The determining factor for replacing old wooden windows with new ones, metal-plastic or PVC, is their ability to retain heat in a house or apartment. Naturally, when installing double-glazed windows, few people were interested in how they would behave in the future. Will the cold be allowed in, is it possible to insulate plastic windows if necessary, and is this necessary? If so, how to prepare windows for winter and the better way to ensure thermal insulation of windows and openings.

A plastic or metal-plastic window, like any composite structure, has weak points. They are the potential “gates” for heat leakage from the room.

Blowing from a plastic window - find and eliminate

Where can it blow from plastic windows?

To understand why it blows from a PVC window, you need to inspect the components, and for this you need to know the design principle of the window unit.

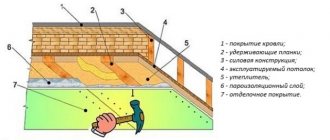

The structure of a window unit - the main elements

Construction of a plastic window and door - list of elements

The most common places for blowing:

- window glazing bead (glass unit holder);

- rubber compressor;

- window fittings (for example, blowing from under the hinges, into the handle);

- the perimeter of the window frame - the junction of the slopes, window sill, walls.

How to determine where it is blowing from a plastic window?

The presence of a defect in one of the components of the window unit leads to blowing from plastic windows. There are three ways to determine the exact location of heat loss from metal-plastic windows:

- tactile hand. To identify a gap, just run your palm over the surface of the window block;

- lighter. The search procedure is similar to the previous one, but the light is more sensitive to drafts and can detect even the weakest blowing.

- paper. An ordinary sheet of paper is pressed against the window (put into the open window and clamped by completely closing the sash), if you pull the corner of the sheet and it easily pulls out, then the seal is not pressed enough (this may indicate that the window is operating in summer mode, the old seal is in this mode does not press well to the frame).

Why does it blow from plastic windows - reasons for heat loss

- installation error. This is the most common reason associated with ignorance or non-compliance with the correct technology for installing a plastic window. 15 years ago, this service was so in demand that everyone who had at least some idea about installing window units became installers. Naturally, few people installed PVC windows according to GOST;

- window distortion due to shrinkage of the house. A pressing problem for residents of new buildings and wooden houses;

- an attempt to save money. One of the weighty arguments in competition is always price, especially during an economic crisis. The price reduction often occurred at the expense of quality: saving on foam, on insulation, ignoring the need to protect the heat insulator, using low-quality components when assembling windows - all this over time led to the fact that the consumer is forced to change or additionally insulate PVC windows;

- physical wear of window components, in particular sealing rubber bands, or weakening of the pressing force of the sashes;

- violation of the operating rules for plastic windows, which include the need to wash the window seal and treat it with glycerin. This care prevents the seal from losing its elasticity and cracking.

What to do if it's blowing from a plastic window

Of course, eliminate the source of the draft. From a practical point of view, there are two simple options - call a specialist to repair and adjust (expensive) windows or do it yourself (cheap).

The desire to seal all the cracks yourself using improvised means is nullified because: firstly, it is not aesthetically pleasing, and secondly, there are no guarantees.

When is it advisable to hire professionals:

- The plastic window was recently installed. The installer company is responsible to the consumer for the reliable operation of the windows (if the warranty covers this period);

- the window opening is located at a considerable height (in a multi-story building). It is better to entrust any high-altitude work to professionals (industrial mountaineering services). If the window is located on the second floor or higher, the work will be associated with increased risk;

- if there is a manufacturing defect. For example, obvious manufacturing or installation defects that appeared during the warranty period;

- if necessary, replace parts. It is better to install “original” fittings if it is necessary to replace individual elements of the window unit;

- work is carried out in winter. Knowledge of installation technology and how to insulate plastic windows for the winter allows installers to complete the work quickly, without significantly cooling the living space.

However, often, the cost of hiring specialists is equal to the cost of installing a new window, and this fact makes it more profitable to do the insulation work yourself.

What you can do yourself:

- internal insulation of the window opening;

- insulation of the frame contour;

- window sill insulation;

- replacement of seals.

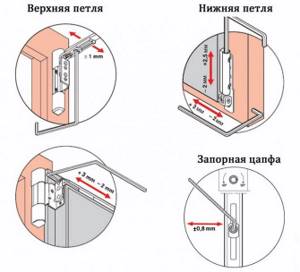

Adjusting the clamping mechanism

During operation, the window is exposed to mechanical and climatic factors. As a result, loss of sealing rubber volume may occur. What causes air to get inside the house. To solve this issue, it is not at all necessary to resort to replacing the gasket, unless, of course, it is completely in unusable condition. You just need to adjust the clamping mechanism.

To begin, find the protruding cylinder - the axle - in the cut places of the metal plug. Then move the hooks to the required position or adjust the trunnions. To change the position of the hooks, loosen the bolts. When moving to the street side, the pressure increases, and in the opposite direction decreases.

How to insulate plastic windows with your own hands

When to insulate windows for the winter

Repairs and insulation must be carried out before the onset of cold weather. This is due to the following requirements:

- more comfortable working conditions;

- material requirements. Some building materials, such as dry mixes and sealants, can only be used in a certain temperature range. Otherwise, they lose their characteristics;

- optimal humidity;

- no draft;

- the ability to simultaneously perform internal and external insulation;

- reducing the risk of catching a cold among apartment residents.

How to insulate plastic windows at home

The choice of insulation depends on the location of the blower.

Insulating window openings for the winter

To insulate a window opening, you can use different materials and methods:

- polyurethane foam. As the foam expands, it fills all the voids around the perimeter of the window opening, preventing air movement. Due to the fact that foam is 90% air, it is an ideal insulation material. However, the foam needs protection from ultraviolet radiation, high and low temperatures. This means that it is not advisable to use it by itself;

- mineral wool. An excellent thermal insulation material for insulating window sills and internal slopes. Cotton wool has a more limited range of uses when insulating windows;

- polystyrene foam/expanded polystyrene. Used for insulating slopes of plastic windows;

Note. Rigid insulation is used when the thickness of the installation seam is no more than 3 mm; in other cases, it is better to give preference to mineral wool.

- silicone sealant. A reliable way to eliminate air leaks between plastic window elements;

- dry mixtures for finishing slopes, used if necessary to insulate the window from the outside;

- construction tape. Glues on top of the sealant or instead of it;

Advice. It is not recommended to use ordinary masking or window tape; after sticking it, unattractive marks remain on the plastic of the window frame that are difficult to remove without damaging the front covering.

Insulation of a window block

- seal;

- construction tape;

- sealant;

- heat-saving film for windows (energy-saving);

- mechanical methods of insulation, for example, tightening (adjusting) fittings.

After the question of how to insulate has been resolved, we will deal with the question of how to insulate a double-glazed window, frame, plastic, aluminum profile, etc.

What materials are suitable for thermal insulation?

In order for all the activities carried out to have a positive result, it is necessary to select the right materials. The following is used as a heat insulator for slopes:

- Mineral wool (basalt, slag or glass wool).

- Styrofoam.

- Extruded polystyrene foam.

- Polyurethane foam.

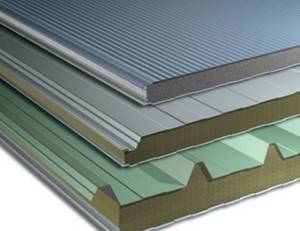

- Sandwich panels.

- Fiberglass, one side of which is covered with a layer of foil.

In the process of selecting the required material, the dimensions of the window opening and the places where the insulation will be installed are taken into account. Mineral wool, for example, performs its functions with a thickness of at least 10 cm, which is not always convenient for insulating a window from the outside.

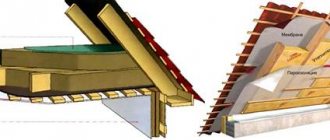

In addition, cotton insulation requires the use of a water barrier on both sides. This is due to the fact that after getting wet the material loses its insulating properties.

An affordable and popular option is to use polystyrene foam and extruded polystyrene foam (penoplex). Moreover, the latter material is preferable because it has a higher density with a smaller thickness. It is important to protect the polymer insulation from the sun in a timely manner. When exposed to ultraviolet light, foam becomes brittle.

If polyurethane foam was used during the installation process, then there is no hope for complete thermal insulation. Of course, if the voids are densely filled, some of the heat will still be retained in the room, but if the house is located in a region with low winter temperatures, then you will have to take care of additional insulation.

A good option that solves two problems at once would be sandwich panels. The top layer is a decorative material, the bottom layer is insulation. At the same time, it is possible to choose an option for your home if the facade is already lined, but the slopes had to be insulated later. In addition, some creators of such panels offer options with different insulation materials.

A new option for insulating slopes is fiberglass with a foil base. It is difficult to install such material with your own hands, so you need to take the help of professionals. But you will be 100% sure of the result. The insulator perfectly protects against moisture and penetration of cold air currents.

How to insulate plastic windows from the outside

External window insulation is carried out in the following areas:

Insulation of slopes of plastic windows

The first step to increasing the thermal insulation properties of the window. No matter what insulation measures are taken in the house, until the slopes from the street are insulated, the cold will still flow inside. At the same time, external insulation allows you to shift the dew point, which will prevent the appearance of dampness and the development of fungus. Covering the cracks is a temporary measure, because... Over time, the layer of plaster will begin to crack and expose the mounting foam, which will collapse under the influence of atmospheric conditions. But as protection for insulation, plaster is an excellent solution.

How to insulate the slopes of plastic windows from the street

Work order:

- preparation of material (rigid insulation);

- cleaning slopes from dirt and protruding parts;

- surface primer;

- installation of insulation on an adhesive solution or special adhesive foam. It is preferable to use foam because it eliminates wet work, has a minimum setting time, and holds the insulation sheet more securely;

- sealing all cracks with glue;

- installation of perforated corners;

- installation of polymer mesh;

- finishing with plaster.

Advice. When installing insulation, you need to make sure that it covers part of the window frame and completely covers the installation seam.

Insulation of plastic window sills

To insulate the ebbs, it is enough to foam all the cracks or place heat-insulating material in them. To avoid water getting on the heat-insulating material, a metal strip of window sill is installed on top. The plank is installed at an angle (at least 5o), its horizontal edge extends from the facade (by 20-30 mm), and the side edges are turned up. It is recommended to treat the area where the plank joins the surfaces with sealant.

Sequence of work on external thermal insulation

The outer slope also needs to be insulated, and this process should be taken seriously. Material that is laid outdoors is constantly exposed to destructive factors such as:

- Atmospheric moisture.

- Negative air temperature.

- Ultraviolet radiation.

- Exposure to wind.

- Insects, rodents and birds love to make their nests out of insulation materials.

Therefore, unprotected material quickly becomes unusable. Insulation of external slopes is carried out according to the following points:

- Remove excess polyurethane foam.

- Cover the slope with soil with an antibacterial composition.

- If there are large differences, the surface is plastered. Select plaster for external use.

- Once again they resort to priming. The composition will protect against fungus and mold, and will also increase adhesion with the following materials. Don't skip this step.

- Start with insulation. For external treatment of slopes, a denser material is chosen, for example, penoplex. It is glued to an exterior adhesive suitable for polymer materials.

- For greater reliability, the heat insulator is fixed to the slope with dowels with a wide head. It is not necessary to do this indoors, since there is no exposure to gusts of wind.

- The corners of the slopes are covered with corner elements. They will make the edging more neat and attractive. In addition, making a beautiful corner will be much easier.

- The insulation is covered with plaster with mandatory reinforcement. If you do not use a mesh, during the first year of operation the layer may crack and crumble.

After the layer has dried, decorative finishing is performed. Sheathing materials are used only those that can withstand external load.

Internal insulation of plastic windows

Insulation of windows from inside the room is carried out in the following areas:

1. Insulation of internal slopes of plastic windows

Internal slopes are less susceptible to the influence of external factors, but put forward more demands on the aesthetic component. Therefore, it is important to know how to insulate the slopes of plastic windows without losing the attractiveness of the window.

Work order:

- treatment of cracks: removal of dirt, removal of old foam, falling parts, etc.;

- applying a primer;

- sealing cracks with foam;

- removing excess foam after it dries;

- installation of thermal insulation materials (foam or cotton wool);

- installation of drywall;

- finishing drywall with putty and paint.

Insulation of the window sill of plastic windows

The gaps between the wall and the window sill are one of the places of significant heat loss. Before deciding how to insulate the window sill of a plastic window, you need to determine its weak point, i.e. where is it blowing from? For example, blowing is possible between the plastic parts of the window and window sill. In this case, it is recommended to use a sealant.

Heat loss between the window sill and the wall is also possible. In this case, insulation is carried out before installing the window sill by laying a layer of heat-insulating material. And also after its installation - by foaming the distance between the window sill and the concrete wall or brickwork.

Insulation by adjusting the plastic window

Elimination of distortion of the PVC window sash

To reduce heat loss, you need to adjust the fittings (components) of the window unit.

how to adjust the fittings of a plastic window and door

How to adjust plastic windows for the winter - video

Replacing the seal in plastic windows

Elimination of blowing of plastic windows is possible by replacing the rubber seal. You can change the seal yourself, everything is simple - just pull out the old seal and insert a new one into the groove (groove).

Which seal is better? Please note that there are window insulation in black and gray colors on the market. The black seal is more flexible, but the attractive light color is due to various additives that reduce the cost of the window seal and at the same time worsen its properties (tightness).

Replacing the seal in plastic windows - video

Main types of window sills

Today, to create such structures for windows, mainly metal or plastic is used. Experts distinguish the following varieties:

- metal structure made of galvanized steel. Thin metal with a thickness of about 0.5 mm is suitable for its manufacture. It is coated with a layer of zinc, thanks to which the metal receives reliable protection against corrosion. The thickness mentioned is considered optimal. It gives rigidity to the window sill and dampens vibrations that occur when hail and large raindrops hit the structure. The width of such ebbs is 90-400 mm, and the length is 3 m. Galvanized products are considered the cheapest, however, they are susceptible to acids;

- polyester shimmers. In essence, this is the above-mentioned galvanized window structure, coated with a polyester layer, which serves as a decorative and protective coating. The advantage of this product is increased strength and resistance to acidic environments. Another advantage is the large selection of shades. Polyester products are only afraid of scratches. With proper care, the structure will last for 20-30 years and will reliably protect the window and wall from moisture;

- aluminum castings. Aluminum is considered a stable, durable material that can withstand rain, snow and other precipitation. The structure, made of aluminum, can be painted in any shade. The main disadvantage of the product is its high cost;

- plastic casts. This design is created from polyvinyl chloride, which is considered a practical and durable material. The main advantage of plastic sills is excellent window sound insulation. So, during rain you will not hear the sound of drops. In addition, plastic structures do not crack or fade in the sun. They are easy to care for and do not require additional protection from various damages. Finished window sills are moisture and fire resistant. Their installation is not difficult, but they become very fragile at sub-zero temperatures.

Today you can find other types of window sills on sale. For example, these could be products made from natural or artificial stone. Installing such heavy structures on a window is not always easy, so it’s worth enlisting the help of a professional.

Additional ways to insulate plastic windows

- Washing windows. Paradoxically, cleaning the glass unit helps save heat. After all, dirty glass loses its ability to transmit sunlight, but continues to transmit rays in the infrared spectrum.

- Thick curtains. Which also trap heat indoors.

- Insulating windows with improvised means. This method somewhat spoils the appearance of the window, but in critical cases it can be a very worthy alternative to replacing the window unit. The following materials are used as insulation: foam rubber, soaked paper, window tape, strips of white fabric, etc.

- Insulation of windows with heat-saving film. The energy-saving film is glued to the entire surface of the window (on the sashes). The main thing is to do the gluing correctly, without air bubbles or folds. The film reduces heat loss through glass by 75%.

- Electric window heating. In this case, a heating cable is placed around the window, which heats the heating coil, or an oil radiator is installed on the window.

- Electric heating of double-glazed windows. The most technologically advanced way is to install plastic windows with heated glass. The technology is applied at the window production stage. It involves installing a special conductive film (transparent film with conductive threads) on the inside of the glass, which heats the glass from the inside.

- A complex approach. The most appropriate for insulating windows in an apartment or private house, since it allows you to eliminate all possible causes of heat leakage through metal-plastic or PVC windows.

Insulation of window glass with energy-saving film - video

Advice from professionals

To quickly and effectively reduce heat loss in a room, you must use the following recommendations from experienced professionals:

- It is best to carry out thermal insulation work in the spring and summer, in dry, warm weather and in the absence of wind.

- For complete insulation, an integrated approach is required. It is necessary to deal with issues of heat conservation both from the outside and from the inside.

- Complete sealing of a metal profile window structure often becomes a source of black mold. To avoid such problems, you will need to take care of high-quality ventilation. It is necessary to install a compact fan on the windowsill.

- One of the simplest solutions to eliminate the leakage of warm air from a room is to use self-adhesive film. The plastic window is pre-cleaned, wiped with a dry cloth, degreased, and with an allowance, the film is straightened using adhesive tape and fixed to the frame. To level it, use a glass cleaning brush.

- Insulating plastic windows when they are bent is only possible if all the fittings are adjusted - it is necessary to achieve tightness at all points of contact between the sash and the frame.