurred in the last couple of decades. This happened due to the intensive construction of country houses, as well as increased heating prices. This is where the material is very popular.

Over time, the quality of basal wool has improved significantly. Now it is an environmentally friendly and safe product. The main advantages include several aspects:

- Fire safety . The material can easily withstand high temperatures without losing its properties.

- Low hydrophobicity . The substance repels moisture, which significantly increases the service life of the insulation.

- Compressibility . Basal wool is very resistant and does not undergo deformation.

- Chemical resistance . Rotting, fungus, rodents, mold and harmful microorganisms will no longer become a threat to your home.

Despite the coincidence, the materials are of excellent quality, do not deform or crumble. The substances are used everywhere and have many positive reviews. With such insulation, your walls can last for more than 100 years.

What is the difference between polystyrene foam and polystyrene foam?

*

Both materials have a lot in common. Considering that polystyrene foam is essentially the same polystyrene foam, however, they have significant differences due to their production technology. Let's first consider the positive and negative properties of polystyrene foam. The positive characteristics of this material include:

- Low cost of finished products, which is one and a half times lower than the price of extrusion material.

- Long service life subject to installation and operating conditions.

- High degree of thermal insulation with proper installation and further operation. Light weight, which facilitates transportation and installation.

- In the structure of the material, if it is used in dry conditions, fungi, mold and other microorganisms do not develop.

- It is easy to process (cut, saw, break) with any available tools and even by hand. It does not require the worker to be provided with protective equipment, since it is an environmentally safe material - it does not emit harmful odors and dust, and does not prick. This can be confirmed by the production of disposable tableware and toys for children from polystyrene.

Application of foam plastic

- It can also be used as sound insulation, when a three-centimeter slab of polymer material can completely muffle sounds.

- The temperature range for using polystyrene, without loss of thermal insulation properties and mechanical strength, is from -60°Ϲ to +95°C. Practically does not absorb moisture.

- Does not support combustion. Extinguishes within 4-5 seconds after contact with an open flame.

The negative properties of polystyrene foam include its non-contact with solvents and relative fragility. If a room where polystyrene foam was used catches fire, toxic smoke can cause death. Domestic rodents often live in porous material.

Polystyrene foam is not a problem for mice

Comparison of foam and extruded polystyrene material

*

Quite often, when choosing insulation, consumers ask themselves whether polystyrene foam or polystyrene foam is better, what is the difference between these insulation materials, which is warmer, easier to install and more economical. To understand, you need to consider the technical characteristics of both materials:

- The thermal conductivity of foam plastic is 0.04 W/mK, for penoplex -0.032 W/mK.

- The mechanical strength of foam plastic is inferior to extruded material.

- The density of foam plastic is 20-30 kg/cm3, penoplex 30-45 kg/cm3.

- Vapor permeability is 0.022 and 0.005 mg/mchPa, respectively, for polystyrene foam and penoplex.

- Due to the higher density, which is achieved by a better molecular connection, the mechanical compressive and flexural strength of extruded polystyrene insulation is higher, as is the ability to withstand a greater range of temperature changes.

- Polystyrene foam can absorb no more than 3% of water from its mass, penoplex - no more than 0.4%. If you are choosing a material for insulating a bathhouse, it is better to choose the second option.

- The shrinkage of polystyrene foam is much greater than that of polystyrene. The first is afraid of sunlight and large mechanical loads. The second one is more resistant to both UV radiation and loads. Therefore, polystyrene foam products can be used for insulating facades with subsequent plastering, when installing heated floors, which cannot be said about ordinary polystyrene foam.

In terms of flammability, both materials are equally susceptible to fire, but when fire retardants are added to styrene at the production stage, neither polystyrene foam nor extruded polystyrene support open combustion. Both have the property of self-extinguishing unless they are in the center of a fire.

If you are choosing insulation and you don’t know what is better - buy extruded polystyrene foam or go with cheaper foam, take into account all the characteristics of the materials.

Service life of foam plastic as insulation

Another frequently used insulation material is polystyrene foam. It is generally accepted that the shelf life of expanded polystyrene reaches several decades. Manufacturers guarantee the durability of the material for 50 years. However, with the correct insulation procedure, this period can be doubled. This is one of the main reasons why it is so popular.

It should be borne in mind that there are several types of insulation made from polystyrene foam:

- Polystyrene . A material made in the form of foam rubber. Suitable for protecting a room from the inside. Has very high performance characteristics.

- Polyvinyl chloride substances are very elastic. They have a very high durability rating.

- Polyurethane foam . It is considered a durable thermal insulation that will last for quite a long time, hardens quickly, forming a very strong protection that can withstand many external influences.

Based on the above materials, we can conclude that the service life of polystyrene foam is very long and fully lives up to expectations.

Brief overview of popular materials

The following materials are in greatest demand on the insulation market:

- cork substrates;

- mineral wool;

- expanded polystyrene;

- expanded clay

Synthetic products are affordable and have a long service life. Extruded polystyrene foam has high compressive strength. Insignificant ductility is compensated by resistance to aggressive substances.

The insulation has a pronounced porous structure, does not allow air to pass through, preventing the formation of condensation in the room. The long service life of the product is due to the low level of chemical activity.

Available expanded clay is used in the construction of wooden floors. The porous building material does not contain toxins that are dangerous to people and the environment.

Cork substrates attract homeowners due to their thin thickness. Natural material has been used for many years without revision. It replaces a full-fledged floor covering with insulating properties. The only disadvantage of cork backing is its high cost.

Service life of insulation, which insulation to prefer

Many competent sources claim that the service life of mineral wool and expanded polystyrene is 25 - 35 years. At the same time, a wall that is insulated with these insulation materials made of brick or concrete lasts more than 100 years. Therefore, the wall insulation must be changed at least 3 times during its service life. Was the insulation chosen correctly, due to which it is necessary to carry out a major overhaul of the building in such a short time?

How long do inexpensive insulation materials last?

The main question is where does the 30-year service life of cheap insulation come from? Today, some mineral wool manufacturers indicate in the technical specifications for individual brands of their products that their service life is 50 years.

Moreover, this figure is not explained in any way; there is only a footnote that today there is no standard for determining the shelf life of insulation materials.

Scientific articles regarding artificial insulation indicate that insulation containing artificial organic substances can last no more than 35 years.

During this period, organic matter is destroyed, the substance ages, and the insulation “cakes” or “dries out.” The main thing is that as a result of this, the insulation loses more than 1/3 of its heat-saving ability. Consequently, mineral wool or expanded polystyrene insulation must be completely replaced within a period of up to 35 years.

How is it in Europe?

Now in European countries, according to legislation, an energy audit of every new home, including private ones, must be carried out after its construction is completed. Based on the results, an energy certificate is issued for the building.

Proven energy savings have a very significant impact on property values in Europe.

Repeated energy audits should be carried out after 25-30 years, after a period equal to the service life of conventional insulation materials. The next one will follow after approximately the same period of time.

As a result, it becomes clear how much the building has lost its heat-saving properties, which enclosing structures and how much they have reduced the resistance to heat transfer, where it is necessary to change the insulating material or carry out other repairs.

Like we have

In our country, such studies are not mandatory, although they are recommended by regulations. As a result, in most cases they are not carried out, and it is not possible to find out exactly the real service life of insulation materials by examining them after many years. It remains to use data coming from abroad, according to which the indicated figures were taken.

It is advisable to carry out energy audits of new buildings and periodic checks of the heat transfer resistance of building envelopes within the time limits recommended by regulations. Then it will be possible to monitor changes in the insulation of the building and carry out the necessary repairs in a timely manner.

When to change insulation

An exact answer to when to change the insulation can only be given by a special examination of the heat-saving properties of the building (energy audit). But since over the past 20-25 years, when the use of insulation materials such as foam plastic and mineral wool began, we have not carried out such examinations, all that remains for subsequent checks is to compare the results obtained with theoretical calculated values. But there are no reliable statistics on the failure of insulation materials.

Accordingly, it is necessary to use recommendations for replacing non-mineral insulation materials within the time limits specified above.

Experts agree that the service life of existing insulation materials with organic components is several times less than that of the enclosing structures that are insulated with them. The use of such insulation materials entails premature major repairs of buildings. How to avoid this?

Dense mineral wool and aerated concrete with a long service life

There is a unanimous opinion that denser mineral wools last longer. Partly because the quality of workmanship is ensured by renowned manufacturers, and partly because denser mineral wool contains less binding resins (in total, mineral wool contains from 3 to 10% organic binders). Denser (more than 80 kg/m3) mineral wool samples last longer.

A successful replacement for mineral wool is now aerated concrete made in autoclaves with a density of not much more than 100 kg/m3. This material has a thermal conductivity coefficient comparable to organic insulation - 0.5 - 0.8 m W/mS.

But most importantly, this is a completely mineral compound, which is essentially a foamed stone, so its service life (in the absence of excessive moisture) is comparable to that of heavy building materials - brick, dense concrete.

The use of insulation without organic matter will eliminate many problems in the future, especially when it comes to insulating multi-layer walls (as walls lined with clinker bricks are insulated),

Low-density aerated concrete is a vapor-permeable insulation material, its use is similar to the use of mineral wool.

Eternal foam glass

Another well-known organic-free insulation is foam glass, which has a service life of more than a hundred years. This insulation has been used for a long time (in particular in the secret weapons sector), it has less heat-saving capabilities compared to effective insulation by about 1.5 times, it does not allow water vapor to pass through it and does not accumulate water.

But its distribution is limited due to the increased price, although it is popular for insulating expensive houses.

Among foam plastics, extruded polystyrene foam stands out for its predicted resistance to harmful factors and durability. It does not accumulate water, does not allow steam to pass through it (similar to foam glass), has a denser structure and has twice the specific gravity compared to foam plastics (over 35 kg/m3).

But due to the higher price, it is used mainly in difficult conditions, in soils, for foundations, plinths, basements. In any case, among plastics it is more recommended for use in terms of “survivability” than other plastics.

As you can see, to insulate the building envelope, it is better to choose insulation with a minimum of organic substances or without them at all.

About the durability of polystyrene foam

April 06, 2018

A person buying something is always interested in its quality. Good quality usually determines the longevity of a purchase. When buying clothes, for example, he sensibly estimates how long they will last – from one season to several years. Then it will simply go out of fashion, become dilapidated, or will need to be repaired.

When choosing finishing materials for renovation, a person also assumes that they will not last forever, and someday you will simply want to change them. But there are things when purchasing which we are only interested in their durability. I think it’s unlikely that anyone will want to buy a new drill or lawn mower for their home just because the old ones are out of fashion.

Or, following the same principle, change the pump in your own boiler room. Moreover, we wish such things to work forever! Unfortunately this is not possible. At the same time, even a complete breakdown of such mechanisms is not associated with great difficulties in replacing them.

But there are materials that are quite difficult to change if they lose their properties and, as a rule, this will be associated with high costs.

Here we will talk to you about the durability of insulation. In particular, insulation with non-extruded, expanded polystyrene foam, or as we usually call it - polystyrene foam.

We are not currently considering extruded polystyrene foam as wall insulation for a number of reasons that we will not mention in this article.

Much has been written about the service life of mineral slabs, but for polystyrene foam, it is difficult to find any results of serious research.

When building a house, a person hopes for the reliability of what he is building. He wants his children and grandchildren to use the creation of his hands, and for as long as possible, without any unnecessary repair work.

In Russia, houses are now insulated. And not because it has become accepted, but because it is necessary. There are both economic benefits and comfort. Insulation, as a rule, is located inside, in the layer. In monolithic construction for insulation, polystyrene foam is placed between various blocks and facing bricks.

In private, low-rise housing construction, after appropriate preparation and laying of a special reinforcing mesh, plaster is placed on it, making the so-called “wet” facade.

Construction from vulture or sandwich panels involves laying foam plastic at the stage of their production, when a layer of expanded polystyrene sheet is fixed between sheets of OSB or painted rolled steel by gluing. In general, almost always, any insulation is protected, in a layer.

Minslab, for example, is afraid of moisture, and after it gets inside, it becomes useless as insulation, so it must be reliably protected from precipitation. They have little effect on foam plastic, but one of its few disadvantages is that it is afraid of the sun, or more precisely, ultraviolet radiation.

In general, it is clear that, given the inaccessibility of the location of the insulation, replacing it if it loses its low thermal conductivity and mechanical strength will not be easy, and sometimes almost impossible. For example, in the case of construction using sip or sandwich panels, this will essentially be equivalent to new construction.

So how long does foam plastic “live”?

One of the authors was puzzled by this question for the first time when he was present in 2004 at the demolition of an old “trailer” for temporary residence of construction workers. When the facing board was torn off, in the interior space, the polystyrene foam was mostly in the state of a foam granule, not fastened to each other in any way. We can’t even talk about the heat resistance of such a home.

But this example does not in any way reflect the durability of polystyrene foam as a material, but rather speaks of the dishonesty of some manufacturers, their violation of the technological process, the quality of raw materials, the percentage of added secondary raw materials in the manufacture of products and other factors. Despite its apparent simplicity, foam production has many professional subtleties.

Here we will not talk about the correct choice of foam brand for a specific type of insulation, and we will not discuss different manufacturers. By default, we will talk about polystyrene foam produced in accordance with all GOST requirements.

Polystyrene foam is a relatively new material in construction. Almost a hundred years passed from the discovery in 1831 by the French physicist Bonastre of a material he called styrene to the start of industrial production of expanded polystyrene in 1937. In the USSR, its production using the press method began in 1939.

But we owe the appearance of expanded polystyrene foam, which we now call “foam plastic,” to the BASF concern, which patented the polystyrene foaming method in 1949. In 1951, BASF began industrial production of thermal insulation material under the Styropor brand, which is still in production today.

And in 1958, the production of pressless expanded polystyrene (PSB) was mastered in the USSR.

That is, the history of insulating houses with polystyrene foam does not even go back a hundred years.

In laboratory conditions, using various tests, we can of course draw conclusions about the durability of the material. But a person always wants to touch with his hands, what condition will this sheet of foam plastic be in, say, in 10, 20, 30 years? This can be understood if you remove this sheet from some old, insulated structure.

Which is what BASF did again. In 1986, the concern's employees removed sheets measuring 20x20cm from the flat roof of their production building in Ludwigshafen, installed 31 years earlier. They were studied by the Munich Research Institute, thermal insulation, giving conclusion number 411/86 dated 07.11.

86, from which it follows that:

– over 31 years there has been no irreversible change in the dimensions of the slabs, for example due to shrinkage or compression.

– the slabs had no signs indicating any changes that had occurred since installation.

– no deformation, settling or change in length was observed at the edges of the slabs.

Fig.1. Removing a sheet fragment from a flat roof. Fig.2. Extracted leaf fragment.

Based on the results of the control inspection, the condition of the expanded polystyrene slabs without any restrictions can be considered very good.

Expanded polystyrene slabs, used as a thermal insulation layer in unventilated flat roofs, fully retained their consumer properties 31 years after installation.

It should be taken into account that the waterproofing layer laid on top of the thermal insulation layer was not protected by either a gravel backfill or a slab flooring, as a result of which the thermal insulation layer was subjected to additional thermal loads.

From the above we conclude: it will definitely be enough for 31 years!

But 31 years is not a long time, especially for our citizens, who have recently become accustomed to building not only missile launch silos, but also their own homes, thoroughly and for a long time. And besides, Germany is not Russia, the climate there is milder and there are no such high temperature differences as ours. Where are our, so to speak, domestic research on the material?

Here they are.

In the laboratory of NIISF (Research Institute of Building Physics)

tested Styropor polystyrene foam (trade name for expanded polystyrene), foamed and blocked from BASF raw material granules, for durability.

They rightly reasoned that the most dangerous periods for the material are periods of air temperature transitions through zero, since during such transitions changes occur in the phase state of moisture in the pores of structural materials. This leads to a change in the physical, mechanical and thermophysical characteristics of the foam.

The climatic conditions of central Russia were considered. Most temperature fluctuations that cross zero occur, as a rule, in the autumn and spring periods.

Based on meteorological data, the amplitude of temperature fluctuations during these transition periods and the average annual value of such periods were determined.

Temperature data with characteristics of its continuous duration above or below zero, and the rate of its fluctuation were analyzed.

We calculated how many cycles of exposure to samples of structural fragments in a climate chamber followed by keeping them in water are equivalent to one year of operation of a thermal insulation layer in structures in the conditions of central Russia. Below we present the daily cycle of impacts on the material based on the results of this calculation.

The beginning of the daily cycle of influences is a decrease in temperature to minus 40⁰C at a rate of about 60 degrees/hour; exposure at a temperature of minus 40⁰C for 1 hour;

temperature rise from minus 40⁰C to plus 40⁰C at a rate of 53 degrees/hour; exposure at a temperature of plus 40⁰C for 1 hour; temperature drop to minus 40⁰C at a rate of about 50 degrees/hour; exposure at a temperature of minus 40⁰C for 1 hour; temperature rise from minus 40⁰C to plus 20⁰C at a rate of 60 degrees/hour. After the end of the cycle, the samples were kept in water for 16 hours.

A total of 80 such test cycles were carried out on samples of polystyrene foam boards with a density of 19 kg/m3.

Upon completion of testing of slab fragments, the physical and mechanical

characteristics of the samples and comparison of these data with the characteristics of control samples that were not subjected to temperature and humidity influences.

A comparative analysis of the data obtained allows us to draw the following conclusions:

- The thermal conductivity of the samples after 80 test cycles increased by 2.5% compared to the control ones, which is within the measurement error;

- Water absorption by volume increased by 6.3%;

- The decrease in compressive strength at 10% deformation of the samples after 80 test cycles compared to the control ones was 8.3%;

- The static bending strength indicator decreased by 4%;

- No changes in the shape of the slab samples that passed cyclic tests were noted.

Thus, polystyrene foam boards successfully withstood cyclic tests for temperature and humidity influences in the amount of 80 cycles, which can be interpreted as the corresponding number of conditional years of operation in multi-layer enclosing structures with an amplitude of temperature influences of ±40⁰C.

The loss over 80 years of operation of only 2.5% of its main property - low thermal conductivity, in our opinion, is an excellent recommendation for foam plastic for the most demanding consumer in terms of service life.

So, by insulating your homes with polystyrene foam, you are certainly insulating them for a long time and for future generations.

We wish your home many years of warmth!

Source: https://teplo-max.ru/blog/o-dolgovechnosti-penoplasta

Brands

It is used in the widest areas of construction, from insulating the facades of private houses and apartments in panel high-rise buildings to large factory and sports facilities, roads and railway tracks. But among the population there is a misconception that polystyrene foam is quite fragile and short-lived, so it is risky to use it as insulation. Why wrong? The fact is that the most advanced types of foam plastic are used for construction - PSB-S-35 and PSB-S-50 have high density and strength, resistance to moisture, temperature, other atmospheric factors, as well as corrosion, so the service life of the foam can be be not only tens, but also hundreds of years.

Types of foam plastic and their performance characteristics

For construction and thermal insulation work, mainly foam insulation materials, their slab and non-slab varieties, are used. The most common types of thermal insulators for building facades are:

PSB-S-25 is the most versatile type of foam, resistant to moisture, suitable for both external and internal work. The service life of this material is tens of years (from 40 to 80), and it is unpretentious in maintenance.

PSB-S-35 is a very durable and dense material used for progressive waterproofing. Ideal for areas with high humidity levels due to constant rainfall. Its minimum service life is 120 years, and its outstanding qualities allow it to be used to create eco-friendly facades.

PSB-S-50 is the most durable and durable type of thermal insulation. The service life of foam plastic as insulation is about 200 years, and the aging level is extremely low. The material is resistant to fungus, mold, and corrosion.

The most commonly used additional materials for polystyrene foam are:

polyurethane foam rubber - suitable for cladding internal walls of the facade, as well as cladding a number of structures where rigidity is not important; is an excellent alternative to heat insulators such as eco-facades;

polystyrene boards are the most convenient material to work with. The slabs can be unpressed or pressed;

polyethylene is a flexible and elastic material that looks like an air film. Used only in the packaging process, it is the most fragile and short-lived;

polyurethane foam is a leader among building materials for thermal insulation. It is applied from special reservoirs, sprayed onto the wall: when it hardens, it forms a dense film that can withstand any negative environmental influences.

What is better to insulate with polystyrene foam?

- It is recommended to insulate brick or block walls of houses with foam plastic. When using it, a high thermal insulation effect is achieved, and no dew point is observed.

- Most often, expanded polystyrene is used for insulating foundations and various engineering structures that are located underground. When in contact with wet soil, nothing will be done to the material, and it will last for decades.

- The material is also effective for insulating the horizontal part of house foundations. Polystyrene foam slabs are laid lengthwise and backfilled. Additionally, a waterproofing layer is laid. In this case, the foundation is reliably protected from frost.

- PPS is often used for floors and floors. Insulating material is placed under its slabs, and everything is filled with concrete on top.

- Non-ventilated roofs are insulated with PSBS foam with a waterproofing layer on top.

- Among other things, this insulation is used for thermal insulation of freezers, refrigerators, and special isothermal vans.

What determines the service life?

Practice has shown that the shelf life of polystyrene foam will depend on the type of load it will have to withstand. If the manufacturer of a professional façade specifies a minimum service life of 80 years, then this figure means operation under ideal conditions. You can increase the service life of foam plastic by using additional materials for insulation - chipboard, plywood, air film, polyurethane foam.

It should be borne in mind that, contrary to popular belief, polystyrene foam can easily withstand the influence of the aggressive environment of gypsum, plaster or concrete.