Owners of a summer house, cottage or any other country house are interested in the question of what to put into the heating system so that it does not freeze in winter. In such buildings, the user may not live permanently, for example, come on weekends, so defrosting pipes is considered a pressing problem.

First, let's understand the concept of coolant. In general terms, this is a hot liquid or steam that flows from the boiler to the radiators, gives off some of the heat and returns through the return pipeline to the heat generator. In most cases, users use the coolant for their home heating system in the form of a liquid. It could be:

- regular tap or distilled water;

- non-freezing liquids, antifreeze (propylene glycol or ethylene glycol).

Important! To reduce the effect of corrosion on the surface of metal pipes, special substances and additives can be introduced into the composition of any coolant.

All heating fluids have their strengths and weaknesses. Let's look at this in more detail later.

What is a coolant, requirements, properties

A coolant is a liquid substance that meets a number of operational requirements and is capable of effectively transferring thermal energy from the heating boiler circuit to the radiators in the room. In a simplified form, the principle of its operation is the following algorithm:

- The flow of substance washes the heating circuit of the heating boiler.

- Having acquired a given temperature, it then passes through pipes to receivers - radiators.

- In contact with the internal structures of the batteries, the thermal agent cools and transfers heat to the walls of the device, which in turn release it to the surrounding space.

- The cooled coolant, leaving the radiator, returns in the return line to the heating circuit and the cycle repeats.

Moreover, not every liquid can be used as a heat agent.

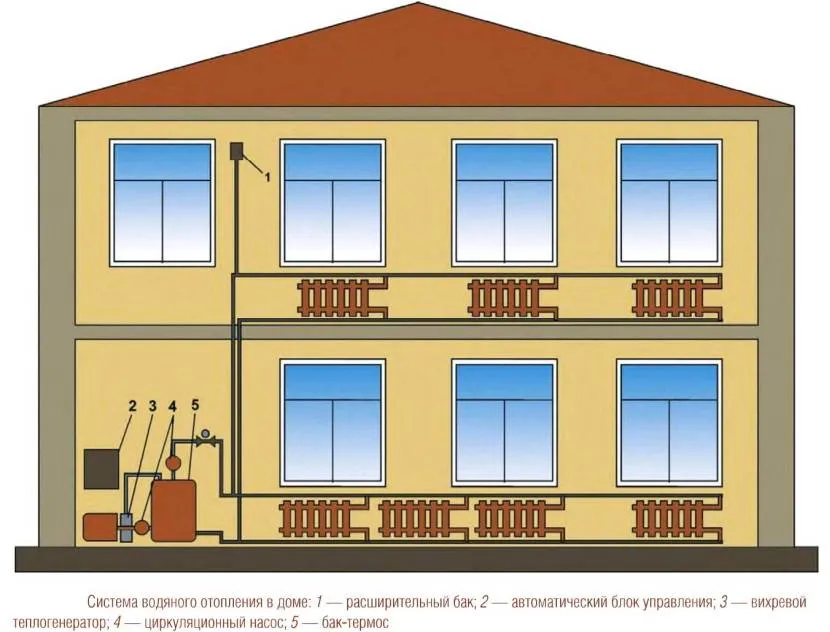

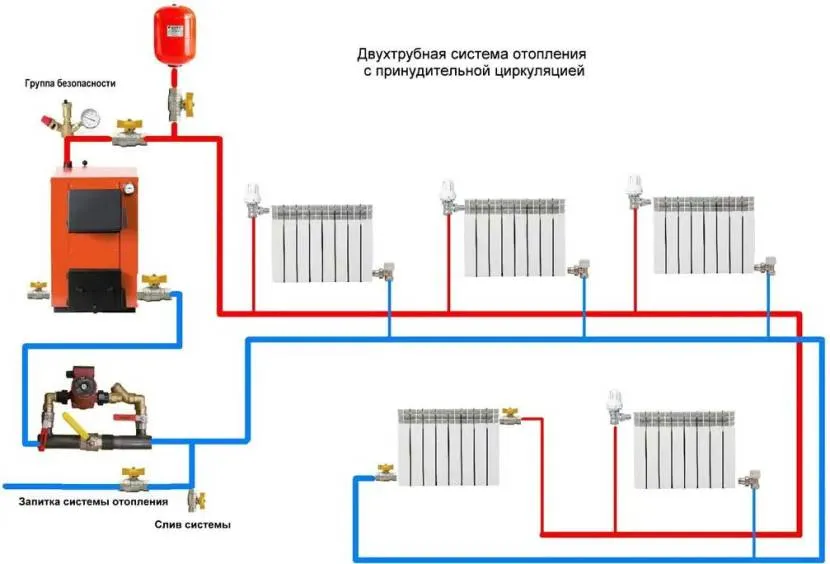

Scheme of autonomous heating at home Source survival.com.ua

Requirements

For successful and safe use, the liquid substance must meet the following series of requirements:

- The ability to quickly and fully absorb, transfer and release heat - which corresponds to a high value of heat capacity.

- Neutrality or the minimum possible chemical activity with contacting material - equipment, pipes, radiators and sealing elements.

- Wide range of operating temperatures – both in the heating and cooling zones. Ideally, the heating liquid should not boil quickly and turn into a vapor state at standard boiler operating rates. It should also not thicken or completely crystallize when cooled well below 0 °C and lead to destruction of system equipment in winter.

- The absence of dissolved components in the composition that can crystallize with constant heating of the liquid. Since they can be deposited in the form of insoluble growths on the walls of pipes, radiators and boiler circuits. This will lead to a narrowing of the working clearance and a deterioration in the heat transfer of the equipment, as well as a load on the pumping station.

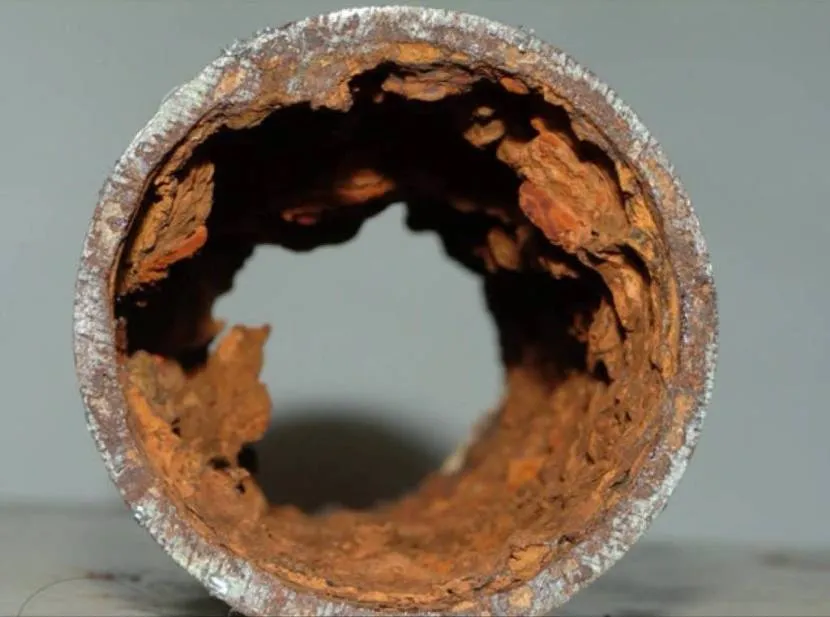

Clogging of pipes with insoluble sediment Source ds-m.ru

- Absence or minimal corrosion activity on the metal surfaces of system elements.

- Chemical stability - the absence of processes of decomposition or transformation of coolant components into other compounds under the influence of heat, time of use and other factors.

- Constancy of performance characteristics - fluidity indicators, thermal capacity, chemical inertness, etc. - throughout the entire period of operation and under given conditions.

- Absolute safety for the residents of the house. Absence of toxic, flammable, explosive, radioactive and other components hazardous to life and health.

Important! Whatever the requirements, an ideal coolant does not exist in nature. Therefore, in each individual case, it is necessary to select a fluid that matches the nature of the application, equipment configuration, type of building, climate and other operating factors. Some boiler manufacturers directly recommend specific brands of products for filling the system.

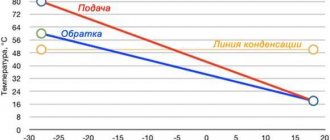

Antifreeze supply system Source remont-book.com

Rating of the best non-freezing liquids

TOP 5 antifreezes for the home will allow you to easily choose what you need. If problems arise, you can always contact the manager of a specialized store.

Knowing the advantages and disadvantages, it is important to buy a good heating fluid. The following brands of antifreeze are the most popular among users.

DIXIS-65

Ideal for use in gas and electric boiler equipment of any type of installation. Excellent transfer of heat at external temperatures from -65 °C to +9 °C.

This antifreeze composition is ideal for cast iron, copper, aluminum, and brass heating pipes. Does not damage joints, does not harm pipelines and plastic tanks. Together with the anti-freeze system, a sticker is issued for the heating boiler, where you can see fields for entering the fill date, volume and other details - this is indispensable when maintaining the system.

Experts gave the leading position in the rating to this particular non-freezing liquid, since its crystallization occurs only at -66 °C. This is the best substance for heating lines in northern regions - it will survive severe frosts and keep the pipeline and radiators intact.

When used in regions where the temperature in winter is not lower than -20 °C, the antifreeze liquid is diluted with water 1 to 1 - this is a serious money saving.

Pros:

- fire resistant;

- increased antifreeze rate;

- five-year warranty;

- protection of containers from burglary.

Minuses:

- liquid heat capacity is 10% lower;

- high viscosity;

- cannot be used in galvanized heating pipelines;

- prohibited in boiler equipment with electrodes.

THERMAGENT-65

Domestic liquid produced from German raw materials. The unique technology of Organic Technology is used in production. The antifreeze substance does not contain amines or other toxins. It is poured into boiler systems operating on liquid fuel, gas and current.

According to consumers, the drug does not spoil rubber, sealants and parasites. The manufacturer included additives that prevent the growth of bacteria and foaming, so the heating pipes will remain clean and with high-quality permeability.

The non-freezing coolant is included in the TOP 5, as it has a low level of crystallization at a temperature of -65 ° C, as well as a long service life. It protects against rust for up to ten years and is used for up to twenty seasons without losing its properties. This is more than economical.

Pros:

- raw materials for the production of antifreeze composition for heating are imported from Germany;

- the liquid does not freeze at low temperatures;

- can be bred;

- contains no toxins.

Minuses:

- ethylene is present;

- cannot be used in Galan type heating equipment;

- when combined with water, the quality of rust protection is reduced;

- functions poorly with wood-burning boilers due to overheating.

RODA

Antifreeze liquid from a well-known brand that creates boiler equipment from neighboring countries. The manufacturer also took care of the careful handling of heating systems.

Glycerin-based coolant is one of the safest. Contains an anti-foaming additive. The liquid does not freeze even at -30 °C. It boils after +105 °C, so it is suitable for a larger number of heating lines and equipment.

Contains a fluorescent dye for rapid detection of leaks in pipes and heating radiators. Non-freezing liquid is produced in containers of 10 and 20 kg. It is poured into the system in proportions of 113 kg per 100 liters.

Experts recommend this liquid for heating networks with open circuits, where the expansion tank is not equipped with a sealed lid. The organic antifreeze composition is not dangerous when evaporated. Therefore, this type of heating fluid can be used even in food industry enterprises. The advantage of the coolant is that it is allowed to be used in galvanized pipelines.

Pros:

- service life eight to ten years;

- fire resistance;

- will not harm circulation pumping equipment;

- When switching to this type, there is no need to flush the heating line.

Minuses:

- relatively high price for 10 kg;

- it is forbidden to overheat the liquid;

- cannot be used with non-polar plastic materials.

AMT-300

Antifreeze heating agent from a domestic manufacturer, supplied to the market in barrels weighing 20, 30 or 180 kg. This makes it possible to immediately buy the required volume for your home at an affordable price. It is based on an oily substance with flavorings. Products must undergo catalysis and adsorption for a higher level of purification.

Not suitable for open communication systems. The density of the oil substance is 940 kg/m3, therefore it is suitable for relatively warm climates. Antifreeze from this manufacturer is mainly used in southern regions, where it rarely gets colder than -15 °C.

Antifreeze for heating entered the TOP due to its increased thermal stability when heated and the impossibility of ignition under the influence of high temperatures. The boiling point of the oil is almost +300 oC. Therefore, it is even poured into equipment that runs on solid fuel, but only with powerful pumping units to increase circulation so that the non-freezing coolant does not overheat in the exchanger.

Pros:

- almost zero acidity is gentle on heating system components, rubber, plastic, metal, sealant;

- high-quality fluidity in a heated state;

- high anti-corrosion properties, regardless of the period of use;

- does not accumulate condensation and does not form plaque.

Flaws:

- antifreeze composition is prohibited for open boilers;

- crystallizes at -15°C;

- it is necessary to use powerful pumping equipment.

Water as a coolant - pros and cons

Ordinary water is the most commonly used liquid for heating a private home. The main reason for this is accessibility. There are also a number of other advantages of its use:

- Natural prevalence . This makes water a free, accessible and easily replenished resource for any heating system. This not only reduces, but completely eliminates coolant costs for maintenance and repairs.

- Maximum heat capacity – high efficiency of heat transfer from the boiler to the radiator.

- Optimal technical indicators - fluidity, operating temperature, stability.

- Operational safety for people, animals, the environment and the equipment itself - does not burn, does not explode, does not poison.

However, the use of water in the heating system also has its disadvantages:

- High freezing point . When the ambient temperature drops below 0 °C, crystallization will occur with all the ensuing negative consequences - rupture of pipes, batteries, damage to equipment.

- Corrosivity . Water is easily and quickly saturated with oxygen, which, when in contact with metal surfaces of equipment, leads to rusting and destruction of its structure.

Pipes destroyed by corrosion Source gidpokraske.ru

- Formation of scale, growths, siltation. Due to the presence of dissolved impurities of various substances in ordinary water from natural sources, deposits of salts, silt and other components often form on the inner surface of pipes, circuits and batteries. As a result, the clearance narrows, heat transfer properties deteriorate and the service life of the equipment decreases.

Recommendation! Despite the obvious disadvantages, water is the most popular coolant for the heating system of a country house. However, in order to avoid the disadvantages associated with its use, some manipulations are carried out on it. For example, to get rid of impurities, it is boiled, distilled, passed through filters, or special additives are added to it.

Features when starting the heating system

Different compositions of solutions affect the operation of the heating system. Thus, the presence of ethylene glycol affects the initial stage of system startup. The heating process must be started at low power, then gradually increased to the required level. This method will reduce the toxic effects of this substance.

A product based on propylene glycol does not require such adjustments when starting heating equipment.

When all the requirements are met, then there is no need to be afraid of using “anti-freeze” as a coolant. It will solve a lot of problems if used skillfully.

Prices for non-freezing liquid vary, and so does the quality. The policy here should be this: when it is not possible to buy a good product, it is better to stick with water. In this case, you must ensure that the coolant is drained from the system before the onset of frost, or turn on the heating devices on time.

Antifreeze, types, features

Water purified from harmful impurities and inhibited by special additives still does not become an ideal coolant. Since it is impossible to get rid of the main drawback - freezing at 0 degrees. Therefore, today special antifreeze liquid is widely used everywhere.

Antifreeze antifreeze down to -30 degrees Source antifreez.ru

Properties and features of antifreeze

The main feature of using such a liquid is the operating temperature range suitable for winter operating conditions. Antifreeze for heating freezes at a much lower temperature than ordinary water. Besides this, it has other obvious advantages:

- The structure of antifreeze does not allow it to completely crystallize when the temperature drops, but only to transition from a liquid to a gel state. This essential property preserves the integrity and performance of pipes, circuits and batteries. Therefore, even if the temperature drops below critical due to an unexpected shutdown of the system in cold weather, the equipment will not defrost.

- Economical use due to the possibility of diluting the concentrate with distilled water. Most formulations are sold in concentrated form. The lower limit of their operating temperature is -60-70 °C. However, in most regions the ambient temperature rarely drops below -40-30 degrees. Therefore, the liquid can be diluted without loss of properties according to the factory instructions.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

- Chemical stability and inertness. Antifreeze contains components that do not decompose when heated within the performance parameters and are inert with respect to the equipment material. In this case, the liquid lasts for at least 5 years.

With all the obvious advantages and superiority over ordinary water, however, antifreezes also have a number of specific disadvantages:

- High viscosity values. For normal circulation through the antifreeze fluid system, it is necessary to provide greater pressure, which means using a more powerful pump. At the same time, it is unacceptable to use antifreeze in variations with natural circulation.

- Up to 15% lower heat capacity than water. For this reason, the overall efficiency of the system will be reduced. Consequently, greater energy consumption, the use of radiators with an increased area and an increase in their number will be required in order to achieve a normal heating effect.

- The high degree of fluidity of the substance forces a more careful approach to the selection of sealing elements and more frequent procedures for their maintenance, repair and replacement in all connecting units.

Replacing seals in the radiator Source stroy-podskazka.ru

- Toxic components in many coolants pose a direct threat to all living things in the surrounding space.

- The need to install a larger expansion tank is due to the increased expansion coefficient.

Important! It is unacceptable to use inexpensive options for an open-type expansion tank with antifreeze for two reasons - loss of the substance through evaporation and contamination of indoor air with toxic fumes.

Varieties

Non-freezing heating fluid can have a different chemical basis. On this basis, antifreezes are divided into the following categories:

- Ethylene glycol.

- Propylene glycol.

- Glycerol.

- Bishofite.

There are also compositions specifically used in electrode-type heating boilers. In addition, many users recommend using regular antifreeze as an alternative to modern antifreeze. Let's look at the features of each option in detail.

Ethylene glycol coolant Source dialrus.com

Ethylene glycol

This is the most common, accessible and cheap antifreeze for the heating system of a country house. Available in two forms - concentrated and diluted. The second option is applicable at temperatures down to -30 °C, concentrate - up to -65 degrees. Among the main features of its operation are the following:

- Foaming under strong heating and, as a result, the formation of gas plugs. Eliminated by adding additives and temperature control.

- Oxidation of zinc-coated surfaces despite the use of inhibitors.

- Chemical decomposition when heated above 110 °C. The problem is eliminated by automatic control of the boiler temperature.

- Possibility of insoluble precipitate formation due to overheating. As a result, the entire pipeline system becomes clogged.

Ethylene glycol is poisonous. Therefore, it can only be poured into closed-loop systems.

Closed heating Source ytimg.com

Propylene glycol

A non-freezing liquid for the heating system based on propylene glycol is at least twice as expensive as the analogue considered. However, despite this, he is in great demand. The reason is complete harmlessness to humans. In purified form, the compound is often added even to confectionery products as a flavoring additive. When used in heating systems, antifreeze exhibits the following series of properties:

- Increased fluidity, which implies strict control over the tightness of the system and places high demands on the sealing elements.

- Oxidation of zinc surfaces.

- Easy flammability - at 421 degrees.

- Service life – up to 10 years.

- Operating temperature – up to -50 °C.

Propylene glycol antifreeze can be used in open systems, as well as double-circuit junctions, when there is a risk of coolant getting into household water.

Glycerol

Glycerin coolant for heating is actually an analogue of the antifreeze discussed above. At the same time, it is 25% cheaper and is characterized by the following number of advantages:

- Non-toxic.

- Wide range of operating temperatures – from -30 to +110 degrees.

- Does not destroy pipes when frozen.

Glycerin-based coolant Source fabrikatepla.ru

Antifreeze classification

There are many types of these products on the market. Antifreeze liquid for heating boilers can be made based on an aqueous solution of glycerin, ethylene glycol, propylene glycol, and so on. Since all substances are highly aggressive, the liquids contain special additives.

Each type has certain specific characteristics:

- Ethylene glycol-based liquid is common among buyers because it has the most affordable price. But it is the most toxic and cannot be used for double-circuit boilers. May pose a health hazard if released into water supplies. If the boiling point rises above 110 degrees, the substance may produce a precipitate that can stop the operation of a number of system elements;

- from propylene glycol - the properties of the composition are almost similar to the previous one, but it is less harmful and safer;

- based on glycerin - environmentally friendly antifreeze, non-toxic, protects the system from corrosion. When it turns into a solid state, it does not increase its volume, and in order for the system to start, it just needs to be warmed up;

- from a natural bischofite solution - has a high level of heat transfer and heat capacity, the freezing point is low and the boiling point is high;

- salt carriers - are produced on the basis of solutions of sodium, calcium and other mineral salts. They have high corrosiveness to pipes.

The product can be sold both in finished form and in the form of a concentrate for preparing a solution. Different types of antifreeze have their own freezing point. Experts believe that it is best to use compounds whose freezing point is 20-25 degrees below zero.

Rules for choosing antifreeze

An objective concept of which coolant is best to use in the heating system of a private house under specific conditions arises when taking into account the following series of criteria:

- Type of base and its applicability to equipment and operating conditions.

- Freezing and boiling points, optimal operating heating range - taking into account the dilution of the concentrate.

- Possibility of reducing concentration by adding water.

- Life time.

Note! Antifreeze is not recommended for use in open systems and with natural circulation. In addition, the antifreeze liquid should not come into contact with an unprotected galvanized surface and rubber, silicone seals, as well as oiled tow. In addition, only reliable automation can provide accurate control over compliance with its heating parameters.

Pouring antifreeze into the heating system Source hstream.ru

Can antifreeze be used?

heat supply diagram with antifreeze instead of water

Antifreeze or antifreeze liquids are known to almost everyone. They are widely used in car cooling systems in winter. In a car engine, antifreeze transfers excess heat away from the engine, cooling it. Moreover, even in the most severe frosts it does not freeze. It is these properties - the ability to transfer heat even at the lowest temperatures - that led to the use of antifreeze for the construction of heating systems. It is especially important to use such a coolant in a system where part of the pipeline runs through open areas.

A good feature of “anti-freeze” is that it provokes less corrosion on the inner surface of pipeline systems than ordinary water. Another undoubted advantage is the absence of suspended limestone solutions in non-freezing liquids - so you don’t have to worry about possible scale formation.

There are several modifications of antifreeze liquids that can be used in heating systems. The choice of a specific type is made taking into account the climatic conditions and configuration of the heating system of your home.

What is flushing fluid for the heating system and does it need to be flushed?

In addition to the coolant itself, when operating the heating system, you will also have to purchase a liquid intended for flushing the pipeline and heating radiators.

Of course, as a last resort, you can wash the inner surface of the pipes with ordinary tap water, but it is better to do this with the help of special liquids that contain special chemical additives.

heating flushing

An alternative washing option may be to use water with a caustic soda solution added to it. This mixture is poured into the heating system and remains inside it for about an hour. The soda solution comes into contact with the scale on the inner surface of the system and dissolves it. In addition, the baking soda solution will dissolve areas with corrosion.

How to choose a liquid for a heating system?

- First of all, it is necessary to determine the operating parameters of the system. Here two extreme values will be important to you - the maximum coolant temperature when heating in the boiler and the minimum ambient temperature.

- Next, you need to carefully study the technical characteristics of your heating system. Actually, the main attention should be paid to the characteristics of the heat exchanger in the boiler. Some manufacturers may not allow the use of antifreeze fluids.

- And finally, after determining the permissibility of using non-freezing liquid and its possible temperature parameters, proceed directly to choosing the brand of liquid, focusing on its lowest toxicity. Still, the heating system will be located in a living room, and possible liquid leaks should not lead to poisoning.

Using alcohol as a coolant

No matter how blasphemous it may sound to the male ear, it is allowed to use alcohol as a coolant. Alcohol does not freeze and can be used in a wide range of temperatures. Naturally, industrial alcohol is used in this capacity, which is a deadly poison for humans. However, many manufacturers of boilers and heat exchangers are critical of the use of liquids such as bischofite or ethylene glycol as a coolant.

bischofite

The disadvantage of using pure alcohol as a coolant is its high volatility - about five liters per year will evaporate through microscopic pores in the system.

Tips for use

Before you start pouring antifreeze into the heating system of a private home, you must consider the following set of recommendations:

- It is almost impossible to make a fairly accurate calculation of what concentration and corresponding physicochemical parameters an antifreeze liquid will require. Therefore, after filling, it may be necessary to increase the pump power, increase the volume of the expansion tank, increase the number of battery sections and even the cross-section of the heating circuit.

- Automatic valves for bleeding gas plugs may not work properly. Therefore, it is better to immediately install manual analogues, such as the Mayevsky crane.

- Before filling in new artificial coolant, the system must be washed with a special agent.

- To dilute the concentrate to the desired concentration, only distilled water can be used.

- After filling in compliance with all recommended standards, the system can only be started gradually. This is necessary to check the compatibility of all components with the new type of coolant.

How to choose a coolant for heating

Drawing up a wiring project and installing heating in a private house should be carried out together with the choice of the type of coolant. The type of liquid selected depends on the boiler power rating and the performance of heating devices, the selection of such an important unit as a circulation pump and the purchase of other materials and components.

If a two-pipe heating system with bottom wiring will be used throughout the winter, then water is considered the ideal choice. At the moment, such a liquid is considered the main coolant. Water can be collected from a well or borehole, and it is absolutely free.

TOP 10 best antifreezes

In order to choose the best antifreeze for your heating system today, you need to consider the TOP 10 products from modern manufacturers:

- DIXIS-65.

Universal for gas and electric boilers. Works down to -65 degrees. Service life 5 years.

- Warm House Eco.

Based on propylene glycol - harmless. Compatible with sealants and tow. Does not destroy pipes when frozen.

- THERMAGENT-65.

Retains properties for up to 20 seasons. Suitable for low temperature climate areas. Contains ethylene glycol.

Features of using antifreeze

Please note the following points:

- it is necessary to purchase and connect a circulation pump that could produce sufficient pressure in the pipes;

- the boiler must have at least 20% power reserve.

.

if you use an electrode electric boiler, then it requires a special “anti-freeze”

Pay attention to the recommendations from the manufacturer; If you have a double-circuit boiler, then you will have to abandon the non-freezing liquid. There is a danger of liquid entering the DHW circuit; Low temperature solution should not be used in a system with galvanized pipes

The chemical reaction will cause the antifreeze to lose its basic properties; Filling a system with an atmospheric expansion tank with antifreeze is a bad idea. Firstly, you and your loved ones will constantly inhale harmful fumes from the antifreeze, and secondly, the volume of antifreeze will constantly decrease due to evaporation.

Advice: is it possible to pour anti-freeze into the system after water? Experts answer that it is possible, but it is important to pay attention to one aspect of the pump’s operation. It may happen that the unit, which previously operated at low or medium speeds, will simply need to be switched to its maximum power, and this will be quite enough for correct operation. If the pump power is not enough, or you see that something has gone wrong (the batteries heat up poorly), then the unit will still have to be replaced

If the pump power is not enough, or you see that something has gone wrong (the batteries do not heat well), then the unit will still have to be replaced.

Video description

Video about what you need to consider when pouring antifreeze into the heating system:

- RODA.

Glycerin coolant, works down to -30 degrees. Does not require rinsing before filling. Completely safe.

- AMT-300.

Designed for closed systems, applicable down to -15 degrees. Does not cause corrosion. Requires powerful pumping equipment.

- Hot Stream.

Based on ethylene glycol with additives. Serves for 10 years, works at temperatures down to -30 degrees. Available in diluted form.

- Teplokom.

Based on food grade glycerin. Completely safe. Suitable for use in systems with steel and aluminum radiators. Valid down to -50 degrees.

- WARME BASIC-65.

Contains ethylene glycol. Applicable down to -65 °C. Suitable for northern regions. Service life 2 years.

- Thermagent Eco 30.

Based on propylene glycol. Maintains performance characteristics at temperatures down to -30 degrees. Safe, lasts up to 10 years.

- FTX-30.

Coolant with additives based on propylene glycol. Freezes below -30 degrees. Does not corrode seals.

When choosing a coolant, price is not the last thing. However, more important characteristics are equipment efficiency and safety.

Choosing an “anti-freeze” for heating

Tip number one: buy and fill in antifreeze only in extreme cases - for periodic heating of remote country houses, garages or buildings under construction. Try to use water - regular and distilled, this is the least troublesome option.

When choosing a frost-resistant coolant, follow the following recommendations:

- If your budget is limited, take ethylene glycol from any well-known brand - “Teply Dom”, Dixis, Spektrogen Teplo Coolant, Bautherm, Termo Tactic or “Thermagent”. The cost of the concentrate -65 °C from Dixis is only 1.3 USD. e. (90 rubles) per 1 kg.

- If there is a danger of antifreeze getting into household water (for example, through an indirect heating boiler, double-circuit boiler), or you are very concerned about the environment and safety, buy harmless propylene glycol. But keep in mind: the price of the chemical is higher; a ready-made Dixis solution (minus 30 degrees) will cost 100 rubles (1.45 USD) per kilogram.

- For large heating systems, we recommend using premium class HNT coolant. The liquid is made on the basis of propylene glycol, but it has an increased service life of 15 years.

- Do not buy glycerin solutions at all. Reasons: sedimentation in the system, too high viscosity, tendency to foam, a large number of low-quality products made from technical glycerin.

In the light of the flashlight, tiny white flakes are visible - a sediment of technical glycerin - Electrode boilers require a special liquid, for example, HNT-35. Before use, be sure to consult with a representative of the manufacturer.

- Do not confuse automobile antifreezes with chemicals used in heating systems. Yes, both formulations are glycol-based, but the additive packages are completely different. Engine coolant is not compatible with residential water heating.

- For open and gravity-flow heating systems, it is better to use water, or, in extreme cases, propylene glycol diluted at minus 20 °C.

- If the heating distribution is made with galvanized pipes, there is no point in purchasing glycol mixtures. The substance will deal with zinc, lose the package of additives and quickly degrade.

Clarification. It is not profitable to use frost-resistant liquid for an open heating system. Hot antifreeze will evaporate into the atmosphere through the expansion tank, the antifreeze will have to be constantly topped up, and money will be spent. It is unacceptable to pump in ethylene glycol, since its vapors are toxic.

There is a lot of debate about the harmfulness of ethylene glycol compounds, including on the pages of construction forums. Without denying the harmful effects of the chemical on human health, let us draw attention to a convincing fact.

Homeowners whose closed systems are installed well have been using inexpensive glycol for years without any problems. Let's listen to the expert's opinion in the video:

Features of pouring coolant into the heating system

For successful and trouble-free operation of autonomous heating of a private home, it is important not only to know which coolant is best to use in the heating system, but also how to fill it correctly. There are two main ways to do this:

- By gravity.

- By pump.

In the first case, the liquid is poured through an open socket at the highest point of the heating piping system. The method is quite simple, but requires a lot of effort and time. More suitable for small-volume open systems operating in a one-story house.

The second is more preferable when large volumes of coolant need to be filled. In this case, the use of both submersible and pressure testing pumping equipment is allowed. The main nuance of pumping coolant in this way is to eliminate or minimize the entry of air into the system.

The procedure for pumping coolant into the heating system must be carried out by experienced specialists strictly in accordance with the technology and control of technical parameters of pressure and volume, as well as the removal of air pockets.

Volume calculation and filling

To avoid emergency situations, liquid must be poured into the heating system strictly in a certain volume. It is calculated taking into account the following factors:

- type of heating system;

- its material;

- internal volume of the boiler;

- the area of the room that is planned to be heated.

It is recommended to carry out calculations according to the instructions for the equipment, and also take into account whether antifreeze can be used in it at all. But there are situations when the technical documentation does not contain any information on this matter, then the calculation is carried out by studying the relevant literature. And in some cases, you will need the help of a specialist who will help you carry out all the calculations and put the system into operation.

After filling, do not forget to test the equipment

You also need to know how to properly fill the coolant into the system. If there is already old media in it, then it will need to be drained. It is also necessary to check the degree of contamination; the system may need to be cleaned first, otherwise mixing two anti-freeze agents will cause an unexpected chemical reaction.

In a closed system, the filling point should be located below other heating devices. Antifreeze is poured using pumping equipment, but the pressure in the pipes must be no higher than 3 atmospheres. And if it is open, then filling must be done through the upper expansion tank.

After this, the operation of the equipment is tested. The temperature in the system increases, during which the tightness of the components and the absence of unnecessary noise during the circulation of the coolant are checked.

During the period of use of the system, antifreeze will need to be added periodically, so it is better to purchase it with some reserve.

Briefly about the main thing

The coolant for heating a private house allows you to efficiently and safely transfer thermal energy from the heating circuit of the boiler to the radiators, which in turn release heat to the surrounding space. The coolant must meet the following series of requirements:

- Complete heat transfer.

- Chemical inertness.

- Optimal operating temperature range.

- Absence of harmful components.

- Stability and constancy of operating parameters.

- Safety for people and the environment.

Water can be used as a coolant. It tolerates heat best, is free and accessible. However, it freezes already at zero degrees, causes corrosion and can form insoluble salts. Non-freezing liquids do not have such disadvantages.

Antifreezes are divided according to their chemical composition into ethylene glycol, propylene glycol, and glycerin. There are also special ones for electrode boilers and mineral ones. Antifreeze cannot be used as a cheap alternative. You can add antifreeze manually or with a pump. At the same time, monitoring performance characteristics and strict adherence to technology are extremely important.

Ratings 0

When not to use antifreeze in a heating system ↑

As a rule, we are fully informed about the benefits - marketers never tire of taking care of this. As for various kinds of nuances that may be associated with restrictions on the use of a particular product, the same marketers try to keep quiet about this.

However, such information is more than important. Below I will tell you in what situations antifreeze cannot be used as a coolant in the system.

- Antifreeze liquid cannot be used in double-circuit boilers. The thing is that the design of dual-circuit systems does not allow us to give a 100% guarantee that the coolant will not leak into the water supply circuit in some abnormal (emergency) situation. And this is fraught with serious health consequences - all antifreezes are toxic in their chemical composition.

- The use of antifreeze in open heating systems at home is also prohibited - where evaporation is possible.

- Antifreeze is not used for galvanized pipelines. Interacting with them, materials may lose their original properties, and undesirable chemical changes are possible.

- It is not recommended to pour antifreeze into cast iron boilers. One way or another, you need to make sure that you have paronite gaskets in your equipment; they can at least partially prevent the harmful effects of your antifreeze on the material.

You also need to remember:

- The heat capacity of antifreeze is higher than that of ordinary water, so radiators must be more powerful.

- Antifreeze liquids are more viscous than water, which is why circulation pumps need more power.

One way or another, the final decision about what is better to choose in your situation: water or non-freezing liquid is yours. Think hard, study the pros and cons, be sure to consider safety issues, and then you can make an informed decision. And what is better: water or antifreeze in the heating system, there is no definite answer to this question; it is always decided exclusively in relation to individual conditions and in a specific situation. And if you can’t figure out all the nuances, it’s better to seek practical advice from a specialist, then it will be easier to avoid mistakes.

Recommendations for the selection and operation of coolants - which one is better to choose

None of the coolant manufacturers will deny the fact that in case of stable operation of the heating system in winter, water is the best option as to which coolant to choose for heating. It is better if it is a special distilled liquid with modifying additives, as mentioned earlier. Those homeowners who consider purchasing store-bought water a waste of money usually prepare it themselves, softening it and equipping the system with the necessary filters.

If a decision has been made to use non-freezing coolants, it is important to have information about the conditions that exclude the likelihood of their use:

- If the house has an open type system.

- When using natural circulation in the circuits: the system simply “will not cope” with such a concentrated coolant for heating.

- The presence of pipes or other elements in contact with the coolant that have a galvanized surface is unacceptable.

- All connecting units equipped with seals made of tow or oil paint must be repacked, since glycol substances will destroy them very quickly. As a result, antifreeze will begin to leak out, creating a real threat to people in the room. You can use the old tow as a new sealing material by treating it with a special sealing paste “Unipak”

- It is prohibited to use non-freezing liquids in systems that are not equipped with devices for accurately maintaining the temperature of the coolant. The heating level, which is dangerous for glycol antifreezes, begins already at +70-75 degrees: these processes are irreversible and fraught with the most unpleasant consequences.

- Usually, after pouring antifreeze into the system, it is necessary to increase the power of the pumping equipment, install a larger expansion tank, and increase the number of battery sections. Sometimes it is necessary to change the pipes to wider ones.

- Incorrect operation of automatic air vents after adding antifreeze has been noticed: it is recommended to replace them with Mayevsky taps.

- Before adding antifreeze, the system must be thoroughly cleaned and flushed. This is done using special compounds.

- To change the level of antifreeze concentration, it is allowed to use only distilled water. In this case, it is better to refrain from even using purified and softened water.

- The correct concentration of antifreeze coolant for heating systems is of exceptional importance. It is better not to count on the winter not being very harsh by diluting antifreeze excessively. It is recommended to adhere to the threshold of -30 degrees even in traditionally warm regions. In addition to protection from abnormal frosts, this will create optimal conditions for inhibitors and surfactants, the effectiveness of which is noticeably reduced with excessive water content.

- After filling with new coolant, it is prohibited to immediately turn on the maximum system mode. It is best to increase power gradually so that the antifreeze has time to adapt to new conditions and elements of the circuit.

- Research shows that propylene glycol is currently considered the most reliable non-freezing coolant. Ethylene glycol is too dangerous, and glycerin is so controversial that it is used very rarely. So it’s better to overpay, but sleep peacefully at night.

Advantages

The use of antifreeze is considered an ideal solution for regions with cold climates. In addition, it is perfect for use in homes where the room is not heated for some time. Antifreeze liquid has increased viscosity. This property can be eliminated by adding clean water in permitted proportions. This allows you to save a noticeable amount of coolant, and therefore money. In addition, circulation pumps will work much longer, since they will not work at full capacity.

Main advantages:

- there is no need to drain the coolant from the system when it is turned off for a significant period;

- all components of the heating system remain filled with liquid, which prevents direct access of oxygen and, accordingly, corrosion;

- additional additives inhibit the formation of corrosion and scale;

- the freezing temperature of the coolant ranges from -30 to -65 - it all depends on the amount of added water;

- heating can be started without any unpleasant surprises in the form of a cracked pipe or anything else.

Important! Anti-freeze helps extend the life of heating system components.

*

Blitz tips

- “Anti-freeze units” are ideal for heating houses that are rarely visited in winter and the system is turned off most of the time;

- Choose special equipment for using antifreeze;

- It is better to purchase radiators with a power 30–40% higher than conventional ones;

- Due to the increased viscosity of antifreeze agents, it is advisable to use pumps with enhanced hydraulics;

- If you need to prepare a solution from the concentrate, use only distilled water for this;

- Do not mix different types of antifreeze; it is better to use one. But if there is no other way out, then first mix them in a container and observe whether a precipitate forms;

- It is unacceptable to use automobile antifreeze in heating structures, since it contains components whose use is unacceptable in residential buildings;

- It is better not to use a concentrate with a freezing threshold of -65 degrees Celsius in its pure form, as this will lead to overheating of the heat exchanger and decomposition of the additives;

- But if the system uses a solution with a freezing temperature of no more than -25 degrees, and the temperature drops below (which is unlikely), then there is no need to worry. The heating installation will not be damaged at all. The antifreeze will thicken, and when the temperature rises, it will return to its original state, without loss of properties.

- To avoid leaks at the sealing joints, you can use automotive sealant.

Manufacturers of coolants

Antifreezes consist of 30-65% glycol, 30-50% distilled water, 3-4% additives that prevent foaming, metal corrosion, and sedimentation. The market offers a wide range of antifreezes designed for the heating system of a country house. They are made mainly from imported raw materials and are sold at approximately the same price. If a product is too cheap, you should doubt its quality. You can check the composition using soda. Since counterfeit antifreezes are mostly acidic, you can mix a pinch of soda with a small amount of coolant. If hissing is observed and foam forms, the product is of poor quality; if no reaction occurs, the antifreeze is good.

Choice for polypropylene pipes

Polypropylene pipes are in great demand due to a huge number of advantages, such as long-term operation, low price, resistance to corrosion, high hardness and low density. They come in two types: some contain aluminum, and others contain fiberglass. In addition, polypropylene pipes provide:

- maintaining high temperature conditions;

- long service life;

- absence of noise during coolant circulation.

What coolant is best for polypropylene pipes? Many options are suitable, which is why it is worth carefully studying the recommendations for use.