Stylish and inexpensive, this is what one can say about modern aluminum radiators. This is true, but you should not rely on these 2 qualities when choosing a radiator for a house or apartment. These designs have numerous advantages, but, as is usually the case, there is a fly in the ointment, and they also have disadvantages.

When there is a desire to install aluminum heating radiators in a room, technical characteristics when choosing a model should prevail over its stylish appearance.

Types of aluminum radiators

Aluminum batteries differ in manufacturing technology:

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

Casting technology

This production method means that each section will be constructed separately. They are cast from silumin (a composition of aluminum and silicon additives). The amount of silicon in this mixture is no more than 12%. This amount is enough to ensure that the device is quite durable and reliable.

The manufacturing process is carried out as follows:

- The mold for casting the battery section consists of two equal parts. Before the composition is poured, both parts are joined under high pressure in a casting unit.

- At the next stage, the finished alloy enters the finished mold through special channels.

- The molten composition spreads through all channels of the mold, where it cools and crystallizes.

- After the crystallization process is completed, the mold must be opened and left until it cools down.

- As soon as the composition has cooled, the neck is welded to the section blanks.

- The next stage: in a special bath, under high pressure, the sections are checked for leaks.

- Then the inner and outer aluminum walls are coated with an anti-corrosion compound, and then they are cooled and dried.

- After the above-described manipulations, the sections are painted using powder enamel.

- At the final stage, the sections are assembled into radiators and are tested for strength and tightness.

This method of manufacturing radiators allows you to create batteries of absolutely any shape.

Foreign manufacturers most often resort to the production of aluminum radiators by casting, because Such products are characterized by a long service life and high safety.

Extrusion technology

The extrusion process is based on forcing a softened molten metal through a special molding extruder. In this way, a part of the required profile is obtained.

This production method does not imply instant production of radiator parts with a closed volume. Initially, the front and rear parts are formed, which are subsequently connected to each other by thermal pressing.

Using the extrusion method, both individual sections and solid manifolds are manufactured.

The technical indicators of devices made by extrusion are lower than those of batteries made by casting technology. First of all, this is due to a smaller surface area, and therefore lower heat transfer. Another disadvantage is that pressing seams are usually not able to withstand high pressure and quickly begin to rust under the influence of an aggressive coolant environment.

Anodized radiators

Such batteries are made from an alloy in which aluminum has undergone high-quality purification. Its amount in the composition is 90% or more. Both the internal and external surfaces of the product are subjected to anodic oxidation (anodizing).

The standard anodizing process for aluminum radiators is as follows:

- Initially, the batteries are washed well; for this, the radiator is placed in a bath with an alkaline solution and there its surface is cleaned of all kinds of contaminants.

- Then “chemical milling” is carried out. The surface of the aluminum is cleaned of the oxide film, and the thin top layer of metal is also removed.

- The next stage is clarification. Heavy metals are removed from the outside of aluminum.

- Next, the radiators are lowered into a bath of electrolyte; under the influence of this negative charge, an electrochemical reaction occurs, as a result of which a protective oxide film AL203 is formed.

- At the final stage, the layers are compacted by clogging the pores.

To connect all parts of the anodized radiator to each other, external dry couplings are used. Due to this, the inside of the batteries remains smooth. This connection ensures that the device is protected from stagnant processes and the coolant circulation process occurs with minimal hydraulic resistance.

Due to the fact that aluminum batteries are completely smooth inside, they have high heat transfer.

The only drawback of this type of aluminum radiators is the high price.

Criterias of choice

To correctly select a steel radiator, you should consider such aspects as:

- device type;

- design features;

- method of connecting the radiator to the heating system;

- dimensions;

- power;

- manufacturing company.

Types of steel radiators

Steel radiators are manufactured in two types:

- panel heating devices;

- tubular batteries.

Panel radiators consist of one, two or three profiled plates connected to each other by welding. To increase the heat transfer rate, special fins are installed between the plates.

Panel type steel battery design

Several types of panel radiators are produced, each of which differs in the number of panels and overall dimensions. The most popular batteries are:

- 11 types, having one plate and one row of converter fins. Such radiators are characterized by low power and minimal cost;

- 22 types, in which there are two plates and two rows of convectors (most suitable for city apartments);

- 33 types with three panels and three convectors respectively. They are characterized by maximum power and high cost. They are mainly installed in country houses or in large premises.

Tubular radiators are made of round or profiled steel pipes connected to each other by guides.

Tubular steel battery

Tubular batteries are characterized by their ability to withstand higher system pressures and higher costs.

Types of batteries depending on design

Depending on the design, there are:

- horizontal steel radiators, whose maximum overall size is length;

- vertical batteries differing in height.

Vertical battery

Vertical radiators are original, but are mainly installed in country houses, since more free space is required to accommodate heating equipment.

Selecting a connection method

After determining the type and design of the radiator, it is necessary to determine additional parameters, including the method of connecting the equipment.

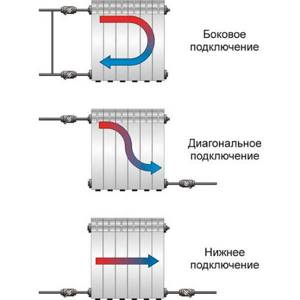

Batteries of any type and kind can be connected:

- in a side way. This type is generally more versatile and is used in most apartment buildings. With a lateral connection, the loss of thermal energy is reduced, the radiator heats up almost evenly, and there are no voids;

- in a diagonal way. When choosing this method, it should be taken into account that heat loss is minimal. In most cases, diagonal connections are made for long panel radiators;

- the bottom way. Bottom-connected batteries heat up unevenly, which contributes to the loss of about 10% of power. Mainly used when laying a heating system in the floor.

Radiator connection methods

When choosing a specific method, you should take into account the location of the pipes in the apartment. If you choose a radiator with an inappropriate connection method, the system will need to be modified.

Determination of dimensions

The next stage is determining the overall dimensions. What are the best radiators? When choosing dimensions, you should take into account the availability of free space in the intended installation location and installation rules.

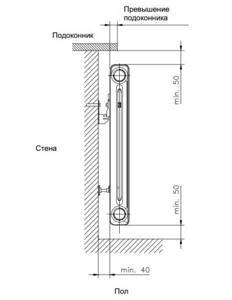

Radiators are installed:

- at a distance of 40 mm from the wall;

- at a distance of 50 mm from the floor and from the window sill or other structure located above the heating equipment.

Criteria for correct installation of a steel radiator

An additional selection criterion is the determination of the center distance (the distance between the inlet and outlet pipes). If you choose a radiator with a distance that does not correspond to the pipes, you will have to make adjustments to the heating system.

Distance between inlet and outlet pipes

Power determination

Power calculations are made based on the following factors:

- room volume;

- number of windows;

- number of doors.

Experts have proven that for a comfortable stay you need a heating device with a power of 40 watts per 1 m³ of volume.

If the room has windows facing the street, then an additional 100 W will be required for each window.

If the room has doors facing the street, then a reserve of 150 W is made for each door.

The following formula is used for calculation:

P (power) = V (room volume)*40 + heat loss from windows + loss from doors

Thus, to heat a room of 30 m² with 2.5 m ceilings with one window and one entrance door, a battery of 30 * 2.5 + 100 + 150 = 325 Watt is required.

Advantages and disadvantages

Aluminum heating radiators have many positive characteristics:

- The devices are lightweight. The weight of one section is no more than 1.5 kg.

- Batteries of this type are very compact, so you can place them anywhere.

- They are characterized by high thermal conductivity and heat up in a short period of time.

- High efficiency, which is ensured by high heat transfer.

- If necessary, you can easily reduce or, conversely, increase the number of working sections.

- Radiators equipped with thermostats have a temperature control function. You can change the temperature at any time: increase or decrease.

- The devices are very aesthetic, the design is quite simple and discreet, but at the same time very attractive. Therefore, aluminum batteries will fit perfectly into any interior.

Despite the large number of advantages, aluminum radiators also have a number of disadvantages:

- The devices are sensitive to the pH level of the coolant. It is important to control that it does not exceed 7-8 units, because if its indicators are higher, the aluminum will rust and the batteries will quickly fail.

- When installing aluminum radiators, you will have to install an air vent, which will protect the sections from possible rupture in the event of a threat of gas formation.

- It is necessary to connect the device to pipes made of aluminum or plastic, otherwise, upon contact with other materials (for example, copper), the aluminum radiator may undergo electrochemical corrosion.

- The described type of battery can withstand very low operating pressure.

Qualitative characteristics

No less important are the values of the quality characteristics of aluminum heating radiators. It also needs to be taken into account at the time of drawing up the project and purchasing the main components.

Properties of coolants

Aluminum radiators can be used with two types of coolants: water or special antifreeze. The choice of the latter is determined depending on their characteristics and chemical composition:

- Salt - mainly used in heating systems with a secondary circuit. Able to withstand temperatures of -20°C and below. It differs from other antifreezes in its low viscosity level. The main disadvantage of the salt composition is its high anti-corrosion activity, which decreases depending on the temperature.

- Ethylene glycol and propylene glycol - capable of functioning in temperature ranges from -20 to +130°C. Regardless of the degree of heating or cooling, they remain in the same viscosity state. Ethylene glycol antifreeze is considered more popular. The popularity is explained by the lower cost and level of toxicity inherent in this composition.

Antifreeze for filling into heating radiators Source koffkindom.ru

Technical characteristics of aluminum batteries

Aluminum radiators are attractive not only for their appearance, “beautiful” price and practicality. Many technical characteristics of such devices have quite high performance.

| Options | Meaning |

| Operating pressure | 6-25 Atm |

| Heat transfer of one section | 150-212 W |

| Maximum permissible coolant temperature | 110°C |

| Section volume | 250-460 ml |

| Section weight | 1-1.5 kg |

| Center distance | 200-800 mm |

| Lifetime | 10-15 years |

The most common sizes are aluminum radiators: 200, 350, 500 mm. These parameters indicate the value of the center-to-center distance between the collectors, but on the market you can also find models with a distance from 200 to 800 mm.

The most important indicator on which the quality and efficiency of aluminum radiators depends is the operating pressure.

In addition to the working pressure, the passport of aluminum radiators also indicates the testing pressure, the indicators of which are slightly higher. This indicator is very important, because used in tests when starting the heating system after it has been drained.

Types of models

The modern market offers a wide range of models of steel batteries, but all of them can be divided into several types:

- The most popular and effective are panel radiators, which can consist of one, two or three panels and be equipped with (or without) heat exchangers .

- Vertical heaters are divided into tubular and panel. They differ in their “height”, since their minimum height is 1 m, while for ordinary ones it reaches 600 mm, and for tall ones it reaches 900 mm. These types of steel batteries look stylish, heat a little less efficiently, and are very expensive. This is especially true for designer models.

- Plate steel radiators are rarely found, and only in government institutions.

As a rule, most consumers choose panel heaters because of their harmonious balance between quality and price, but, like any other devices, they do not last forever and can break. It is better to foresee the possibility of an accident by paying attention to the “signals” that the system gives.

Service life of heating radiators in residential buildings

The average indicator of the period of stable operation according to GOST, depending on the material of execution, is as follows:

- Steel – 15-20 years;

- Cast iron - 25-35 years;

- Aluminum - 20-25 years;

- Bimetallic - 25-30 years.

However, these characteristics contradict the actual data. The stability of the system depends on its actual technical parameters and conditions of use. The operation of heating radiators in residential buildings depends on:

- coolant operating pressure;

- chemical composition of the substance;

- average water temperature in the system;

- the likelihood of water hammer occurring.

Service life of aluminum heating batteries

The degree of resistance to negative influences that can affect the longevity of the battery is determined by the metal from which the device is made. Thus, the operation of aluminum heating radiators is designed for a period of 20-25 years with a warranty period of 5 years from the date of actual installation and inclusion in the system.

It is worth noting that such a long period of operation is ensured only with proper care and ideal conditions of use. There are a number of factors that can reduce the longevity of this type of battery to zero:

- High working pressure;

- Low resistance to water hammer;

- Susceptibility to corrosion due to the high pH level of the coolant.

Service life of cast iron heating radiators

Despite the stated service life of up to 35 years, if all rules are followed, the operation of cast iron heating batteries can reach more than 50 years. This phenomenon can be explained by the high resistance of cast iron to corrosion processes. For apartments in Moscow, this option is an ideal solution, having a combination of advantages and disadvantages in comparison with equipment made from other types of metals.

". We selected the material over the phone and explained everything as needed. The master did his job 100% perfectly!”

Client: Peter What we did: Replaced the batteries and heated towel rail

“We selected the material over the phone and explained everything as needed. Master Galich Andrey arrived on time and did his job 100% perfectly. Well done!”

". We wish you good clients and continue in the same spirit!”

Client: Dmitry What we did: Replacement of two radiators

“We first talked with Andrey. He explained everything clearly and clearly. Installed by master Sergey. We are very pleased with his work. In the future we plan to install radiators again in another apartment, we will definitely contact you. We wish you good clients and continue in the same spirit.”

". I’m glad that I didn’t have to waste time on the measurer and on the preliminary visit.”

Client: Olga What we did: Replaced 1 radiator

“I thank the manager for the excellent consultation over the phone; after that there were no questions left. I was also satisfied with the work of the master. I’m glad that I didn’t have to waste time on the measurer and on the preliminary visit. I liked the cultural communication and the prompt resolution of the issue.”

". This is not the first time I have contacted your company and I am very pleased with your work!”

Client: Alexander What they did: Replaced 5 batteries in 1 day

“The manager explained everything clearly; there was no need for a surveyor to come out. Master Sergey is simply brilliant. The work was completed quickly, clearly and beautifully; many years of experience are evident. There would be more such masters. This is not the first time I have contacted your company and I am very pleased with your work, I wish you growth and prosperity.”

". Thank you for a job well done and reasonable prices!”

Client: Mustaev Nail What they did: Replaced 4 radiators

“Manager Artem explained everything clearly over the phone. Sergey is a true master, he did everything quickly and beautifully, many thanks to him for a job well done. Reasonable prices, good reviews about your company, I wish you to continue to maintain your brand!”

Leading classification

This will depend on the type and quality of the material used in the manufacture of radiators. The main varieties include:

- made of cast iron;

- made of bimetal;

- made of aluminum;

- of steel.

Each of the materials has some disadvantages and a number of features, so to make a decision you will need to consider the main indicators in more detail.

Made from steel

They function perfectly in combination with an autonomous heating device, which is designed to heat a significant area. The choice of steel heating radiators is not considered an excellent option, since they are not able to withstand significant pressure. They are extremely resistant to corrosion, lightweight and heat transfer performance is quite satisfactory. Having an insignificant flow area, they rarely become clogged. But the working pressure is considered to be 7.5-8 kg/cm2, while the resistance to possible water hammer is only 13 kg/cm2. The heat transfer of the section is 150 W.

Steel

Made from bimetal

They do not have the disadvantages that are found in aluminum and cast iron products. The presence of a steel core is a characteristic feature, which made it possible to achieve colossal pressure resistance of 16 - 100 kg/cm2. The heat transfer of bimetallic radiators is 130 - 200 W, which is close to aluminum in terms of performance. They have a small cross-section, so over time there are no problems with contamination. Significant disadvantages include the prohibitively high cost of the products.

Bimetallic

Made from aluminum

Such devices have many advantages. They have excellent external characteristics and do not require special care. They are strong enough, which means you don’t have to worry about water hammer, as is the case with cast iron products. The working pressure is considered to be 12 – 16 kg/cm2, depending on the model used. Features also include a flow area that is equal to or less than the diameter of the risers. This allows the coolant to circulate inside the device at tremendous speed, which makes it impossible for sediment to deposit on the surface of the material. Most people mistakenly believe that too small a cross-section will inevitably lead to low heat transfer rates.

Aluminum

This opinion is erroneous, if only because the level of heat transfer from aluminum is much higher than, for example, that of cast iron. The cross section is compensated by the area of the fins. The heat output of aluminum radiators depends on various factors, including the model used, and can range from 137 to 210 W. Contrary to the characteristics given above, it is not recommended to use this type of equipment in apartments, since the products are not able to withstand sudden temperature changes and pressure surges inside the system (during the run of all devices). The material of an aluminum radiator deteriorates very quickly and cannot be subsequently restored, as is the case when using other materials.

Made from cast iron

The need for regular and very careful maintenance. A high rate of inertia is almost the main advantage of cast iron heating radiators. The level of heat transfer is also quite good. Such products do not heat up quickly, and they also give off heat for quite a long time. The heat output of one section of a cast iron radiator is equal to 80 - 160 W. But there are a lot of shortcomings here and the main ones are considered to be the following:

- Tangible weight of the structure.

- Almost complete lack of ability to resist water hammer (9 kg/cm2).

- There is a noticeable difference between the cross-section of the battery and the risers. This leads to slow circulation of the coolant and fairly rapid contamination.

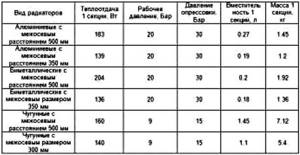

Heat transfer from heating radiators in the table

Types of aluminum radiators

There are three types of such heating devices, each of which is made in a certain way:

1. Sectional aluminum heating radiators cast under pressure. In the manufacture of such radiators, an alloy of aluminum and silicon is used. It comes in first and second grades. For example, European factories use only high-quality raw materials that meet the required standards.

Sometimes unscrupulous manufacturers use low-quality materials, which significantly deteriorates the quality of radiators and also shortens their service life. Heating devices made in this way are the most popular among Russian consumers.

2. Sectional extrusion radiators. In the manufacture of such devices, sections are welded together using upper and lower collectors. Some manufacturers glue them together with composite glue, which increases the likelihood of the devices leaking.

3. Aluminum heating radiators with anodized coating. This is a more expensive type of heating device, as it is made of aluminum that has undergone thorough cleaning. By being anodized, the material receives reliable surface protection from corrosion. These products have great heat transfer and a long service life. Due to the high price, such devices are in rather low demand among consumers.

Technical characteristics of aluminum radiators

To choose a quality device, you need to be guided by the following criteria:

1. Working pressure – from 6 to 24 atmospheres. 2. Power – from 82 to 212 W. 3. One section weighs no more than 1.5 kg. 4. The coolant temperature reaches 110 degrees. 5. The amount of water in 1 section is up to 0.46 l. 6. Service life – up to 20 years.

Review of models and manufacturers

The rating of aluminum heating radiators and a review of manufacturers will help you choose the best option for a country house or apartment with autonomous heating:

- The Italian manufacturer Faral produces two types of products with a distance between the axes of 30 and 50 cm. The depth of the devices is 8.5-9 cm. The minimum number of sections is 3, the maximum is 16. Steel nipples are used to connect individual sections. The tightness of the connections is ensured by special gaskets. Popular manufacturer models:

- GREEN HP 350 and 500 – maximum pressure not higher than 16 bar, weight 1.12-1.48 kg, power 136-180 W, capacity 0.26-0.33 l;

- TRIO HP 350 and 500 - maximum pressure no more than 16 bar, weight 1.23-1.58 kg, power 151-212 W, capacity 0.4-0.5 liters.

- The Italian company Radiatori 2000 uses modern technologies to manufacture its products, so the company's products are distinguished by good heat transfer and corrosion resistance. The paint is applied to the surface using anaphoresis and fixed with epoxy-polyester spraying. The best products from this company:

- Radiatori 350R - operating pressure is within 16 bar, weight 1.4 kg, power 144 W, capacity 0.43 l;

- Radiatori 500R - operating pressure not higher than 16 bar, weight 1.6 kg, power 199 W, capacity 0.58 liters.

- The Italian company Fondital produces products specially designed for Russia and the CIS countries. During the production process, Russian GOSTs and European standards are observed. Radiators are made by high pressure casting. Aluminum alloy is used for production. Popular products from the manufacturer:

- Calidor model Super 350 at 100 – maximum pressure around 16 bar, weight 1.3 kg, power 144 W, capacity 0.24 l;

- Calidor model Super 500 at 100 – maximum pressure no more than 16 bar, weight 1.32 kg, power 193 W, capacity 0.3 liters.

- The products of the domestic Rifar plant are adapted to our heating systems and comply with all GOST standards. Radiators differ from imported analogues in their high operating pressure, which reaches up to 20 bar. Popular models:

- Alum 350 – maximum pressure not higher than 20 bar, weight 1.2 kg, power 139 W, capacity 0.19 l.

- Alum 500 – maximum pressure is 20 bar, weight 1.45 kg, power 183 W, capacity 0.27 l.

The selection of a suitable aluminum radiator is carried out taking into account its technical characteristics. Domestic models are in no way inferior in quality and performance to their imported counterparts, but have a more reasonable price.

Advantages of aluminum heating radiators

Such devices have a large number of positive qualities:

1. Small size and high heat dissipation. 2. Easy to carry and install yourself. 3. Ability to heat up in a small amount of time. 4. Optimal price-power ratio. 5. Perfect appearance (thanks to powder coating). 6. Aluminum radiators are heated by convection, so dust does not collect between sections.

This type of radiator is best used in private houses or cottages, since in apartments with central heating there are frequent pressure surges, and the water may not be of the best quality. This can significantly degrade the performance of the equipment.

Cast iron radiators

Modern cast iron batteries are spectacular and stylish products that have retained the technical characteristics of their predecessors. Radiators are ideal for operation in a central heating system.

Advantages of cast iron heating appliances:

- metal conducts heat well: it takes a long time to heat up and cool down. After the heating is turned off, the battery continues to emit heat. The apartment is heated for a certain time - 30% more than other types of radiators

- durable walls withstand pressure drops in the system and are not afraid of water hammer up to 16 bar

- batteries can be connected to any type of pipe

- resistant to corrosion and aggressive substances in water

- variety of shapes and sizes of products. Can be hung on the wall or placed on legs

- if necessary, you can add additional sections

- ease of installation

- affordable price

Disadvantages of heating devices:

- heavy weight

- Bulky brackets are used for fastening to walls

Water leakage may occur between sections of cast iron radiators due to wear of the gaskets. This problem is not difficult to fix, since the product is disassembled into sections.

Aluminum radiators, their models, calculation of sections

All types of radiators, including aluminum ones, are installed in a private house. They are not suitable for central heating for several reasons. Firstly, there is high pressure in multi-storey buildings. Secondly, there is no water in the pipes in the summer, it is drained. Thirdly, various impurities can be added to the water, provoking a reaction with aluminum.

As for individual heating, aluminum radiators have proven themselves to be excellent. They have good heat dissipation, attractive appearance, low cost and are easy to install. They consist of sections twisted together. Sections come in different heights and depths.

Steel radiators

Steel batteries are in second place in popularity after cast iron radiators. The range of products is varied, the main difference is the manufacturer and the type of connection.

You should not rely on a well-promoted brand; you need to compare the technical characteristics when choosing. For less popular companies, products may not differ in basic parameters.

The connection type can be: bottom, side and diagonal. You must choose a device that is suitable for connection to your heating system.

Radiators come in two main types: panel and tubular.

Panel steel batteries

Panel radiators are one, two or three steel plates that have a ribbed shape. The device can be equipped with a convection grill. In the device of three plate products, two or three such gratings are installed, inside which the coolant circulates. In its absence, the heat transfer of a steel radiator will be lower. The plates are connected to each other using spot welding.

pros

The main advantages of panel radiators:

- fast heating of products and good heat dissipation

- the surface is treated with paint, protecting against various types of damage

- choosing the appropriate size and number of convection grilles

- can withstand high coolant temperatures - up to 100–110 degrees

When purchasing a radiator, check that the paint is applied evenly. Poorly painted areas have a risk of corrosion.

Minuses

Disadvantages of steel panel batteries:

- high energy consumption when operating under autonomous heating conditions. The battery holds a small amount of water, which is why the boiler needs to be turned on frequently

- cannot withstand water hammer

- the inner surface is exposed to aggressive water (hardness not higher than Hp 3–9.5 units)

- heavy weight of three-panel radiators with three convective grilles. Product thickness can reach up to 160 mm

The walls of steel panels are thin, so they may not withstand water hammer. If there is crackling and extraneous sounds in your heating system, it is better not to purchase this type of radiator.

Tubular steel radiators

Tubular batteries are sections in the form of pipes, which in appearance resemble heating devices made of cast iron. The product is sold assembled; additional sections cannot be added. Therefore, it is important to correctly calculate their number and power to heat the room. The number of pipes can be from two to six pieces. The height of the products can reach up to three meters.

Models can be selected in accordance with the design of the room and placed in a convenient place: on the wall or on the floor, in a vertical or horizontal position, in a semicircle and in a corner.

Vertical batteries are available in four forms:

- in the form of columns - pipes of the same size

- in the form of segments - sections of the same diameter

- radius - resemble a semicircle

- diagonal - tubes of different sizes, with a smooth decrease in length diagonally in any direction

The original shapes of the products are suitable for the individual interior of private houses and cottages.

pros

Advantages of tubular batteries:

- Tightly welded sections eliminate the possibility of leakage

- resistance to aggressive substances in the coolant and corrosion

- various shapes and sizes

In houses with central heating, when installing radiators, it is recommended to additionally install a gearbox to protect the batteries from water hammer.

Minuses

The main disadvantages include:

- there is no possibility to add additional sections if heating is insufficient

- low operating pressure 8–10 bar

- average degree of heat transfer

- high price

Tubular radiators are not recommended for installation in apartments with central heating. Most often they are used in cottages and houses with several floors, offices, and shops. Such batteries retain their performance characteristics when operating under autonomous heating conditions.

Bimetallic radiators

The best solution for an apartment building with central heating is to install a bimetallic radiator. The heating device is made of two metals: aluminum and steel, less often copper and steel.

The production process consists of three parts:

- welding of steel core. The product is manufactured without a single seam, to prevent leakage of coolant and its contact with aluminum

- the workpiece is filled with an aluminum alloy with silicon (12%) in a special mold

- painting the finished radiator in two stages: in the bathroom for anaphoretic painting, then applying powder enamel

This technology gives the products strength and prevents corrosion.

Bimetallic radiators from aluminum batteries are lightweight and compact; from steel ones, they eliminate leaks and rust formation.

Copper-aluminum batteries are a non-separable structure, inside of which a copper coil is located. The outer layer is aluminum plates, which are fixed with a special press. The case heats up to a maximum of 43 degrees, which ensures the safety of its use. The copper tube is soldered in such a way that eliminates the possibility of leaks.

A radiator made of copper and aluminum is suitable for heating systems in which antifreeze is added to the coolant. The copper tube is resistant to aggressive substances.

Bimetallic radiators can be of two types:

- monolithic - the internal manifold is welded as a single product. If the heating of the room is insufficient, additional sections cannot be added. Service life - up to 50 years. Working pressure level - up to 100 bar

- sectional - the radiator consists of separate sections. Service life - up to 25 years. Working pressure level - up to 35 bar

Heat transfer in both types is at the same level. The cost of monolithic products is higher. It is recommended to install such batteries in apartments of multi-storey buildings (10 floors and above).

pros

The main advantages of bimetallic batteries:

- compact size and light weight

- use of any coolant in the heating system

- high level of heat transfer

- equipment strength

- Corrosion resistance thanks to steel core

- easy installation

- suitable for residential premises with any type of heating system

- withstand water hammer

- Requires a little water for circulation

Due to the high cost of devices, it is not profitable to purchase a radiator for heating country and private houses. An individual heating system allows you to control the pressure and quality of the coolant, so it is better to install steel or aluminum batteries.

Minuses

The disadvantages of bimetallic radiators include their high cost. On the other hand, a quality product cannot be cheap. Therefore, when purchasing a radiator at a low price, you must carefully read all the technical characteristics so as not to confuse it with a semi-bimetallic or aluminum radiator.

How to choose a bimetallic radiator

The correct choice of radiator determines its service life and the quality of heating the room. To install it in an apartment, you must take into account the following parameters.

Number of sections in the radiator

The number of sections in the battery determines how warm and comfortable the room will be. When purchasing, you must correctly calculate the power of the sections and their number. To do this you need to consider:

- minimum water temperature in the heating system

- room area and ceiling height

- heat loss: quantity and quality of windows, location of rooms - corner or central

- climatic conditions in the place of residence

To heat ten square meters in the middle zone, you will need a battery of ten sections.

Specifications

You must carefully read the product data sheet. Pay attention to the thickness of the walls. Some manufacturers reduce the thickness to reduce costs, which negatively affects the service life of the radiator.

Check that the maximum pressure indicated in the passport is not less than the operating pressure in the system.

Type of coverage

Carefully inspect the surface of the product. The paint should be applied evenly. Check for external damage: scratches or chips. If available, do not purchase such a product. Defects can lead to corrosion.

When choosing, keep in mind that a matte finish has a high degree of heat transfer compared to a shiny finish.

Battery material

Many consumers confuse bimetallic radiators with semi-bimetallic ones. The main difference is that the core is made of two types of metal: vertical elements made of steel, horizontal elements made of aluminum. The quality of the product is lower due to the content of aluminum parts, which, as a result of prolonged contact with an alkaline environment, are susceptible to corrosion. Therefore, when purchasing, carefully study all the information.

In appearance and design, bimetallic products cannot be distinguished from aluminum ones. Therefore, purchase products from trusted places and request technical documentation for it.

Connection type

The connection diagram depends on the pipe layout in the apartment. The heating system can be single-pipe or two-pipe, vertical or horizontal - the type of connection depends on this:

- upper

- lower

- diagonally

- parallel

- sequential

When purchasing, make sure that the battery matches the type of connection in your apartment.

Copper radiators

Copper radiators are high-quality devices that will serve for a long period of time under central heating conditions. In appearance, the batteries fit well into the interior of the room. The high cost of products is associated with the quality of the metal, the technical characteristics of the battery and its service life.

During long-term use of batteries, a layer is formed on their inner surface that protects the metal from various damages and exposure to chemicals. The lumen of the pipes does not narrow over time, since limescale does not deposit on them.

Copper radiators are used to heat residential buildings, shops, administrative buildings, offices and other premises. There are no restrictions on the use of this type of heating device.

pros

Advantages of copper batteries:

- high thermal conductivity. Of all types of metal, copper is the leader in heat transfer (not counting gold and silver) - six times higher than products made of cast iron and steel, two times higher than aluminum

- does not corrode

- long service life - up to 50 years

- can withstand temperatures up to 150 degrees

- pipes do not burst when the heating system defrosts

- the aggressive composition of the coolant is not capable of destroying copper

- water hammer resistance

- withstand pressure up to 45–50 bar

- environmentally friendly material. On the internal and external surfaces of products, metal stops the growth of bacteria

Copper batteries can be decorated with a natural wood shield.

Minuses

The only disadvantage of a copper battery is its high cost. Good performance characteristics correspond to the price of the product.

When installing, it is not recommended to connect a copper battery to a steel pipe. It is necessary to use brass fittings or replace the pipes with copper ones. Otherwise, the radiator may be destroyed at the joint.

This type of radiator is best used in apartment buildings with a central heating system.

Recommendations for choosing a radiator:

- a quality product must withstand water hammer, which cannot be excluded when working in a central heating system

- it is important to assess the resistance of the device to corrosion, its service life will depend on this

- correctly calculate how many sections are required to heat the room, especially when purchasing a monolithic product

- The power of the device must correspond to the maximum temperature of the coolant - up to 120–130 degrees

- The service life of the product must be at least 25 years

- The coolant contains a large amount of harmful substances that negatively affect the metal. Therefore, it is best to choose radiators with thick walls. When the water contains antifreeze, the best option is to buy a copper battery or a bimetallic one with copper insides

- carefully study the technical characteristics of heating devices

- buy radiators from trusted stores

There is a wide variety of radiators on the building materials market: cast iron, aluminum, copper, steel and bimetallic. The choice of product depends on the type of heating - central or autonomous, technical characteristics and type of connection.