Connection options

Currently there are two main connection schemes:

- dependent - considered the simplest, therefore most often used;

- independent - gained popularity relatively recently; it is widely used in the construction of new residential areas.

Below we will look at each method in more detail to find out which solution will be the most effective for ensuring comfort and coziness in your room.

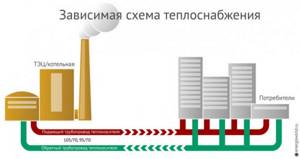

Dependent connection method

This connection option usually requires the creation of in-house heating stations, often equipped with elevators. In their mixing unit, superheated water from the external main network is mixed with the return water, which allows it to be reduced to the required temperature, usually below 100 °C. Thanks to this, the heating system inside the house is completely dependent on external heat supply.

| Advantages | The main feature of the scheme is that water enters the heating and water supply system directly from the heating main, so the costs in this case pay off in a short time:

|

| Flaws | As in any scheme, here you can find not only positive aspects, but also negative ones, among which it should be noted:

|

Connection methods:

- direct connection

; - with elevator

; - with on the jumper

; - with mounting of a pump on the supply or return

; - combined option - elevator and pump

.

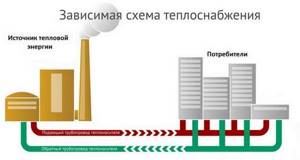

Independent connection method

Experts say that this heat supply option makes it possible to reduce resource costs by almost 40%.

In today's situation with their constant rise in price, this will significantly save money in the family budget.

- The operating principle is as follows:

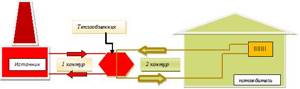

- connection of the heating system of subscribers is made using an additional heat exchanger;

- heating occurs thanks to two hydraulic isolated circuits - the main heating main heats the coolant of the closed internal heating network;

- in this case, no mixing of water occurs.

- The coolant circulates in the heating mechanism due to a circulation pump, which regularly supplies it through the heating elements. An independent connection scheme may provide an expansion tank with a supply of water in case of leaks. In this case, it is possible to maintain the circulation of the coolant with a certain amount of heat even in the event of a heating main failure. In fact, this means that if the supply of hot water through the heating main stops, the temperature in the heated rooms will not drop sharply for a long time.

- The scope of application of this connection method is quite wide. For example, it is used:

There is one condition - the pressure in the return must be more than 0.6 MPa.

- Advantages of the method:

- the instructions allow you to adjust the temperature;

- great energy saving effect.

- Flaws:

- high price;

- complexity of repair and maintenance work.

Comparison of schemes

- The dependent option has one important advantage - low implementation cost. An elevator unit in a small country house is easily assembled with your own hands from shut-off valves, which can be purchased in a store or on the market. The only expensive part will be the nozzle, on which the power of the elevator depends.

- An independent scheme allows you to:

- adjust the coolant temperature;

- increase the efficiency of use, bringing this level to 40%;

- Large amounts of contaminants, such as scale, sand and mineral salts, do not enter the heating system. The coolant can be purified water or antifreeze liquids.

- You can easily heat clean drinking water for hot water needs.

Independent

An independent heat supply system allows you to save consumed resources by 10-40%.

Operating principle

The consumer heating system is connected using an additional heat exchanger. Thus, heating is carried out by two hydraulically isolated circuits. The external heating circuit heats the water of the closed internal heating network. In this case, mixing of water, as in the dependent version, does not occur.

However, such a connection requires considerable costs for both maintenance and repair work.

Water circulation

The movement of the coolant is carried out in the heating mechanism thanks to circulation pumps, due to which there is a regular supply of water through the heating devices. An independent connection circuit may have an expansion vessel containing a supply of water in case of leaks.

This connection method allows you to maintain the circulation of water with a certain amount of heat in case of heating main failures. Those. During an emergency, the temperature in heated rooms will not decrease.

Components of an independent system.

Scope of application

Widely used to connect multi-storey buildings or structures to the heating system, which require an increased level of reliability of the heating mechanism.

For facilities that have premises where access to outside service personnel is undesirable. Provided that the pressure in return heating systems or heating networks is higher than the permissible level - more than 0.6 MPa.

Advantages

- possibility of temperature adjustment;

- high energy saving effect;

- possibility of using any coolants.

Negative points

- high price;

- difficulty of maintenance and repair.

Comparison of reliability and durability

The practice of operating technically complex and multi-level systems shows that they are less maintainable and more often must be subject to preventive inspections with maintenance measures. It cannot be said that independent connection of the heating system reduces the overall level of reliability and safety (in some cases it even increases it), but the tactics for carrying out repair and restoration activities should be at a different and more responsible level.

At a minimum, an increase in labor and time resources will be required when inspecting the heat exchanger and adjacent piping. Possible uncontrolled accidents at this site can lead to damage to the pipeline. Therefore, experts recommend installing several sensors that monitor pressure, temperature and tightness. The latest manifold cabinets also provide for the use of self-diagnostic systems for continuous monitoring of the system condition. As for the closed heating infrastructure, such control and measuring equipment will also not be superfluous, but in this case its need is not so high.

Pros of independent systems

Already at the approach to the main consumers of the home water supply network, a whole range of preparatory measures is provided to ensure distribution, filtration and adjustment of coolant pressure. All loads fall not on the final equipment, but on the heat exchanger with a hydraulic tank, which directly receive resources from the main source. Such resource preparation is practically impossible on a private basis when operating dependent heating systems. Connecting an independent circuit also allows you to rationally use water for drinking needs for optimal purification. Streams are divided according to their intended purpose and each line can provide a separate level of preparation that meets technological requirements.

Disadvantages of dependent heating systems

Among the negative aspects of operating such systems, the following are noted:

- Intensive contamination of working circuits with scale, dirt, rust and all kinds of impurities, which may well end up in consumer equipment.

- Higher requirements for carrying out repair activities. The fact is that dependent and independent heating systems in such cases require the involvement of specialists of different levels. It’s one thing to carry out repairs on the main line once a year, and another to carry out a comprehensive monthly inspection of the elevator assembly piping at home.

- Water hammer is possible. Incorrect connection of communications or excessively high pressure in the circuit can lead to pipe ruptures.

- Low basic quality of the coolant in composition.

- Difficulties in control and management. At technological stations of municipal water heating, the process of updating the same shut-off valves is quite slow, hence disturbances in pressure balances may occur.

Independent heating system

A fundamental feature of this system is the presence of an intermediate collection point. In private residential buildings, it can be implemented as a regulating station (including for reducing pressure), but the integration of a heat exchanger makes this scheme independent. It performs the functions of rational and balanced redistribution of hot flows, also maintaining, if necessary, optimal temperature conditions. That is, with an independent connection of the heating system, the heating network as such does not act as a direct source of supply, but only directs flows to an intermediate technological point. Then, in accordance with the settings made, in a more targeted version, it can supply both drinking water and hot water for heating and other household needs.

Which heating scheme is better?

There is another drawback with gas non-volatile heating boilers - they do not have the ability to control the weather and control the unit using an external thermostat, which determines the temperature regime, for example, in the most remote room. Accordingly, it is not possible to program the temperature for a long period, for example, two weeks.

About the types of heating systems in detail in the video:

In apartment buildings, the overwhelming majority use the central heating network for heating. However, the quality of such services depends on many factors, including the condition of the heating main and equipment. The connection diagram of the house to the heating network is also important. In this case, you will learn about dependent and independent connection methods, as well as how to make heating in an apartment energy-independent.

Dependent heating system

The central link of such communications is the elevator unit, through which the tasks of regulating the coolant are performed. From the heating main to the distribution unit of a residential building, water is supplied through a pipeline, and mechanical control is carried out by a system of inlet gates and valves - standard plumbing fittings. At the next level there are locking mechanisms that regulate the supply of hot water to the return and input circuits. Moreover, the heating system in a private country house may include two connections - for the return line and the supply channel. Next, after the home taps, there is a chamber in which the coolants are mixed. Hot streams can indirectly contact water in the return circuit, transferring some of the heat to it. Summarizing this part, we can conclude that water is sent to the hot water supply system directly from the central heating main.

Advantages of dependent heating systems

In addition to the already mentioned reliability and reduced maintenance costs (at least on the user’s part), we can emphasize the fairly high performance and stable maintenance of hot water temperature at an average level from 95 ºС to 105 ºС. At the same time, both dependent and independent heating systems can equally regulate the thermal regime. Only in the first case will utilities be responsible for this regulation, integrating radiators into distribution systems to mix water at different temperatures. It is for multi-apartment buildings that this is the optimal solution in terms of performance and financial feasibility.

Terminology

Let's clear up the confusion first.

Energy independence

- this is the ability of heating equipment to operate in the absence of electricity. The ability is undoubtedly pleasant, but we are not talking about it now. However, we will also touch on this topic.

What is the difference between independent and dependent heating systems? Connection diagram to the heating main.

Dependent circuit

Imagine an ordinary residential building. How is it built?

- Input valves cut off the elevator from the route.

- Behind them, on the supply and return lines, there are valves or valves embedded through which hot water can be supplied from the supply or return pipeline.

- After the hot water supply inserts, we see the elevator itself - a nozzle with a mixing chamber. A stream of hotter, high-pressure water from the direct pipeline heats up part of the return water and draws it into recirculation.

- Finally, house valves cut off the heating system. They are closed in summer and open in winter.

The key feature of a dependent heating scheme is that water enters the heating and water supply systems directly from the heating main.

Independent circuit

Now let's imagine another diagram:

- Water from the supply pipeline enters the return pipeline, giving energy to the heat exchanger along the way. Water, we repeat, is not used for heating and hot water needs.

- Drinking water from the water supply is supplied to the same heat exchanger, but to a different circuit. It heats up and enters the heating system. It can also be used for household needs.

Actually, we have comprehensively described the independent connection scheme for the heating system.

Types of circulation in heating circuits

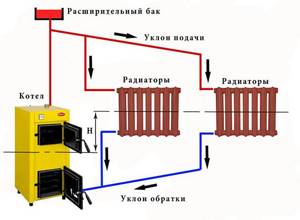

To deliver heat to the batteries, you need to move the coolant heated by the boiler. Natural circulation is used in the heating system and forced movement of water using a circulation pump. Natural circulation is used in simple heating systems; it requires a minimum of equipment with minimal installation and operating costs.

To implement this method of moving the coolant, a change in the physical properties of water when heated is used. The speed of movement depends on the temperature difference and on the magnitude of hydraulic resistance, which is reduced by increasing the diameter of the pipes.

Open heating circuit

An open gravity heating system with natural circulation has undoubted advantages.

Advantages of open natural coolant circulation:

- simplicity and low installation costs;

- efficiency;

- easily converted into a system with forced circulation; the circulation pump is usually installed in the “return”.

Therefore, the heating system for a one-story house with natural circulation is very popular and is successfully used. The main disadvantages of such heating are high inertia. In addition, the presence of an open expansion tank determines the answer to the question - is it possible to pour antifreeze into the heating system of a house. You can fill it, but it will constantly evaporate, which will make the operation of the system unprofitable.

Closed heating circuit

The coolant in a closed heating system has no contact with atmospheric air. To compensate for thermal expansion, sealed membrane expansion tanks are installed. A closed heating system can have any design; it is equipped with a circulation pump to move the coolant. The absence of contact of the coolant with air significantly increases the service life of pipes and heating circuit equipment.

If during installation the slope of the pipes is provided, then in the absence of mains voltage and the bypass is switched, natural circulation will occur in the closed heating system of the house. Of course, the efficiency of the system will drop, but the heating will be operational and will continue to heat the home.

The main advantages of a closed heating system:

- the use of a sealed expansion tank eliminates the evaporation of liquid; in closed systems, antifreeze can be used as a coolant;

- the absence of contact between water and air protects circuit elements from internal corrosion;

- a closed heating circuit has low inertia and high efficiency;

- the use of a circulation pump allows you to reduce the diameter of the pipes and reduce the cost of purchasing them;

- for heated floors and complex branched circuits, an additional pump is installed in the heating system, which will ensure their efficient operation.

Comparison of solutions

The dependent heating connection scheme has, in essence, only one advantage, but a very important one - low cost of implementation. You can assemble an elevator unit for a small cottage with your own hands from consumer-grade shut-off valves

The only thing noticeable against the background of wiring batteries around the house will be the cost of manufacturing the nozzle - the only exclusive one made, the diameter of which determines the thermal power of the elevator.

What are the assets of an independent scheme?

Incomparably more flexible temperature control. It is enough just to reduce the flow of coolant through the heat exchanger - and the house will become colder.

- The practical consequence of flexible adjustment of heating to the needs of the home is efficiency.

Relative to the dependent system, it is estimated at 10-40 percent. - Finally, the main thing: in a dependent system we are forced to use water with a lot of pollution.

It carries sand, scale and a lot of mineral salts.

There is no talk of using water as drinking water; moreover, in some regions it is undesirable to even wash with hot tap water. An independent circuit makes it possible to use purified water or even non-freezing coolants as a coolant.

It is not a problem to heat drinking water for DHW needs.

Electricity addiction

Now let's return to energy dependence. When does a heating system need electricity to function, and when can it be done without?

Solid fuel boilers

The canonical solution is a conventional steel or cast iron boiler with a water jacket in the firebox and mechanical adjustment of the blower using a thermostat. This unit is completely energy independent.

The photo shows a classic solid fuel boiler.

However, this design has an important drawback: the boiler requires frequent loading of fuel. Three technical solutions allow you to make heating as independent from humans as possible:

- A hopper and a conveyor belt

supply new portions of sawdust or pellets as the fuel burns out. Electricity is required at a minimum for the transporter to operate. - divides combustion into two stages: pyrolysis of wood with a limited supply of oxygen and combustion of the resulting gas. In this case, the gas combustion chamber is located below the pyrolysis chamber. The movement of combustion products against the vector of natural draft requires the operation of an electric fan.

- An upper combustion boiler

can operate on one load of coal for up to five days. Only the top layer of fuel smolders; air is supplied to it from top to bottom, and the ash is carried away by a stream of hot combustion products. Air circulation is provided by... that's right, an electric fan.

Gas

Non-volatile gas heating boilers use manual ignition using a piezoelectric element and flame regulation by a mechanical thermostat. When the main burner is extinguished at a high coolant temperature, the pilot burner continues to operate.

Boilers with electronic ignition stop the gas supply completely when idle. As soon as the coolant cools below the critical temperature, the discharge ignites the main burner and heating resumes. In addition, electricity often drives a blower fan that supplies air to the burner.

Which scheme is better? If you have frequent power outages, a non-volatile gas heating boiler would be more appropriate. Precisely because he is able to do without electricity in principle. On the other hand, these devices are less economical: up to 20% of the total gas consumed is spent maintaining the pilot flame.

Another useful feature that gas-independent heating boilers lack is the ability to control the weather and control it using an external thermostat, which takes the temperature, for example, in a remote room. Of course, we are also not talking about programming the temperature for a day or a week.

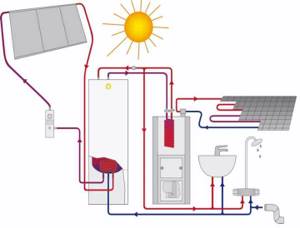

Solara

Everything is simple here: solar boilers are COMPLETELY identical to gas boilers with electronic ignition. Only the burners differ. In fact, a lot of dual-fuel units are being produced.

It is clear that without a forced-air fan and electronic ignition, the devices simply will not be able to work.

Question details

Electricity addiction

Information about the design of independent and dependent heating systems for ordinary users is usually for informational and reference purposes only, and for this reason, where centralized heating systems are used, namely in cities, designers and utility workers deal with the issues of connecting buildings to heat.

In villages and other populated areas where there are private houses, there are simply no centralized heating systems.

The question of the energy dependence of the heating system becomes much more relevant, since in the private sector, where every house has an autonomous heating device, problems with the supply of electrical energy are far from uncommon, especially if the weather outside is bad. So, let's see how you can create individual heating that does not depend on electricity.

Solid fuel boilers

A solid fuel boiler is, of course, considered truly independent. It does not require a centralized supply of fuel and electricity. In a house where there is such a unit, even with perfect isolation from the whole world, it will be warm if the owner of the building has enough firewood or coals (fuel).

But it should be taken into account that all of the above will apply to those solid fuel boilers that have a simple design, in which fuel will be added manually after a time interval of 4 hours. Any modifications of it, which were created in order to reduce user participation to a minimum, need to be provided with electrical energy :

- Pellet boiler - in this case, granular fuel is used, called pellets, which is presented as pressed chips, or cake. The granules are small and uniform in size, so they can be thrown into the combustion chamber using a screw feeder. Simply put, the user will only need to load a certain supply of fuel into the bunker, for example, for a couple of days, and then the boiler will operate in automatic mode all this time. In this case, electricity will only be required to power the screw motor.

- Pyrolysis boilers - the firebox in such a boiler is made in the form of two chambers, and in one of them the firewood is kept at high temperature and with a limited supply of air (which is also called primary). Under these conditions, the wood will release a mixture of combustible gas (this process is called pyrolysis), and it, in turn, enters the second combustion chamber and is burned there. To burn the gas, a large amount of air is pumped into the chamber, and this is already called secondary. In order to maintain optimal operating conditions, air in a certain volume must be supplied to both the first and second chambers, and this is only possible when the fan is operating. To operate such devices, of course, electricity is required.

- A boiler with a top-combustion type fits the definition of “independent heat supply scheme,” but in this case, perhaps, it will be possible to find an exception, since certain models of top-combustion boilers are considered energy-dependent. The duration of work on one stowage is possible due to the fact that the fuel will be laid in the form of a column or tower, and then set on fire from above.

- Boilers with forced addition of air - the firebox in such a boiler is usually single-chamber, but only slightly enlarged. The difference from a standard boiler here is that there is a fan and a gravity damper in the ashtray, which, when the fan is idle, will lower under its own weight and block the access of air inside the firebox.

A device with forced air supply works according to the following scheme:

- While heating of the coolant is required, the fan operates and holds the damper open, thereby forcing air inside the firebox.

- When the temperature sensor gives a signal to the controller that the coolant has reached a certain temperature, it will immediately turn off the fan. The damper will fall, and air access to the firebox will be blocked, causing the fire to go out.

- After the coolant has cooled down, the controller, based on a signal from the thermal sensor, will turn on the fan again, and it will fan the fire in the firebox.

Please note that such a boiler will not function without electricity, since it is needed for both the fan and the automatic system (thermal sensor + controller).

Gas boilers

And even a gas boiler can be energy-dependent, since this model will work according to the following principle - the user lights one burner, which from the moment it is turned on will burn constantly, and from time to time it will light up the main one. This automatic safety system is mechanical, namely in the sense that its action is based on a change in the volume of the material due to changes in temperature.

The disadvantage of an energy-dependent gas boiler is that the pilot burner, although it seems small in appearance, consumes a fairly large amount of gas, and in this case an energy-dependent boiler with electronic ignition will still be much more economical.

Safety and efficiency of independent heating systems

To be able to save money on heating, several conditions must be met:

- Develop and approve the project with the permitting authorities. Without an approved GIP and a project agreed upon with all authorities, all modifications will be illegal. Therefore, you will not be able to use the results.

- Install or reconstruct existing equipment according to the design solution.

- Install a heat energy meter. This will allow you to pay for the received thermal energy exactly in the volume in which it was consumed.

- Provide the necessary level of automation or manual regulation. CHP plants do not respond particularly quickly to temperature changes in weather conditions and can continue to fire their boilers to the fullest. And through the heat exchange tank, unclaimed energy will be transferred to the networks of consumers who open windows and vents from excess heat.

Installation and connection of an independent heating system

Installation work is not much more complex than a gravity route. Among the additional measures, it is worth noting the need to organize an uninterruptible power supply. This will make it possible not to be left without heat during a power outage and is implemented by automatically turning on a battery-powered uninterruptible power supply or a liquid fuel electric generator.

In addition, existing centralized routes are also subject to modernization by separating coolants with a heat exchange tank, installing a forced circulation pump and an uninterruptible power supply. Replacement or dismantling of pipelines with radiators is not required.

There are two types of schemes by which heating devices are connected. Depending on the use of the circuit, two types of heat supply systems are distinguished - dependent and heat supply.

The meaning of an independent heat supply system is that the subscriber's equipment is isolated from the heat supplier using hydraulics. And in order to provide subscribers with heat, auxiliary exchangers of central heating points are needed.

In the case of using a dependent system, it is necessary to constantly connect it to the energy carrier. Such a system consists of pipes and a boiler, which are interconnected into one whole. The meaning of a dependent heat supply system is to circulate hot water in a circle in a continuous mode. Due to the fact that the dependent system is completely tied to the heating main, which is the main source of thermal energy, when using it it is impossible to adjust the water temperature or even, in case of warming, turn off the heating.

Diagram of a dependent heating system

When using an independent heating system, different types of fuel can be used. It should be noted that installing such a system is quite expensive. Unlike a dependent system, in an independent system water can be used for other needs. Another advantage is that the independent one is much easier to install in a building.

Among other things, such a system makes it possible to save money due to the fact that its operation requires a small amount of fuel. The amount of fuel can be adjusted at will, thereby creating comfortable conditions in the premises.

Diagram of an independent heating system

Principle of operation

As noted above, for the operation of the dependent system, process water is used, which during operation leaves salts and sand in the pipes, which disrupts the permeability of water in the pipes. In the case of independent, it is possible to use purified. In this case, the equipment can be shown to have a fairly long service life.

An independent heating system can do without electricity. It may only be needed if a bunker and conveyor are installed in order to supply fuel to the boiler.

You can also use a boiler operating with. Such boilers are a structure consisting of mechanical, thermostat, and steel tanks. Such a system does not tie you to the gas main.

Independent heat supply scheme

Circulation pump at a thermal power plant for the city heating main

An independent heating circuit consists of a main and additional circulation circuit, separated by a heat exchanger. The coolant is sent from the thermal power plant or boiler house to the central heating point. Next, it moves to the heat exchanger (main circuit), and then goes to the heat supply of the house (auxiliary circuit). Both circuits are isolated, water does not mix.

In an independent line, the coolant moves forcibly - due to the circulation pump. Water flows through heating devices constantly. In case of leaks there is an expansion tank.

Dependent heating system

A dependent system is often called an open system. And it is called that because a heat carrier is taken from the supply pipe to provide the house with hot water. The dependent circuit is often used in administrative, multi-apartment and other buildings that are intended for public use. The peculiarity of an open system is that the coolant flows through the main networks and enters directly into the house.

If the temperature of the coolant in the supply pipeline is no more than 95°C, then it can be sent to heating devices. But if the temperature exceeds 95°C, then it is necessary to install an elevator unit at the entrance to the house. With its help, water that comes from heating radiators is mixed into the hot coolant to lower its temperature.

Previously, no one paid special attention to coolant flow, so this scheme was often used. Dependent heating system does not require large installation costs

There is no need to lay additional pipes to provide your home with hot water.

But in addition to the above advantages, we can also highlight the disadvantages of a dependent heating system:

- Regulating the temperature in rooms is problematic. Valves quickly fail due to poor quality of the coolant.

- From the main pipes, various dirt and rust enter the heating radiators. Steel and cast iron radiators continue to operate without any changes. But in aluminum batteries, the ingress of rust and dirt has a detrimental effect on operation.

- Although the coolant undergoes all the required desalting and cleaning, it still passes through rusty main pipelines. Accordingly, the coolant cannot be of good quality. This factor is a big disadvantage, since the coolant is used for water supply.

- Due to repair work, pressure drops in the system or even water hammer often occur. Such problems can seriously affect the performance of modern heating radiators.

The influence of air on the operation of the heating circuit

When, for one reason or another, air appears in the heating system, the normal operation of the system is disrupted. Circulation worsens or stops altogether, with all the ensuing consequences. In such cases, experts say that the heating system is airy and measures must be taken to remove air pockets.

The presence of air in the circuit can cause unpleasant phenomena:

- noise when water moves through radiators and vibration, which causes loosening of screw connections and sometimes destruction of welding points;

- in remote utility rooms, lack of circulation can lead to defrosting of the system;

- slight airing causes a decrease in operating efficiency and excessive fuel consumption;

- air causes corrosion of metal pipes and housings from the inside, which sharply reduces the service life of the equipment.

To successfully remove air from the circuit, vents are used in the heating system, which can be manual or automatic. Of the manual air vents, the most famous is the Mayevsky valve. It is installed at the end of the battery and with its help the accumulated air is released. An automatic air vent removes air from the system during operation.

Air vents are installed in critical places, such as pipe turns and the highest points of heating systems.

Dependent open heat supply system

The main feature of the dependent system is that the coolant flowing through the main networks directly enters the house. It is called open because coolant is taken from the supply pipeline to provide the house with hot water. Most often, this scheme is used when connecting multi-apartment residential buildings, administrative and other public buildings to heating networks. The operation of the dependent heating system circuit is shown in the figure:

When the temperature of the coolant in the supply pipeline is up to 95 ºС, it can be sent directly to the heating devices. If the temperature is higher and reaches 105 ºС, then a mixing elevator unit is installed at the entrance to the house, whose task is to mix the water coming from the radiators into the hot coolant in order to lower its temperature.

The scheme was very popular during the Soviet era, when few people were concerned about energy consumption. The fact is that the dependent connection with elevator mixing units works quite reliably and requires practically no supervision, and installation work and material costs are quite cheap. Again, there is no need to lay additional pipes to supply hot water to houses when it can be successfully taken from the heating main.

But this is where the positive aspects of the dependent scheme end. And there are many more negative ones:

- dirt, scale and rust from the main pipelines safely enter all consumer batteries. Old cast-iron radiators and steel convectors didn’t care about these little things, but modern aluminum and other heating devices definitely don’t;

- Due to a decrease in water intake, repair work and other reasons, a pressure drop in the dependent heating system, or even water hammer, often occurs. This has implications for modern batteries and polymer pipelines;

- The quality of the coolant leaves much to be desired, but it goes directly to the water supply. And, although the water in the boiler room goes through all stages of purification and desalting, kilometers of old rusty mains make themselves felt;

- Regulating the temperature in rooms is not easy. Even full-bore thermostatic valves quickly fail due to poor quality coolant.

Independence from power supply

With frequent and long-term power outages in private homes and country cottages, an independent heating system is in demand, the heat source for which is a gas or solid fuel boiler. They are easy to operate, but require compliance with certain rules during operation.

The main disadvantage of a solid fuel boiler is the need to constantly reload fuel. To ensure the functioning of the heating device with minimal involvement of people for maintenance, you can

use long-burning boilers. However, they require a fan to operate, which is powered by electricity. Gas boilers are more independent of the power supply, since the fuel can be ignited manually using a piezoelectric element, and a mechanical thermostat is used to adjust the burner flame.

The movement of coolant in a non-volatile heating network occurs due to the difference in density of the heated and cooled working environment. For the effective operation of a gravity heating system, the following conditions must be met:

- during installation, the boiler is placed below the radiators;

- when laying and connecting pipes, maintain a slope in the direction of movement of the coolant;

- the diameter of the pipes must be sufficient to reduce hydraulic resistance and is usually 35-50 mm.

In addition to its independence from electricity, the gravitational heating circuit is characterized by simplicity of design and maintenance. Among its disadvantages are:

- low efficiency;

- difficulty in regulating battery heating;

- impossibility of connecting a “warm floor” system;

- low heat transfer;

- the complexity of masking large diameter pipes.

The forced heating system is free of these shortcomings. It allows you to maintain a given temperature in the premises and does not require special conditions for the location of heat sources and radiators. In this case, the coolant is moved using a circulation pump, the operation of which requires the presence of an electrical network. Therefore, heating networks with forced transportation of the working fluid are energy dependent. The circulation system is closed: it is equipped with a membrane expansion tank and is characterized by the tightness of all structural elements. When such a network operates, there is no evaporation of the coolant, and its quantity is regulated using a special tank.