Electric boiler for heating a private house

Let's try to understand the types of such equipment - what is the difference between them, what are the main advantages and disadvantages, how valid are the established opinions about them, which sometimes either give electric boilers a completely negative reputation, or, on the contrary, attribute absolutely “fantastic” properties to them.

What are the benefits of an electric heating boiler?

The creation of any traditional heating system based on the transfer of liquid coolant along a pipe circuit from the boiler to radiator-heat exchangers is a fairly large-scale and complex task, requiring careful calculations and planning, and considerable material costs. And, by and large, its fundamental design depends little on the type of boiler, that is, all material and physical costs will be approximately the same. The installation of the heat generator itself is a different matter - significant differences can already be seen here, and the electric boiler in this regard immediately acts as a leader in terms of efficiency and ease of implementation of the project. Judge for yourself:

A.

Gas equipment, which is very economical to operate, will require the mandatory preparation of a project, its approval by various authorities, and installation work with the mandatory involvement of relevant specialists.

Will an electric boiler really be useful?

In modern conditions, gas is not accessible to everyone. Some settlements are located far from the main highway. And at times, purchasing and installing a gas boiler makes no sense at all.

For example, for a country house, which is not used very often, it is not advisable to use expensive gas equipment. And boilers that use solid fuel have many disadvantages. For example:

- Most of these units cannot operate on one load for more than five hours;

- There is no way to control the heating temperature;

- Fuel must be prepared ahead of time and in large quantities.

If you take all this into account, then an electric boiler for a private home will indeed become a good and more reliable option.

The main advantages of an electric boiler:

Electric boilers take up less space. Electric boilers can be installed anywhere you like because they don't have a chimney that needs to be routed through your home. There is no mandatory condition to install an electric boiler for heating a private house near an external wall.

An electric boiler for heating a private house can be located in the center of the cottage or in any other place that you really like. An electric boiler does not require a fuel tank, like oil or propane units. This means you save space that would normally be devoted to fuel.

Advantages of an electric boiler:

- High degree of automation;

- It does not require a separate room;

- It is possible to control the heating temperature;

- Easy and fairly quick installation, simple connection and maintenance;

- Can be mounted even on the wall, without outside help;

- Doesn't make noise;

- There is no need to connect it to the chimney.

Electric boilers are safer than gas boilers. You won't have to worry about gas leaks in your home when you rely on an electric boiler. For this reason, these devices are completely safe and can be placed outside your home. They are not that difficult to install. You will feel safe as the heating system will provide the necessary amount of heat without causing any problems.

Cons of electric boilers

While electric boilers have quite a few advantages, there are some disadvantages to using these hydronic heating systems in your home. Electric boilers can potentially cost more than gas boilers. An electric boiler also limits the amount of hot water it can produce. And most importantly, electric boilers leave you at the mercy of the power companies in the event of a power failure.

- If the boiler power is over nine kilowatts, keep in mind that they are produced only for a three-phase voltage of 380 watts;

- A separate cable is required to connect to the meter;

- You have to pay more than usual due to the high electricity tariffs.

Electricity is simply more expensive than gas in most regions of Russia. This means that by relying on electricity to heat your water and home, you'll end up spending more money. Even if your device consumes electricity more efficiently than a gas boiler. In most cases, the financial costs are higher to generate the same amount of heat.

Characteristics

There are different types of equipment designed to heat buildings. Boilers differ in operating principles and use different types of fuel. Each variety has its own characteristics.

Electric boilers also have their own parameters. You should know them in order to understand what functions such equipment can perform and what expectations will not be met.

On a note! A simple electrical outlet can only connect a low-power heating unit that consumes a maximum of 3.5 kW.

The calculations are very simple: all outlets are marked with a maximum voltage of 16 amperes. If the voltage is 220 volts, then the maximum permissible power will be 3520 W (multiply 16 amperes by 220 volts). Exceeding the obtained value is dangerous.

Electric boiler diagram

What types of electric heating boilers are there? There are modern units on the market with a power of 12 kW, designed for connection to a single-phase line, but experts recommend connecting units from 6 kW to a 380 V network.

In order for the heating device to receive power, a cord with a cross-section of at least 1 mm and designed for loads of 8 A is drawn from the panel.

The efficiency characteristics of the unit are impressive, since all the electricity consumed is used for heating. Naturally, some models may experience energy losses that go towards heating not the coolant, but the structural parts and its body. If the boiler is installed directly inside the heated room, the heat is consumed only for its intended purpose, remaining in a closed circuit of the room.

Ignore advertisements claiming that their devices are highly efficient: there are more significant parameters that should be taken into account when choosing a heating boiler - these include the safety and duration of use of the unit, ease of installation and operation, cost, power and efficiency.

Places of heat loss in a private house

Heating with electricity is not cheap; it is used exclusively when other options are not available or as backup heating. You should prepare for the fact that your electric heating bills will be high.

Electric boilers have both pros and cons: both should be taken into account. The main advantages are, first of all, ease of installation and use, safety

How to choose?

Many people wonder how to choose a good electric heating boiler for heating. One of the most important properties for this type of equipment is the efficiency indicator, which has already been mentioned. The efficiency of such devices and operating costs depend on it. But in the case of the equipment under consideration, this coefficient is not so important due to the fact that all models have an efficiency of around 96–98 percent

Therefore, you should pay attention to other characteristics

The most important is power. It is usually measured in kilowatts

It determines how much heat transferred to the liquid will enter the heating mechanism. The power of boilers is usually provided by the operation of electric heating elements, which are located inside the heat exchanger.

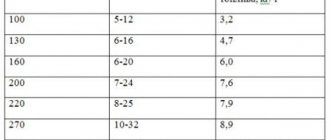

For electric boilers, this characteristic ranges from two to sixty kilowatts. In order to correctly select the power of the electric boiler, a thermal engineering calculation should be made for the entire building. It is best if specialists do this. This characteristic should be determined at the rate of 1 kilowatt per 10 square meters of room area. If you still need to heat the water, then the power should be at least a quarter more.

Another important characteristic is the control mechanism. With its help you can significantly reduce heating and hot water costs. Different models of thermal generators offer different options for reducing energy consumption. Typically, automatic control mechanisms are used, which are responsible for regulating the operation of units. The simplest such device is a thermostat. The essence of its operation is extremely simple - you need to set the desired temperature of the coolant at the outlet, when it increases to the required value, the thermostat turns off the heating elements.

Another important factor that you should pay attention to when selecting an electric boiler is its configuration. This point affects both the price of the unit and the efficiency

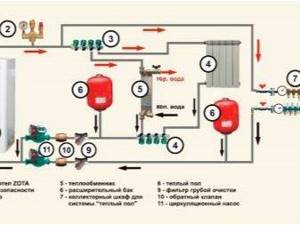

It was mentioned above that purchasing models with incomplete components entails additional financial costs for the purchase of parts and time losses for installation. If we talk about the complete set of electric boilers, then a number of models are miniature boiler rooms. They have a circulation pump, an expansion tank, remote-type temperature sensors, a filter that is responsible for purifying the coolant, an anti-freeze mechanism, and others.

The criterion that you should pay attention to when selecting an electric boiler is the voltage of the electrical network. Although this factor does not apply to the devices themselves, it cannot be ignored

Powerful boilers require 380 volt line voltage. For this reason, before purchasing a boiler, you should find out whether such a line can be drawn to the desired object. If not, then it is better to be content with a single-phase 220 volt solution. Naturally, not the last point, in addition to the indicated properties, when selecting an electric boiler is its manufacturer.

Coolant circulation systems

The first system is based on gravity fluid flow (natural circulation). The electric boiler in such a system is located at the basement level. And the expansion tank of increased volume should be located above the level of the batteries. That is, on the roof. Cold liquid is heavier than hot liquid, according to the laws of physics. Therefore, the coolant from the tank will be pushed into the system, starting circulation. To simplify this process, larger diameter pipes will also be required. They were replaced by systems of the second type.

The second system uses a pump (forced circulation) to pump liquid. Therefore, it is less demanding on the dimensions and position of the structural elements of the system. It is much more efficient and eliminates the need to install a tank on the roof. And given the electricity consumption of the boiler, the costs of operating the pump can be ignored. Yes, such an electric boiler does not consume less than 3.5 kW with an efficiency of 100%. If someone offers a more economical and efficient system, you shouldn’t even pay attention to the scammer. On average, an approximate calculation of the required power of an electric boiler is made as follows: 1m2 x 170W. For example, for a house of 50 square meters. m. you need to purchase a boiler of at least 8500 W or 8.5 kW. For dual-circuit systems, a boiler approximately 25% more powerful will be required. Two-circuit heating systems mean that not only the heating system fluid flows through the boiler, but also water is heated for hot water supply. Because of this, an additional load is placed on the boiler.

Features of heating a house with electricity

If you do not take into account operating costs, the choice in favor of such a heating system can only be characterized positively:

- No chimney required.

- There is no risk of fire (provided the connection rules are followed), explosion and gas poisoning.

- No design or permission from government agencies is needed.

- Full automation. Unlike the gas analogue, it is safe to start the device in the absence of occupants for a long time.

- The heating output is regulated within a wide range without reducing efficiency.

- The boiler is inexpensive.

But there are also negative points:

- High electricity costs.

- Low reliability. The overhead power grid is the most vulnerable part of the infrastructure.

After storms and hurricanes, populated areas are the first to remain without electricity. Therefore, it is risky to make do with an electric boiler alone; it is recommended to additionally connect at least a low-power solid fuel device to the heating system as a backup. The list of units is on the website bigkotel.ru.

Selection principle

When purchasing, you need to pay attention to a number of factors:

- Network connection type. It can be 220 or 380 volts. The more powerful the equipment, the more voltage it needs to operate.

- Worn wiring. For the old one, it is better to choose equipment with a power of up to 6 kW, for a new one - up to 12 kW.

- Power. If it is more than 12 kW, a three-phase network is required for the installation to operate. The indicator depends on the size of the room.

Advantages and disadvantages

Positive sides:

- Economical work.

- Easy to install. There is no need to install a chimney.

- Availability of remote control.

- Elimination of fire.

- Easy maintenance.

- Easy temperature adjustment.

- High-quality wire insulation.

The main disadvantage is low resistance to sudden voltage surges.

Models and prices

There are different models of electric boilers for baths, which differ in price, technical characteristics, and build quality:

- EVAN Next 7. Price - 11,000 rubles. These are single-circuit systems. The temperature can be changed from 30°C to 85°C. You can fill the pipes with ordinary water and antifreeze liquids. Efficiency indicator - 99%. Power - 7 kW. These indicators are enough to warm up rooms up to 70 m2.

- ZOTA Balance 6. Price - 7000 rubles. Boiler power - 6 kW. The equipment is designed to heat rooms up to 60 m2. Connects to a 220 volt network.

- EVAN EPO 4. Price - 10,000 rubles. Small floor standing boiler. Equipped with a temperature control system. The kit includes a remote control. Power - 4 kW. This is enough to heat a small bathhouse, office or apartment.

- EVAN Warmos-IV-5. Price - 20,000 rubles. Electric boiler with additional security system. The power is sufficient to heat rooms up to 50 m2.

- Protherm Skat 12 KR 13. Price - 40,000 rubles. The equipment is suitable for large rooms. Can be used to heat rooms up to 120 m2. It has an attractive appearance and takes up little space.

- Vaillant eloBLOCK VE 12. Price - 43,000 rubles. Electric boiler with microprocessor control. The kit includes an LCD display to monitor settings and equipment operation. The power is enough to heat rooms up to 120 m2.

- Bosch Tronic Heat 3000 9. Price - 45,000 rubles. Maximum power - 9 kW. Convenient control with LCD display. Can be combined with a heated floor system.

- Protherm Slope RAY 12 KE /14. Price - 36,000 rubles. Power - 12 kW. This indicator is sufficient for bath complexes. Efficiency - 95%. Temperature changes within 28–85°C are possible.

- EVAN EXPERT 12. Price - 50,000 rubles. Power - up to 12 kW. Efficiency - 99%. An automatic valve for releasing pressure from the system and a circulation pump are installed inside. There is a self-diagnosis function for equipment errors. The controls are convenient, the kit includes an LCD display.

- Kospel EKCO. L2 12. Price - 41,000 rubles. Suitable for heating rooms with an area of 120 m2. Equipped with a temperature regulator. Efficiency - 99%.

Types of electric boilers

Photo source: stroyploshadka.ua

Electric boilers can be roughly classified as follows:

- installation - wall or floor;

- purpose - only for heating (single-circuit) or for heating together with hot water supply (double-circuit);

- in terms of supply voltage and thermal power, respectively - single-phase (up to 6 kW) and three-phase (more than 6 kW).

Depending on the area of application, electric boilers can be domestic or industrial.

No. 2. Types of electric boilers by type of heating element

Depending on how the water is heated, all boilers are divided into heating elements, electrode and induction.

Heating elements new boilers

This is the most popular design option, and so popular that when talking about electric boilers, as a rule, they mean designs with heating elements. This unit works on the principle of a boiler. Electricity is supplied to a tubular electric heater (TEH), it heats up and transfers heat to water, which is used as a coolant. The heating element consists of a nichrome spiral and a durable shell made of steel, aluminum or titanium. The space between the spiral and the shell is filled with quartz sand or other dielectric filler.

The rated power in such boilers is achieved abruptly, approximately 10-15 minutes after switching on. Heating element boilers operate in flow mode and can be single-circuit or double-circuit. As a rule, several heating elements are placed in the boiler tank.

Since there is no direct contact of the heating coil with water (the dielectric plays the role of a separator), there is no need to be afraid of a short circuit. The main problem of such boilers is different. The surface of the heating element comes into contact with water; scale appears on it relatively quickly, which can gradually damage the boiler. To slow down this process or even avoid it completely, it is better to use distilled water in the system. Special liquids are also sometimes used. The boilers are protected from overheating of the coolant by a thermal regulator, but if a leak occurs, the unit risks overheating and failure.

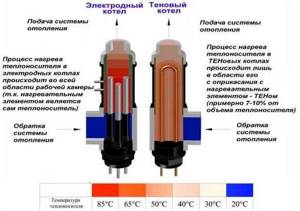

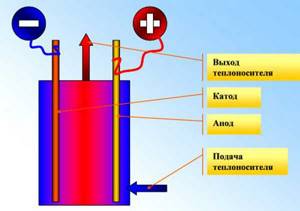

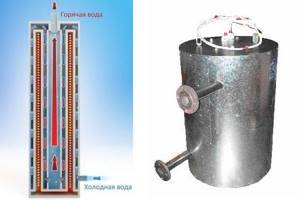

Electrode (ion) boilers

The design of this boiler involves the presence of two electrodes immersed in a heat exchanger. Electrical energy is supplied to them, due to which a potential difference is created. Due to the presence of salts in the coolant, it turns into a current conductor. Electricity passing through the high resistance electrolyte causes it to heat up. Just a couple of minutes is enough for the boiler to reach its rated power. Specially prepared water or ethylene glycol-based liquid is used as an electrolyte (coolant).

Boilers of this type are quite economical in operation, and to provide the same thermal power as a heating element boiler, they consume almost half as much electricity. Such units, as a rule, have reliable, well-thought-out automation and rarely fail, since, in fact, there is nothing to break here. If a leak occurs in the system, overheating will not occur - there is no electrolyte. Electrode boilers also perform well under unstable voltage conditions. If it drops down to 180 V, the unit will continue to operate and generate heat.

The only downsides are the cost of the equipment and the need to use specially prepared coolant. Its composition will determine how much energy the boiler will spend on heating. Another nuance is the need for reliable grounding. The electrodes will have to be changed periodically.

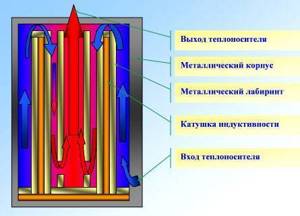

Induction boiler

Boilers of this type began to be used back in the 80s of the last century, but at first they were installed only in production. The production of household models began only towards the end of the 90s. Their operating principle is quite complex and resembles a transformer. The heart of the unit is an induction coil, which converts electrical energy into a magnetic field, directing it to the core. The latter is a system of steel pipes with coolant inside.

The system performed well. Induction boilers are economical and very compact, durable (service life 30 years or more) and fireproof, and the problem of scale is not a problem with them. There are no strict requirements for the coolant, as in the two previous types of boilers - even purified petroleum products can be filled.

The main disadvantage is the high price. In addition, induction boilers weigh decently, despite their miniature dimensions. You won’t be able to find a model lighter than 20 kg.

Which boiler is better to choose depends on your budget and your requirements - all three types can be found on sale.

Electrode boilers

Such electric boilers for heating a private home heat water or other liquid through electrolysis. Steel electrodes are located inside the device. After connecting the current, a potential with an alternating sign is formed and thus the movement of ions occurs.

The polarity changes along with the network frequency - approximately fifty times per second. This causes the liquid to heat up quickly. In order for the entire process to take place at the desired level of intensity, a very important nuance is to maintain the electrolyte density at a stable level. The liquid acts as this electrolyte.

But do not neglect the user instructions for the newly purchased boiler. Take, for example, the rather popular model of the Galant electrode type. The instructions indicate the requirements for the liquid, which must comply with GOST 2874-82. This means that drinking water for this boiler must be endowed with a resistivity of 1.3 thousand ohms per 1 cubic centimeter.

For liquids that will be heated in a boiler of this type, preliminary preparation is necessary, as well as vigilant density control. Otherwise, the power and efficiency of the device inevitably decreases, and it may become insufficient to warm the house.

The strengths of such boilers:

- medium sizes;

- low cost;

- complete safety. If a liquid leak starts, the electric boiler will turn off and not burn out, as can happen in the case of a heating element.

Weak spots:

- The importance of constantly monitoring the density of the liquid;

- Over time, the electrodes dissolve, so they must be replaced periodically.

Varieties

Electric boilers can be divided into 2 large groups depending on the design, characteristics, operating principle:

- Induction, electrode. A progressive space heating system is based on such installations, but they have not gained popularity among residents of Russia and the CIS. This is due to the characteristics of the installations. For example, electrode boilers require an additional water purification system. If it is of poor quality, the equipment will fail. For induction installations it is necessary to equip an additional room.

- Heating elements units. Popular models of electric boilers. This is due to a small number of problems during operation. It is better to choose models with filters for water purification.

The last group of equipment does not take up as much space as induction boilers.

Solving some problems in the operation of electric boilers

The boiler itself, no matter what coolant heating system is used, is very reliable.

A little preventive work to remove scale is all that is required for its stable operation. It is also worth cleaning the coarse filter once a year. The only danger is the high power of the device. For it, it is worth drawing a separate line from the shield with large-section wires. Otherwise, they may heat up and catch fire. But there are 2 more elements of the system that need to be constantly monitored.

The first, which is logical, is the pipeline. The entire load falls mainly on the pipes through which cold and hot liquids flow, and sometimes hot steam. Therefore, all solder joints and the quality of the pipes must be very good. There will always be a stray current flowing through the pipes, which will pierce through the metal. Over time, metal-plastic will lose its metal component in places of breakdown, and all-metal pipes will become covered with rusty spots. Nothing can help avoid this. The only material resistant to this scourge is plastic, but it should not be used in electrode and induction systems. Otherwise, you just need to check the condition of the pipes from time to time in order to carry out replacement and repair if necessary. This is also required once every few years.

The second unreliable (relatively) element of the system is the temperature and water pressure control relay. Every few years they break down and require replacement. Such repairs are not very cheap, but they guarantee stable operation of the electric boiler for several more years. If the temperature relay becomes unusable, the heating element may malfunction and the temperature in the system may increase. As a result. Instead of liquid, hot steam will flow through the pipes, which can rupture the pipeline. A similar problem can arise due to the presence of a large amount of air in the system, due to which the pump will run dry. The solution is provided in the design itself. With a sharp increase in temperature and pressure in the system, heating stops, and excess steam is removed through a special discharge system. When air leaves the system, part of the coolant will also be discharged. The expansion tank helps to catch them and return them to the system to save money.

Selecting a location for heating equipment

All types of heating boilers are produced mainly in a floor-standing version, electric in a wall-mounted version, and gas in both a wall-mounted and a floor-mounted version. The latest variation is best installed in a spacious separate room. Such heating equipment is characterized by great power and massiveness.

A wall-mounted boiler will be an ideal solution for small-sized houses, where every square meter counts

And due to the fact that the weight of floor-standing boilers is not limited in any way, manufacturers install a cast-iron heat exchanger in it, which is much more reliable than a steel one.

Wall-mounted heating equipment is compact in size and fairly light in weight. But this type of boiler is limited in power. This minus is especially relevant for dual-circuit systems - the performance of the heating circuits will be quite low.

You should choose wall-mounted boilers only if the heated area does not exceed 200 m2 and the hot water consumption is no more than 14 l/min. If the needs are greater, then it is better to give preference to the floor-mounted variation of heating equipment.

It should be noted that many buyers, regardless of the size of their living space, prefer floor-mounted systems that are equipped with a cast-iron heat exchanger. After all, such devices are less demanding on the quality of power supply.

Features of installing induction heaters

Induction electric heating systems should only be installed with a closed circuit with a membrane expansion tank and a circulation pump. Forced circulation is required primarily because intense heating and the small volume of the core prevent natural air exchange; water begins to boil immediately after creating conditions for gravitational circulation.

We recommend: Features of repair of heating boilers

If an induction heating electric boiler is used as a heat generator, then you need to use plastic pipelines in the circuit or separate the metal pipes from the boiler by installing plastic fittings. The boiler must be properly grounded. Installation requirements are the same as for all electric boilers: from the distance of the floor or ceiling - 80 cm, from the wall - 30 cm. Installation of a safety unit with a pressure gauge, air and safety valve is considered mandatory, as for all indoor heating systems. Cottages usually use a standard connection system.

Induction heater

Installation of induction heating systems must be carried out in accordance with the rules specified in the technical data sheet. The device must be in a vertical state, the lower input pipe is connected to the run-in, the upper one to the supply. For this, only metal or metal-plastic pipes should be used. If you decide to install the boiler yourself, do not forget about grounding. Nearby you need to install a control box security group, at the input - filters and a flow mechanism.

At the time of purchasing the system, check the operating power, which should not decrease during operation. The ideal option would be 60 W per 1 square meter. It is important to consider the size of all rooms. If you have poor thermal insulation, then you need to use a powerful heating boiler.

The latest models of systems can maintain low temperatures in rooms that are not often used. They are economical due to minimal system inertia, reliability, stability, and good automation. Such equipment is installed as additional equipment in cottages and for heating offices and retail areas.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- How to install an induction heating boiler?

- How do central heating boilers work?

- Features of repair of heating boilers

- Pros and cons of combined gas-electric heating boilers

- How to make a hydrogen heating boiler?

- How do combined solid fuel heating boilers work?

Selection of solid fuel boiler

When selecting a solid fuel boiler, the following features should be taken into account:

1

The thermal output of the boiler (the amount of heat generated by the boiler per hour) can vary greatly depending on the type of fuel used and the combustion phase.

2

The rated thermal power of the boiler, as stated by the manufacturer in the technical specifications, is achieved by burning Anthracite coal, which is coal with the highest calorific value. Therefore, if it is intended to use other types of fuel, then when calculating the power of a solid fuel boiler, increasing factors are used:

- 1.05 for coal

- 1.18 for brown coal

- 1.25 for peat briquettes

- 1.25 for dry firewood with a humidity of 15-20% (two years of drying)

- 3.33 for wet firewood with a humidity of 70-80%

3

Manufacturers define the rated thermal power of a boiler as the average hourly power generated by the boiler during the combustion of one full load of anthracite coal, while the combustion process proceeds in normal mode with an excess of oxygen.

As a rule, the burning time of one load in this mode is no more than 4 hours. This means that the first and last hour of combustion the boiler can produce 70% of the rated power, and for two hours of the active combustion phase it can operate with a power of 130%. The rated power in the technical characteristics of the boiler will be indicated as an average of 100% = (70 +130 +130 +70)/4.

It is very important to take this feature into account when calculating a solid fuel boiler and choosing its piping scheme. 4 When choosing a solid fuel boiler, it is recommended to take a power reserve relative to the power of the heat consumption system of about 25-30%. The boiler power reserve will allow:

The boiler power reserve will allow:

4

When choosing a solid fuel boiler, it is recommended to take a power reserve relative to the power of the heat consumption system of about 25-30%. The boiler power reserve will allow:

- cover heat losses not taken into account in calculations

- level out the discrepancy between fuel quality and declared values

- increase the burning time of a single fuel load, since boilers of higher power usually have a larger loading chamber volume

- cover the power required to heat hot water if the boiler was selected for the load of the heating system.

To take into account the above factors, when calculating a solid fuel boiler, designers often use even a twofold increase in power, although the reserve leads to cost overruns on its purchase.

5

Regardless of what manufacturers write in the characteristics of the boiler, if it is not pyrolysis, it will not burn for more than 12 hours. In order for a solid fuel boiler to burn for 12 hours, it must burn in smoldering mode with a deficiency of oxygen in the firebox, which significantly increases the ash content and reduces the efficiency of fuel combustion. Otherwise, this mode is not recommended at all by any manufacturer, but is rather used simply as a publicity stunt.

Therefore, if loading the boiler with a frequency of 4-6 hours is unacceptable for you, it is better to give preference to pyrolysis boilers or use a connection diagram with a heat accumulator.

6

Some fuels burn quickly, others slowly. This feature should also be taken into account when calculating a solid fuel boiler if the frequency of fuel loading is an important factor for you. The above online calculation will determine the amount of thermal energy generated from one load of fuel in kWh and its combustion time.

Features of selecting a solid fuel boiler for a heating system

When choosing a heating boiler, you should take into account that the estimated thermal power of the heating system is required for no more than 5-7 days of the heating period.

The thermal power of the heating system is calculated for the temperature of the coldest five-day period, the eight coldest winters over the past 50 years. On average for Ukraine, the estimated outside air temperature, depending on the region, ranges from -19 to -23°C.

The average heat consumption of the heating system during the heating period is approximately half of the calculated heat load. Therefore, if a solid fuel boiler is selected with a recommended power reserve of 30% for the design temperature of the outside air, that is, 130% of the required power at the design temperature, then with an average winter load its power reserve will be 260% of the required.

It follows from this that the warmer it is outside, the longer the burning time of a single load of fuel will be.

Choosing an electric boiler for heating based on the heating principle

According to the mechanism of heating the coolant, electric boilers for heating a private house are divided into three main types:

- electrode;

- heating elements;

- induction

This parameter seems to be the most interesting, so we will analyze each type of heat generator in more detail.

Electrode boilers

The heating circuit of the coolant in an electrode boiler is not so easy to understand: the fact is that the electrodes themselves do not heat up during operation - they only transfer electrical energy to the water. Due to the work of electricity, water is divided into negatively and positively charged ions, which move along their own electrode. The movement of ions leads to intense heating of the coolant. An unpleasant aspect of this scheme is that over time, a precipitate of salts forms on the electrodes, which reduces the efficiency of the device.

The negative features of such devices also include the following aspects:

- requires preparation before starting (works with water with a certain resistivity value);

- it is necessary to control the coolant level in the system (insufficient level can lead to boiling);

- as the electrodes fail, they will have to be replaced with new ones;

- It is impossible to use non-freezing liquid as a coolant.

However, this model of electric heating boiler also has a number of advantages, which include:

- low price;

- absolute safety;

- miniature sizes;

- gradual reaching the specified power.

Heating boilers

The operating algorithm of heating elements devices is much easier to understand, because the mechanism of its operation is somewhat similar to a conventional electric kettle. Water is heated by heating elements - hollow metal tubes that heat up when electricity passes through them.

Heating elements units have become widespread due to their simplicity of design, miniature size and unlimited customization options.

In such heat generators, the temperature of the coolant can be regulated according to two schemes:

- First, the sensor measures the coolant temperature, and depending on this indicator, the device increases or decreases the heating power.

- The second is that the temperature sensor measures the air temperature in the room, and depending on its value, the device regulates the heating to a predetermined number. In the second case, the temperature sensor will have to be removed separately from the boiler, but this arrangement will allow you to more accurately regulate the temperature in the room and reduce energy costs.

A significant disadvantage of a heating element boiler is the need to periodically replace the heating element (heating element) and clean it. The fact is that when heated, salts that are in the coolant are deposited on the heating element. These salts interfere with heat transfer and significantly reduce the efficiency of the heat generator.

Induction boiler

The operating algorithm of an induction boiler is based on the laws of electromagnetic induction: water circulates through tubes made of ferrimagnetic material. This conduit is part of the secondary winding or core. Tubes of ferrimagnetic alloys, heated under the influence of an electromagnetic field, transfer heat to the water circulating through them.

An induction electric heating boiler has the following advantages:

- high level of security;

- high reliability (due to the absence of detachable elements, the occurrence of leaks is completely excluded);

- possibility of using any type of coolant.

At the same time, this boiler model also has disadvantages, of which there are only two - too large in size and extremely high price.

Induction boilers

These electric boilers for your own home work thanks to eddy currents that warm the core. An inductive coil is placed in the housing. It also houses the core. Under the influence of current, a magnetic field is formed in the environment of the coil, which creates eddy currents.

Such heaters have been used in the industrial sector for a long time. There they operate at a frequency of approximately 50 Hz. As for domestic boilers, they operate at a frequency of ten to one hundred megahertz. And due to this they are completely silent. The induction electric boiler produces slight vibration, but due to the high frequency the vibration is not felt. By the way, it also protects equipment from scale, preventing particles from settling on heating parts.

The strengths of such boilers:

- The owner can easily install and connect the electric boiler without outside help;

- Long service life without the need for repairs;

- Due to the absence of detachable connections, leaks are completely eliminated;

- You can heat not only water, but also any other liquid;

- Small sizes;

- Self-defense against scale.

Equipment weaknesses:

- The inductor has the potential to become the main source of unwanted magnetic radiation. So it would be better not to neglect the choice of the manufacturing company;

- With similar power, such electric boilers are significantly more expensive than heating boilers.

According to the manufacturers themselves, such boilers are more economical. Compared to heating elements. However, practice says that with the same power level, their output is also approximately the same. They are economical if we only talk about the duration of use.

If you have a strong desire and certain skills, you can make such an electric boiler manually. It will be much more budget-friendly, and in terms of power they are not at all inferior to purchased ones. Although in terms of aesthetics, homemade boilers are inferior to purchased ones.

Operating principle and design

Heating devices of the described type consist of a metal body into which tubular heating elements are built. They are controlled by a thermostat. Each of the heating elements is a high resistance conductor, which is placed in a ceramic shell. The conductor housing is sealed and made of steel or aluminum. This design allows you to significantly increase the area of interaction with air, providing heating. The temperature of the element can vary from 60 to 100 degrees. Before heating your garage, you should familiarize yourself with the operating principle of the convector. After switching on, the heating elements begin to warm up. According to physical laws, air whose temperature decreases begins to fall down. It enters the structure through the lower grille and passes through the heating elements. This allows for constant air movement. The process of repeated air circulation allows you to create a comfortable microclimate in the garage. If necessary, you can use fans, with the help of which natural convection will be accelerated. If you are thinking about how to heat a garage, you should remember that convectors, due to their design features, have one main drawback, which is expressed in uneven heating of the air. Thus, the temperature at the floor surface remains lower compared to that at the ceiling. However, it is worth noting that this disadvantage is characteristic of water heating. Another additional disadvantage is the rise of dust, which occurs during the circulation of flows. In order to eliminate this drawback as much as possible, you should choose more modern convectors that do not have these features.

Boilers on heating elements

Boilers of this type have many disadvantages. Among them:

- When water leaks, heating elements overheat and, as a result, burn out. In theory, they should turn off automatically, but this does not always happen.

- Over time, scale builds up on tubular heaters, which reduces the power of the equipment and increases the likelihood of heating elements overheating. But at the same time, since the water circulates in a closed loop, there is not so much lime in it that scale becomes a serious problem.

- Boilers with heating elements are not suitable for small rooms, since they have significant dimensions.

Heating connection details

All types of electric boilers, and all models are equipped with fittings that are used to connect equipment to the system. The best option is a radiator system or so-called heated floors. Electricity is far from a cheap resource, and the option of heating a house from the bottom up will help reduce the temperature somewhat.

An electric boiler for heating a private home differs from those that require solid fuel. They are able to operate in systems with natural circulation. Automation, available, for example, in heating element boilers, instantly turns off the equipment if there is a threat of overheating.

We recommend using soft (boiled) water for the mentioned boilers, due to the risk of scale formation. And for electrode boilers, as mentioned earlier, all the nuances regarding the heated liquid are described in the instructions for the model.

The Sangai boiler is the best option for heating small spaces

When the owners have figured out all the nuances and know how to choose an electric boiler based on reliability and cost criteria, they face another task. It consists in selecting a heater to meet the thermal needs of a building with a certain area.

In this case, owners of small houses and small apartments should pay attention to products from the Sangay brand. This Russian manufacturer supplies the market with good budget boiler models that have a limited power reserve

In the brand’s line, you can choose a decent electric boiler for 100 sq. m, which will become a source of heat during the cold season. When buying a Sangay electric boiler, reviews of which are mostly positive, property owners should familiarize themselves with the specific features of devices from this brand

This Russian manufacturer supplies the market with good budget boiler models that have a limited power reserve. In the brand’s line, you can choose a decent electric boiler for 100 sq. m, which will become a source of heat during the cold season. When buying a Sangay electric boiler, reviews of which are mostly positive, property owners should familiarize themselves with the specific features of devices from this brand.

Features are presented in the following list:

- presence of a built-in control panel;

- long service life;

- the ability to connect the pump group through an input contact device;

- smooth power adjustment;

- compatibility with non-freezing coolant;

- a diverse product line (it contains electric boilers 3 kW - 12 kW, designed for heating buildings with an area of 30 to 120 square meters);

- the ability to save energy by using thermostat settings.

Design features

A double-circuit heating boiler has a simple design, although it performs the function of a mini-boiler room. Both of its circuits can work either individually or in pairs, heating the house and providing hot water at the same time. The equipment in question consists of the following components:

- heat exchanger;

- boiler;

- heating elements;

- expansion tank;

- circulation pump;

- air vent;

- safety valve;

- automation;

- control unit.

Electric double-circuit models differ from single-circuit models by the presence of a built-in boiler in the design.

In appearance and main design features, electric boiler models can be:

- wall-mounted – compact and relatively light;

- floor-mounted – massive, with a high power rating (more than 60 kW).

As the name implies, heating equipment of the first group is mounted on walls or on specially installed metal frames. The second group of boilers is placed directly on the floor in a specially designated area. It should be noted that modern electric boilers are quite aesthetic and in no way can spoil the interior of the room.

According to the heating method, they can be divided into three groups:

- Heating elements - highly reliable, having one or more heating elements in the form of a metal tube inside the container;

- electrode (or ionic) – heating the coolant as it passes through a liquid alternating current medium. They have the ability to switch off independently in the event of a short circuit, a maximum increase in temperature and a decrease in the volume of water to a critical value;

- induction - operating thanks to inductance coils. Refers to energy-saving devices.

The first option refers to indirect heating of the coolant, and the second is considered as direct heating.

In terms of power, electric boilers intended for heating needs can be:

- single-phase (up to 12 kW);

- three-phase (more than 12 kW).

It is recommended to select power with the help of specialists, since only they can make a competent calculation. The method of selecting a boiler based on the area of the house is incorrect, since in addition to this parameter, a number of others are also taken into account (wall thickness, number of openings, orientation to the cardinal points, etc.).

As a rule, household heating units operate from a 220V network.

Types of electric boilers

Electric boilers vary in how they convert electricity into heat. The essence of their performance can be based on both direct and indirect heating. By the way, physical and chemical processes are involved in it.

Electric boilers for private homes are induction, heating element and electrode. In the first case, heating element type heaters are built into the electric boiler. In the second, as the name implies, electromagnetic induction is used to heat the liquid. The latter work using electrolysis.

The structure and size of boilers, along with the nuances of maintenance, depend on the type and model. Therefore, before choosing one or another type of electric boiler for heating a private home, it is important to understand the details and take a closer look at the strengths and weaknesses.

Installation of gas equipment is always associated with the preparation of design documentation

In addition to running a gas line to the boiler installation site, an indispensable condition is ensuring the removal of combustion products and creating a ventilation system. If we take into account all the bureaucratic delays and the level of prices for the services of gas specialists, who are absolute monopolists in this area, then there will be a considerable headache, and so will the financial expenses.

B.

Installing solid or liquid fuel boilers will also require a lot of organizational costs. Such equipment should be placed in a separate room allocated for the boiler room, with a properly organized chimney and ventilation to eliminate the possibility of carbon monoxide poisoning. Such heating devices are the most vulnerable from a fire safety point of view, and will most likely require approval from the relevant regulatory authorities.

About the coolant used

Electrode boilers do not require a specially prepared coolant; ordinary water can be used for this (provided that its resistivity does not exceed 1.3 kOhm/cm). In this regard, the water still needs some preparation. So, if you simply fill it with distilled water, it will not bring any success, because it does not conduct electricity.

The preparation process consists of conducting experiments, as a result of which the resistance increases (baking soda is used for this, for aluminum appliances - ASO-1) or decreases (melt or rainwater is added).