Home / Installation, repair, maintenance / Insulation / How to insulate a concrete ceiling?

Concrete ceilings can cause a lot of trouble for the owners of an apartment or private house with reinforced concrete floors. The main problem is their ability to perfectly transmit noise from neighbors and poor heat-saving characteristics. Only owners of apartments in high-rise buildings face the problem of noise from neighbors, but the problem of insulating a concrete ceiling affects all owners of both apartments and private houses. Therefore, next, we will talk about the insulation of such floors.

How to insulate a concrete ceiling outside and inside?

Reinforced concrete is an excellent composite material that has good strength characteristics, which cannot be said about its thermal insulation qualities.

Insulation of a concrete ceiling from the inside and outside

Heavy concrete has a fairly high thermal conductivity coefficient - 1.7 watt/(m*deg), which makes it an unsuitable material for enclosing rooms where the temperature inside must be positive in winter. At the same time, concrete has a heat capacity of 840 J/(kg*deg), which allows it to accumulate heat well and release it if necessary, if the thermal insulation is done correctly.

Construction of a multilayer thermal insulation “pie”

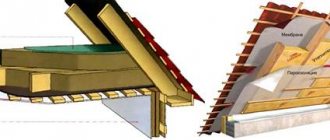

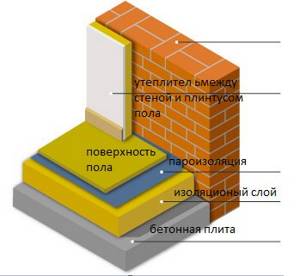

Proper thermal insulation consists of several layers. In cross-section, such a design will look like a kind of pie. Regardless of which method of thermal insulation will be used, work must begin with certain stages.

- If repairs and thermal insulation of a concrete floor are being carried out in an already erected building, the old screed must be completely dismantled, then the sand and gravel cushion must be refilled and compacted thoroughly.

- Fill the resulting cushion with a layer of “lean” concrete, which will act as a base for heat and moisture insulation.

- Wait until the concrete base gains strength and hardness, and lay waterproofing material on it.

Construction of a multilayer thermal insulation “pie”

Try to do everything with maximum compliance with the instructions. Any mistakes can lead to moisture penetrating into the thermal insulation, and this will have an extremely negative impact on its performance properties. After some time, the moisture will reach the finishing screed, which will lead to an increase in air humidity in the room. The floors will always be cold, and the screed itself will soon collapse. To avoid all these negative consequences, the waterproofing material must be laid with an overlap and all joints must be taped.

After completing the installation of the waterproofing material, you can safely begin laying the insulation. Plates and mats are fixed using special glue. The materials themselves should be placed in space. This approach allows you to reduce the risk of cold bridges and achieve higher strength of the insulation layer. Along the perimeter of the thermal insulation, as well as between the edges of the material and the wall surface, you need to place a damper tape.

After the main thermal insulation material has been completely laid, you need to fix another layer of moisture insulation on top of it, place a reinforcing mesh on it for greater structural strength, and then pour a rough screed from concrete mortar. At this stage of the work, you can perform additional insulation of the concrete floor by replacing crushed stone with perlite or expanded clay.

If you decide to do this, remember that perlite and expanded clay are characterized by specific performance properties, due to which such insulation materials are recommended for use in “semi-dry” concrete screed. It is better that the mixture contains filler from as many different fractions as possible. This will allow you to achieve the most dense filling of the solution and will significantly increase the strength of the screed.

The screed must dry completely and gain the required strength. Only after this will it be possible to begin installing the finishing coating. At this stage, it is also possible to increase the thermal insulation properties of the floor. You just need to lay a special insulating substrate and select materials that are characterized by normal thermal conductivity. The substrate in this case is foamed polyethylene or cork material.

Foamed polyethylene

For example, foamed polyethylene cannot be combined with linoleum; in this situation, cork is better suited. So before purchasing a reinforcement liner, be sure to check with your sales consultant to see if it is compatible with the finish you have chosen.

Cork backing

How and how to insulate the concrete ceiling of your home?

In order for thermal insulation measures to work, it is necessary to ensure the technological correctness of the work so that all the physical properties of the materials involved in the work retain their specified characteristics. First of all, the insulation must be protected from moisture and from physical impact (birds, rodents).

Insulation of concrete floors is relevant only for the upper floors of the building. There are, of course, unfavorable situations related to the social situation in depressed settlements, where residents move out of their apartments en masse. And the remaining residents of multi-storey buildings have to fight to maintain heat in their apartments.

Concrete floors can be insulated both from the inside and outside.

The negative aspect of insulation from the inside is that the reinforced concrete slab ceases to be a heat-intensive structural element, and the cold boundary moves closer to the heated room, forming new cold bridges.

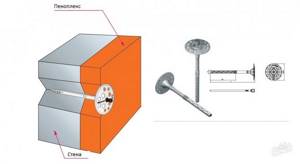

Insulation of concrete ceiling with polystyrene foam

When installing internal thermal insulation from materials based on polystyrene foam (foam), first you should clean the ceiling surface from dirt and crumbling particles. Next, the expanded polystyrene slabs are glued to the ceiling using polyurethane foam or regular tile adhesive, and the initial fixation of the slabs should be ensured to prevent them from falling. This is done with the help of “umbrellas”. It is recommended to lay out expanded polystyrene boards with gaps that are subsequently filled with polyurethane foam.

Finishing options for such insulation can be:

- putty applied to a reinforcing mesh fixed over the insulation;

- suspended ceiling made of plasterboard, lining, decorative panel;

- the most practical option is a suspended ceiling.

Also, when using polystyrene foam, good sound insulation is provided.

Insulation with mineral wool

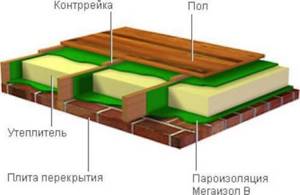

If mineral wool insulation is used indoors, it is necessary to make a frame from timber or special galvanized building profiles, secure the insulation, install a vapor barrier using special membrane fabrics, and complete the installation of the ceiling. If the insulation is of poor quality, moisture will penetrate through the insulation and condense on the surface of the floor slab, which will lead to saturation of the insulation with moisture and, accordingly, loss of its properties (the work will have to be redone).

Insulation with cotton wool from the inside video:

It is preferable to insulate concrete structures outside the building; with this method of insulation, concrete also participates in retaining and preserving heat.

Floors can be insulated with bulk materials such as expanded clay, slag, sawdust. In the case of sawdust, it is necessary to ensure protection against accidental fire. These methods do not require any additional costs.

The method of insulation using mineral wool is quite simple. A layer of vapor barrier (special fabric materials, roofing felt) is laid on a flat concrete floor, then a layer of insulation is placed directly, and a layer that protects from wind and moisture is placed on top of the insulation (special fabric materials, roofing felt).

Exterior insulation with mineral wool video:

Insulation with polyurethane foam

When insulating the floor with polyurethane foam, you will have to use the services of specialized organizations, but the result will justify the money spent. Polyurethane foam is sprayed under pressure into an aerosol, the two components of the polyurethane foam immediately react, and the resulting foam expands to fill voids.

If the attic space is used and a durable floor is needed for movement, wooden logs are installed from a board with a section of 100 by 50 mm in increments of 500 mm (depending on the thickness of the floorboard). The logs are installed at a level at a height that provides the required layer of heat-insulating material. After installing the logs, insulation is placed, it can be any of the above materials, and upon completion of the insulation, a wooden floor is laid. In this case, the tree will also participate in thermal insulation.

The floor can also be made of concrete if a dense material like extruded polystyrene foam is used as insulation. Expanded polystyrene is laid on a flat floor surface, then a reinforcing mesh is laid on top and a concrete or mortar screed is made. If the floor slabs are laid unevenly, it is recommended to make a leveling screed.

Thermal insulation work must be carried out after thermal engineering calculations.

Thermal insulation for floors: types and features

Insulation is required for all floors in the house - attic, basement and basement, interfloor. But when choosing a material, different heat loss indicators for rooms for various purposes are taken into account:

- up to 30% is lost through walls;

- the roof causes up to 20% losses;

- door and window openings give losses within 25%;

- up to 25% goes through the foundation and floors.

This difference occurs due to different temperature conditions, therefore the choice of a heat insulator should be approached individually. It is also necessary to take into account the features of laying and operating the material, the possibility of using certain materials.

When choosing the characteristics of a thermal insulation material, it is necessary to take into account the heat transfer resistance. For this, a special formula is used: R=δ/λ, where R is the resistance value, δ is the thickness of the heat insulator, λ is thermal conductivity. Table values are substituted into the formula, taking into account the location of the insulation and the climatic zone:

| Type of design | I zone | II zone | III zone | IV zone |

| Cold attic floors | 3,3-4,95 | 3-4,5 | 2,6-3,9 | 2,2-3,3 |

| Cold basement ceilings | 3,5 | 3,3 | 3 | 2,5 |

| Overlapping plinths and basements located above ground level | 2,8 | 2,6 | 2,2 | 2 |

The main materials for insulating floors are mineral wool, expanded polystyrene and polyurethane foam, and various types of bulk materials. They all differ in installation methods and technical and physical properties, which allows you to select the most correct insulation for a particular type of floor.

Mineral wool in mats or rolls is the most common material, which has a number of advantages:

- environmental friendliness;

- affordable price;

- excellent fire resistance;

- resistance to aggressive environments;

- high rates of heat and sound insulation.

Installation of this material is extremely simple; it does not require special equipment or high qualifications. It is this material that is used for interfloor ceilings and attics, providing warmth and comfort.

Polystyrene foam has similar characteristics to mineral wool, but it is produced in the form of rigid slabs. Its price is quite low, the material has excellent noise and heat insulation properties, and resistance to humidity. But for residential buildings it is recommended to use only special fire-resistant material, the price of which is significantly higher than the cost of conventional foam plastic.

Expanded polystyrene with a dense structure and relatively light weight is usually used for attics and crawlspaces. The slabs are easy to cut and lay, the material has excellent thermal insulation properties, while it is strong and durable.

Polyurethane foam is a sprayed material; it is applied using a special installation, that is, the services of qualified materials are required. The advantages include strength and a relatively thin layer of insulation, low weight, and dense filling. The properties of polyurethane foam insulation make it one of the best options, but cost and complex installation prevent the material from becoming as widespread as mineral wool.

Bulk materials are used for subfloors and attics. The most inexpensive option is expanded clay, but it is not suitable for attic floors due to its heavy weight. Another option is eco-wool, made from recycled cellulose. This is an inexpensive, high-quality material that is lightweight, resistant to combustion and biological damage. The material can be applied using various methods, among which bulk is the simplest and most undemanding. Sawdust insulation for attic floors is rarely used today, since the material is flammable, although it has a minimal price compared to other heat insulators.

How to insulate a concrete ceiling with thermal insulation materials

The need to insulate a concrete ceiling from the inside often arises among owners of the upper floors of buildings with a flat roof. If it is possible to insulate the ceiling from the attic side, then this is the best option to keep the apartment warm.

Multi-storey buildings in cities traditionally have inter-storey floors made of concrete slabs . Some private houses have the same floors, resting on the foundation or its continuation - the ground floor, where utility rooms for various purposes are located.

Floor slab - ceiling and floor at the same time in apartment buildings. The slabs rest on load-bearing walls, the ceiling is covered with several slabs. The sealing of the seams between the slabs and the places where the slabs rest on the walls cracks: either due to shrinkage of the building, or poor work of the builders. Part of the heat leaves apartments precisely through the joints of the slabs: wall or ceiling.

Houses in need of major repairs are usually insulated from the outside using the thermal fur coat method . This method is applicable for insulating the ceiling from the inside. Having some construction skills, you can insulate the ceiling from the inside yourself.

Liquid thermal insulation AKTERM Concrete - insulation of an apartment from the inside

Arrangement of thermal insulation of residential and industrial premises is one of the most important stages of finishing work. If you do not pay enough attention to this issue, in winter the walls will freeze through, despite the heating, and the corners will be constantly covered with condensation, the presence of which will ultimately lead to the spread of pathogenic mold. However, the development of construction technologies does not stand still, and today you can equip your home or office with the most reliable thermal insulation thanks to AKTERM Concrete without damage to your wallet or much labor.

How to insulate a concrete ceiling

Houses that were built 20-30 years ago were designed taking into account maintaining heat in the house with excessive consumption of thermal energy . This is due to the fact that gas and electricity were cheap, and therefore the requirements for thermal conductivity of building panels were low. But the times of cheap energy consumption are over; houses still operate with heat losses, for which the owners pay.

The natural desire to reduce heat loss is to insulate the building . There are enough methods and materials for this.

But if putty is supposed to be applied over the material, this condition is not necessary.

In the course of the work that you will now see, decide what tool and material you need.

1. Preparing the ceiling. Remove the peeling plaster, seal the cracks and cracks with cement mortar. Apply two coats of primer perpendicular to each other.

2. Leveling the ceiling : using a thin layer of putty if the ceiling is flat, or immediately after priming, level the ceiling with a 50 x 50 or 50 x 70 mm beam along the location of the slabs and at a distance so that the joint falls on the central axis of the beam.

The primer is applied with a roller or brush. If the ceiling is smooth and covered with a thin layer of putty, then make notches with a spatula, clean it and prime it with a spray bottle: this additionally blows away dust from the ceiling, and the primer under pressure penetrates deeper into the pores of the concrete slab.

3. Then apply a sheet of insulation , mark the boundaries of the sheet and apply a layer of 1-2 mm KNAUF Sevener plaster-adhesive mixture and smooth it with a comb spatula.

Selecting and applying a primer

The labels on many packages of modern plaster compositions state that they can be applied to the ceiling immediately, without first covering it with a layer of primer. However, most finishing specialists are unanimous in their opinion: priming is not just necessary, but necessary! Here are the reasons for this opinion:

- The cost of priming in the overall estimate is relatively small.

- The priming process also takes a little time and effort.

- The result of working with a primer is much better than without it.

- If you plan to paint the plastered ceiling, the primer will reduce paint consumption and become an additional guarantee that the layer of plaster will not collapse on your head.

Therefore, it is worth applying a primer before plastering work. Even though you have to wait until it dries, the cost of time and money to redo it if the plaster cracks or collapses will be much higher.

The primer should be applied to a thoroughly cleaned ceiling in two layers. The first layer is absorbed into the pores of the base material, and the second will cement the plaster and improve its adhesion. But before applying each new layer, the previous layer must be thoroughly dried.

The choice of a specific primer mixture depends on the budget and the type of mixture used for plastering work. It is most optimal to use two types of primer. First, the ceiling is rolled with a deep permeability compound. It fills all the pores of the concrete and prepares it for further work.

Read the article for mortar for plastering the stove: here

The second layer is a “concrete contact” type composition. It is thicker and often tinted so that it stands out well against gray concrete. Thanks to the addition of dye, you can notice which area is not well treated. After this composition has dried, it can be plastered.

Do not save the primer. If the first pass resulted in all the primer being absorbed into the concrete, invest the time and money into additional priming. But the plaster will adhere well to a well-primed ceiling and will last for many years.

Insulation of the ceiling in the basement of an apartment building

The choice of insulation method depends on the purpose of the basement:

- Premises for storing agricultural products;

- Placement of heating and plumbing equipment;

- Arrangements for gyms, billiard rooms;

- Premises for other purposes.

Of these, it is necessary to designate: heated and unheated basements. This is important for residents of the first floors of apartment buildings. As a rule, residents insulate concrete floor slabs with basements by installing additional thermal insulation on the floor side . It is not only effective, but also cheaper.

In most cases, it is necessary to open the floors down to the cement screed and eliminate defects (potholes, cracks); You can additionally pour a thin layer of self-leveling cement mortar, and after hardening, make a substrate from the thermal insulating material Parkolag from ICOPAL - a Finnish thermal insulating substrate for laminate, linoleum, parquet.

This substrate is laid on a flat surface of a cement screed without waterproofing or vapor barrier, because the bottom layer of the substrate has micro-gaps with the floor and this achieves ventilation between the laminate and the concrete floor.

In another case, storage facilities for agricultural products . In addition to maintaining a certain temperature, such cellars must be dry so that the food lasts longer. Warm air, rising upward, encounters a barrier in the form of a cold cement slab, where it cools to the “dew point” on its surface and falls in the form of droplets from the ceiling. To prevent this from happening, you must prevent warm air from coming into contact with the stove. Installing ventilation with temperature control will solve this problem, but we need to look at what energy consumption occurs.

A simple “vent” device, natural ventilation , directs the convection flow in the desired direction and prevents air vapor from depositing on the surface of the slab. Another thing is maintaining the temperature. This is where it is necessary to insulate the ceiling, and possibly the entire basement room, in order to increase the temperature inside. The insulation method is not new - it is the same as for walls:

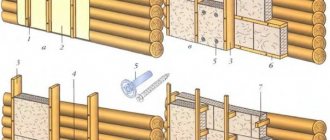

- Additional beams are attached to the ceiling, from wall to wall: an edged board 20 mm thick and 100 mm wide, impregnated with an antiseptic solution, is attached to the ceiling with an edge using corners along the entire length with a distance of 50-60 cm between each other.

- The junctions with the ceiling are foamed with polyurethane foam. Between the beams prepared in this way, roll insulation is laid, then a vapor barrier is fastened with a stapler, and the seams are taped.

- Then a spacer strip 10-15 mm thick is nailed along the beams.

- They cut sheets of gypsum board or gypsum board "Knauf", you can use moisture-resistant plywood and sew them to the slats.

You can use a stainless metal profile, attaching it to the ceiling on hangers and also laying thermal insulation with subsequent filing of gypsum boards.

Energy efficient house

- 1. Thermal insulation of basement floors

- 2. Insulation thickness

- 3. Basement design

Basement floors above cold undergrounds can be beams or slabs. To insulate them, as a rule, various fiberglass or mineral wool thermal insulation materials are used.

Thermal insulation of basement floors

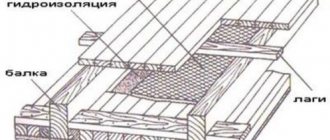

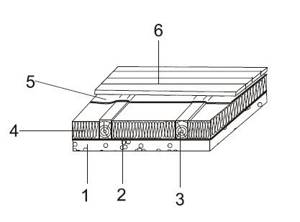

When insulating slab basement floors, the thermal insulation is laid on load-bearing slabs, placing it between joists installed on a reinforced concrete slab through gaskets made of roofing felt, waterproofing material or other waterproofing material (Fig. 4.23).

The thickness of the insulation is determined depending on the heat-shielding properties according to the thermal conductivity coefficient of the material λ (Table 4.3).

A vapor barrier is placed on top of the insulation, which prevents the thermal insulation from being moistened by water vapor from the internal air. The panels of vapor barrier material are rolled out with an overlap of at least 100 mm, after which the seams are taped with a special tape or tape to ensure tightness.

The name “Gidroizol” has many analogues under different trade names: hydrostekloizol, stekloizol, steklogidroizol. Gidroizol is a popular waterproofing material that consists of bitumen, filler and other technological additives, which, after going through a process of mixing and melting, are continuously applied to two sides of the base.

The use of hydroglass insulation is most common in the construction of bridges, platforms, tunnels, hydraulic basements and for building foundations. In addition, the material is widely used in anti-corrosion coating of pipelines and when laying flat roofs. For more details, see https://www.izoart.ru/gidroizol.html, https://www.stroyportal.ru/vendors/brand1693.html.

When using foil vapor barrier materials, they are installed with a shiny surface towards the warm room. In this case, a small air gap must be provided between the vapor barrier and the base of the floor.

Insulation thickness

Table 4.3. Determining the thickness of insulation when insulating slab basement floors

Thermal conductivity coefficient of insulation, W/(m×°C)

Insulation thickness, mm

Rice. 4.23. Insulation of slab basement floors: 1 - floor slab; 2 - gasket made of roofing felt or waterproofing material; 3 - wooden beam; 4 - insulation; 5 - vapor barrier material; 6 - floorboards or subfloor

When thermally insulating floors, care must be taken to eliminate “thermal bridges”. In Fig. Figure 4.24 shows the elimination of the “thermal bridge” at the junction with the outer wall of the building.

Insulation of a concrete ceiling in the basement of a private house

Additional rooms for various uses are being built in the basements of private houses. The insulation of agricultural product storage premises is similar to that for the basements of apartment buildings. It’s another matter when basements are insulated for the purpose of additional space for living activities.

Such rooms are usually always heated. Their heat is insulated when the basement is located under a terrace, garage or other unheated premises. The method of insulation is the same as for apartments with attic floors, if it is not possible to insulate from the outside.

Insulation of a concrete ceiling in a private house

If it is possible to insulate the ceiling from above, then the scheme is as follows.

On the side of the heated basement, in order to preserve heat, it is recommended to insulate the walls , and the ceiling is more insulated for sound insulation purposes, so high-density foam plastic is attached to the ceiling with an adhesive solution. Extruded polystyrene foam (XPS) boards can also be attached. This material has a dense structure and high thermal insulation and sound insulation properties.

In addition to the above methods, a more expensive method may be suitable - applying a polyurethane foam (PPU) layer to the insulated surface . Without special equipment, high-quality components for foam formation, mixing and application technology, it is impossible to make thermal insulation yourself.

So, to successfully insulate your basement, determine the cause of heat loss, the location of the leak, and the formation of condensation in the insulation.

The situation urgently needs to be corrected. For questions regarding thermal insulation of basements, please contact specialized construction organizations . A specialist will determine the method of thermal insulation of a particular room. Additional waterproofing or installation of drainage systems may be required. This will be determined by a specialist from a company engaged in complex work on thermal insulation and ventilation of premises. Only a professional approach to this problem will reduce the costs of this work.

Insulation using foam plastic

Polystyrene foam is one of the most popular materials for insulation. It is lightweight and easy to cut even with a regular cardboard cutter. In a word, working with polystyrene foam is convenient, fast, pleasant and, in principle, not difficult. The main thing is to take the correct measurements and not cut off too much from a whole sheet. But even if you overdo it, there is nothing fundamentally terrible about it: this place can be easily filled with polyurethane foam. Let's present the advantages of polystyrene foam in the form of a short list:

- it is easy to cut;

- easy to transport to the top;

- it is not afraid of moisture and is not sensitive to temperature;

- it is not suitable for consumption by insects and rodents;

- if the foam is laid correctly - on a dry base treated with an antiseptic, the likelihood of fungal formations (mold) appearing is minimized;

- the material has a relatively low cost.

The list can be continued, but I think this is quite enough. We have listed the main positive aspects of the material.

But foam plastic can also be different. Yes, there are different manufacturing companies, but that’s not about that now. The fact is that the sheets are produced in different parameters. In this case, we are interested in thickness.

For insulation of residential premises, sheets with a thickness of 5–7 cm are usually used, and their density, as a rule, is 15 kg/m³. Of course, the higher the density, the higher the material’s thermal insulation ability. You can, of course, choose 25 kg/m³, you can lay the sheets in two layers - this is not forbidden.

But, nevertheless, there is a recommendation: if you are going to install an attic floor made of hard material (for example, fiberboard/OSB boards), then it is enough to choose polystyrene foam with a density of 15 kg/m³. If you do not plan to install a hard surface, for better thermal insulation you should choose sheets with a density of 25 kg/m³.

In general, if there is such a possibility, then a hard floor should be installed in any case. This will allow you to store various things in the attic or even turn it into additional living space, if, of course, it is properly equipped.

But if there is no hard surface above the sheets, then it is not advisable to walk on them often, much less move objects. Simply, they are not designed for this, no matter what density indicator they have.

Insulation from a wooden or brick attic is not fundamentally different: in both cases, the process consists of simply laying polystyrene foam on the floor of the attic. More specifically, the following work needs to be done:

- check the entire wooden structure for rot. If you find a rotten area, it must be cut out and replaced with a new piece of wood, pre-treated with an antiseptic. In general, it would be a good idea to treat all elements of the wooden structure with an antiseptic. Even if these measures were taken during the construction of the house, prevention will never be superfluous. Moreover, in matters related to construction;

- clear the attic floor of debris (including small ones) - the base must be clean;

- take the necessary measurements and make calculations;

- cut foam sheets according to calculations;

- lay polystyrene on the surface. Be prepared for the fact that this material will cost more than the foam itself, but it is quite justified. In essence, there are alternative options, and in some cases they can do without it at all;

- lay prepared foam sheets on the attic floor;

- fill the gaps between the sheets with polyurethane foam. The distance between the sheets and the supporting structures also needs to be foamed.

How to insulate a concrete ceiling?

Concrete ceilings can cause a lot of trouble for the owners of an apartment or private house with reinforced concrete floors. The main problem is their ability to perfectly transmit noise from neighbors and poor heat-saving characteristics. Only owners of apartments in high-rise buildings face the problem of noise from neighbors, but the problem of insulating a concrete ceiling affects all owners of both apartments and private houses. Therefore, next, we will talk about the insulation of such floors.

Vapor barrier: barriers and membranes

The problem of moisture condensation is a key issue in the insulation process. If this phenomenon is not taken into account, the entire procedure may be useless.

The danger also lies in the fact that after installing the insulation from the inside, the state of the ceiling slab becomes unknown , all the processes occurring in it are hidden from the view of the observer. The owner often finds out about the presence of damage when the ceiling is completely damaged.

One of the effective ways to eliminate moisture condensation is to install a vapor barrier film or membrane. Let's look at them in more detail:

Vapor barriers

A vapor barrier (or vapor barrier) is an ordinary polyethylene film that forms an airtight barrier to water vapor. You can use specialized types made for vapor barrier of surfaces, but you can use a simple polyethylene sleeve - the result will be the same.

The vapor barrier is installed in strips, with an overlap of at least 15 cm and an overlap of about 10 cm on the walls (at the end of the work, the excess film is carefully cut off). Longitudinal joints are glued with special tape, which makes the insulation sheet airtight.

The vapor barrier is installed on top of the heat insulator when installed from the inside or between a wooden floor and an impenetrable insulator when insulating from the attic side. On concrete floors, a vapor barrier is installed only when insulating from the inside, on top of an impenetrable heat insulator.

Membranes are films with one-way permeability . They do not allow moisture to enter, but they are not an obstacle to the release of steam outside.

Membranes are installed to protect the insulation from getting wet.

For example, when insulating a concrete slab from the attic side with mineral wool, in order to prevent the insulator from getting wet, a vapor-waterproofing membrane is installed. It allows water vapor to escape freely, but does not allow external moisture to enter the insulation, allowing it to maintain its performance qualities.

Options for arranging an insulating layer

The most important factor when creating a heat-saving layer will be the type of construction. If this is a private house, then all work can be carried out from the attic, but in a city apartment, this is only possible on the last, upper floors of buildings. But, usually it is the residents of these apartments who feel the need for this procedure.

In an apartment building, you will have to insulate from the inside of the premises, and here the choice of material will be of great importance - it should be as thin as possible, and at the same time retain heat very effectively.

In private houses, insulation work can be carried out by placing a heat insulator in the internal cavities of the ceilings. Here you can use a lot of different materials - from sawdust to the most modern heat-insulating coatings.

Recommendations for choosing thermal insulation for concrete floors

At the stage of choosing a material for floor insulation, it is necessary to pay attention to some important characteristics

Recommendations for choosing thermal insulation for concrete floors

Density. The weight of thermal insulation directly depends on it. The less dense the insulation, the more pores it contains and the greater the amount of heat will be retained inside the room.

Strength. It is better that the strength of the material is as high as possible.

Thermal conductivity. This coefficient reflects the ability of thermal insulation to transmit heat. It is better for this indicator to be as low as possible.

Moisture resistance. The higher it is, the better.

Moisture permeability. This figure should be minimal. Otherwise, the insulation will very quickly become saturated with moisture, against which its thermal insulation characteristics will noticeably deteriorate.

Durability. At this point, everything is very clear: the greater the durability, the longer the selected material will last.

Environmental friendliness

Those who plan to build an environmentally friendly building using natural and completely safe materials should pay attention to this parameter.

Popular insulation materials for concrete floors

- Basalt and mineral wool. The most popular and widely used insulation materials. Among the advantages, low density and relatively low thermal conductivity should be noted. Also, mineral wool insulation is characterized by high sound insulation properties. The main disadvantage is the low environmental friendliness of the insulation. It also absorbs moisture, which does not have the best effect on its characteristics as a heat insulator and overall durability.

- Styrofoam. Along with mineral wool insulation, it is a very popular material. The only drawback is poor environmental friendliness. Otherwise, if we consider polystyrene foam as insulation, there are no complaints about it.

- Extruded polystyrene foam. Its properties are similar to polystyrene foam, but it is noticeably ahead of it in almost all respects.

- Polyurethane foam. It withstands temperature changes, water ingress and various mechanical loads well. For many years it perfectly performs its main function without deteriorating its thermal insulation qualities. The only negative point is that it is artificial and not environmentally friendly.

- Expanded clay. Characterized by very high thermal insulation properties. It is an environmentally friendly material with low thermal conductivity. Despite all the advantages, expanded clay is also not without its disadvantages. First of all, this is a fairly large weight of the finished insulation layer. Secondly, the material absorbs and retains moisture for a long time, which somewhat worsens its properties and can lead to other problems.

- Foam glass. It has many undeniable advantages, for example, low weight, very low thermal conductivity, environmental safety, moisture resistance, durability, etc. Among the significant disadvantages, one can highlight only the relative fragility of the insulation, i.e. it is not adapted to large mechanical loads.

- Cork. A completely natural material with good thermal insulation properties. Cork works best when used in the construction of raised floors, and also as a heat insulator under the main covering.

- Perlite. According to the method of application, it has much in common with expanded clay. The only difference is that perlite is noticeably superior in quality to expanded clay, which makes its use much more preferable.

The following is a simple table in which you can consider the main characteristics of existing insulation materials. Be sure to take them into account when choosing a material in order to choose the insulation that is best suited specifically for your concrete floor.

Table

Material selection

It is possible to insulate a concrete ceiling using almost the same materials that are used for other types of buildings. The only difference will be that the reinforced concrete floors are not hollow, and it will not be possible to take advantage of the existing voids.

The main and most popular insulation, regardless of the type of construction, is mineral wool. It has many advantages over other types of insulating materials, but it also has a significant drawback - it is necessary to lay a sufficiently thick layer of mineral wool to ensure high-quality thermal insulation.

If the height of the room where the ceiling is supposed to be insulated is not too large, using mineral wool is not the best idea. It will “eat up” too much space under the ceiling. The only option when this parameter will not be of fundamental importance is thermal insulation of the ceiling of the upper floor of the building. All work can be done from the outside of the ceiling, and this will not in any way affect the existing height of the rooms.

The second, no less popular insulation material, which is used with great success for the same purposes in city apartments and private houses, is polystyrene foam. It is laid in a much thinner layer, which no longer reduces the height of the premises so much. It can also be used for outdoor installation.

All bulk insulation, such as expanded clay, or mixtures of sawdust with various other materials, can only be used externally. They cannot be used indoors for thermal insulation of the ceiling.

Foam plastic and expanded clay

The structure of polystyrene foam resembles foamed plastic material with a cellular structure. Most often it is found in the form of square sheets measuring 1mx1m. Its peculiarity is that it is used not only as an internal insulation, but also as an external one. The thickness of the foam varies from 20 to 100 cm. It is also used as a base for putty. When the ceiling is insulated from the inside with polystyrene foam, it can perfectly level the surface. This material has a number of other advantages:

- universal;

- has a low price;

- durable;

- reliable;

- provides a good level of thermal insulation.

Fastening foam plastic is similar to installing penoplex

Expanded clay is made from clay; in appearance it resembles balls. The principle of installing expanded clay on the ceiling is to pour it on the floor of the attic. Therefore, this method of insulation is applicable only for private houses. But at the same time it has the following advantages:

- does not decompose;

- fire resistant and fireproof;

- eliminates the possibility of insects and rodents appearing in the material;

- has good sound insulation;

- waterproof and frost-resistant;

- has good heat dissipation;

- has an affordable price.

If you are planning to insulate your ceiling with expanded clay, pay attention to the following recommendations:

- Before laying expanded clay, you should take care of the waterproofing layer on which the material will be poured.

- The first thing to cover is the rafters and chimney.

- To ensure high-quality thermal insulation, the expanded clay layer must be at least 16 cm.

Insulation methods

The only difference in the methods will be that some of the heat insulators can be mounted on a specially constructed frame, and some can be laid on the outside of the ceiling, which is the floor in the upper room.

From the inside of the rooms, you can simply glue foam tiles to the ceiling, immediately obtaining both the design of the ceiling with a beautiful finishing material and a small heat-saving layer.

But such insulation, as a rule, is not enough. More significant measures need to be taken. And with this, the same polystyrene foam can help, but with a greater thickness than decorative tiles.

Its advantage is that you can glue foam boards directly onto the ceiling using regular tile adhesive. After gluing, the foam plastic is plastered over the mesh and finished with a finishing layer of decorative coating. The method is inexpensive, but requires fairly good plasterer skills for subsequent finishing.

If you don’t have such skills, you can use any insulation, like mineral wool. They are not just attached to the ceiling, but placed in a special frame. It has to be collected.

Assembling the base is exactly the same as for any suspended ceiling system. First, a vapor barrier is laid into the frame base. The overlap of adjacent strips must be at least 10 centimeters. All joints of the material are taped with reinforced construction tape.

Next, you need to lay a layer of mineral wool or other similar insulating materials. Its thickness in each case is calculated separately, but, as a rule, it is equal to the thickness of the concrete floor.

On top of the insulation, another pass is made with a vapor barrier, gluing all joints and overlaps.

After this, you can install a plasterboard finish on the frame, or use another finish. One option could be plastic or wood-imitating panels.

When creating a heat-saving pillow outside, all work begins with laying a vapor barrier film or glassine. Other vapor barriers can also be used.

Next comes the insulation. Options are possible here, since on the outside there is usually an attic, the height of which can be sacrificed and cheaper types of insulation can be used, which require laying in a thick layer.

If you plan to walk on an insulated surface, it is necessary to lay joists for the future floor. The cells obtained after their installation are placed sequentially - a vapor barrier film or other types of insulators, an insulating layer, and again a vapor barrier.

Next, a sheathing is constructed that creates the necessary ventilation gap between the floor and the layer of insulating material. It is necessary to ensure the release of moist air.

The subfloor is laid on the sheathing slats, which is subsequently covered with a finishing coating.

External garage roof insulation technology

Since the room itself is not always heated, it is extremely important that the material itself retains its insulating abilities at any room temperature. An equally important point concerns machine exhausts and vapors from fuels and lubricants, which accumulate on roofing insulation over time and can reduce their fire resistance. This is why you should choose mineral wool or fiberglass as insulation.

If the installation of the insulating layer will be carried out in the garage with your own hands, it is worth considering the option of foam insulation or polystyrene foam, which are easy to use. These same materials are resistant to possible deformations and retain their original elasticity throughout their entire service life.

That is why it is worth choosing mineral wool or fiberglass as insulation. If the installation of the insulating layer will be carried out in the garage with your own hands, it is worth considering the option of foam insulation or polystyrene foam, which are easy to use. These same materials are resistant to possible deformation and retain their original elasticity throughout their entire service life.

How to insulate a concrete ceiling?

Concrete ceilings can cause a lot of trouble for the owners of an apartment or private house with reinforced concrete floors. The main problem is their ability to perfectly transmit noise from neighbors and poor heat-saving characteristics. Only owners of apartments in high-rise buildings face the problem of noise from neighbors, but the problem of insulating a concrete ceiling affects all owners of both apartments and private houses. Therefore, next, we will talk about the insulation of such floors.

Options for arranging an insulating layer

The most important factor when creating a heat-saving layer will be the type of construction. If this is a private house, then all work can be carried out from the attic, but in a city apartment, this is only possible on the last, upper floors of buildings. But, usually it is the residents of these apartments who feel the need for this procedure.

In an apartment building, you will have to insulate from the inside of the premises, and here the choice of material will be of great importance - it should be as thin as possible, and at the same time retain heat very effectively.

In private houses, insulation work can be carried out by placing a heat insulator in the internal cavities of the ceilings. Here you can use a lot of different materials - from sawdust to the most modern heat-insulating coatings.

Consequences of the lack of protective layers

Thin insulation that does not have important protective layers or excessively thick insulation cause equal damage to a home. In this case, a distinction is made between mechanical and chemical destruction of concrete structures.

The absence of a heat insulator leads to the following mechanical damage:

- temperature changes, freezing/thawing cycles of building structures;

- frequent cycles of drying/wetting walls;

- destruction of concrete under the influence of wind and water.

Chemical damage includes bimetallic corrosion, the action of acid and alkaline vapors in the air, as well as corrosion from stray currents, as a result of which the carbonization process occurs on concrete, when alkalinity around steel embedded parts and reinforcement units is lost.

Material selection

It is possible to insulate a concrete ceiling using almost the same materials that are used for other types of buildings. The only difference will be that the reinforced concrete floors are not hollow, and it will not be possible to take advantage of the existing voids.

The main and most popular insulation, regardless of the type of construction, is mineral wool. It has many advantages over other types of insulating materials, but it also has a significant drawback - it is necessary to lay a sufficiently thick layer of mineral wool to ensure high-quality thermal insulation.

If the height of the room where the ceiling is supposed to be insulated is not too large, using mineral wool is not the best idea. It will “eat up” too much space under the ceiling. The only option when this parameter will not be of fundamental importance is thermal insulation of the ceiling of the upper floor of the building. All work can be done from the outside of the ceiling, and this will not in any way affect the existing height of the rooms.

The second, no less popular insulation material, which is used with great success for the same purposes in city apartments and private houses, is polystyrene foam. It is laid in a much thinner layer, which no longer reduces the height of the premises so much. It can also be used for outdoor installation.

All bulk insulation, such as expanded clay, or mixtures of sawdust with various other materials, can only be used externally. They cannot be used indoors for thermal insulation of the ceiling.

Why is it necessary to insulate?

According to modern requirements, single-layer insulation is practically not performed. The composition of the heat-protective cake is determined by:

- installation location: outdoor/external;

- characteristics of the wall;

- the type of insulation chosen.

If you ask a professional how it is preferable to insulate the walls of a residential building, from the outside or from the inside, the answer will be unequivocal - from the outside.

Internal thermal insulation is installed only as a last resort, when there is no other possibility, for example, the building is an architectural monument or the small distance between adjacent walls does not technologically allow the installation of insulation.

External insulation protects at cold temperatures, and to prevent household moisture from getting on the thermal insulation material, waterproofing is installed, in this case the dew point moves much further from the room to the street.

To prevent water from collecting between the wall and the heat insulator, a vapor barrier will need to be installed. Innovative heat-protective building materials are produced with a pre-installed vapor barrier layer.

In cases where the heat insulator is applied to the outside of wall structures, a wind barrier made of a vapor-proof membrane must be installed on top. It fences off the heat insulator from cold air masses hitting it.

Many novice craftsmen believe that there is no such thing as excess thermal insulation; this is not entirely correct. In thermal protection of buildings, the term used is excessive or excessive insulation.

A thick layer of insulation can disrupt the ventilation system of building structures. In connection with this, condensation will begin to accumulate, increasing the humidity in the room, which contributes to the occurrence of rotting processes and the formation of mold.

Insulation methods

The only difference in the methods will be that some of the heat insulators can be mounted on a specially constructed frame, and some can be laid on the outside of the ceiling, which is the floor in the upper room.

From the inside of the rooms, you can simply glue foam tiles to the ceiling, immediately obtaining both the design of the ceiling with a beautiful finishing material and a small heat-saving layer.

But such insulation, as a rule, is not enough. More significant measures need to be taken. And with this, the same polystyrene foam can help, but with a greater thickness than decorative tiles.

Its advantage is that you can glue foam boards directly onto the ceiling using regular tile adhesive. After gluing, the foam plastic is plastered over the mesh and finished with a finishing layer of decorative coating. The method is inexpensive, but requires fairly good plasterer skills for subsequent finishing.

Stages of external thermal insulation

For external insulation, the presence of an attic non-residential space is required. The process of laying mineral wool is simpler than during interior work and takes less time, because the mineral wool is attached not to the ceiling, but to the floor.

We follow the following procedure:

We cover the entire area of the attic floor with a layer of glassine, laying the sheets overlapping (10-15 cm is enough). We glue the joints or reinforce them with tape.

The effectiveness of the vapor barrier layer will increase several times if it is reinforced with sheets of 5-centimeter polystyrene foam. We lay rolled mineral wool of the standard 150-200 mm. We make sure that there are no gaps between the plates. If the rolls are covered with foil on one side, the insulation process ends here.

The sheets must be positioned so that the foil is on top. We fix the material with slats; it is not recommended to pierce the thermal insulation directly with nails. We stretch a thick film over simple mineral wool (without foil) (you can use greenhouse film) and fix it with slats. We glue all joints and joints with double-sided or regular tape.

External insulation with mineral wool - laying slabs on the attic floor

A floor made of any available material is laid on top: chipboards, plywood, boards. Sometimes the roof also requires additional insulation. Thermal insulation is carried out according to the same principle as the option for apartments, but with one caveat - instead of a powerful frame, a light sheathing of counter-battens is sufficient.