The house is insulated with mineral wool, serious money and a lot of time have been spent, but for some reason there is no expected effect. The rooms are cold, the walls and roof are damp... This is a fairly common situation for irresponsible builders and overly frugal customers. But it was necessary to take just one more step - cover the heat insulator with membranes...

Modern housing is becoming more complex and technologically advanced every year. It is not surprising, because recently the requirements for insulating materials and the characteristics of almost all elements of buildings and structures have increased significantly. The issues of thermal insulation of residential buildings, in particular, have become the subject of government regulation in many countries. As a result, multilayer structures using fiber insulation have become widespread. These are framed external walls, ventilated facades, insulated pitched roofs and ceilings.

However, an insulator based on mineral wool itself needs reliable protection. The fact is that wind pressure, atmospheric moisture, and vapors from rooms significantly reduce the thermal characteristics of mineral wool and the building as a whole. The use of building films and membranes allows maintaining the design efficiency of multilayer structures and avoiding the formation of condensation on building elements. At one time, membranes became a real breakthrough in building heating engineering; now it is impossible to imagine a residential building built without the use of this material. Membranes have proven themselves in practice, and they continue to be improved.

How membranes work

What is insulation afraid of?

It is believed that mineral wool does not absorb water, but it contains many pores and air channels, so that moisture can move within the material and be retained within it. The weight of stone wool insulation can increase up to 5% of its own weight. Moisture displaces air from the fibers - the thermal insulation characteristics drop (by 20–30% even with one percent humidification, many technologists claim), and cold bridges are formed. With significant temperature fluctuations, water freezes and melts repeatedly, expanding and destroying the internal structure of the insulation. If the enclosing and drainage structures work properly, water can enter the wool through diffusion from the premises, as a product of human activity, or from the outside - with moist air.

Air can penetrate into insulated facades and roofs, and then into rooms, from outside under the influence of wind and temperature pressure. The wind not only presses on the walls, but also creates turbulence. Somewhere cold and humid air is pumped into the structure, somewhere it is sucked out of the insulation, taking heat with it. This is how unplanned infiltration of structures occurs with a deterioration in their thermal resistance.

In ventilated structures of roofs and facades there are air gaps that act as convection channels. Air passing through the ventilation gaps, even at low speeds, “pulls” heat from unprotected wool, which immediately reduces the thermal insulation performance of the building as a whole to 30–40% of the design value. Moreover, convective air currents are capable of “weathering” binders, as well as fibers of most types of wool, also destroying the structure of the insulation.

Special properties of films and membranes

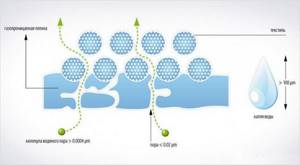

The main task of building membranes is to protect building structures from wind and atmospheric moisture. But at the same time, films used on external walls and roofs must allow water vapor to pass through them from the premises to the outside. From a physics point of view, any membrane is a semi-permeable film, a shell that separates two environments, regulating the unidirectional transport of substances from one zone to another.

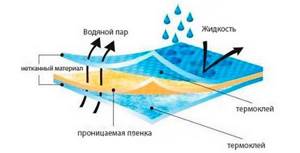

The main feature of most building membranes is the presence in their structure of diffusion layers with microperforations and micropores that are capable of conducting water vapor in one direction. Most often, vapor-permeable membranes have one thin functional layer and one or more protective layers that provide physical and chemical stability.

Some membranes (often called construction films) do not allow steam or water to pass through at all. They consist of several non-perforated layers of polyethylene, usually on a mesh backing. This is the so-called “vapor barrier”.

When choosing construction films and membranes, special attention should be paid to two main consumer properties:

- degree of vapor permeability

- moisture resistance

Construction membranes are made from synthetic fibers (polypropylene, polyethylene) in the form of textile woven or non-woven fabrics. Depending on the tasks assigned, building membranes can have a single-layer or multi-layer structure, including with a reinforcing mesh made of polyethylene fibers or an additional aluminum coating. With a small thickness, the membranes have very high strength and low elongation. They are resistant to ultraviolet radiation for a certain time and are not affected by fungi and microorganisms.

Some manufacturers offer membranes that not only regulate humidity conditions, but also have their own heat transfer resistance, which allows them to compensate for heat loss in the air gap zone. These are multilayer needle-stitched materials with a thickness of 10–15 mm, made on the basis of polypropylene.

The fire resistance of building films is also a fairly pressing issue, which can be solved in two ways. There are membranes whose polymer materials contain flame retardants in bulk; the second option is impregnation of finished canvases or application of protective compounds to their surface.

Another important nuance is the service life of the membrane. Obviously, the membrane must last as long as the enclosing structure as a whole. You should not use materials whose manufacturers are silent about their service life or limit it to 10–15 years.

The technical characteristics of membranes are significantly reduced due to aging of the material under the influence of high temperatures. The common declared indicators “up to +80°” are not always enough, especially in insulated metal roofing, where temperatures can reach much higher values.

So, a building membrane is a film that allows or does not allow vapor to pass through, but always stops water and wind. This is the basis of film technology.

Types of vapor barrier

Let's first understand what a vapor barrier is. This is a material that belongs to two types - preventing moisture from heated air from penetrating further or allowing it to pass through. In fact, the first type is a film, the second is a membrane. However, these concepts are often confused due to a lack of understanding of the difference, and due to the difficulty of translating instructions from foreign manufacturers

A one-way membrane is a layered material with special properties. It allows water molecules to pass through only in one direction; its thickness is comparable to the size of the molecule. Of course, they are attached so that the steam-permeable layer faces the warmer room - inside the house. In such cases, manufacturers ALWAYS indicate which side to place the membrane during installation and mark the required surface.

Double-sided membranes allow steam to pass through on both sides, so the mounting side is not important. The whole “trick” is in the special structure of the material.

At the same time, the membrane itself has low strength, therefore, to improve performance characteristics, it is supplemented with a layer of textile or non-woven material on one or both sides. The structure may also have a reinforcing layer in the form of a mesh, a reflective layer of aluminum foil. This type of vapor barrier is called “reflective”.

Types of building membranes

Depending on their purpose and, accordingly, some structural features, building membranes are divided into:

The vapor barrier layer is installed from the inside of the insulation; it should isolate the wool from moisture from vapors occurring in the premises of the building. An example of an application would be an insulated roof or the ceiling of an “attic” floor, where the wool underneath must be covered with a film. Also, a vapor barrier is necessarily used when insulating walls from the inside. The vapor barrier membrane has no pores or perforations; the lower its vapor permeability, the better. These materials are reinforced or unreinforced polyethylene film, sometimes with a layer of aluminum foil. Note that the use of vapor barrier significantly increases the level of humidity in the building, so special attention will have to be paid to ventilation of the premises.

Films with an anti-condensation coating can be considered a separate type of vapor barrier membranes. They are used under roofing materials that are afraid of corrosion - corrugated sheeting, galvanized iron, some types of metal tiles without internal coating. Such a membrane does not allow vapors to pass to vulnerable metal elements. The anti-condensation film is laid with a rough textile (absorbent) layer downwards, where moisture accumulates and is gradually removed without flowing back into the insulation or coming into contact with the metal. There must be a gap of 20–60 mm between this membrane and the wool.

Frequently asked questions about the installation of building membranes

Which side of the insulation should the membrane be attached to?

On an insulated façade, mineral wool is covered with vapor-release films only on the outside.

In insulated roof structures, diffusion, anti-condensation or volumetric membranes are mounted on top of mineral wool, similar to installation in ventilated facades.

Roof elements without insulation are protected with vapor barrier membranes from the bottom of the rafters.

If the walls are insulated from the inside, a continuous vapor barrier is needed - a non-perforated film is installed on top of the wool on the side of the room.

The insulation of the upper floor with the cold attic above is covered with a vapor barrier from below.

Which side should the membrane be laid on?

Vapor barrier films are usually double-sided (it doesn’t matter which side the material faces), but there are exceptions. Anti-condensation membranes are attached inside the room with a textile absorbent layer. Metallized films are also one-sided - the foil should face the room.

Installation of vapor removal (diffusion) membranes on one side or another must be carried out according to the manufacturer’s instructions. The same company can produce both double-sided and unidirectional films. The reference point is usually the different colors of different sides of the membrane, one of which most often has a clearly defined marking. In most cases, the “colorful” side of the membrane should face outward.

Is there a need for a ventilation gap near the membrane?

An air gap (about 50 mm) must be installed at the bottom of the vapor barrier films to ventilate possible condensation. The inner lining is not allowed to touch the vapor barrier.

Diffusion membranes are attached directly on top of insulation or a continuous coating of OSB or moisture-resistant plywood. But on top of such membranes it is simply necessary to make a ventilation gap to remove moisture. The ventilation gap in the roof is made using counter-lattice bars; in the design of a ventilated facade, the required layer is provided by racks or perpendicularly located horizontal profiles.

The anti-condensation film on both sides should have an air gap of about 40–60 mm.

How should the overlap of the canvases be?

Construction films and membranes are often marked with a line along the edge of the sheet, which indicates the size of the overlap - from 100 to 200 mm. For roofing, the membrane performs a waterproofing function, therefore this size can vary depending on the slope of the slopes (from 30° - 100 mm; 20–30° - 150 mm; up to 20° - 200 mm).

The diffusion membrane in the ridge area overlaps by 200 mm. In valleys, the material overlaps by 300 mm, plus, for small slopes, a second layer is laid along the entire length in the form of an additional strip extending 300–500 mm onto both slopes.

Note that the membranes must cover not only the total area, but also the ends of the insulation. Roofing membranes are installed on a drain gutter or on a metal drip.

Do I need to tape the joints? If yes, then with what?

Construction membrane sheets must be glued together. The joint must be airtight. For these purposes, special self-adhesive tapes are used, which are made on the basis of various non-woven materials: polyethylene, polypropylene, polyethylene foam, butyl, butyl rubber. They can be bilateral or unilateral. These tapes repair tears and damage to the canvas.

The choice of a specific type of connecting tape should be made in accordance with the manufacturers' recommendations.

The use of packaging tape (especially small width) to join construction films and membranes is a common cause of depressurization of joints.

How to attach the membrane?

Nails with wide heads and staples from a construction stapler can be used as temporary fasteners. However, truly reliable fixation can only be achieved with the help of counter rails.

The situation is somewhat more complicated when installing curtain facades. After installing the brackets, mineral wool slabs are laid, each of which is secured with one or two disc dowels. Next, a diffusion membrane is rolled out over the insulation, cut at the passage points of the brackets and fixed to the wall through a layer of wool using the same dowels. The number of fasteners must be at least four per square meter. If there is a choice, you need to drill in the area where the panels meet.

On roof slopes, membranes along the entire perimeter are glued to the structures using double-sided tapes. Using the same materials, regulating building films are fixed to various elements of the building: windows, doors, pipes, ventilation ducts, antenna stands... Tapes do not help on rough surfaces - polyurethane, acrylic, rubber adhesives, “fixers” are used here.

How long can the membrane be left open?

The resistance of building membranes to ultraviolet rays is limited. Usually it lasts up to 4–5 months, then the material loses its thermal resistance, and the material ages with the loss of most useful characteristics. Obviously, it is necessary to minimize the illumination of the membranes and install the cladding as soon as possible. No matter how hard we try to seal all joints and holes, these roll materials only work in tandem with the finishing outer layers, so heavy rain can cause the thermal insulation and structural elements to get wet. That is why it is better to install insulation, films and membranes in stages, and not for the whole house at once.

What mistakes should you avoid when installing windbreaks?

Of course, the first mistake is to install the film outside the house and, conversely, a vapor-permeable membrane inside the room. You need to remember that the membrane cannot perform the function of waterproofing, but the film will cope with this quite well.

It is also worth considering the features of the building itself and weather conditions. If storm warnings are not uncommon in the region, the house is subject to shrinkage, temperature changes, etc., then this all affects the connections of the windbreak sheets. Therefore, vertical overlaps are often additionally pressed with slats.

Some people use windbreaks as temporary roofing. Such a “greenhouse” will not last long. Since the membrane is not designed for such loads, it will quickly tear. Even on walls, it is not recommended to leave the membrane unprotected for a long time. It will be damaged by rain, hurricane or hail. The same applies to sheet wind protection. She may get wet. Therefore, it is worth planning your work in such a way as to close this layer as quickly as possible.

Instead of an epilogue

The use of building films and membranes is a prerequisite for the correct functioning of multilayer structures. Only with their help can one ensure proper temperature and humidity conditions inside the building. When working with membranes, there is usually no particular difficulty; you just need to choose the right material needed in a particular case and install it correctly.

Practice has shown that it really makes sense to protect insulation, especially when you consider that the cost of films and membranes during the construction of a cottage does not exceed 0.5% of the total estimate. But there is a lot at stake - the microclimate of the premises, the durability of building elements, the level of energy costs.

In order for a building to serve for a long time, while creating comfortable conditions for people to work and live, one cannot do without high-quality insulation. Nobody argues about this in the construction world anymore. It is necessary to insulate any buildings, regardless of their purpose, since building structures are not able to withstand high temperature loads.

If insulation is not carried out, the structures will freeze during the cold season. However, just using modern insulation is not enough. The developer must work thoroughly to create a full-fledged thermal insulation “pie”. The windproof membrane plays an important role in its composition. Many people use the Izospan moisture-proof membrane, which provides good protection from moisture and wind.

Wind and waterproof membrane Izospan: advantages

The peculiarity of this material is that it has good thermal insulation characteristics, which make it possible to provide a high level of protection of any buildings from negative factors such as wind and moisture.

The windproof membrane eliminates the possibility of high humidity in attics. This is ensured due to the presence of high heat-reflecting properties in the Izospan material, which provide protection against condensation. When installing a vapor-permeable membrane, connecting tapes are used, which ensures high tightness of the fastening. In addition, the material provides a high degree of wind protection for the building.

Currently, windproof membranes are widely used. It is used when carrying out internal and external work on thermal insulation of floors and walls . A windproof membrane is also used when solving problems of insulating floors. The use of this material protects structures from condensation and prevents damage to the finish.

When working on flooring, the Izospan windproof membrane is often used as a floor substrate. The use of this material for this purpose provides good reflection of infrared rays, which direct the heat flow directly into the room. In addition, good wind protection is provided.

When using the Izospan moisture-proof membrane, reliable protection is provided against:

- exposure to high humidity;

- occurrence of condensation;

- wind entering the premises.

Thanks to the functional aspects that are characteristic of the Izospan windproof membrane, it is possible to significantly reduce the temperature load affecting any building under conditions of temperature changes. The use of a windproof membrane as a moisture-proof material provides protection:

- roofs;

- walls and interfloor ceilings;

- floor.

The use of vapor-permeable material allows you to create favorable conditions for living in a house that has high-quality insulation. Note that windproof material is used to make special suits, which keep the person wearing such clothing dry in rainy weather and are well protected from the wind.

A membrane from well-known manufacturers that provides reliable wind protection, which is available in a large assortment on the market, is characterized by:

- good wind protection of roofing systems;

- reliable vapor barrier for walls and ceilings;

- connecting material joints using sealed tapes.

How to properly install Ondutis films and membranes?

In order for insulation films to function correctly, they must be installed according to the manufacturer's specifications.

Let's look at the features of installing building films and membranes using the example of materials

Moisture and wind protection of walls

Classic films for moisture and wind protection A100 and A120 can be laid with either side facing the insulation, while A100 Smart and A120 Smart with adhesive tapes already attached are installed with the logo facing up, with the tape facing the insulation.

Sequence of work when installing a ventilation façade:

— The roll is rolled out horizontally so that the strips lie tightly on the insulation. The canvases are mounted with a horizontal overlap of 10 cm, a vertical overlap of 15 cm. The film is secured with a stapler to the frame bars.

— The joints of the membrane sheets are glued with OndutisBL double-sided tape (with the exception of “Smart” films).

— Next, the film is fixed using vertical bars so that the gap between the film and the facade cladding is at least 3 cm.

— At the bottom of the insulating material, it is necessary to ensure unimpeded drainage of condensate.

The film can be used as temporary protection of insulation before installation of the cladding for no more than 2-3 months.

Roof waterproofing

Waterproofing films are used for cold roofs

OndutisRV, Ondutis RS, Smart RV, wind and waterproof A100, A120, A100 Smart and A120 Smart.

They protect the under-roof space from condensation and moisture seeping under the metal covering.

— The listed films are mounted with the logo facing up (clean side towards the attic).

Let's look at installation using OndutisRV as an example, as the most budget-friendly and sufficient option.

— The material is cut into sheets along the length of the roof and laid horizontally from the eaves to the ridge. A 1-2 cm slack is made between the rafters to drain condensate, and the film is fixed with a stapler on the rafters.

— Ondutis RV strips are installed along the valleys and inclined ridges (under horizontal stripes).

— The lower edge of the film is secured to the dropper using Ondutis BL tape. It is prohibited to discharge the film into the gutter.

The figure shows an option with insulation

— The joints of the film are glued with Ondutis BL tape.

— Ondutis RV is secured with an antiseptic bar along the rafters. The height of the bar is at least 3 cm for profiled coatings and at least 5 cm for non-profiled ones.

— We proceed to the installation of the sheathing under the roofing.

For an insulated attic roof you can use:

1. The same films as for cold roofing (OndutisRV, Ondutis RS, Smart RV, wind and waterproof A100, A120, A100 Smart and A120 Smart)

The difference in installation is that the part of the film sagging between the rafters should not touch the insulation. To do this, a 50mm high block is placed along the rafters, or part of the insulation is mounted under the rafters.

This ensures a double ventilation gap - between the insulation and the film and between the film and the roofing.

Otherwise, the installation is carried out in the same way as for a non-insulated roof (see above).

When using Smart films, you must remember that the protective tape is removed simultaneously with the installation of the top sheet.

The intersections of the film with ventilation ducts and chimneys are carefully insulated. A small cut is made on the panel, similar to the letter “H”, tapering towards the bottom.

On the passage element, the lower and upper flap (as well as the sides of the cut) are fixed using

Ondutis BL tapes.

2. For waterproofing insulated roofs, it is ideal to use superdiffusion membranes OndutisSA115 and OndutisSA130.

The membranes easily pass water vapor that has entered the insulation from the residential attic, and on the other side they provide reliable protection of the insulation from under-roof condensation and from blowing out insulation particles.

Therefore, the membranes are laid directly on the insulation (with the logo facing up)

, fixed with a block 50mm high, then comes the sheathing for the roofing.

Vapor barrier

For vapor barrier from inside the room, use the universal film Ondutis R70 or the most convenient and modern version Ondutis R70 Smart (with mounting tape already attached)

For vapor barrier of steam rooms or for additional heat retention in the room, Ondutis R Termo film with aluminum coating is used.

These films are applicable with any insulation in any structure (walls, ceilings, attic, flat roof).

Vapor barrier of walls

Ondutis R70 and Ondutis R70Smart are laid with the smooth side towards the insulation, the rough side towards the room, Ondutis R Termo - with the metallized side towards the room.

First, the Ondutis film is cut to the required length. The canvases are attached to the wall horizontally with an overlap of 10cm. The film is mounted close to the insulation and secured with a stapler. When attaching to concrete and brick, OndutisBL tape is used (with the exception of “Smart” type films).

The joints of the canvases are sealed with OndutisML mounting tape.

To seal the joints, Ondutis BL tape is used.

When arranging paired rooms, the seams must be taped with aluminum or metallized tapes.

Ondutis ML tape must be glued at a distance of 5 cm from the edge of the top sheet.

When installing Smart films, the protective tape is removed from the adhesive layer simultaneously with laying the top panel.

It is very important to make a vapor barrier layer without breaks!

Next, profiles or bars for finishing cladding are mounted. The gap between the vapor barrier and the cladding must be at least 50mm.

Vapor barrier of floors and ceilings

When vapor barrier of insulated floors, the film is fixed on top of the floor beams using a stapler with a slight sag. All joints are hermetically sealed with Ondutis BL tape.

A block is attached on top along the beams to create a gap with the floor covering.

From below, the vapor barrier is attached to the rough ceiling (the joints are glued) and is also fixed with a block.

Previous article Next article

Return to list

Source: https://www.novbiz.com/articles/kak-pravilno-vypolnyat-montazh-plenok-i-membran-ondutis/

| Wind-moisture-proof vapor-permeable membrane Izospan A is used to protect roof and wall elements from wind and condensation during the construction of buildings for any purpose. The membrane is installed under the roofing or external wall cladding on the outside of the insulation. The outer side of Izospan is a water-repellent smooth surface. The inner side has a rough anti-condensation structure designed to retain condensation with subsequent evaporation of its droplets in the air flow. Izospan A does not allow condensation to penetrate from the external environment into the insulation and structure, and ensures the weathering of moisture. When using Izospan A, the heat-shielding properties of the insulation are significantly improved and the service life of the structure increases. Made from modern polymers, Izospan A has a number of advantages compared to conventional materials:

Application of materials Izospan AIn the design of an insulated roof Izospan A is used as an under-roof wind and moisture protective membrane for the construction of insulated roofs with an angle of at least 35°, covered with profiled sheets or tiles - flexible bitumen, natural, metal tiles. The membrane is installed under the sheathing on top of the rafters with a gap above the insulation. It is designed to protect structures and insulation from the formation of sub-roof condensation, and additionally protects the roof and insulation from gusts of wind. |

| 1. External cladding 2. Counter batten 3. Izospan A 4. Insulation 5. Vapor barrier Izospan 6. Interior decoration |

| Timber wall |

| 1. External cladding 2. Counter rail 3. Isopan A 4. Insulation 5. timber |

In the designs of ventilated facades of multi-storey buildings

Izospan A is used to protect insulation in the structures of ventilated facades of multi-storey buildings with external insulation. The material protects the insulation from wind, atmospheric moisture and snow penetrating into the ventilated gap under the outer cladding, and helps remove moisture from the insulation.

| 1. Decorative finishing 2. Isopan A 3. Insulation 4. Elements of the installation system5. Bearing wall |

Wall protection

When using the windproof membrane for walls Izospan, its installation is carried out directly on insulated and ventilated facades. It is also used in the construction of houses built using frame technology. Unlike the roof, there are no horizontal areas on which moisture could accumulate. For this reason, the requirements for the windproof material used are somewhat different.

If a conventional façade is facing and insulated, then in this case you can use absolutely any windproof material that has good permeability. The main purpose of using a windproof membrane is to prevent the penetration of moisture and prevent the accumulation of condensation in the insulation layer.

High-quality wind protection is especially necessary in ventilated facade systems . When installing them, it is an impossible task to ensure that the cladding elements are tightly connected to each other. For this reason, wind and moisture can penetrate through the joints into the ventilated façade. Strong wind currents may arise behind the cladding of a ventilated façade, which can destroy the unprotected insulation with their force.

Mineral wool is especially susceptible to this negative factor. The use of a windproof membrane ensures the fixation of the heat insulator and its reliable protection from destruction. As a result, the insulation structure is preserved in its original state and the microclimate in the premises of the building does not undergo major changes.

Wind protection for floor

In all houses built of wood, a windproof membrane is installed for the floor . These buildings differ from buildings that have concrete floors in that they are able to allow wind to pass through the floor. For wind protection of wooden floors, the choice is usually made in favor of options based on polyethylene or propylene. This is due to the fact that the windproof membrane has good waterproofing properties. Good properties in terms of moisture protection are also characteristic of a suit made of membrane fabric.

When installing the floor, it is necessary to lay waterproofing and a layer of insulation on the joists, and then wind protection. When these operations are completed, you can begin laying the finished floor. If the installation of the windproof membrane was carried out correctly, then a favorable microclimate arises when living in the house, while the installed insulation does not lose its performance characteristics for a long time. When installing wind and water protection, preference should be given to the material that is most suitable for each area of the house.

How does wind protection work?

Windproof film actually performs two functions. Not only does it prevent air masses from penetrating into the insulation when there is wind, but it also acts as a moisture barrier.

A separate type of film is used for arranging insulated roofs. Such films are often called under-roofing membranes, by the way, for some reason many builders neglect them, as it turns out in vain...

Roofing membrane

The windproof membrane consists of polymer fibers sintered in a special way. The film itself is designed in such a way that on one side it is smooth and does not allow moisture from the street to penetrate into the house, on the other it has a rough surface.

Windproof membrane: price

When building a house, many people take the choice of materials for building a house, insulating structures and insulating insulation very seriously. When choosing a windproof membrane, you need to pay attention to the technical characteristics , and do not forget about such a thing as price. Having data on the cost of a windproof membrane, you can make the right choice and calculate in advance the cost of insulation work. When choosing a suit made of membrane fabric, which perfectly protects against moisture, the cost of the product is also an important point.

When choosing a windproof material, you need to familiarize yourself with the assortment of several stores, and then decide on the place where the membrane with optimal technical characteristics is offered. You should do the same thing when you are looking for a suit made of membrane fabric. This approach makes it possible to avoid unnecessary expenses and get a product with high quality characteristics.

If we talk about the situation on the market at the moment, the price for high-quality windproof material varies in the range from 1500 to 3000 rubles per roll . A suit made of membrane fabric will cost less. Of course, the price of a protective membrane may vary depending on the manufacturer, as well as its density and the material from which it is made. Products made from polyethylene and polypropylene are widely represented on the Russian market.

How to choose wind protection

When choosing wind protection for ventilation facades, experts pay attention to:

- toxicity of building materials.

- resistance to temperature changes, UV radiation, and high humidity.

- length of service life.

- fire resistance, fire safety.

- type, type, category, density.

- degree of reliability.

- resistance to tearing, sufficient degree of elasticity.

- chemical resistance to acids and alkalis.

Important! Give preference to building materials that can be installed in any season of the year.

Pay attention to the cost and reputation of the manufacturer. Building materials that are too cheap in price do not have all the necessary technical properties. The best option is diffuse, superdiffusion films.

Windproof films

Wind protection is used when it is planned to install a ventilated façade using external insulation.

Do not think that only new buildings are insulated in this way. This option can also be used to insulate an old building if necessary.

Moreover, this method is successfully used for insulating not only frame and wooden houses - it is suitable for concrete and brick walls.

Windproof films are also used to protect floors, ceilings, and roofs. The only condition is to use them only on the “cold” side: directly under the roofing, subfloor or on the street side of the external walls.

All windproof films are divided into two types:

- Moisture and windproof films are materials that have high vapor permeability (≥ 3000 g/sq. m per day), but low water resistance (approximately 250 mm of water column). These are two-layer films, the smooth outer side of which protects the insulation from atmospheric moisture in the form of rain or sleet, and the internal porous side releases water vapor from the insulation, sending it into the ventilation gap between the wind barrier and the façade cladding. This film also protects the insulation from the effects of air pressure that occurs during strong winds.

- Superdiffusion membranes - with a vapor permeability of 1000 g/sq.m per day, they have a water resistance of about 1000 mm of water column. They are more expensive than conventional windbreaks and are designed for use in areas with high rainfall and strong winds. In such conditions, if the tightness of the wall cladding is insufficient, the insulation can become heavily moistened, which significantly affects the energy efficiency of buildings. The three-layer structure of the membrane perfectly removes steam from the thickness of the insulation, reliably protecting it from snow and rain, which increases the service life of the thermal insulation several times.

How to correctly: or not to install vapor barrier in ventilated facades

In the process of building a house, every owner or developer pays special attention to heat and waterproofing functions. Most people give preference to the highest quality and most expensive materials, thereby striving to achieve maximum comfort, warmth, high energy efficiency, and high-quality moisture protection for their housing.

For these purposes, facade technologies are used that imply multi-layer wall structures: frame walls, curtain ventilated facade technology. One of the layers of such structures are wind- and moisture-proof membranes. Windproof film is used both to protect private housing construction and high-rise buildings. Of course, these are different types of membranes.

More details about everything.

What is wind and moisture protective film and where is it used?

A moisture and windproof membrane is a fireproof construction fabric that protects insulation from moisture and heat loss during air movement.

In general, windproof film is used in various areas of construction: in roofs, ceilings, partitions, floors, and in finishing bath walls. But we, as professionals in the field of facade construction, are only interested in membranes laid on insulation in ventilated facades, frame walls, and in any wall cladding with external insulation, but without a ventilation gap.

Why do you need a windproof layer?

Moisture and windproof films protect the surface of the insulation from water and moisture, from mechanical damage, and also prevent heat loss due to longitudinal filtration of air in the insulation. Protection is especially important during slanting rain, then the insulation is abundantly wetted and, if there is no ventilated gap that quickly dries the surface, there is a risk of freezing of the walls. Wet insulation loses up to 90% of the energy saving characteristics declared by the manufacturer. The vapor barrier film must be laid with the smooth side facing out.

Does the wind membrane burn?

The windproof membrane for cladding the facades of expert buildings must correspond to the group of non-combustible materials - NG. All manufacturers declare compliance with the NG group. Has anyone tried to set fire to a piece of vapor barrier film with a lighter? Those involved in the construction of facades have probably tried everything.

The film burns out, the flame dies out, it does not support combustion, but there is a certain emotional moment in the subjective assessment. Porcelain tiles, metal bracket - NG, which is logical. Set fire/don’t set fire, at most the element will become smoky. But the membrane behaves differently, it burns down to the base, but fades away. It turns out that the film itself does not burn, but with an external source of fire, the flame will spread across it.

However, there are permits issued by competent and authoritative authorities.

The permitting documents for windproof membranes used in facades are:

- Technical certificate of suitability for use in construction (specifically for the installation of a wind-waterproofing layer in the construction of suspended facade systems);

- Certificate of compliance with the requirements of TU 8390-001-96837872-2008 as amended. No. 1

- Fire test report for assigning a group and flammability class in the system

- Durability test report

- Test report for determining vapor and air permeability

- Sanitary and epidemiological conclusion

Based on an analysis of the permitting documentation from a number of manufacturers, it is possible to come to conclusions regarding the typical properties and characteristics of windproof membranes.

Characteristics and properties of building fabrics

The requirements for windproof membranes used in private and public buildings are different. At a minimum, because public buildings are subject to state construction expertise. The scale of the consequences of using low-quality film when cladding high-rise buildings is more extensive. By not very high-quality film, the editors first of all understand that it does not comply with the flammability group NG is a non-flammable material.

- The ability to resist fire determines the material’s compliance with a certain flammability group. Films approved for use in ventilated facades have a flammability group of NG - non-flammable. Consequently, the fire hazard class of building materials is “KM-0”.

- Vapor and air permeability is determined by the fabric’s properties to resist air penetration under wind loads and when warm steam escapes outside. A good vapor-permeable membrane corresponds to a vapor permeability value: 0.1 m2*h*Pa/mg. Air permeation resistance: 1500 m2*h*Pa/mg.

- Windproof films for walls must have low water permeability to protect against rain and snow.

- The fabric must have high tensile strength. This value affects the determination of the number of sheet attachment points. The number of attachment points will increase in proportion to the height of the building, this is due to an increase in wind load.

- Each linear meter of fabric must be able to elongate by at least 6 cm both lengthwise and crosswise before breaking. Elasticity ensures the safety of the fabric when stretched.

- Durability of at least fifty conventional years.

Let's consider the most common way of using windproof membranes in facades

The fabric is supplied in rolls, 1.2 m wide and 50 m long. Designed for installing a wind-hybrid barrier layer in enclosing structures, incl. in the designs of facade systems with an air gap, to increase their resistance to air permeation and protect the insulation from adverse atmospheric influences. The membrane can be used in all climatic regions, at temperatures from -60 to +60 degrees, in mildly and moderately aggressive environments.

Follow these simple recommendations to ensure that the installation of vapor barrier film in ventilated facades is of high quality:

- Which side to lay the vapor barrier on - strictly, with the smooth surface facing outwards.

- Which side to attach the vapor barrier - it is permissible to lay the membrane horizontally and vertically, but it is necessary to observe the direction: from top to bottom, with an overlap of at least fifty centimeters of the top layer on the bottom. The location of the panels should ensure the natural drainage of moisture penetrating under the cladding.

- Use as many attachment points as are drawn in the design of the ventilation façade for the building. Remember, the taller the building, the more attachment points there are. A poorly secured section of the canvas in the place where it sag can “slap” under the influence of strong gusts of wind. Check the tight fit of the fabric to the insulation. In the worst case, the wind can tear off the film. How to attach a vapor barrier, what type and size of anchor - everything is in the project. Sometimes the use of plastic anchors is unacceptable.

- Wrap the ends of the insulation around window and door openings so that the layer of fabric extends under the thermal insulation to a length of at least 25 cm to avoid wind blowing under the film.

- Install fire cut-offs around window openings, in places of emergency exits, on the internal corners of the building, if the distance from the internal corner of the building to the window is less than 1200 mm. All fire protection measures are specified in the Album of technical solutions for the specific brand of facade subsystem you have chosen.

Windproof film installation technology

The main condition for the functionality of wind protection is its correct installation. The technology itself is simple.

But the work must be carried out with the utmost conscientiousness:

- Rolls of windproof film are mounted horizontally, starting from bottom to top. It is very important to sew the film on the correct side - usually the outer side is the side on which the manufacturer's logo is applied. In other cases, you just need to carefully read the instructions included with the material.

- When installing the film, it is necessary to observe the amount of overlap between adjacent panels: horizontally - 100 mm, vertically - 150 mm.

- The film should fit as tightly as possible to the surface of the insulation - this is an important condition for its proper operation. You can fix the windbreak to the insulation frame with galvanized nails or a construction stapler.

- All film joints are taped with special tape so that there are no gaps.

- The bottom of the film should not have contact with the ground. A drain must be provided there to remove condensate formed on the surface of the film.

- Then the film is attached to the insulation frame with vertical bars at least 40-60 mm thick. This will ensure a snug fit of the windbreak and create the necessary ventilation gap between the insulation and the sheathing.

Wind protection features

If we are talking about sheet material, then everything is more or less clear. But, if we are talking about rolled wind protection, then before installation it is worth considering that this material can be in the form of parchment, film or membrane. The first type is the simplest and cheapest, but also the least reliable. Specialized films are installed indoors to protect the insulation from steam from the inside. They are smooth on one side and rough on the other. The membrane looks the same from all sides. But, it is mounted from the outside, that is, on top of the insulation, but from the street side. Membrane materials are vapor permeable and at the same time protect the insulation from the harmful influences from the street.

The main feature that needs to be remembered is that the film is laid with the smooth side on the insulation. The membrane can be placed however you like. But, most often, rolled material is rolled out as it lies in the roll. Also, some manufacturers mark which side the material should be applied to the insulation.

Healthy! As a rule, the manufacturer’s company logo is applied to the outside of the material. If there are no “identification marks”, then you can roll out the material as it is more convenient.

Sheet wind protection can be in the form of OSB boards, fiberboard boards, isoplat and many other materials. It is also installed from the outside. Of course, each material has its own subtleties, but usually the most questions arise when installing rolled wind protection.

Advantages and disadvantages of a wind barrier

It would seem that using wind protection only has a positive effect. But its use has disadvantages that you also need to be aware of.

Advantages of using wind protection:

- protection of insulation from penetration of atmospheric moisture;

- preventing air filtration through the insulation;

- the ability to protect the insulation during downtime during wall cladding work;

- preventing the destruction of fibrous insulation when exposed to wind (emission of insulation fibers), as a result of which its thickness gradually decreases.

But there are also disadvantages, which mainly arise due to improper execution of work and errors in the design of a ventilated facade.

The disadvantages are as follows:

- Covering the ventilation gap with a windproof film is possible if the film does not adhere tightly to the insulation. The consequence of this is poor ventilation under the skin, which leads to poor removal of water vapor.

- When using films with low vapor permeability, there is a high probability of the insulation becoming waterlogged and losing its heat-protective properties.

- Careless builders often use windproof film to try to hide flaws made during the installation of thermal protection: insufficient thickness of mineral wool slabs, poor fit between them and other violations of technology.

- High flammability of synthetic films and membranes. The latter drawback even caused bans on the use of these materials in some regions.