Sealant for windows and doors in Moscow

Seals for windows and doors and other products can be purchased at Leroy Merlin in Moscow at low prices. Select the product you are interested in on the website and buy it in our online store. The range of products presented in the catalog is extremely wide. Among them there will certainly be a position suitable in all respects.

All products presented in the “Sealants for windows and doors” section are produced by well-known companies that have proven themselves to be of high quality for their products.

You can always place an order and pay for it online on the official website of Leroy Merlin in Russia. For residents of the Moscow region, we not only have low prices for products in the “Sealants for windows and doors” category, but also fast delivery to cities such as Moscow, Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo, Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye, Dolgoprudny, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Ivanteevka, Dubna, Yegoryevsk, Chekhov, Dmitrov, Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky, Solnechnogorsk, Istra and Zhukovsky.

Classification of sealants by texture: liquid foam rubber, flexible and pile tapes

Based on texture, flexible, liquid and pile types of products are distinguished. Each type of seal is used for specific purposes. Flexible tapes have the form of profiles with a smooth surface. Silicone and rubber are used for their production. This category also includes magnetic gaskets for door structures.

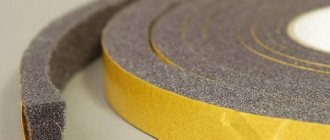

Foam rubber is the most popular material for gluing doors and windows.

Liquid options are used to insulate the fabric. The material is under pressure inside the cylinder. This version of the seal resembles the liquid equivalent of foam rubber. Pile products were among the first to appear on the market. Felt is mainly used for their production. Pile sealants are available in the form of tapes and strands. There are artificial analogues of this material made from synthetics on sale.

Features of using liquid door sealant

Liquid seals are designed to insulate metal entrance doors. The non-standard form of release requires careful handling of the material, as well as compliance with certain rules when applying it. Foam rubber in liquid form is located inside a metal container. The composition is applied to the required area of the structure by spraying. The insulation on the door hardens in a matter of seconds. Therefore, you need to act not only carefully, but also quickly. After hardening, the material significantly increases the thermal insulation qualities of the door structure.

A distinctive feature of the liquid sealant is its dislike for areas with high humidity levels. It is not recommended to use the material where there is constant dampness. Proper spraying of foam rubber requires some knowledge and good dexterity. It is advisable to practice before doing this or entrust this work to professionals, otherwise you can ruin the appearance of the door structure.

Note! Insulation materials in liquid form do not contain harmful substances. This material is not hazardous to the environment or human health, so there are no special restrictions on its use.

Sprayable liquid insulation can be used to seal doors

Characteristics of pile seals for doors

Pile sealants include felt products. You can also find synthetic analogues of this material on the market. Since felt is made from natural animal hair, it provides excellent sound and thermal insulation. Analogs of artificial origin are much inferior to it in these indicators. There are several types of felt. Taking this nuance into account, products are marked in a certain way. All types are suitable for sealing door structures. To properly install the product, you need to correctly cut the material taking into account the size of the canvas.

Advantages of natural felt:

- wear resistance;

- long service life;

- ability to withstand operation in harsh weather conditions;

- environmental cleanliness and safety;

- large margin of safety, the material retains its structure;

- high density, ideal sound absorption;

- fire safety.

In the category of artificial analogues, thin-thick pile strips, which are fixed to the surface using an adhesive base, are in particular demand among buyers. These products prevent dust from entering the living space. Artificial materials are used extremely rarely as a sealant on entrance doors. They are more suitable for compartment-type cabinets.

Pile compactors of various sizes

Description and characteristics

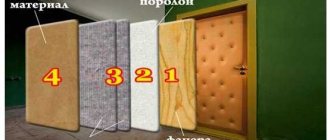

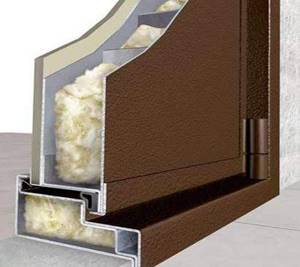

When thermally insulating an entrance door, various types of materials can be used. Each of them has its own thermal insulation qualities and installation methods.

Honeycomb insulation

The material received this name due to the method of installing the filler into the canvas. This technology is very similar to the honeycomb layout.

In the photo - honeycomb insulation for doors

The main material is corrugated cardboard. It is characterized by high rigidity, low weight and an affordable price.

Minvata

This door insulation is obtained from the rock of silicate melts. It is characterized by a fibrous structure, as a result of which the resulting insulation has excellent heat and sound insulation properties. Mineral wool is not afraid of the influence of water, aggressive chemical substances and sudden temperature changes. Additional advantages of the material include environmental friendliness and low price.

The photo shows mineral wool insulation for doors

But such insulation has a number of disadvantages, among which is the settling of mineral wool, which results in the formation of voids. But it is possible to eliminate this problem. To do this, it is necessary to install additional ribs that will keep the mineral wool from crawling.

You can see what self-adhesive insulation with foil looks like and how it is used in the photo in this article.

This information will help you understand how to use a seal for wooden doors.

You can understand which self-adhesive insulation for windows is the most effective if you read the contents of the article: https://resforbuild.ru/paneli/utepliteli/dlya-okon-samokleyushhijsya.html

You may also be interested in knowing which sealant is best to use for metal doors.

Styrofoam

This door insulation material is characterized by low heat conductivity. In addition, polystyrene foam perfectly insulates from noise. The next advantage of insulation is its long service life. If you use the material correctly, it will not deteriorate and retain all its original properties.

In the photo - foam insulation for doors

In addition, one cannot but rejoice at the low price of the material. The disadvantages of polystyrene foam include its susceptibility to combustion. When burned, the heat insulator releases toxic components. But what are the thermal insulation properties of polystyrene foam and how they are determined is described in this article.

Foamed polyurethane

This product is classified as artificial, since its structure is made up of numerous balloons. Using rubber material, you can evenly and tightly fill the voids inside the entrance structure. The advantages of the material include resistance to the negative influence of environmental factors, light weight and environmental friendliness. But what is the price of sprayed polyurethane insulation polynor, you can find out by reading this article.

On the video, self-adhesive insulation for doors:

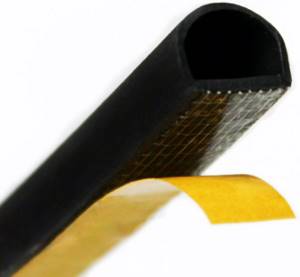

Self-adhesive seal – convenience and practicality

Today, a lot of different sealing materials are offered, but many of them need to be installed in a special way, which is not suitable for all cases and not every person can handle it. Self-adhesive seal for doors or (it can also be used for windows) allows you to achieve maximum tightness with very simple installation.

The practicality of self-adhesives is that you can stick them anywhere. They adhere perfectly to any type of surface, be it wood, plastic, metal. These products are reliable and discreet and do not require any maintenance or other costs. In addition, they will not be able to damage the surface of the products. If you need to remove the seal, this can be done as easily as installing it. In this case, not even the slightest trace will remain on the surface.

And even more - modern sealing materials do not absorb moisture, do not accumulate odors, do not oxidize, do not crack from exposure to direct sunlight, and are not eaten by insects. Seals can be used in extreme temperatures. They can retain their characteristics for a long time.

Corrugated cardboard. Aka cellular insulation

Corrugated cardboard is very often called honeycomb insulation, although this name is not too “connected” with the characteristics of the material and its consumer characteristics. If you look at it globally, this is nothing more than ordinary cardboard, which was shaped into an “accordion” during production. Manufacturers' assurances of the high efficiency of such insulation are, to put it mildly, greatly exaggerated. Insulating doors with corrugated cardboard can be compared to installing an OSB board cut to size in a window opening instead of a metal-plastic double-glazed window - the result is questionable, but effort is still required.

Corrugated cardboard has good thermal conductivity , so it doesn’t “look” very attractive as insulation. It is also not suitable for creating a soundproofing layer, although the cellular structure, which is dominated by numerous folds, should a priori prevent the free penetration of sound waves. If we discard the laudatory reviews of manufacturers about the high thermal insulation properties of the material, in reality it is only a filler that performs the task of filling the empty space in a hollow door.

Technology for installing a door seal: how to glue and secure different types of products

In most cases, a new metal door will already have sealing material. If you don’t have one or need to replace it, you can perform the procedure for installing it yourself, adhering to certain rules.

How to glue a seal on an iron door correctly:

- high-quality door structures usually have special grooves for gluing the seal, which greatly simplifies the process;

- Preliminary surface preparation is required. It is necessary to remove dirt and dust. If the seal is replaced, the remnants of the buffer tape are removed with emery;

- the surface must be degreased. This is done with alcohol, acetone or solvent;

Installing a magnetic seal on a door

- Better sealing will be provided by multi-layer gluing. To do this, the door is sealed with sealant several times. For the structure leading to the entrance, 2 layers will be enough. If the door goes directly to the street, triple pasting will be required (inner side of the canvas - frame - outer side of the canvas);

- When using a self-adhesive seal, you need to check the expiration date of the glue on it, otherwise the product will be unsuitable for installation. It is advisable to take options where the adhesive part is mixed with small particles of fiberglass;

- if the paint on the door has been renewed, then you need to wait at least 20 days before gluing the seal;

- rubber products are attached with silicone glue. To do this, the composition is applied in a dense layer over the tape, after which it must be pressed well to the surface.

Helpful advice! When choosing products, you must pay attention to all labels, check the expiration date, type of material, and carefully study the manufacturer’s information. Only in this case the compaction result will be of high quality, and the profile itself will last quite a long time.

What is it for?

To make you feel warm and cozy at home on cold evenings, it is necessary to insulate your home for the winter. But it is not enough to replace windows with double-glazed windows and seal the walls. Still, the main heat loss occurs through the door. This is what needs to be insulated first. You just need to do this in advance, and not with the arrival of the first frosts.

Insulating a door block is not only an excellent way to retain heat and protect from drafts, but also good noise insulation, as well as protection from condensation and foreign odors.

Self-adhesive insulation: review, types, characteristics and reviews

Currently, self-adhesive insulation has gained high popularity. The reason for this was the properties of the material. It is also worth noting the wide scope of application. It can be used to insulate windows, pipes, walls and other surfaces.

According to reviews, the increased demand for self-adhesive insulation, the price of which depends on the thickness, width and length of the sheet, is also explained by the fact that it can perform two important functions at once: sound absorption and sealing.

This material prevents the formation of drafts, freezing and other things. An equally important property is the ability of the insulation to absorb moisture.

Thanks to its use in construction, heat exchange is normalized, which guarantees maximum efficiency.

What types of self-adhesive insulation are there? What is its main purpose? How to install correctly? It is to these questions that we have to find answers in this article.

Types of insulation

Currently, insulation material comes in the following types:

- self-adhesive;

- roll;

- foil.

The easiest to install is self-adhesive insulation. For its manufacture, different materials can be used, such as:

- PVC;

- polyethylene foamed with foil;

- penoplex;

- foam;

- rubber.

Thermal insulation material can be purchased in the form of plates, rolled tape and mixture.

The manufacturer also took into account the range of colors. Available in brown, white, and black. Self-adhesive foil insulation, the thickness of which is 10 mm, has a high level of durability and copes well with its main purpose - sealing cracks. The cost of such insulation starts from 49 rubles. per m2.

Foamed polyethylene

Foamed polyethylene with foil is the most popular. Now models from Penofol are in demand on the market. This same type of insulation is used most often. It is used both in the industrial sphere and in everyday life. It is necessary in the construction, gas and oil production, and food industries. Options from buy in 99% of cases. This is due to the fact that it supplies foil foam.

Other manufacturers create less effective options. There is no point in using penoplex in its pure form, since it does not give any result. And the reviews confirm this.

Insulation tape

Paper-based insulation is often used for windows. Such models are sold almost everywhere, they are quite popular. Before tape material was invented, regular paper and soap were used. Essentially, this insulation works according to the same scheme. But due to the presence of an adhesive layer, soap no longer needs to be used. Often foam rubber is placed under such tape.

Foam rubber insulation is used to ensure maximum sealing. It is also capable of compressing quickly and to the maximum without harming the surface in any way. Foam models are not only easy to install, but they are also much cheaper.

Insulation film

The last type of insulation is film, which is needed in order to minimize the escape of heat from the apartment through cracks in the windows. As a rule, it is placed only on one side. It should be installed using metal spraying. The insulation should “look” towards the street.

This film can not only protect against heat loss, but also perfectly retain solar color. It is better to use it in conjunction with another insulation option, then complete thermal insulation will be achieved.

Tips for sticking

All self-adhesive insulation can be easily installed independently; this does not require the help of professionals. A separate advantage should be noted that they all have decorative finishing. This means that there is no need to create a special quality during installation.

If we are talking about a roll or tape model, then a detailed installation plan is drawn on their protective films. That is why no difficulties should arise. However, you need to adhere to certain rules when performing installation.

In order for self-adhesive foil insulation, the price of which is low, to adhere as successfully as possible, it must be applied to a clean and dry surface. In addition, it needs to be freed from stains and dust.

If you need to stick rolled material onto a concrete wall, you must first use a primer. After applying it, the surface must be dried. When using insulation on a brick wall, plaster should be used. Immediately after it dries, it should be rubbed with sandpaper and then removed from dust.

There is no need to treat wooden coverings, the main thing is that there is no sawdust on them. You can cut the sealant with a knife or large scissors. Some insulation materials have a measuring grid, which allows you to cut the pieces as evenly as possible.

How can you decorate it beautifully?

The front door is practically the calling card of any home. It shows the owner’s tastes and his financial condition. The door can be decorated differently on both sides so that on one side it looks good with the interior decoration, and on the outside with the cladding of the house.

Entrance doors can be made of wood, plastic, metal, and can also have glass inserts. More unusual options are finished using artificial leather, pieces of genuine leather or stone. Some glamor lovers decorate their canvases with precious stones and crystals.

You can make the door more attractive and beautiful by using certain finishing materials.

Vinyl plastic and laminate

Vinyl plastic is most often used to decorate entrance doors. This is a two-layer panel made of fiberboard with PVC film applied to it. Over the years, vinyl plastic fades, as it is easily exposed to ultraviolet radiation. It also practically does not protect the canvas from external influences. At temperatures below 20 degrees, the film peels off and becomes cracked. But the main advantage of vinyl plastic is the huge number of patterns and shades.

Some vinyl plastic manufacturers use anti-vandal plastic coating. In this case, a large number of advantages appear: the material is almost not scratched, does not fade and becomes waterproof. Thanks to this, it becomes possible to use doors with this coating in private homes. Also, anti-vandal coating can imitate literally any surface.

Another common plastic covering is laminate (hardboard panels with a thin film applied to them). It is simple and unpretentious to use.

Tree

Wood flooring needs no introduction. It stands out for its reliability, and always looks elite and relevant. Some types of such finishing can make a door a real masterpiece. Various types of wood are used for decoration, such as oak, wenge, walnut, etc.

Cheaper doors are called veneered. This is a base made of MDF or chipboard, covered with a thin layer of wood - veneer. Its texture is quite attractive and it is often given shades of natural wood. Doors with wooden or plastic trim have additional thermal insulation, so they rarely freeze.

Entrance doors are also decorated with mosaics in a very elegant and unusual way.

How to attach the seal?

Most often, a new metal door is already equipped with a seal. But if it is not there or replacement is required, then you can install it yourself.

They do this taking into account the following recommendations:

- If the door is of good quality, then it already has special gutters for installing the seal.

- Before installation, the surface must be prepared: cleaned of dust, remnants of old tape (preferably treated with sandpaper) and be sure to degrease. To do this, simply wipe the surface with acetone, alcohol or another solvent.

- For good sealing, it is better to use 2 or 3 layers of sealant. Two are preferable for the door that opens into the entrance, three for the one that opens to the street. The first is mounted on the canvas from its inside, the second layer is installed on the box, and the third is glued to the outside of the canvas. The external one should be the most resistant to any factors: temperature, light, humidity.

- If the surface has been painted, then the sealing of the metal entrance door can be carried out no earlier than after 20 days.

- If the product is made of rubber, it is glued using silicone glue. The substance is applied to the tape in a fairly dense layer and pressed against the surface.

- If you use a self-adhesive seal for metal doors, then the film must be removed gradually, fixing the tape around the entire perimeter of the door leaf. As the tape is glued, it smoothes out.

Don't miss: Installing hinges on a door

The most difficult thing when installing a seal with your own hands is the corners. In them, the tape often wrinkles, comes off, and it is impossible to lay it flat. Therefore, you need to be especially careful in these places. For a more even fit, the rubber seal for iron doors pulls back slightly when gluing. When the product is completely glued, all excess is cut off with a knife.

Even an insulated metal door needs a seal installed to ensure there are no gaps at all. High-quality fittings will protect the room from noise and dust and provide thermal insulation. You should not save when choosing insulation, then it will last a long time.

Installation of self-adhesive seal

On one side of the tape there is a paper strip that covers the adhesive. There is no need to immediately remove it along its entire length. It is better to proceed gradually, opening a small section of the seal and immediately gluing it. It is recommended to use a solid tape, since the gaps provide a bridge for air penetration. It is important to carefully paste over the corner areas of the vestibule. Here the material may lie unevenly.

When the work is finished, the excess tape is cut off. If in some areas the material lags behind or does not hold tightly enough, glue or sealant is applied. This measure will make the structure more reliable, and the seal will not separate from the vestibule when opening.

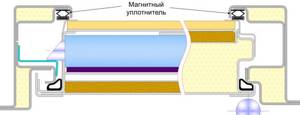

Installation of magnetic seals

This type of product is treated with an adhesive on one side; here the tape is covered with special paper. The seal is a thermoplastic material containing a rigid insert with magnetic properties. You can install it by removing the protective paper. You should proceed gradually, exposing areas of material with adhesive as you attach the tape.

The difficulty of installing such a product lies in the impossibility of installing it in areas with complex configurations, since it will be difficult to bend around the protruding elements due to the presence of a rigid magnetic insert inside. In addition, it must match the parameters of the door. So, if the magnet intensively attracts the sash, it will be difficult to open it, and if the force of attraction is low, on the contrary, it is impossible to provide sufficient pressure.

Installation Tips

Let's figure out how to properly install a seal on a metal door.

First, the old sealing material is dismantled. Surfaces are thoroughly cleaned. To do this, it is advisable to use fine sandpaper. At the end of the preparatory work, the ends of the door are washed with an alcohol solution or acetone, which helps to degrease the surfaces.

Often a metal door is installed at the entrance to a room. In this case, it is recommended to install several layers of sealant. This approach allows for the most reliable sealing of joints. Several contours are superimposed on the door frame and the inner edge of the leaf, while the remaining one is mounted on the outer surface of the door. At the same time, the main requirement for the quality of the external seal is: resistance to mechanical damage, temperature changes, and moisture.

Installation of rubber products is carried out using glue. How to properly stick a seal on a metal door? During the work, the surface of the tape is gradually covered with a binder as it is applied to the end and pressed tightly against the surface. If it is necessary to install a rubber product on a painted base, at least several weeks must pass from the moment of painting.

The simplest solution is to install a self-adhesive seal. For installation, it is enough to remove the protective strip that covers the inner surface of the product, and then evenly distribute the material along the edge of the door leaf. If the seal begins to sag as it is used, it is worth additionally securing it with glue or sealant.

It is not recommended to use separate pieces of material during installation. Such actions entail poor-quality sealing of joints. Particular attention should be paid to sealing the corners. This is where the risk of wrinkling and insufficient adhesion of the material increases.

Preparing for work

Before starting work, identify the causes of the draft. A well-known way to find cracks through which cold air enters is by burning a candle. Heat leakage may be caused by improper installation. In this case, the canvas does not fit tightly and you can fix it yourself. Adjustment is carried out using awnings. Sometimes the cause of a draft is a worn or damaged seal.

How to properly replace a seal

The rubber seal is an important detail in the design. It's easy to replace, but you need to take the measurements correctly. By measuring the perimeter of the box, you will know what length of seal to purchase. To find out the thickness of the elastic, measure the gap between the canvas and the box.

When the seal is too thin, gaps remain. When the thickness is greater than necessary, the door does not close well.

A piece of plasticine wrapped in a plastic bag will help make the measurement easier. Press the plasticine against the door and you will see how thick the seal you need.

It is better to choose a black seal, because the dye reduces its service life.

It is easy to glue the seal. One side of the elastic is covered with a sticky compound, from which the protective strip is removed and glued. After this, the canvas is insulated.

Sequence of work

In order to insulate a metal entrance door, you will need the following tool:

- tape measure and pencil;

- screwdriver;

- electric jigsaw;

- self-tapping screws;

- polyurethane foam;

- universal glue.

Let's take a closer look at all the stages:

- The structure is removed from its hinges for greater convenience.

- Remove the lock and handle using a screwdriver or screwdriver.

- Remove the inner sheet of decorative trim. To open the door, use a screwdriver or a regular knife. This only applies to blocks with a split design.

- Using a knife, cut out pieces of foam plastic of the required configuration so that they fit tightly between the stiffeners.

- The resulting foam blocks are smeared with glue and glued to the canvas.

- The remaining gaps between the insulation and the ribs are filled with polyurethane foam.

- After the foam has dried, the sheathing is reinstalled.

- Put the lock and handle in place and hang the canvas on the hinges.

The task will become more complicated if the block is one-piece, for example, made in China. In this case, the metal door can only be insulated using outer skin, which is mounted directly on top of the metal sheet.

- The canvas is removed from the hinges, the lock and handle are dismantled.

- An electric jigsaw is used to saw off the slats from which a wooden frame is made. The width of the slats is 3 cm, the thickness is 2 cm.

- Screw the wooden structure to the metal panel with self-tapping screws.

- Insulation blocks cut to size are glued to the canvas and wooden frame.

- Cracks and empty spaces that are not filled with polystyrene foam are filled with polyurethane foam.

- After the foam has completely dried, a pre-cut fiberboard or MDF sheet is screwed to the wooden frame with self-tapping screws. To make it lie more evenly, it is better to start screwing it from the top.

- The inner lining is sanded and decorated with oil paint or another method.

Insulation

By completing the work consistently and carefully, you will end up with insulated iron entrance doors.

Mounting types

There are sealing elements with self-adhesive tape, with magnetic fastening, and also with an additional clamping mechanism.

Magnetic seals

This new product appeared on our construction markets relatively recently, but has already become quite popular.

A magnetic seal for metal doors is a special frame that exactly follows the contours of the door opening. The product consists of a special magnetic insert, as well as a soft sealing part. The material used is thermoplastic elastomer. It has several advantages - after the product is worn out, it can be sent for recycling. In addition, thermoplastic elastomer is highly resistant to adverse factors and temperature changes.

Magnetic seals are also resistant to ultraviolet radiation and moisture, reliably protecting the room from extraneous noise and drafts, dust and dirt. With these elements, the door will close quietly, and powerful magnets will attract the metal leaf to the door frame, thereby ensuring high tightness and silent closing.

For metal doors, triple seals should be used. The first two are located on the canvas, and the third is on the door frame.

Advantages and disadvantages

The thermoplastic elastomer door seal has the following characteristics compared to other similar products:

- durability of the material - designed for a service life of over 11 years under systematic loads;

- does not lose its original properties during operation;

- the material is able to reliably protect residential and other premises from dust and other negative factors

- elasticity and softness of the sealing element;

- the product is distinguished by a set of good qualities and soft shock absorption;

- with the help of fittings they hide defects in the installation of the opening, for example, gaps or backlash when closing;

- with the correct calculation of the magnet power, the doors will close without additional effort.

Magnetic seals have the following disadvantages:

- Features of the product require accurate calculation of the magnetic force. If magnets are installed stronger than necessary for the opening, difficulties will arise when opening. Especially when there are small children in the family. If the magnet is weak, the door will open freely.

- The seal has a high price level in comparison with other products of this type.

- It cannot be repaired on your own; if there is a problem with the doors, you will need to call an installation company employee.

Don't miss: Replacing locks on an iron entrance door: step-by-step actions depending on the type of locking mechanism

Principle of operation

The operating principle of a metal door seal is that during the closing process, the doors are attracted to each other by built-in magnets with opposite poles. This connection ensures a complete fit of the frame to the canvas, which guarantees the tightness of the structure better than self-adhesive rubber material.

Magnetic elements are installed on an iron or steel type of canvas.

Installation of magnetic seals

This process will not take much time and will not require any special skills. Of course, it is better if professionals do this. Such systems are installed on canvases where there are no decorative elements.

Although this seal for metal doors has many advantages, it is not suitable for everyone. The main thing is to choose the right strength of the permanent magnet so that children do not have any difficulties.

How to choose a seal for a metal door?

The first step is to decide on the size of the tape, its type and shape. Most often, this fittings are sold in rolls of 6 meters, which is quite enough for a standard entrance door. But for good insulation, several layers of sealant are used, this must be taken into account immediately when purchasing.

Tips for choosing a seal:

- The required thickness and shape of the tape is selected for the door itself and the resulting gaps. The easiest way to do this is with a piece of plasticine. It needs to be wrapped in film (bag) and inserted into the gap between the box and the canvas when the doors are closed. After this, you can measure the required thickness of the seal.

- If the thickness of the gap is insignificant (from 1 to 3 mm), then you can choose a seal for rectangular metal doors made of polyvinyl chloride or polyethylene foam.

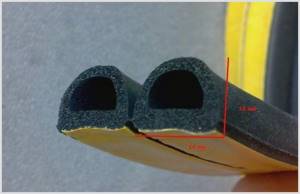

- If the size of the cracks is more than 3 mm, then you need to buy rubber material. Its shape can be different, which is determined by its thickness. The thinnest ones up to 3 mm have the appearance of an E or K profile (reminiscent of these letters in cross-section). If the gap is up to 5 mm, then you should opt for P or V-shaped products. D or O shaped profiles are used for the largest gaps from 5 to 7 mm.

- It is better not to purchase a foam rubber seal for a metal door. Iron entrance structures are installed at the entrance of the room, they are often opened and closed, and foam fittings are short-lived.

- If the seal is not self-adhesive, then you need to immediately buy good quality silicone glue for it.

In addition to these characteristics, the color of the material is also important; it is selected depending on the design of the door. But the most successful product is considered to be black: no dyes are added to it, and they usually reduce the quality of the product. It is the black seals that are installed on the outer door, where the insulation requirements are maximum.

What to look for when purchasing?

When choosing a seal for steel doors, you need to carefully inspect it and check its quality.

In particular, you should perform the following actions:

- Read the label on the product, which indicates the expiration date, all the necessary information about the seal and the material used for its manufacture.

- By pressing it is worth checking the elasticity and tightness characteristics. The material should be medium hard, then it will not interfere with the door closing well. When pressed, it should quickly restore its original shape. This is a sign of high quality material.

- If the seal is on self-adhesive tape, then you need to find out the expiration date of the glue. Otherwise it could just dry out. Also, small particles of fiberglass should be applied to the adhesive part.

Most often you can find such products on sale from Germany, Sweden, Poland or Turkey. A good product should not harden when the temperature drops, or peel off when it fluctuates; release toxic compounds into the air.

Preparatory work

To insulate the door leaf, you should go step by step, stage by stage. This approach allows you to achieve good results and eliminate errors. And first there is preparatory work to be done.

To ensure that nothing interferes with the work, you need to remove the door leaf. This is done using a mounting tool or a nail puller . It is enough to pry the canvas from below and it will rise from its hinges. If the rotary axis is slightly rusty, then it must be lubricated with machine oil. After this, with small forward movements you can move the hinge and remove the door leaf.

When the door is outside the frame, all existing elements must be removed from it. The hinges, handles, peephole and lock are carefully unscrewed and put aside. If the door is not made only of wood, then it is necessary to remove the sheet of inner lining to gain access to the interior of the door leaf.

Application

Door insulation can be glued in several ways. To understand which one is right for you, you need to consider them separately.

Along the perimeter of a metal door

If the door does not fit tightly to the door frame, then gaps will appear when it is closed. It is because of them that cold air will come in from the street.

To solve these problems, it is necessary to evaluate the evenness of the door frame and the operation of the hinges. Perhaps the reason for the penetration of cold lies in the misalignment. After this, install insulation around the perimeter of the box. It will have a strip of rubber or foam. This type of insulation can be used for wood, metal and metal-plastic materials.

Video of insulation around the perimeter of the door frame:

The advantages of the method include ease of installation, low cost of materials and efficiency. The disadvantages of this installation include low durability.

Insulation of the door frame

To insulate the door frame, it is necessary to seal its internal space using the selected heat insulator. This insulation option is often used for iron structures. It is this kind of door that quickly cools and freezes.

The inside of the door is represented by several compartments. They are separated by stiffening ribs, lock design and other elements. Place the material inside the box. In this case, it is worth using insulation that is light, reliable and resistant to fire.

Most often, mineral wool and polystyrene foam are used for these purposes. In addition to thermal insulation, the inside of the box must be covered with polyethylene film. Seal all cracks with sealant.

Video: rubber insulation tape for the front door

On video, self-adhesive insulation for metal doors:

The advantages of this method include high efficiency, low price of materials and excellent thermal insulation properties that the entire box receives. The only disadvantage of thermal insulation is that it is very difficult to open the door without the help of a specialist.

External door insulation

With this insulation option, mineral wool insulation is installed on the outside of the door structure. In addition, you need to attach a protective coating. For these purposes, you will have to use leatherette or a leather substitute. Today you can also buy material made from genuine leather.

You can carry out work of this kind yourself. Before insulating the entrance structure from the outside, you need to assess its integrity. Be sure to also calculate where the door peephole will be located. By using this option for installing insulation, you can save personal time and not pay money for unnecessary material.

Video of external door insulation:

Cutting and laying insulation

The next stage of insulating the door leaf will be laying material that will make it warmer . To do this, you need to arm yourself with a stationery knife. Thermal insulation is cut to the length and width of the sheet so that there is no empty space left. If the door is a frame with voids, then they need to be filled with insulation.

The insulation is tightly inserted between the bars

All pieces must be tightly inserted between the bars to prevent the formation of cold bridges. At the same time, the material should not bubble, which would indicate an excessively large supply. In this case, it is worth cutting off a little excess material. Once everything is adjusted, you need to secure the insulation with staples. A construction stapler allows you to do this quickly and efficiently.

Types of seals for iron entrance doors: classification according to installation location

Existing products can be classified by location. Depending on the installation area, seals are:

- threshold;

- contour;

- fire protection.

Threshold varieties are not only magnetic. Most often, such seals are equipped with an automatic control system. Thanks to this, the profile can be “adjusted” to the size of the gap that forms between the floor and the door leaf. Moreover, both in the open and closed positions. These seals are used in cases where the door structure does not have a threshold to prevent the formation of drafts.

Contour products are the simplest and most common. During installation, they are fixed around the entire perimeter of the door frame or leaf. This allows you to eliminate all existing gaps and cracks. Contour options are ideal for entrance doors. In such cases, it is advisable to use products with a triple profile.

Important! Three-circuit seals are installed on fire doors. Such products significantly increase the thickness of the door leaf and its weight. For this reason, it is advisable to strengthen the box and install particularly durable fittings.

Placement of the door seal on the threshold

In rooms with a high level of fire hazard, it is advisable to use a special type of contour seal - thermally expanding. Exposure to heat or smoke triggers a chemical reaction. The material foams or expands, preventing air from entering the room. Due to lack of oxygen, the fire decreases. These products are called fireproof.

We insulate the threshold

Insulating a wooden door with your own hands also means repairing the threshold. Therefore, having compacted the structure, we move on to the bottom of the box. If the threshold has already outlived its life and is rotten, it should be completely dismantled. Now you need to install a new one: first, a wooden beam is selected, cut to size and mounted in place of the old element.

The standard threshold can be replaced with a leatherette roller. In modern interiors such products are used very often. The threshold roller, as in the case of insulating the perimeter of the box, is made from foam rubber. It is necessary to create a structure whose width, length and height will allow the bottom of the box to be insulated. The foam rubber is wrapped in leatherette and mounted in place of the threshold. It can be secured using construction nails. In the video you can see how to insulate the threshold of a wooden door with your own hands.

Which one is suitable for a Chinese metal door?

Such designs are of poor quality, so they gradually lose their shape and dents appear on the surface. It is better to use a rubber seal on a metal entrance door. If the gap is minimal, it is permissible to use a foam strip. To prevent the material from failing ahead of schedule, it is recommended to apply an additional layer of glue to the rubber tape, which will ensure increased reliability of fastening. If the seal is made of foam rubber, it is better not to do this, otherwise it will be difficult to dismantle it.

How to find where the cold penetrates

There can be several channels.

Canvas

It shouldn't be too cold. Under normal conditions, the inner plate is heated by the room. A surface with a low temperature, ice, frost and condensation are signs that the sash is conducting cold. The larger its area, the more intense the cooling of the room. One of the reasons is the low quality of lining and filling. Chinese and domestic manufacturers are trying to make their products accessible and supply kits at low prices. This affects the quality. Even if technical standards are met, the level of insulation may not be sufficient.

The layer installed from the inside may have defects. When wet, its throughput increases. Moisture gets inside if the production technology is violated or due to the lack of waterproofing, which protects the pores and fibers from steam in the air. Leaks occur through cracks between soft slabs.

Types of sealing strips for doors by configuration type

Existing types of products are classified according to different criteria. They differ in material, shape, color, size and purpose.

There are several types of configuration:

- Tape - soft products in the form of cords about 9 mm wide. The section of the tape has a rectangular shape.

- Tubular - widely used as a seal for iron doors, although the ability to seal the structure is much lower than that of strip doors.

- Groove - made in the form of soft rubber profiles, they are hollow inside. On one side of the products there is a brush, which facilitates the installation of the seal in the groove.

- Mortise - designed for door structures made of wood. Installation is carried out in a pre-cut recess in the box.

- Spring - products are installed not on the door, but directly on the frame. The area where they are installed must have a perfectly flat surface, otherwise the seal will not be able to fully perform its function.

- Folding - intended exclusively for doors with a folding leaf. These include interior structures such as a book or an accordion.

Grooved rubber seals

A rubber profile with a complex configuration is considered a universal option. It is installed on both entrance and interior structures. Available in several types of rubber with varying degrees of density. Standard width is from 8 to 10 mm.

General tips and tricks

When you decide to insulate your front door, don’t miss the slightest nuance:

- Locate the location of the heat leak.

- Having found the source of the leak, choose a method of insulation: upholstery or sealing cracks. It's better to use both methods.

- Check the door itself. Perhaps it just needs to be replaced with a new product.

- When insulating the door leaf itself, do not forget about the other components of the door block.

- If you decide to install a second door as insulation, make sure it looks nice.

Watch the video on how to insulate your front door with your own hands.

Seals for entrance doors: features and advantages of use

A seal for a metal entrance door is a flexible product in the form of a small strip or tube. It is installed in the gap between the door leaf and the frame around the entire perimeter. Thanks to its easy and simple fixation, the material has a wide range of applications. It applies to pasting window frames, interior doors, compartment-type cabinets, and vents. With a high-quality seal, the front door takes on a finished look. This product eliminates a large number of shortcomings in its design.

All rubber seals differ in type and method of installation.

The material is universal because it can perform several functions simultaneously:

- protects interiors from drafts;

- prevents the penetration of dust and odors from the outside;

- ensures the tightness of the structure;

- used as door insulation;

- provides sound insulation;

- dampens the door leaf, reducing the noise level when closing.

Note! The insulation is able to compensate for minor defects in the door leaf, for example, small errors in size, bends of sheet metal, providing a more comfortable and tight closure.

Thermal Insulation Benefits of Door Gaskets

The main purpose of door seals is to eliminate gaps and cracks, preventing wind and cold air from entering the room. This is an indispensable attribute of structures in a private house facing directly onto the street.

If the door is made of wood, it will react sensitively to dampness and moisture during the rainy season. During the hot season, the material is susceptible to drying out. Under such conditions, the door frame is greatly deformed and the tightness of the door leaf is lost. You can replace the structure with a new one, but such an undertaking will cost a pretty penny. There is a budget option for solving this problem - using a seal, which can be easily and quickly replaced if necessary. It will retain heat in the room and extend the life of the door structure.

Door seals provide additional thermal insulation

As a door insulator, the gasket acts on both sides: it limits the entry of cold air from the street and retains heat from the inside. If the design does not have a seal, then the efficiency of heating devices is reduced by 40%. That's how much heat goes out. Taking into account heating prices, without installing insulation, the owner loses a large amount of money, especially in the winter months.

Soundproofing benefits of door seals

The noise-insulating properties of the products are useful if there is a construction site, a railway or highway, or a children's playground near the house. In such an environment, residents will suffer from noise due to insufficient sound insulation. The shock-absorbing properties of rubber seals for doors reduce the impact force if the door is suddenly closed due to a draft. Usually such a servant is heard not only by the residents of the house, but also by the neighbors.

In this case, the seal performs two functions at once:

- Softens the blow, absorbs unpleasant sounds.

- Extends the service life of the door structure, because strong claps contribute to rapid wear of hinges and other parts.

The shock-absorbing properties of products for metal doors are especially beneficial. These structures make a lot of noise during operation. The issue of choosing a high-quality seal with good soundproofing properties is relevant for city residents. Large cities are active both during the day and at night. In order not to suffer from city noise around the clock, it is advisable to choose products that provide enhanced sound insulation.

Sealing tape can prevent dust and noise from entering the room

Note! High-quality products can withstand temperatures ranging from -65 to 95°C. Having made the right choice, you don’t have to worry about the material cracking if it’s severely frosty or, conversely, hot outside.

General recommendations

When deciding to insulate your entrance doors, take into account all the details:

- Find where the cold is coming in.

- After this, decide which method of insulation you will use: door trim or sealing holes. It's best to use both methods.

- Inspect the entire door. It is likely that the blade needs to be replaced.

- When insulating a door, do not lose sight of other structural elements.

- If you decide to install a second door for insulation, take care of its beauty.

- By taking these steps focused on door insulation into account, your home will always be warm and cozy.

How to choose a seal for different types of doors

When purchasing a seal, you must first take into account the type of door and where it will be used. This is important because the choice of a product with certain properties and characteristics depends on the operating conditions.

Seals can be installed on different types of doors:

- Input - predominantly a tubular version made of rubber is used. If you have a good budget, it is possible to install a magnetic door seal.

- Glass - products made of aluminum and silicone.

- Plastic - rubber types of products with a special configuration and groove type of installation.

- Interior - foam rubber products on an adhesive base and brush seals for compartment-type doors.

Important! It often happens that only one seal is suitable for a specific model of plastic door. In such cases, it will not be possible to find an analogue. Therefore, when choosing doors, you must check whether it is possible to replace the seal on the front door with products from another manufacturer. Otherwise, in case of repairs, you will have to update the entire structure.

Self-adhesive tubular seal for entrance door

Features of tape self-adhesive door seals

The simplest and most affordable product option. It is produced in the form of a self-adhesive film of different thicknesses, on top of which foam rubber is fixed. Fixation of the adhesive base depends on the type of door where the tape will be installed. Wallpaper nails are used for wood structures. If you need to install products on a metal door, the optimal solution is an adhesive with an increased safety margin, which is designed specifically for this type of material.

Foam tapes have several disadvantages. Firstly, they do not have good thermal insulation properties. Foam rubber has a porous structure. This feature of the material is clearly visible on tapes with a large width. Air passes freely through the holes in the foam, so the products can let cold currents into the room. Due to weak thermal insulation characteristics, foam rubber tapes are not recommended for use as a seal for metal doors. They are more suitable for interior structures inside residential premises.

Secondly, foam tapes are short-lived. The material is not resistant to wear, so products quickly lose their properties and become unsuitable for further use. In this case, the tape is replaced.

Characteristics of tubular rubber seals for doors

Externally, rubber products resemble a thick rope of dense material. There is a fairly large cavity inside it. Thanks to the special structure of the tubes, as well as the high strength of the rubber, the door leaf fits as tightly as possible, without forming cracks or gaps between itself and the jamb. Manufacturers use porous rubber to make tubular seals. This type of material retains heat well indoors and has increased sound insulation properties.

Tubular P-shaped seal for doors

Self-adhesive rubber seals are often found on sale. Thanks to this, the installation process of products is significantly simplified. The rubber itself is quite durable; the service life of the adhesive base is much shorter. By the time it expires, the bonding compound dries out and the material simply falls off. Despite this, the rubber seal can last for several years. After this, the product can be easily replaced with another.

Helpful advice! It is advisable to select a rubber seal for a door with an average level of hardness. If you install a product that is too soft, it will wear out very quickly. Very hard material will prevent the door from closing properly.

Magnetic seals for metal doors

Magnetic products represent a kind of frame. It completely follows the contour of the door. The frame is carefully adjusted to the design down to the millimeter. This type of sealant is considered the highest quality and most effective because it has a high strength index. For this reason, experts recommend using a magnetic seal for metal doors. The product consists of two parts. One of them is made of soft TEP material (thermoplastic elastomer), the second has the form of a magnetic insert, which ensures the attraction of the metal sheet and smooth closing without unnecessary noise.

The cost of a self-adhesive magnetic door seal is quite high. During the installation process you will need to strictly adhere to the technology. But this type of product can effectively serve for a long time, thanks to its increased resistance to wear. In addition, it provides a good level of shock absorption. When closing, the door makes no noise and seals perfectly. There are absolutely no cracks or gaps.

Magnetic seal is used for metal doors

The disadvantages of the material are related to its magnetic properties. If you incorrectly calculate the force of attraction, the door will fix too weakly or, conversely, additional physical effort will be required to open it. If you go too far with this, the child will not be able to use the door without the help of adults.

Aluminum and silicone seals for interior glass doors

Glass sealing products are produced exclusively for doors made from this material. They exactly match the dimensions of the structures for which they are intended. The profile shape of these seals is individual, the cross-section depends on the characteristics of the door leaf. To create such products, manufacturers usually use silicone. The material is quite soft and has good flexibility. Copes perfectly with the function of retaining heat. An adhesive base is not required to fix the silicone seal. To secure the product, just moisten it with water and immediately press it on the desired area of the door.

Note! Silicone, which is used to make door seals, has special properties. The moistened material sticks firmly if you hold it pressed against the glass for some time. Such good adhesion to the surface cannot be provided by conventional gaskets with an adhesive base.

Aluminum profiles are less popular. To install them, you need to additionally use door sealing rubber, which complicates the installation process and increases its cost.

Silicone rubber seals for glass doors

Silicone seals are widely used to seal doors leading into high humidity areas, such as the kitchen or bathroom. They are ideal for shower stalls with sliding or hinged glass doors. There are combined versions of products on sale - magnetic with silicone inserts.

Brush seals for interior doors

The brush seal is called a Schlegel. The product has a tape at the base with a pile attached to it. Various materials are used to make bristles:

- nylon;

- felt;

- natural bristles;

- silicone;

- metal wire;

- polyethylene.

The width and density of the bristles, as well as the colors, may vary. Their height varies over a wide range - from 3 to 15 mm. The materials used for the production of bristles are resistant to ultraviolet radiation and are characterized by chemical neutrality. The tape itself can be plastic, metal, or sometimes made of polymers. There are products both with and without an adhesive base.

Brush seals can be used for interior doors

In addition to their general functions, schlegels prevent insects from entering the room and can also be used as seals for sliding doors installed in a closet. They are also used in swing structures, when it is necessary to eliminate the gap that forms in the lower part between the sash and the floor. In this case, the seal replaces the threshold.

Related article:

Replacing a door lock: causes of breakdowns and detailed instructions for eliminating them

Common causes of lock failures. Types of castles. Replacement of cylinder, lever and crossbar devices. Replacing the larva. Advice from professionals.

For each type of door structure there is its own type of schlegel:

- Metal and wood sheets are self-adhesive seals.

- Glass sashes are products with a U-shaped profile.

- Windows and some types of doors are sealed with a groove type of installation.

Helpful advice! For sliding doors in interior doors and wardrobes, experts recommend using schlegels with short and dense bristles. It is advisable to select the colors taking into account the interior, so that the buffer tape is not too conspicuous.

Successful examples and options

Let's look at the ideas for insulating entrance doors described in this article:

- Insulating the door with dermantine, decorated with rhombuses.

- Option for a door made of natural wood for a country house.

- This model is also suitable for a country house. It is distinguished by its elegance and high cost. Made of veneer and decorated with glass insert.

- Genuine leather is used to insulate the door. A very beautiful and harmonious option.

- And finally, doors finished with laminate. They look quite solid and reliable.

How to insulate a bathhouse door with felt

Most often, felt is used to insulate door and window frames, as well as for external door insulation. The fact that the material is environmentally friendly and that it breathes allows it to be used even in baths at high temperatures and humidity. Let's look at insulating a bathhouse door with felt from two angles. The first will be the insulation of the box.

This technique is applicable for both entrance doors and the entrance to the steam room. In both cases, insulation for felt doors is laid around the perimeter of the frame at the junction with the movable part. To do this you need:

- roll the felt into a small roll;

- on the side where the edge is visible, the roll is laid around the perimeter of the box;

- fastened with nails or a stapler.

No additional protection is needed. If you need to insulate the front door with felt, then you need to take the panel and secure it to the outside. Then, using furniture nails with beautiful caps, fasten the material you like (usually a leather substitute) over the insulation. The main thing is that the finish is resistant to atmospheric aggression.

A two-pipe heating scheme for a two-story house can be either vertical or horizontal. At the same time, there may also be several methods for laying out horizontal contours for each floor. Some of them: hitching, dead-end, collector.

Heating a country house is somewhat different from the main home. You can read about the best way to heat your dacha in winter in this article.

Do-it-yourself insulation for a bathhouse door - thermal curtain

A thermal curtain will help to effectively ensure thermal insulation of the dressing room.

Make a sealing frame on the inside of the door block. Cut the insulation into strips (2 strips measuring 10 cm * 100 cm and 2 strips 10 cm * 200 cm are enough). Nail them along the perimeter of the door frame 2 cm from the edge, placing them towards the door.

With a standard door size, nail wooden blocks on top of the insulation: two measuring 2x2x184 cm, and two measuring 2x2x80 cm. Wrap them with strips of insulation, cutting off its excess and press it on three sides with cash.

From thick fabric, tarpaulin or leatherette, make a continuous screen measuring 120 * 200 cm. On one side, sew it along the entire height so that a block measuring 2x2x200 cm fits inside this flap.

The other side must be attached to the wall, 10 centimeters from the cash. Cover the edge with a decorative strip. Sew metal rings at the top of the fabric.

Now the final stage of making a thermal curtain for a bathhouse door with your own hands - screw a self-tapping screw above the rail, leaving a 2 cm end outside, to which you should attach a strong wire.

We stretch it through the rings of the screen and secure it with another screw above the door block parallel to the cashing. To the left of the door, attach two springs or rubber bands from a bicycle inner tube, providing them with hooks. Sew rings onto the screen at the level of these springs. The work is done.

When not in use, the screen is located to the right, behind the door. When you enter the bathhouse, move it to the left, securing it to the hooks; the fabric will fit tightly to the sealing frame, blocking the access of cold air.

What is a seal

It is a flexible material that has the shape of a strip of small width and provides a seal between the door frame and the leaf itself. Its fixation is mainly carried out on entrance doors, although due to its versatility it is well suited for a large number of other tasks, for example, for gluing vents, window frames and other things.

The seal is easy to install, since most of the material is fixed to the metal using an adhesive mixture, the layer of which is located on one side of the product. Its installation is always carried out around the perimeter of the door leaf. In some situations, they may have a special groove, which has optimal dimensions for securing the seal. It is not necessary to fix the material in this way, since it holds well even on flat metal, fulfilling its main function.

We insulate an iron door with foam panels

As a rule, for the manufacture of metal doors, sheet material is used, which is welded on the sides with parts in the form of corners. There are voids inside the products that need to be filled to provide additional insulation.

Follow the following pattern:

- Take measurements of the door leaf. Measure the length and width. Based on your measurements, cut out a fiberboard panel that will cover the foam layer.

- Transfer the dimensions of the door onto the plywood, mark the location of the peephole and handle. Cut openings for these elements.

- Place the panel on the door and check if all the measurements taken match.

- Take a well-sharpened knife and use it to cut out sheets of polystyrene foam. This type of insulation is attached to the base using silicone.

Advice ! The size of the corner affects the thickness of the foam.

- Cover the foam with a fiberboard panel. Screw it using a screwdriver and self-tapping screws to the base of the door.

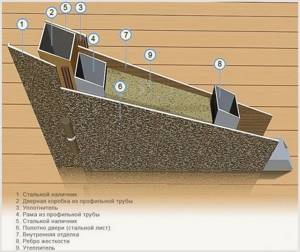

- Please note that the metal door stiffeners are made of a hollow tube that freezes in winter. To eliminate the “refrigerator” effect, take a drill, make a hole in it and fill it with construction foam.

Important ! If you want to insulate a wall, the gaps between the foam plastic can be filled with polyurethane foam.

Related article:

Landscaping a blind area at home: tips for gardeners

What are the types

To seal the ledge of a metal sash, several types of products are used, differing in the type of material:

- rubber;

- polyethylene foam;

- foam rubber or polyurethane foam;

- plastic;

- silicone

The rubber seal lasts a long time, is less susceptible to external factors: it does not allow air to pass through, is non-hygroscopic, and is not prone to cracking. This is a flexible material that is offered at an affordable price. With its help, it will be possible to eliminate drafts, but care should be taken to increase ventilation in the room by forced means, since the use of airtight materials helps to weaken air circulation.

Silicone seals do not contain harmful substances and are elastic. They are often used in steel structures, for example, in entrance doors in facilities such as hospitals, schools, kindergartens. The products represent a group of hypoallergenic materials, for this reason they are recommended for installation in rooms where there are children.

If we consider a polyethylene foam or polyvinyl chloride foam seal, this option is flexible and soft. However, it does not last long due to the high degree of abrasion. It is better to use products of this type to seal interior doors, or you will have to change the sealing tape on the metal entrance door ledge more often. Plastic products are in less demand.

There are three types of seals, differing in the method of fastening:

- Self-adhesive - an adhesive substance is applied to one side of the product.

- With clamping system.

- A magnetic seal for metal doors is more suitable. It consists of several circuits, one of which must be attached to the frame, the rest - to the sash. If the magnetic properties of the tape are strong, the door will be difficult to open.

Classification by seal configuration:

- if the leaks do not exceed 3 mm, use a C-, E-, K-shaped profile;

- for structures with gaps from 3 to 5 mm, a V-shaped version of the product is suitable;

- For doors with leaks from 5 mm, O- and D-shaped profiles are used.

If the gaps are small (1-3 mm), use rectangular material.

Rubber products: advantages and features

The seal for metal doors of this type is highly resistant to various external factors, as well as durable.

Among the advantages of installing these products are a high level of moisture and air impermeability, high resistance to ultraviolet radiation, prolonged exposure to precipitation, and temperature changes. These elements also have a long service life and low price. Even in the worst conditions, the rubber will not crack.

Don't miss: How to clean polyurethane foam from a metal door

They are made from special oil- and acid-resistant rubber of food or high-tech quality. The composition uses special modifiers that provide the material with high durability even in harsh conditions. Also, these elements can be made of special porous rubber. It retains heat much better than usual. Often, such solutions are self-adhesive, which greatly simplifies installation.

In most cases, such a seal is a hollow and fairly dense profile. Due to the fact that the rubber is thick, a reliable and tight fit of the door leaf to the frame is ensured.

Silicone

A seal for a metal door made of silicone is, according to some indicators, inferior to rubber products. This material is characterized by increased elasticity, so the seal can be installed on surfaces of different textures.

But the disadvantage of silicone products is the inability to modernize the composition with special additives, which could slow down the destruction of the floor structure under the influence of moisture, sunlight, and temperature changes. Thus, silicone products are extremely rarely used for sealing external doors.

Foam rubber

Foam rubber sealing is the most cost-effective solution. Often they resort to its use with the expectation of serving for one season. Such products can no longer withstand regular use of doors.

An old foam rubber seal often begins to disintegrate and crumble under the influence of humidity and sudden temperature changes. Over time, the material clumps into a lump, loses its original elasticity and ultimately ceases to cope with the assigned tasks.

Polyurethane

Such products are easy to install, as they are equipped with a special adhesive layer. These elements are very rarely installed on metal doors - they do not have the necessary characteristics. In addition, the material is too dense and not durable for an entrance door. However, such products are characterized by a low price.

Plastic

Plastic seals have increased sealing properties. Many of these products have a hollow internal structure. Due to this feature, it is possible to obtain an additional sealing contour as an air gap along the edge of the door structure. Thanks to it, thermal energy is conserved in the room.

We recommend that you familiarize yourself with the information about standard door frame sizes in this material.

Plastic products are affordable, but the installation process can cause certain difficulties. The reason is that the seal must be mounted in the groove. Hence, it is necessary to select products individually according to the design features of a particular door.

The most popular types

The most commonly used are rubber and silicone products. A foam rubber seal is also in demand, but it is used if the gap is not around the entire perimeter of the sash or it is too small. Then install the foam tape. It can be strongly compressed, which will eliminate leaks in the desired areas, without preventing the door from closing.

Advice from professionals

The following recommendations from experienced craftsmen will help you avoid common mistakes when insulating a wooden front door:

- It is more effective to use heat-insulating material on both sides.

- You should choose consumable components from trusted manufacturers.

- The selected material must have high performance characteristics.

- The outer cladding must be resistant to precipitation.

- Each stage must be treated with full responsibility.

In the video on how to insulate a door with leatherette with your own hands, you can get acquainted with some of the features of the work:

Dimensions and shape of door seals: D-profile, P, V, E and others

The size of the seal depends on its type. The optimal parameters are selected taking into account the size of the gap. When purchasing a product, the size of the door structure is of no small importance. Taking into account its dimensions around the perimeter, the footage required to compact the canvas is calculated. For entrance doors, it is advisable to take wide products with a sufficient level of density. Flexible profiles with a rectangular cross-section are sold in rolls. The footage of the material depends on the manufacturer. Such products are designed to eliminate small gaps that do not cause serious problems during the operation of the door.

In some cases, it may be necessary to install rubber profiles with complex shapes. Such products are suitable for installation on regular and even armored doors with a heavy leaf. There is a D-shaped seal, as well as products in which the cross-section resembles other letters - E, C, O, P, etc. Each configuration is used to eliminate gaps of a certain size.

C-, E- and K-shaped profiles can cope with bridging small gaps, the width of which is no more than 3 mm. P- and V-section seals are suitable for masking gaps up to 5 mm in size. D-shaped and O-shaped seals are used much less frequently. They are designed for doors with large design errors. These products can eliminate a gap that reaches 7 mm.

Sealing rubber D-profile

If the material is soft, it is better to buy it with a reserve. Such seals fail very quickly. It is advisable to have a small supply of material on hand in order to quickly replace it if necessary. Rigid types of seals are made to fit the dimensions of the door structure. It is problematic to independently measure and calculate the required amount of material without making a mistake. It is better to seek help from specialists.

Note! To seal the door, at least 5-6 m of tape is required.

Disadvantages of such insulation

The only drawback of the method is that if you accidentally touch the seal, it can be torn off. Okay. Gluing it in place is not difficult at all.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Warmth and comfort in the house are the main tasks facing every owner of his own living space

Particular attention is paid to the front door, as it is in direct contact with the street. And in the cold season, heat can leave the room through the doorway

To avoid unpleasant consequences, you should insulate the front door. You can do this work yourself. But before you insulate a wooden door in a private house, you should prepare everything necessary for this.

How can you insulate your front door?

The guarantee of future comfort, for the sake of which insulation was started, depends on the chosen material. And if several decades ago only felt, foam rubber and dermantin were available, today the choice is much greater. And here's what the manufacturers offer:

- Mineral wool;

- Styrofoam;

- Izolon;

- Expanded polystyrene.

Mineral wool, like polystyrene foam, is most often used as the basis for insulation for metal door panels. Both materials perfectly retain heat indoors and are not affected by microorganisms. Mineral wool is also worth noting because no rodents will spoil this insulation.

Mineral wool absorbs moisture

But these materials have some restrictions on their use.

The use of isolon is more justified to achieve the goal of heat retention. This material is made on the basis of foamed polyethylene, which gives it minimal thermal conductivity. The advantages of the material include the fact that a sheet with a thickness of 10 - 15 mm will be sufficient for work. This allows you to maintain the attractive appearance of the door leaf without thickening it or making it bulky.

Izolon has low thermal conductivity

Expanded polystyrene has excellent performance. A door insulated in this way will become a reliable and safe barrier between a warm house and a cold street. Among the advantages of polystyrene foam, its non-flammability should be highlighted. When a flame appears, it will gradually disappear on the surface of the material.

For inexpensive insulation, you can always use foam rubber. The material is convenient in all respects and will be a real find for a novice home craftsman. Foam rubber will forgive mistakes and allow you to correct them painlessly.

Tool

It is impossible to get the job done without the right set of tools. To create insulated wooden entrance doors you will need:

- Tape measure and pencil;

- Stationery knife;

- Hacksaw;

- Hammer;

- Screwdriver;

- A flat rod or metal meter;

- Mounting tool or nail puller;

- Construction stapler.

If necessary, this set can be expanded, but for most operations it will be quite sufficient. It should be noted that a hacksaw can easily be replaced with an electric jigsaw. This tool allows you to get the job done with the same quality, but much faster. And if there is no screwdriver in the house, then you can take a simple drill. The main thing is that it has a reverse, which will allow you to unscrew any self-tapping screw or screw if necessary.

In addition to the tools, it is necessary to prepare the covering material. For most door panels, it will be enough to use leatherette, which has an attractive appearance. This material has good characteristics and wear resistance, so the canvas will not need to be repaired for a long time.

And if you like to do everything with your own hands, then we recommend you instructions on how to make a wooden entrance door.

Where and how to start preparation work correctly

First, we inspect the door and frame. If they already have some kind of seal that has ceased to perform its functions, then it needs to be dismantled. Then, if necessary, we pre-clean the surfaces where the obsolete material was, removing its remains. For this we use fine sanding tape.

Afterwards it is recommended if there is a need to adjust the door. Distortions will cause uneven fit and wear of the seal. Different sizes of gaps between the frame and the door from below and above, on the right and on the left will also lead to this if the material of the same thickness is selected for the entire opening. Or you will have to choose a seal for each side of the opening. The critical value of warping and the difference in slot sizes is 1–1.5 mm. If they are larger, then a great option is to remove them by adjusting the door. It happens that performing this operation eliminates the reason why it was decided to seal the opening, and the need for such work disappears.

Door design diagram

Now you need to decide on the installation location and type of seal. This may determine which part of the door or frame needs to be measured in order to find out the required amount of material.

Why is there blowing from the front door?