During the cold season, any house loses heat due to leaks at the joints of building structures, cracks in windows and doors, as well as due to thermal radiation from walls, floors and ceilings into the surrounding space. At the same time, ceilings and roofs account for 15 to 45% of all heat losses. Therefore, the ceiling must be insulated, eliminating heat loss due to the release of heated air and due to heat transfer. Most insulation methods do not require expensive equipment or special qualifications of workers. They are quite capable of doing the work of insulating a house with their own hands.

In addition to the most important task - heat preservation - thermal insulation work also solves one more - maintaining optimal humidity. For this, in addition to insulation materials, vapor barrier and waterproofing membranes are used to prevent condensation from accumulating on ceilings and walls. Semi-permeable membrane films allow water vapor to pass through them in one direction and do not allow moisture to pass through in the opposite direction.

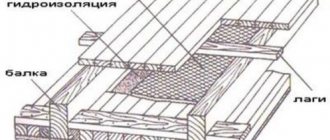

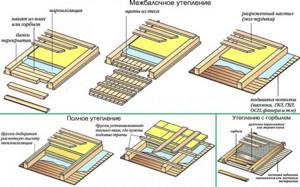

General scheme of ceiling and roof insulation

Ceiling and roof insulation schemes

From the point of view of insulation, all roofs are divided into two types:

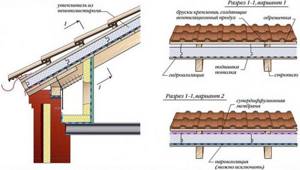

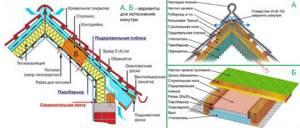

- Warm. Under the roofing material there are several layers: vapor barrier, ceiling insulation and waterproofing. They are held in place by battens - spatial structures attached to the rafters. The ceiling of attic rooms is insulated according to exactly this scheme.

- Cold. They have a layer of roofing material and a load-bearing structure and a layer of vapor and waterproofing placed underneath them. The air gap in the attic is an additional barrier to heat loss. The ceiling located under the so-called cold roof must be insulated and waterproofed.

Waterproofing

To protect the attic from flooding, and the ceilings and repairs from water stains, it is recommended to lay a layer of waterproofing material on the roof slopes.

- Fused - overlapped and joined using a torch. The cheapest option is synthetic materials.

- Sprayable. A one-piece membrane film is created.

- Powder. Water is added to it immediately before installation.

- Liquid – suitable for concrete floors, absorbing into their surface.

- Coating based on bitumen.

Before you buy waterproofing, you need to re-read the properties: the material must allow air to pass through, but retain water. Some cheap films create a greenhouse effect in a cold, unheated attic, causing the walls to become moldy.

Features of ceiling insulation

*

The main feature of insulating a flat ceiling is the inability to arrange condensate drainage, as is done for sloping roofs. Therefore, almost all insulation solutions are aimed at removing water vapor upward, ensuring its unhindered passage through all layers.

Cold overlap

How to properly insulate a ceiling in a cold attic? Air gaps are left above a cold or heat-conducting ceiling (for example, concrete). The first, auxiliary between the vapor barrier film and the insulation, comes into effect when there are large temperature changes and heavy condensation. It must be well ventilated. It is easier to make the main gap between the insulation and the waterproofing layer ventilated - just leave a small gap around the perimeter. It is preferable to insulate a cold ceiling both from above and from below. The insulation used for the ceiling located under a cold attic must be moisture resistant.

Warm ceiling

A floor made of materials with low thermal conductivity, such as wood, is called warm. Such floors, which themselves serve as a heat insulator, need only be insulated from above. Even if condensation forms during extreme temperature changes, it will be absorbed into wooden structures without changing their properties, and will subsequently evaporate. As a rule, this process is invisible to the inhabitants.

The vapor barrier is laid on the ceiling without a gap, then the insulation is laid. The air gap between the thermal insulation layer and the hydrobarrier membrane should also be left and will provide the possibility of its ventilation.

Preparatory part

Before you insulate the floors in the attic of your home, you need to be well prepared.

- selection of wool and related materials;

- calculation of the required amount of material;

Selection of mineral wool

Stone or mineral wool is the name of a whole direction, in which there are dozens of different models. Based on the name, this includes all soft insulation materials made from rocks; the most famous option is basalt wool.

Barriers and membranes

Vapor barriers

Vapor barriers are needed to prevent water vapor from passing through them. For their production, polypropylene films with a thickness of over 55 microns are used.

Polyethylene is unsuitable as a vapor barrier - over time, due to temperature fluctuations, it cracks and begins to let vapor through. However, if you solder a layer of polyethylene and a layer of foil, you get a high-quality vapor barrier.

Folgoizols are also supplied with a layer of fibrous nonwoven material such as padding polyester. This layer collects moisture from the insulation and carries it away through capillaries. If it is present, there is no need to create an additional air gap above the cold ceiling.

Membranes

Multilayer reinforced membrane materials allow vapor to pass in one direction and retain moisture in the opposite direction. The reinforcing mesh layer ensures the strength of the film, prevents it from sagging and guarantees a constant size of the main air gap.

Membranes with a reinforcing layer

Video: we discuss the floor structure in detail

Review of the structural details of the attic floor insulation device. What is a sufficient layer of insulation for a cold attic? What are the specifics of the work on laying thermal insulation for the attic floor?

Sources

- https://DomZastroika.ru/krysha/sposoby-utepleniya-cherdaka-svoimi-rukami.html

- https://dekoriko.ru/cherdak/uteplenie/

- https://uteplenieplus.ru/kak-uteplit/krysha/paroizoljacija-i-vlagovetrozashhita-dlja-holodnogo-cherdaka-osnovy-primenenija-i-montazha/

- https://teplota.guru/teploizolyatsiya/uteplenie-cherdachnyh-perekrytij.html

- https://ZnatokTepla.ru/utepliteli/cherdaka-v-chastnom-dome.html

- https://nashicherdaki.ru/uteplenie/053-kakoj-uteplitel-dlya-cherdaka-vybrat/

- https://viascio.ru/krovlya/uteplenie-cherdachnogo-perekrytiya

- https://roof-project.com/uteplenie/utp-dlya-cherdaka.html

- https://pod-potol.com/remont-i-ukhod/teploizolyatsiya/kak-uteplit-potolok-cherdaka-kharakteristika-materialov.html

- https://StrojDvor.ru/otoplenie/kak-pravilno-uteplit-cherdak-v-chastnom-dome-s-xolodnoj-kryshej/

- https://nashicherdaki.ru/uteplenie/062-kak-uteplit-cherdak-v-chastnom-dome-poshagovye-instrukcii-i-rekomendacii/

- https://vdome.club/remont/dom/uteplenie-kryshi-cherdaka-minvatoy-plyusy-i-minusy-tehnologiya-montazha.html

- https://kryshadoma.com/uteplenie-teploizolyatsiya/kak-uteplit-cherdak-minvatoy-etapy-i-preimushchestva.html

- https://uteplenieplus.ru/kak-uteplit/krysha/uteplenie-cherdachnogo-perekrytiya/

Insulation materials

What is the best way to insulate a cold ceiling? The main thermal insulation materials used for insulating ceilings can be divided into the following categories:

- Solid. Such materials consist of foamed plastics, are little susceptible to moisture, and are easy to install.

- Fibrous. Mats or rolls are formed from compressed fibers. Inexpensive, have good thermal insulation. Sensitive to moisture, when wet they lose their thermal insulation properties.

- Bulk. Traditional bulk materials - sawdust, expanded clay, etc. The cheapest ones have the weakest thermal insulation. Ecowool stands out separately - an expensive, but extremely effective material.

- Sprayable. Modern coatings made of foamed plastics. They are sprayed locally and do not form joints or seams. The best thermal insulation, very expensive equipment.

How to insulate the ceiling, everyone decides for themselves, based on their needs and capabilities.

Mineral wool

Rolled mineral wool

*

The most popular type of fibrous materials. Produced from several types of raw materials:

- Basalt wool from volcanic rocks. High strength and density, short hard fibers. High moisture resistance.

- Glass wool from recycled glass. Low strength, light and elastic, long elastic fibers.

- Slag from blast furnace waste. Low thermal insulation properties, low cost. Not applicable for residential buildings.

To insulate with mineral wool, no special equipment is required; the installation process is simple and quite fast. It is produced both in rolls and in slabs with insulation thickness up to 150 mm.

Mineral wool is harmful to health; during installation you must use a respirator, protective gloves and goggles.

Attention! If fibers get on the mucous membranes, respiratory or digestive organs, you should immediately consult a doctor.

After installation during use, mineral wool is completely harmless to those living in the house.

An important feature of mineral wool that must be taken into account when designing and installing is the large number of joints and junctions. They need to be done so that the gap is minimal, the slabs are laid against the guides and opposite each other. Half-centimeter gaps between slabs can reduce the effectiveness of the coating by a third.

Correct and incorrect installation of insulation

The thermal insulation properties of mineral wool are reduced until they are lost when the material gets wet. Therefore, it is necessary to ensure the removal of vapors and condensate.

Monolithic

The most suitable and popular material for thermal insulation of ceilings is polystyrene foam. It is produced in the form of 1200*600mm panels equipped with tongue and groove. This allows you to make high-quality joints during installation. In addition, cracks and gaps are sealed with polyurethane foam. The material is resistant to moisture and temperature fluctuations. Works great when insulating ceilings both outside and inside

Its disadvantage is low fire resistance. When burned, it releases substances harmful to health.

Insulation with polyurethane foam

Polystyrene foam, or polyurethane foam, is significantly cheaper than polystyrene foam, but has low strength and is prone to chipping. Suitable for insulating ceilings from the inside.

Sprayed and bulk materials

Sprayed materials are very effective, have no joints or seams, and almost do not burn. They can be effectively sprayed into hard-to-reach areas and cavities, providing thermal insulation where other materials can only be placed with partial dismantling of building structures.

The main disadvantage is the extremely high cost of the equipment and the highly qualified operator. This hinders the widespread adoption of this promising method.

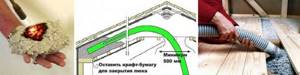

Ecowool

Very promising as bulk and sprayed insulation for roofs and ceilings. Occupies an intermediate position between sprayed and bulk materials. It is made from recycled paper and has the same thermal conductivity as mineral wool. Fibers with the addition of glue are fed to the surface or into the cavity under slight pressure and harden there. When wet, it partially loses its properties, but after drying they return.

Additives in ecowool make it low flammable, environmentally safe and unattractive to rodents and mold. The material does not cause allergies and does not contribute to the development of cancer.

Methods for laying ecowool

Applying ecowool does not require special qualifications, and installation is a little more complicated than a vacuum cleaner. One of the few drawbacks is the requirement for application temperature: not lower than +23°C

Expanded clay and foam glass crumbs (foam crumbs)

When filling with expanded clay or foam crumbs, it is necessary to take into account that its thermal insulation properties are low compared to more modern materials. Therefore, a significantly thicker layer will be required.

Expanded clay - traditional bulk insulation

A few advantages of the material are its low cost, moisture resistance and non-flammability.

Expanded clay is used in budget solutions as an outer layer, while internal thermal insulation is performed with mineral wool

Scheme of two-layer insulation with expanded clay and mineral wool

Sawdust and shavings

These materials can be attractive due to their low cost; sawdust and shavings can be obtained completely free of charge at woodworking factories. Wood shavings have a high fire hazard; sawdust burns much worse.

Before laying, it is recommended to dry them well, and during layer-by-layer laying, moisten them with solutions of boric acid and borax.

Ceiling insulation

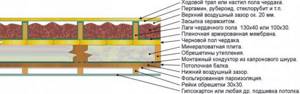

Let's consider the process of insulating the attic ceiling with mineral wool. The technology varies based on the specific designs and circuits chosen.

Outside

The simplest and fastest method of thermal insulation is inter-beam. If the ceiling is made of solid boards, a vapor barrier must be placed around the beams or film wraps must be made on them. If the ceiling is made of thin lining or slats, a foil vapor barrier film is attached below the beams, along the ceiling.

Methods for insulating a wooden ceiling from the attic

A complete insulation scheme requires significantly more labor, materials and time, but it is also much more effective. An above-beam double layer of slabs is added to the inter-beam layer of rolls or mats. The layers must be laid overlapping.

How to insulate a cold ceiling from the inside

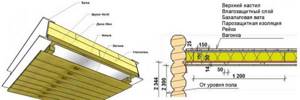

When choosing a method of thermal insulation of the ceiling from the inside, you need to understand that any of them will reduce the height of the room. Minimal height loss will occur in the case of installing a suspended ceiling or suspended ceiling made of plasterboard. In this case, thermal insulation boards can be placed between the guide metal profiles.

Fastening basalt wool to disc dowels

If a suspended ceiling is not planned, then insulation boards can be attached in various ways:

- Still, make guides from wooden slats or metal profiles.

- Secure the panels with special disc dowels. For one mat measuring 1200 * 600 mm you need at least 4-5 dowels

- Glue to the ceiling with mastic.

A reinforced mesh is glued to the lower part of the insulation, and leveling primer and layers of paint are applied to it.

No attic

When insulating buildings without an attic, in addition to solving the problem of heat preservation itself, it is necessary to ensure the removal of excess moisture, both contained in the air in the form of vapor and condensing on cold surfaces.

Scheme for buildings without an attic

A vapor barrier is laid under the light ceiling, and a layer of thermal insulation material is laid on it. It is necessary to provide two ventilated gaps - between thermal insulation and waterproofing and between waterproofing and roofing material. You need to install vents along the ridge or simply lift the ridge cap so that the air can escape freely.

Vapor barrier

The vapor barrier film protects wooden beam ceilings from moisture formed in the air of residential premises. In addition, it protects floors from the appearance of mold and mildew in the insulating material.

Regardless of how the attic floor is made, the vapor barrier for the floor should form a continuous carpet that does not allow condensation to penetrate. Particular attention should be paid at the joints with walls, where there is a high probability of condensation penetration. To do this, the covering film is overlapped and its edges are glued together with tape.

Vapor barrier under insulation

Review of the main vapor barrier manufacturers

There are several popular vapor barrier manufacturers on the market:

- surpasses all other companies in quality (according to the Test Purchase program).

- does not lag behind the leader either in quality or in the use of the latest technological developments. This is a domestic company that produces a very high quality product.

- The product is good for both industrial and residential construction, but is not suitable for creating temporary roofing.

Not included in the top three:

- Polish - the company's products are distinguished by the fact that they can withstand very low temperatures.

- "Ondutis" - low prices, excellent connecting tapes, rolled materials.

- Tyvek products provide ideal wind protection.

- German DELTA - steam and wind protection.

Special cases

*

Let's look at a few special cases

In an apartment building

Apartments on the top floors of apartment buildings are known to be cold. Especially if the builders performed thermal insulation of the ceiling in violation of the technology. Any independent work in the attic of an apartment building is illegal; it is better to spend time complaining to the construction or operating organization and forcing them to fulfill their obligations to ensure normal temperatures. But the claim process is not a quick process, and the rooms are already cold today.

However, you can quickly and inexpensively insulate the ceiling from the inside and do it yourself. You will have to “please” your neighbors by drilling numerous holes in the ceiling for dowels, but the result is worth it.

Ceiling insulation in an apartment building

Another drawback will be a reduction in the height of the rooms by 4-5 cm, and around the perimeter of the ceiling - up to 40 cm. But heat is more expensive.

A system of guides made of wooden slats or a metal profile 4 cm high is installed on the warm ceiling. Sheets of foam plastic 30 mm thick are laid between them and attached to the ceiling with disc-shaped dowels.

After this, a foil vapor barrier is attached along the lower edges of the guides. Slopes with a radius of 40-40 cm are made along the perimeter, ensuring a smooth connection between the planes of the lines of the false ceiling and walls. At the last stage, sheets of moisture-resistant drywall are attached. Curvilinear slopes are covered with foam chips, starting from the short sides of the room. Ecowool is also suitable for this.

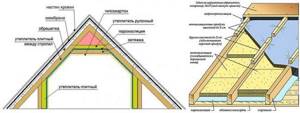

Attic

A residential attic must be insulated. Insulation of a non-residential attic will not hurt either - this will be an additional barrier to the cold on the residential floors. How to reliably insulate the ceiling in a residential attic? The most common scheme is insulation with mineral wool or polyurethane foam slabs laid between the rafters. For vertical walls, you will need to take special cotton wool with a low shrinkage coefficient.

Attic thermal insulation diagram

Particular attention will need to be paid to vapor barrier. In an already built house, the space under the ridge is not always available. In this case, ecowool can help out - it can be blown through temporary technological holes, which are then sealed with polyurethane foam.

Garage and bathhouse

The roof of a garage is often supported by metal I-beams. When installing guides for insulation, drilling holes from bottom to top in a steel beam is inconvenient, so the method shown in the figure is used. Thermal insulation boards are laid in two overlapping layers. Instead of fibrous materials, you can try ecowool. In this case, you can do without foil insulation, and instead lay kraft paper on the false ceiling.

Installation diagrams for bathhouses and garages

For the bathhouse, a standard thermal insulation scheme is used. Increased room humidity requires the use of basalt wool - insulating the ceiling of a building with glass wool is not recommended. Particular attention should be paid to the quality of ventilation of the gaps. Ecowool must be moistened with glue. If a bath ceiling is insulated, working from the attic side, bulk materials such as sawdust and shavings are often used.

Types of attics

When carrying out work, everything depends on the method of using the under-roof space. There are three of them:

- Cold attic. Such an attic is not heated, and air does not flow into it from the premises. In this case, the room temperature is assumed to be +5 degrees Celsius.

- Warm attic. The presence of a warm attic is typical for multi-apartment residential buildings. All ventilation ducts with heated air open into the attic space, increasing the temperature in the room.

- Attic. The under-roof space becomes a full-fledged living space and is heated like all the rooms of the house. In this case, we recommend that you read the article on attic insulation.

In a wooden or any other private house, it is correct to use the first or third option.

This is how you can transform your attic, turning it into a residential attic:

Worker skills and tools

Popular insulation methods do not require expensive equipment or high qualifications. For insulation, a home craftsman will only need general construction skills and ordinary tools:

- knife

- hammer

- screwdriver

- hacksaw

- stepladders

- roulette

When installing the guides, it is best to call an assistant. Help with cutting and laying rolled materials would also be helpful.

Before starting work and purchasing materials, it is necessary to make a sketch drawing. This will help you avoid making mistakes with dimensions and correctly calculate the amount of materials purchased.