Insulation of a cellar in a garage Insulation of a cellar in a garage should be carried out without fail. Not only the safety of the products, but the climate in the room itself will depend on this. After all, dampness will penetrate there too. As a result, fungus may begin to appear. It is best to do all the work during the construction stage. But if this has not been done, the work can be done later. True, this will be a little more difficult to do. Today we will look at the question of how to insulate a basement in a garage in detail. You will have the opportunity to watch photos and videos on this topic and choose the desired insulation option. Instructions for performing this work will also be provided.

How to choose insulation

There are several types of insulation on sale. They can be divided into 2 categories:

- Permeable. Allow water vapor to pass through or ventilate outside;

- Moisture resistant. Completely cut off the surface from contact with moist air.

The basement refers to underground structures. The depth of immersion in the ground requires reliable insulation of vertical and horizontal surfaces, otherwise mold and condensation will inevitably occur. The selection criteria will be:

- Vapor and moisture resistance;

- Strength;

- Ability to withstand temperature changes;

- Rigid form.

The optimal solution is to install penoplex. It is designed for use in conditions of high humidity and cold. Ordinary polystyrene foam is somewhat worse, since its production technology is rarely followed in full.

It is not advisable to use permeable types of heat insulators (mineral wool, expanded clay) as they will become saturated with moisture and stop performing their tasks.

Purpose of the basement

Every house has a basement and is the space formed between the ground and the ceiling. The basement, as a rule, has such a height that it is convenient to place utility rooms in it: most often about 2 m and depends on the height of the base and the size of the foundation, so it is simply irrational to leave such a large space without a purpose. So:

- Not only because of savings, there is another reason for thermal insulation of the basement with polystyrene foam, mineral wool or polystyrene foam. The floor in the house must have a temperature of at least 3 degrees of living room temperature. But the floor slabs for the rooms on the first floor and the basement are common. Therefore, after insulating the basement, the floor in the room will not be cold, which means the residents’ feet will be warm and comfortable.

- This is also a pretty good solution for preventing dampness. After all, from the basement it easily penetrates into the room.

Step-by-step work plan

The procedure for insulating a cellar in a garage is carried out in stages. First, you need to ensure waterproofing of horizontal and vertical surfaces (walls, floors, ceilings).

The most effective means are considered to be bitumen mastic and impregnation with special compounds. It is recommended to apply a layer of antiseptic to concrete walls to prevent the occurrence of unwanted microflora.

High-quality preparation will ensure the effective operation of the heat insulator and will not allow moisture to penetrate from the soil. Attempts to do without preliminary work lead to failures - the insulation gets wet, fungus appears. It is necessary to take into account that it is impossible to insulate only one wall, ceiling or floor. Installation of insulation is carried out on all surfaces, including the hatch and other elements.

Insulation of an old basement

Incorrect drainage system or ventilation design, all these factors may not have a beneficial effect on the insulation of the basement. As a result, you will have to resort to unplanned repair costs. So:

- In an already used room, dismantling the old insulation is possible, but very labor-intensive. If it was not there, then we simply prepare the surface. We remove the previous coating and then apply an antiseptic. We are waiting for complete drying;

- The first step in dismantling is to completely clean the walls of damaged materials. A mandatory requirement will be the complete drying of the room; accordingly, this type of work must be carried out in the summer. Perform waterproofing regardless of the selected material.

- One of the fastest and most effective methods will be treatment with polyurethane foam and polyurea. In just a few hours you can easily treat the surfaces you need and forget about mold, mildew and damp odors in the underground space. Environmentally friendly materials and made with the times, technically convenient and durable polyurea and polyurethane foam.

- Polyurea will protect your foundation, as well as your walls, from unnecessary moisture and condensation. It will serve as excellent protection against rot and fungus for many years. Polyurethane foam will provide high thermal insulation properties and will also serve as waterproofing.

- Polyurethane foam and polyurea materials can be easily applied to any surface, quickly harden and after 12 hours, you will be able to use the basement for its intended purpose.

Insulation based on polyurethane foam

Polyurethane-based materials have proven themselves to be one of the highest quality insulation materials. The composition includes polyurethane foam, which is known to have high thermal insulation and waterproofing properties. So:

- When applied, it creates an even coating without seams. It does not flow down when applied, thereby facilitating insulation work.

- Polyurethane foam has a cellular structure, thanks to this quality it quickly increases in volume and quickly hardens. It has high heat and waterproofing functions.

- Polyurethane foam is widely used both in medicine and in construction. In construction, this material is used for insulation of industrial buildings, as well as residential buildings.

- The insulation made on the basis of polyurethane foam is environmentally friendly, which means it will not cause irreparable harm to the health of the environment. Polyurethane foam is odorless; this material can be used in food storage areas.

You can now do the insulation of the cellar in the garage correctly. The main thing is to choose the right materials. Take your time and do everything thoughtfully. Then dampness will not bother you for a long time.

Insulating the floor from freezing

Many owners prefer to insulate the floor with expanded clay. You can get the desired effect, but you will have to pour a concrete screed on top of the heat insulation layer.

Create a multilayer pack, which includes:

- Leveling sand bedding 5 cm;

- A layer of waterproofing film or geotextile;

- Filling with expanded clay 10-20 cm;

- Steam-waterproofing film;

- Reinforced screed 5-8 cm.

Instead of expanded clay, you can lay several layers of penoplex. It is not recommended to use one row of thick sheets, as moisture will gradually enter through the gaps and cracks. Insulating a garage floor is considered one of the most labor-intensive stages, since the work is carried out in difficult conditions.

Basement insulation, features

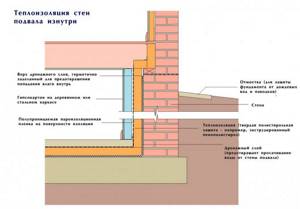

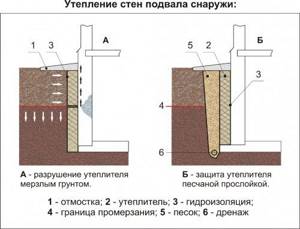

The basement is insulated in different ways, but its external insulation creates the best effect, since with this method of thermal insulation the walls are well protected from freezing.

Thermal insulation scheme

Attention: After insulating the basement from the inside, condensation appears at the joints of the wall and the insulation, which can ruin the coating. For this reason, good waterproofing of the entire wall surface is necessary.

The material for thermal insulation must be selected with good moisture resistance. Therefore, polystyrene foam is considered the most suitable type of thermal insulation material for the basement. Of course, it is worthwhile to insulate the basement, if possible, during the construction of the house. After all, then it is possible to simultaneously install a drainage system and waterproofing.

Preparing to insulate the basement

All work is performed in the following sequence:

- The first thing you need to do before insulating the basement walls is to level them to perfect condition.

- After this, it is worth treating with antiseptic and antifungal impregnation. There is a possibility that the humidity in the basement will increase after insulation, so you need to take care of ventilation, drainage and drainage in advance.

- To equip the basement with ventilation, holes are made in the base of the building, the distance between which should be approximately 5 m. Such holes are closed only during severe frosts.

- To create a drainage system, drainage membranes are installed, drainage pipes are made, or expanded clay filler is installed.

- Then, from the outside, it is necessary to excavate a part of the foundation that is in the ground, cover it with a net or cover it with hollow bricks. Sometimes drainage backfill is also made along the wall. After the soil has been poured into place, material may still be visible, then it should be covered with tiles or brickwork.

- It would be nice to make a blind area of asphalt or concrete along the perimeter of the building; it will drain melt and rain water, thereby protecting the basement. When creating a blind area, it is necessary to very carefully check the joints with the wall of the building so that they are securely closed. The “clay castle” also protects well from groundwater.

Insulation of floors between the basement and first floor

Basement insulation work is divided into the following types: insulation of walls, floors and ceilings. Thermal insulation of floors is necessary only in cases where the air temperature in the basement is significantly lower than in the entire house. So:

- To begin with, you should carefully seal all the cracks, cracks and joints.

- If metal nails and pins were used, they must be covered with insulation from the basement side, because these metal components serve as a kind of cold bridges and heat flows through them from the room to the basement. On the first floor, insulation is laid between the floor and the basement and secured.

- After this, the height of the basement may decrease slightly, but the room will always have a warm floor. By insulating the floors, it is worth preventing condensation from falling out, because water vapor will move through the floor coverings. This point is worth thinking through carefully. A good solution would be to install a vapor barrier on both sides of the insulation; in this way, the thermal insulation material is protected from mold, getting wet and rotting.

- The insulation on the basement side can be protected using external finishing in the form of plaster, panels or paints.

Basement floor insulation

The need to insulate the floor in the basement arises only in cases where it is planned to equip a room there for some purpose, because in this part of the building the temperature is always lower and the humidity is higher. And by installing heated floors, you can make it more comfortable and cozy. So:

- First, the concrete base is leveled and waterproofing is installed. This type of work should not be missed, since in the spring, when due to abundant melting of snow, groundwater often rises even to the level of the ground surface.

- Waterproofing is installed along the walls and horizontal plane. For this purpose, you can take any sheet bitumen material, for example, roofing felt.

- It doesn’t matter whether the basement is insulated from the inside or the outside; the insulation of the floor in the basement should retain its functions for decades. To achieve this result, you can use extruded foam with closed pores, it is almost 100% impenetrable.

Insulation of basement walls

Basement walls must be insulated in cases where you want to arrange a living space or billiard room in the basement. Having chosen foam plastic as a thermal insulation material, it is better to familiarize yourself with its advantages and disadvantages in advance so that you can use it most effectively in your work.

| Advantages | The advantages of polystyrene foam include the following:

|

| Flaws |

|

Taking into account all the listed features of polystyrene foam, in each individual case a decision is made whether it is possible to use it, as well as how to use it to insulate the inside of the basement. Do not forget that polystyrene foam is only suitable for rooms that have high fire safety.

- The basement walls are insulated with 25-density polystyrene foam; quarters along the edges help improve the joining of sheets, especially in cases where minimal fastening is done. It is better to make the first layer insulating by installing the material on the prepared surface. The insulation sheets are secured using an adhesive.

- Having covered the entire surface with polystyrene foam, it is also necessary to apply a cement screed on top with a thickness of approximately 50 mm, using M 100 cement. For the strength of the screed, reinforcement is made with a mesh with 5 mm cells. By resting the screed on the walls, you can reduce the soil pressure on the insulation.

- Upon completion of the above work, you can make another waterproofing layer, because the basement is always damp. To do this, the finished surface is tiled. The type of tile will depend on the purpose of the basement.

- In houses with a multi-layer foundation, the basement is sometimes insulated using additional mineral wool, but it must be protected from damage. When using any material for thermal insulation of a basement, the joints should be sealed very carefully to prevent the formation of cold bridges.

You already know how to insulate a cellar in a garage. Just choose the right material. When working, you shouldn’t rush, you need to do everything efficiently. Make a quality connection of the material and everything will be fine.

What materials exist

The choice of consumables depends on the degree of soil freezing, the type of structure and the depth of groundwater flow.

Naturally, insulation materials must meet important requirements: maintain water resistance, heat and protect against fungal infection. Thermal insulators are different for walls, ceilings and floors.

Mineral wool

Mineral wool is an excellent thermal insulation material that, in addition to everything, allows air to pass through. To insulate walls and ceilings indoors, you can use slabs of medium and soft hardness. This material does not burn and is easily attached to the surface.

Basalt wool, which has higher thermal conductivity and noise insulation properties, has proven itself especially well. It is important to remember that additional vapor barrier protection will be required to prevent moisture accumulation.

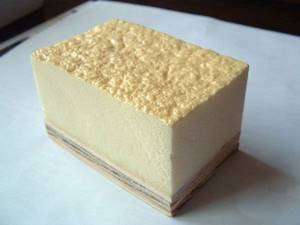

Expanded polystyrene

This is a high quality thermal insulation material that is perfect for a basement. It has high resistance to mold and the spread of rot.

Its important characteristic is almost absolute waterproofness. In addition, the material has a long service life.

Styrofoam

Often used for cellar insulation. It differs from expanded polystyrene in its manufacturing technology and higher vapor permeability. Has the following distinctive characteristics:

- does not allow moisture to pass through and does not change shape under its influence;

- weighs little and does not create additional load;

- affordable.

Reflective Thermal Insulator

New materials include reflective insulation.

In its production, special rolls are used, which, on the one hand, are made of foamed polyurethane foam, and on the other, of polished foil.

This insulation effectively saves room space, since its thickness is 3-5 mm.

Glass wool

Glass wool is used less and less today. But it has one undeniable advantage. It's cheap.

When working with such material, it is worth stocking up on protective gloves, and you also need to protect your eyes. It is necessary to additionally insulate with film or foil.

Warm plaster

This material performs both decorative and heat-insulating functions.

Plaster can be used as an independent raw material, or can be combined with other thermal insulators. In any case, it must be applied in a very thick layer.

Expanded clay

The floor in the basement can be insulated with expanded clay. This is an inexpensive option, very easy to use and effective. The thickness of the expanded clay layer depends on the expected load.

It is recommended to choose two types of expanded clay with fractions of 5-20 mm, this will protect the floor from subsidence. The size of the bulk layer should not be less than 10 cm.

Sand and crushed stone

The construction of sand, crushed stone and screed is also quite effective.

First we deepen and level the floor. The first layer is crushed stone, 10 cm thick, then sand, 5 cm thick. After thorough compaction, fill it with hot bitumen and make a reinforced concrete screed. This is a traditional and inexpensive option.

Application of polyurethane foam

Often a decision is made to insulate the basement using polyurethane foam. This material will not only protect it from cold and moisture, but will also prevent biological and chemical effects, which is very important for vegetable storage. Insulation with polyurethane foam involves some features during the work process. You will need:

- carry out surface preparation;

- make insulation, that is, apply a layer of insulation;

- if necessary, do finishing work.

Cross-section of polyurethane foam.

Preparation includes careful surface treatment. It is necessary to level the walls, lay all the necessary communications and provide ventilation in the garage and basement. After this, you can install the sheathing, which will later serve as the basis for shelves and racks.

The process of applying polyurethane foam is quite complicated, so it is better to entrust it to professional builders. To work with this thermal insulation material, expensive equipment and certain construction skills are required.

Professionals will be able to insulate your cellar quickly and will not make mistakes. In addition, most companies carry out such work with a guarantee. You can be sure that your basement insulation will function perfectly for many years. If you want to save money, you can complete the work on the basement yourself by finishing and furnishing it.

There are many ways to insulate a cellar in a garage. Using the recommendations, you can independently transform the basement in the garage into a functional vegetable storage.

How to make ventilation in a garage with a basement

DIY garage basement

Basement insulation with foam plastic

Astratek

The material astratek is a liquid consistency.

Advantages:

- Ease of use;

- Non-flammable and non-toxic liquid;

- Used in various rooms;

- Has water-repellent and weather-resistant properties;

- The internal area of the room is preserved;

- Complex coating forms are available.

Choosing insulation

We decided to insulate the cellar, but we don’t know how to do it, and most importantly, what material to use.

Let's look at how to insulate a cellar in a garage using modern materials that experts use to insulate basements:

- polystyrene foam or extruded polystyrene foam;

- mineral wool;

- “warm” plaster;

- glass wool;

- reflective thermal insulation.

Insulating a cellar in a garage with the materials described above allows you to achieve good thermal insulation properties and prevent the appearance of fungus in the room, but each material has its own advantages and disadvantages.

Extruded polystyrene foam or polystyrene foam

Advantages:

- simple installation;

- environmental friendliness;

- you can use extruded polystyrene foam for floor insulation;

- service life up to 40 years or more;

- excellent water resistance;

- low cost;

- perfectly tolerates sudden temperature changes.

Flaws:

- is flammable;

- does not allow air to pass through.

Helpful information! Extruded polystyrene foam differs from polystyrene foam in its increased density and strength. Thus, the thermal conductivity coefficient of extruded polystyrene foam will be higher than that of polystyrene foam with the same thickness of the material. In addition, only extruded polystyrene foam is used to insulate the floor covering.

| Characteristics | Expanded polystyrene PSB-30 | Foam plastic PSB-35 |

| Density (kg/m3) | 30−32 | 27−29 |

| Thermal conductivity coefficient (W/mK) | 0,032 | 0,038 |

| Compressive Strength (MPA) | 0,25 | 0,08 |

Important! When using polystyrene foam or extruded polystyrene foam as thermal insulation, it will be necessary to treat all surfaces with a primer before starting work and, upon completion, additionally plaster the walls using reinforced plaster, and make a screed of cement and sand on the floor.

Mineral wool

Advantages:

- allows air to pass through, allowing the room to “breathe”;

- excellent sound insulation;

- excellent thermal insulation;

- affordable price;

- long service life of 30 years or more.

Flaws:

- an additional frame for installation is required;

- allows moisture to pass through;

- work is performed in special clothing and gloves.

Important! If mineral wool is chosen as insulation, then it will be necessary to additionally make a vapor barrier in the basement to prevent moisture absorption by the wool itself and deterioration of its thermal insulation properties.

"Warm" plaster

Advantages:

- excellent thermal insulation;

- affordable price;

- excellent sound insulation.

Flaws:

- it is necessary to apply a thick layer for good thermal insulation;

- difficulty in installation.

Recommendation! It is optimal to use “warm” plaster to cover surfaces together with other thermal insulation materials in order to achieve good thermal insulation.

Glass wool

Advantages:

- low cost;

- good thermal insulation properties;

- good sound insulation properties.

Flaws:

- work is performed in special clothing and gloves;

- an additional frame for installation is required;

- allows moisture to pass through;

- If exposed to moisture, it may emit an unpleasant odor.

Important! If mineral wool is chosen as insulation, then it will be necessary to additionally make a vapor barrier in the basement to prevent moisture absorption by the wool itself and deterioration of its thermal insulation properties. In addition to the vapor barrier material, it is necessary to use film or foil to insulate glass wool.

Reflective Thermal Insulation

Advantages:

- high thermal insulation properties;

- material thickness is only from 2 to 5 mm;

- simple installation;

- possibility to use facing material.

Flaws:

- price;

- possible heat loss

Important! Reflective thermal insulation is quite thin and, like a mirror, will reflect infrared heat when reflected. As a result, it is not efficient enough at convection or induction of reflected heat, which leads to heat loss.

Insulating a cellar in a garage

The peculiarities of insulating a garage cellar include the fact that with normal thermal insulation of the garage, the basement is also insulated from the outside, which prevents freezing. The main difference from other rooms is that high humidity occurs in the garage cellar, and therefore it is important to have waterproofing.

Internal waterproofing of the room is most often used. There are differences when applying thermal insulation materials in a garage compared to other rooms. The most important thing is that there is an increased fire hazard in the garage, and therefore, when choosing and applying the material, you need to pay attention to the flammability of the insulation.

How to insulate a cellar in a garage is up to the owner to decide, but it is, of course, necessary to take care of its safety. In addition, you must remember to insulate all communications if they pass outside. And the electrical wires must be carefully insulated so that if moisture gets in, there is no risk of short circuiting and fire.

Final works

At the final stage, the walls are finished. In the cellar it does not have any decorative value. The main task is to provide the necessary microclimate for the preservation of food supplies.

Final lining of the cellar with clapboard

If the room is dry, you can line the walls with plywood or wood. In this case, it is imperative to treat the cladding material with an antifungal agent. For a basement with high humidity, lining is more suitable.

Wall insulation is not always required in a garage cellar. It happens that it is enough to insulate only the floor. In this case, conventional lime whitening or painting is used to finish wall surfaces.

Insulation of the floor and foundation

First of all, you need to insulate the floor and foundation of the basement. For this, waterproofing is required. It will help with the rise of groundwater, which occurs in the spring due to melted snow. The most used floor and foundation material is concrete. Under the concrete base there should be a sand cushion, as well as crushed stone, and all this must be compacted as thoroughly as possible.

Then you can fill everything with bitumen, and then make a concrete screed on a reinforced mesh.

After the floor is poured with concrete and it hardens, you can leave it as is, or you can apply decorative material or additional sheathing with wooden beams.

We insulate the floor on the ground

Initially, the earthen floor is leveled with sand.

How to insulate the floor in a garage if it is based on ordinary, bulk soil? The work is carried out according to the following scheme:

- surface preparation;

- organization of a hydraulic barrier;

- installation of logs;

- laying insulation;

- second hydraulic barrier;

- fine coating.

Any insulation work will reduce the height of the room by 30-60 cm. To compensate for such losses, it is proposed to organize a pit, if the ceiling between the garage and the basement allows it.

Surface preparation consists of leveling the soil and compacting it. Uncompacted soil may sag over time.

This will disrupt the geometry of the insulating pie. It loses its integrity, and therefore its performance characteristics. Waterproofing prevents the penetration of moisture from the soil to the insulating material and frame. Polyethylene film or roofing felt can act as waterproofing. These are all budget options. The modern market offers geotextiles. It does not allow moisture to pass through, but does not interfere with air exchange. Regardless of the type, any hydraulic barrier is laid overlapping at the joints and on the walls. All joints are taped with construction tape.

A wooden or metal frame is installed on top of the hydraulic barrier. It is assembled from transverse and longitudinal beams. If it is a tree, then choose a beam 200 mm high and 100 mm wide. It must be soaked in antiseptic. Wooden beams at intersections are connected with steel corners. They will give the structure strength.

Thermal insulation is placed in the cells of the frame. Before you insulate the garage floor with your own hands, you need to calculate the required thickness of thermal insulation. This is easy to do based on building codes. Mineral wool slabs, polystyrene foam, and expanded polystyrene are used as thermal insulation. You can use spray insulation. Installation of the slab material is carried out by surprise and without internal gaps. The gaps between the slabs are potential cold bridges where condensation will accumulate.

Once the installation of thermal insulation is completed, the installation of the second layer of the hydrobarrier begins. It should not fit tightly to the insulation. There must be a ventilated gap between them. The waterproofing is fastened using a construction stapler. This is followed by a rough flooring made of 50 mm thick boards and a finishing coating.

We insulate the concrete base

Scheme of floor insulation in a garage on a concrete base.

How to insulate a concrete floor in a garage? The main thing here is to choose insulation with increased density and compressive strength. Only dense and durable insulation will withstand not only operational loads, but also the weight of the finished floor covering. Experts pay attention to C-25 foam and polyurethane foam. They have all the necessary characteristics. Also read: “Insulation for the garage: mineral wool, polystyrene foam, etc.”

The work is carried out in the following order:

- preparing and leveling the surface;

- laying insulation on glue;

- organization of waterproofing;

- laying fiberglass-based reinforcing mesh;

- rough cement-based floor finishing;

- fine coating.

The disadvantage of such insulation is the long maturation period of the cement stone. It is 28 days. During this period it is necessary to spray the cement.

Thermal insulation of the floor with sand

To insulate a bulk or traditional cellar, it is recommended to choose sand as insulation for the floor. It has a relatively low cost, but at the same time it has excellent heat retention qualities. To achieve the best performance, the composition is distributed evenly and covered with finishing or film on top.

Stages of work

To carefully insulate a garage basement with your own hands, it is recommended to follow the sequence of work:

- primary preparation;

- construction of a frame for thermal insulation;

- installation of a ventilation system;

- installation of insulation;

- cladding, fastening of racks.

Building a frame

For better fastening of the thermal insulation, it is recommended to use a special frame that will support the insulation and help with cladding. The assembly of frames must be carried out taking into account the thickness and texture of the material.

For a sheet frame, it is recommended to clearly calculate the location of the joints of the plates and the coincidence of the installation supports with the middle of each sheet. A stacked heat insulator requires significantly fewer conditions.

Important! It is recommended to leave a small space, a couple of centimeters, between the insulation and the finishing and outline the location of future shelving in advance. This will make the final part of the installation much easier.

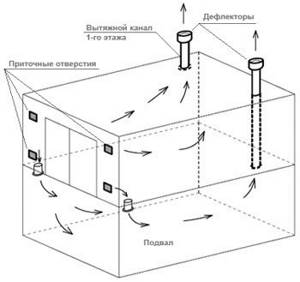

Making ventilation

The basement requires mandatory garage ventilation. However, natural operation will be sufficient, without installing additional fans. To create such a structure, it is recommended to fix two pipes at different heights. You need to install the first pipe at a level of one meter above the garage roof, and the second pipe at the bottom of the wall. Due to the active air exchange of the garage, the basement will also be ventilated. At the same stage, heaters and air conditioners are installed.

Laying the heat insulator

Next, you need to install the heat insulator, carefully securing the insulation to the walls and frame. It is recommended to pay special attention to the typesetting material during installation. Mineral and glass wool tend to roll up and lose shape, causing heat resistance to drop sharply.

When installing sheet insulation, it is recommended to use polyurethane foam to glue the seams. The inner surface must be treated with antifungal solutions and make sure that moisture does not penetrate from the inside.

Wall insulation

When insulating the walls of a garage basement, you need to pay special attention to various types of communications. Walls are most often insulated when the room should not be used for storing cans of preserved food, but, for example, as a billiard room or gym. Foam is best suited for this.

Before applying insulation, it is necessary to level the walls, cover all cracks, and also treat them with an anti-mold and mildew agent. The first step is to correctly size and cut the foam sheets. Material with a density of 25 is well suited for this. Then we fix the insulation to the wall using special glue. A screed should be applied on top of the reinforced mesh.

If the basement is very wet, then it is necessary to apply another layer of waterproofing, and a decorative layer on top. For this purpose, tiles or anything that will look elegant in the room is suitable, depending on its purpose.

It is very important to avoid unnecessary joints when installing thermal insulation. If there are cracks, then moisture will penetrate and heat will escape. If lathing is used to install thermal insulation, then all cracks and inconsistencies need to be filled with foam so that there are no unnecessary gaps.

We insulate the walls

Regardless of what material the walls will be insulated with, all seams and cracks must first be carefully sealed and all walls must be treated with antifungal solutions (quicklime or copper sulfate).

To insulate walls with mineral wool or glass wool, a special frame made of wall profiles is used. This is done so that the wool does not “flow” down under its weight, but is firmly fixed along the entire perimeter of the wall. After this, the frame can be covered with HA sheets, plywood, etc. with subsequent finishing.

An economical solution - insulating basement walls with foam plastic

To fix polystyrene foam or expanded polystyrene to the wall, a special solution and “parachutes” (dowels with a wide cap) are used. All joints between sheets of foam plastic must be carefully blown out with foam. After this, a special mesh is applied to the entire surface of the wall and plastered. After plastering, the walls can be painted.

Important! Before installing foam sheets, it is advisable to level all the walls and remove all protruding parts. This is done to ensure that the foam sheets fit tightly to each other and to the wall, providing good thermal insulation.

Reflective thermal insulation is installed quite simply; it is glued to the wall surface along the entire perimeter. On the wall side the base of the material is polyurethane foam, on the outside there is polished foil. A decorative or cladding coating can be applied on top of the reflective insulation.

Recommendation! Depending on the type of insulation you choose, carefully study the installation process, as some materials may require additional wall treatment.

Ceiling insulation

When you insulate a basement ceiling, you provide heat to the garage floor. This will keep the garage in strong condition for many years. For insulation you will need a sheathing. It can be made from timber or a metal profile. Wood lovers should understand that before installation it must be protected from moisture with a special compound. When the base is ready, you can lay the insulation material. Be sure to install a layer of vapor barrier on top so that the floors in the garage are not damp due to the basement. The next step may be to secure a decorative material, such as plastic.

We insulate the ceiling of the cellar

Before starting insulation work, we check the entire surface of the ceiling in the basement for cracks, potholes, etc. We carefully clean all these defects and seal them with a solution or carefully blow them out with foam. After this, we treat the entire surface of the ceiling with antifungal solutions (quicklime or copper sulfate).

There are a lot of options for insulating a basement ceiling in a garage - from polystyrene foam to reflective insulation.

The ceiling can be insulated with any of the materials described above; for insulation with mineral wool or glass wool, a special frame will be required, which is then sheathed with HA sheets, plastic, plywood, etc. Installation of polystyrene foam or expanded polystyrene can be carried out on parachutes with the preliminary application of a special solution, then the mesh is applied and plastered surface and painted, you can also use facing material (decorative tiles, panels, etc.). Decorative cladding material can also be used for reflective thermal insulation.

Recommendation! Before insulating the ceiling, all electrical wiring for lighting should be done, and the wires should be laid in non-flammable corrugation.

Ventilation

In order to maintain a normal balance between temperature and humidity, ventilation is required in every basement. The garage cellar is no exception. The ventilation system can be different, it is important that it exists and works effectively. It is advisable to install ventilation while the garage and basement are just being built, but this can be done later.

For a garage, ventilation is necessary not only because of the creation of a microclimate, but also because of the presence of exhaust gases and toxic substances, which, in the absence of an exhaust hood, will accumulate in the room, including in the garage basement.

Ventilation can be natural or forced. When installing natural ventilation, two pipes are required, which are at different heights. Sometimes it is enough to simply make holes in the basement to ensure sufficient ventilation.

For forced ventilation equipment, additional mechanisms will be required, which must be assembled strictly according to the manufacturer’s instructions. This complex includes fans that help draw air out of the room. In addition, immediately before the crop storage season begins, regardless of the availability of ventilation, you need to ventilate the garage, open the external doors and the cellar lid.

How to properly make a vegetable pit in the garage: read in detail

The vegetable pit is a practical storage facility in which food can be stored for a long time. It’s easy to install such a “refrigerator” with your own hands in any garage.

Cellar in the garage: what can you store?

If the cellar is made correctly: using heat and waterproofing materials, with forced or natural ventilation installed in it, with the construction of special shelves for storing food, then it can be stored in good condition until the end of spring as canned goods in jars and other containers , as well as fresh vegetables: carrots, potatoes, beets, cabbage, etc. In this case, not only the conditions created in the room are taken into account, but also the requirements for food storage .

The lids should tightly close the jars, the potatoes should be kept in boxes with holes (if they are dry, they rot less), apples and large ranetki should be wrapped in parchment paper, etc. What a cellar looks like in a garage - photo:

Advantages

It makes sense to build a basement if the garage space is owned and expected to be used for many years. What are the advantages of a cellar in the garage?

- It is under lock and key. To get supplies for the winter, you first need to get into the garage. Therefore, “raids” of dubious individuals are excluded.

- The vegetable pit is located directly under the garage in a warm zone , so the cost of thermal insulation is minimal.

- Winter preparations and vegetables are close , just a stone's throw away. There is no need to go somewhere far to your summer cottage or dig out snowdrifts to provide access to the basement.

- The entrance to the cellar can be made directly from the inspection hole. Thus, 2 problems are solved: the workpieces are in the right place, and you can easily repair the car.

- With its compact size, such a room can become a storage facility for a large number of products .

- Since there is no need for a room for storing food supplies, the cellar can be easily converted into a workshop or storage room for things .

See the photo below for an example of a vegetable pit in the garage :

in excellent condition

Selecting a location

A structure for storing supplies of vegetables and fruits should last for more than one year. For quality construction, you need to choose a suitable location. When carrying out such work, it is necessary to take into account some features. For example, the site must be on a hill so that groundwater does not fall into the hole, so the level of its occurrence is determined in advance. You can check it yourself by drilling a well about 2.5 meters deep. They leave it in this form for several days and then check whether water appears there. If the place is dry, then you can safely begin arranging the storage. Another test option is to measure the depth of the adjacent wells.

It is very important that there are no utility lines laid nearby in the selected area. This can lead to damage during digging.

Experienced craftsmen advise making a plan for yourself before starting construction. It will allow you to better navigate when performing work.

Pit construction

After careful planning, you can begin building your own vegetable pit. The first step is to dig a pit for the future cellar. Then you need to dig a trench in it in which the foundation will be installed. Crushed stone is poured onto the bottom (the thickness of its layer should be at least ten centimeters), and on top of it - construction sand in a layer of fifteen centimeters. Both levels need to be properly compacted and leveled. Then you can fill the base with heated bitumen or another similar composition. If you want to make the storage very reliable, you can put a waterproofing material - for example, roofing felt - directly on the sand and cover it with reinforced concrete on top. However, such work will be more labor-intensive and cost much more. Not all cases require such powerful waterproofing. Sometimes wooden boards are placed on the floor on top of the concrete. After the floor in the vegetable pit of a garage or private house is filled, you can move on to the walls. They are most often built from concrete or brick. The following requirements are established for them:

- for strength, concrete must be tied with steel reinforcement rods;

- the brickwork should be at least half a brick thick, but better - a whole brick or even one and a half.

After the walls are built, they are coated with hot bitumen. At the same stage, they can be insulated, and then reinforced with a mounting wall and covered with plaster.

The strength of the ceiling is especially important if there is any building above the cellar.

Having made a vegetable pit in the garage, it is worth remembering that a car will be standing above it. In the case of a private house, everything is even more serious. If the area at the top is empty, then the requirements for the structure are somewhat reduced - the main thing is that it is reliable and does not collapse down. The ceiling can be laid out either from bricks laid on boards, or from concrete - in this case you will need a frame made of reinforcement. At this stage, it is necessary to provide all the required openings: the entrance where the ladder and hatch will be installed, and the ventilation passage points. The most convenient place for a crawl space is the center of the underground. In this case, all the walls will remain free, along which it will be possible to install many shelving units. The final stage is insulating the ceiling. To do this, it is coated with bitumen and thermally insulated with foam plastic or expanded clay. Do-it-yourself water heating in a private house and its installation

Sizing

Before equipping your garage space with a vegetable pit, you need to decide on its size.

When determining the area of the cellar, the thickness of the base and walls is taken into account. Also, when calculating the optimal area, it is taken into account that the size of the room for storing vegetables should be comfortable for the person inside. Therefore, experts advise digging a pit, the width of which will be 70-80 centimeters.

This is enough for a person to move around the cellar without problems. However, in large garages that are designed for trucks, the pit can be made larger.

Since the pit should be located under the garage, its length directly depends on the length of the garage space, as well as on the number of products that will be stored in it. For example, if a cellar is built for a small amount of pickles, then its length can be 2-3 meters. The minimum depth of a cellar for storing pickles is one and a half meters. However, if the owner of the premises is too tall, they dig a pit 160-170 centimeters deep.

Arrangement of a vegetable pit - make the cellar ideal

A pit for storing crops in a garage, as we said, must be waterproofed. You may even have to make a circular drainage system in the cellar. Such measures are carried out in cases where groundwater is close to the bottom of the vegetable storage facility.

Waterproofing a pit for storing crops The easiest way to protect the floor surface of a vegetable pit from moisture is as follows:

- treat the floor with bitumen solution (twice to be safe);

- lay sheets of roofing felt on the bitumen;

- reapply the solution;

- make a filling on the roofing material using coarse sand.

The storage walls can also be coated with bitumen or more expensive penetrating waterproofing can be used. The final touch is installing ventilation in the basement. The easiest way is to make a natural supply and exhaust system. To do this, you will need to place two pipes (for exhaust and fresh air) at a certain height from the floor. Installation of forced ventilation will require more costs. You will need to buy a special electric fan and place it in a pipe with two doors. Your cellar for storing vegetables is ready!

Construction stages

Immediately after choosing a location, you need to dig a pit as provided for in the construction plan. After this, the bottom is covered with crushed stone approximately 10 cm thick and compacted. A 15 cm layer of construction sand is poured on top, which is also carefully compacted. Now you should start filling the bottom of the floor in the vegetable pit of the garage. For this purpose, a bitumen composition or similar material is used. In order for the structure to be permanent, a layer of waterproofing, for example, roofing felt, should be laid on the sand. Pouring is done using reinforced concrete and slabs. The walls of the structure are usually lined with bricks, which is easy to do yourself. The thickness should be one and a half bricks. Before laying, they must be coated with bitumen solution. This method will make the masonry reliable and of high quality. When the walls are laid, they begin to build the ceiling. It is made in the form of a vault using bricks. They are mounted on templates made of wooden boards. You can also additionally equip the ceiling with a concrete floor. If we are talking about a hole under a garage, then it must have increased stability so that it can withstand the load of the car.

In the central part of the ceiling there is an entrance to the vegetable storage. It is recommended to place it in the center of the hole, equipped with a stop for the lid. It is advisable to insulate the ceiling with foam plastic or a layer of expanded clay. The surface of the upper part should be treated with hot bitumen and then the selected material should be used for installation. It is recommended to make a thermal insulation layer of the ceiling at least 20 cm thick. The simplest option for such insulation is a mixture of sawdust and cement, which is often used by village residents. A good alternative to this composition is glass wool. To create an attractive appearance for this part of the pit, modern facing materials are usually used. A good option for such cladding:

Manufacturers of such materials must indicate which technology option is best used to secure them. It is recommended to insulate all parts of the storage facility only after plastering.

Hatch equipment from the inside

The procedure for insulating a hatch is one of the most labor-intensive. We have to ensure that the lid is tightly connected to the shaft and carefully fill all the gaps. The main task is to prevent the entry of external air, which causes freezing, condensation and ice.

It is most convenient to work with hard materials, and the maximum effect is obtained from spraying liquid polyurethane foam. When installing the heat insulator, you should keep a can of polyurethane foam on hand to immediately seal any cracks found.

Many people prefer foamed polyethylene, which can be used to wrap the hatch shaft from the inside. This is convenient if the walls are made of wood - the material is secured with a stapler. Before work, you need to do thorough preparation - apply an antiseptic, abundant waterproofing.

DIY wooden door

Typically, wood is used to make the structure if the house has wooden flooring. When using this material, we make a so-called hidden hatch: visually the subfloor will be almost invisible.

IMPORTANT! Natural wood not only conceals the door in the floor, but also reduces its weight. Wood is often used for hatches under laminate flooring.

For the work to go quickly, you need to have all the necessary materials and tools at hand, namely:

- flooring boards;

- slats for sheathing;

- support bars;

- plywood sheet;

- screws, nails;

- drying oils;

- thermal insulation film;

- shock absorber, sash hinges;

- handles for the cellar hatch;

- chalk, pencil.

Consider making an entrance measuring 80 by 80 cm. With such measurements, the door should be smaller in size so that it fits well to the floor and leaves a gap of 5 mm. Next we follow the instructions:

- We make a “draft” of the flooring: you need to nail 4 beams for support.

- We cut out blanks measuring 79 cm from the floorboard.

- We take a plywood sheet and cut out a square 79 by 79 cm. A gap of 1 cm between the floor and the hatch is needed so that high humidity or sudden changes in temperature do not deform the door.

- To make the lathing for the inside, you need to cut the slats into 79 cm long sections.

- The last step is to coat each element with drying oil, which protects against moisture and fungus.

The design is made in several layers. The first layer is plywood with slatted sheathing. The second layer is thermal insulation to insulate the hatch. The third layer is the overlay of the board.

IMPORTANT! To make the basement door invisible, the top boards must be nailed parallel to the floor.

Metal door

Unlike wood, a metal hatch is more reliable and durable. This option is good to use when the basement is located in the garage. Again we stock up on everything we need:

- sheet steel 1 and 3 mm thick;

- corner 3-4 mm made of metal;

- loops;

- anchors;

- gas closer;

- foam or other insulating material;

- primer;

- rubber seals;

- other tools: tape measure, knife, screwdriver, welding and angle grinder.

To make the design correctly, we again refer to the instructions:

- We take a metal sheet 80 by 80 cm.

- We turn the workpiece over and weld the metal corner.

- Next you need to insulate the door.

- We cover the insulating layer with a sheet of steel 1 mm thick. The edges must be secured with self-tapping screws.

- Now you need to mount and weld all the parts of the cellar hatch. We are installing a frame at the entrance. We weld the parts of the steel angle.

- We fix the frame to the concrete using anchors.

- To reduce heat loss and protect the structure from damage, it is recommended to seal the protruding edges of the metal lining with gaskets.

- The cellar door is attached to the frame using reinforced hinges. To make it convenient to open the door, you need to equip it with a gas closer.

A steel hatch can be made both in the garage and in the house, you just need to cover it with wood or the material from which the floor in the room is made.

Access to the cellar under the tiles

Materials such as tiles are most often used in the kitchen. Therefore, if your basement is located there, you can make this version of the hatch under the tiles. Manufacturing this design takes less time than the two previous options. We will need:

- steel corner;

- steel sheet 3 mm;

- solution;

- tile;

- fittings

The work takes place in several stages:

- We cut out the bottom of the hatch from steel to the same dimensions as the entrance to the basement.

- We weld the corners, making sides. We attach reinforcement inside in the form of cells.

- We make the entrance frame of the basement from corners and fill it with concrete.

- We fasten the sash and support using reinforced hinges.

- Place the tiles on top of the previously mixed mortar.

Heating a cellar in winter: types of heating and arrangement of electricity

Heating a cellar in a country house area efficiently and effectively is not as easy as it might seem at first glance. This is especially true for those owners who want to grow plants or vegetables in the cellar, or if the room requires a person to stay in it for a long time. Heating the floors using a heated floor system will not be enough.

For heated rooms, owners often use a heater. They are quite inconvenient in a small cellar room, and moreover, they do not always solve the problem of heating the room. The solution to the problem could be the installation of a heating system, although this is quite a serious amount of work for the owner of a small underground space.

Loading …

Types of heating systems

Of all existing heating systems, two main types can be distinguished

Water heating at home

Involves the installation of radiators and a boiler, gas or electric.

Water heating heats the air using a boiler, and the main advantage of this system is the constant availability of hot water.

Stove heating

To heat your home with stoves, you need to make a stove or potbelly stove. This type of heating is the most economical in use and installation. Placing a stove does not require much space, unlike a boiler, the installation of which requires careful selection of the planned location.

The stove provides enough heat to heat a small cellar in a private house. Among the disadvantages of stove heating, one can note the arrangement of the chimney, in which it is important to calculate the required number of pipes and sufficient draft.

Calculation of cellar heating

When choosing boiler heating in a room, you need to accurately calculate its area. If it is large enough, from 500 square meters or more, the boiler power should be at least 40 kW. If you only need to heat a cellar in a private house, then only 25 kW is enough.

When heating with a stove, it is enough to decide on the type of heater, which can be a brick stove, a long-burning stove or a potbelly stove. If you choose a potbelly stove as the main means of heating, you need to take into account that it can heat a small space. If you need to heat large areas, you should turn to other types of stoves.

A long-burning stove can heat an area of up to 200 square meters. The power of such a furnace is calculated in the same way as boiler equipment. A traditional brick oven is a hassle-free alternative since there is no need to determine its capacity. In any case, when arranging a stove, the main thing is to correctly calculate the chimney and make a firebox.

The stove should be placed at the bottom of the house so that warm air can rise from bottom to top. If the house does not have a basement or cellar, the stove equipment is placed on the ground floor.

If a brick stove is made, the damper in it must be closed when the fuel has burned out and there is no flame on the coals. This will allow you to save fuel used and heat savings. If this is not done, then all the heat that comes from the coals will go into the chimney.

Installation of heated floors

In a living room, a heated floor can become an element of increased comfort in use. Warm floors are made when there is stove heating, since it is along the floors that cold air moves, which occurs in the ventilation system of the house.

When installing heated floors, it is important to provide high-quality thermal insulation and waterproofing of the foundation. For insulation you need to use mineral wool and polystyrene foam. Waterproofing is needed if in the area where the house is located, groundwater passes close to the surface and there is a danger of flooding.

Heating with electrical equipment

The use of electrical appliances for heating the cellar is one of the most budget-friendly options for heating a room. In order for the heaters to operate normally, it is important to make high-quality electrical wiring in the cellar and calculate the total power.

Electrical equipment can be used in a variety of ways, the main thing is to know its main types and features of their use.

Convector heaters

To heat a large cellar area or in the basements of a private house, it is better to use convector heaters. They can cope with the cold even when there is severe frost outside. Convectors are manufactured in different designs, which makes it possible to mount them both on the floor and on the wall.

The main advantage of this type of heaters is their ability to quickly heat a space, ease of installation, noiselessness, and ability to heat large areas. Among the disadvantages, it is worth noting the increased electricity consumption.

Oil heaters

Until recently, oil heaters were used more often than others. To start heating, it was necessary to heat the oil in the radiator, after which it began to give off heat into the space. The time spent on heating the cellar in this case is much higher than in the case of convector heaters.

Oil-based heaters are very cheap, easy to use, but quite heavy and have some restrictions when moving. The advantages include a long service life, noiselessness, low price and ease of installation.

Infrared heaters

This type of heating in the cellar is rarely used, since the device only heats those surfaces that are located directly in front of it. Thus, heating the air in the cellar will require a very large amount of time and electricity.

The main advantages of infrared cellar heaters are noiselessness, reliability and durability, safety during operation and the ability to quickly heat a certain area. Disadvantages include specific installation, the need for high ceilings and overheating during long periods of operation.

Selecting heating methods for a specific room

Heating a cellar in winter is a rather complex issue that must be approached with all responsibility. It is important to understand the environmental conditions in which you plan to make a cellar.

If this is a temporary home, cottage, or other similar structure, then a simple heater is quite enough. If people will be in the cellar for a long time, then it is necessary to make a more efficient heating system.

In this case, you need to install a stove or boiler. It is important to remember that for the installation of gas equipment it is necessary to allocate separate rooms, and all work must be carried out by special agreement with gas services.

responded with an error: The request cannot be completed because you have exceeded your quota.

Source: https://ProPodval.ru/mikroklimat/uteplenie/obogrev-pogreba-zimoj.html

Conducting communications

It is better to conduct pipelines, power cables, and other communications into the basement before insulation.

The cables must be pulled into a protective corrugated sleeve. Ventilation pipes are fixed to the walls or ceiling slab, ensuring the tightness of the passage areas.

After fixing the heat insulator, it is not recommended to lay communications.

Thermal insulation of the caisson

We are talking about separate storage facilities that are built on the territory of the plots for the subsequent storage of vegetables and preservation. To protect this building from frost, it is recommended to do the following:

- Carry out reliable work to insulate the room from the cold outside (this requires the use of dense soil).

- Create high-quality waterproofing, since moisture is often the main cause of freezing.

- Reliably protect internal structural elements from penetration of cold air through the walls.

- Also, if necessary, a special vestibule is created at the entrance, which contains a thermal insulating air cushion.

Previously, we looked at how to insulate a ceiling in a cellar, which is directly related to the heated building. It should also be clarified that when improving the caisson, it is necessary to do the same series of works, but choose denser materials for this.

Important. Gardeners and vegetable gardeners are often faced with the question of whether it is necessary to insulate cellar walls and other structural elements. Here an allowance should be made for the climatic conditions in the region, as well as the purpose of the storage facility. If it is necessary to maintain a comfortable temperature, thermal insulation is necessary. If low temperatures are required, then internal insulation is not always advisable.

Installation of sheathing

If the insulation used is sheet or roll, it becomes necessary to manufacture sheathing for installation. It is made from metal profiles or wooden sheathing (antibacterial impregnation is required for use in the basement).

The spacing of the beams is most easily determined by the width of the material, especially since this will significantly save costs. Before installing the sheathing, it is also necessary to waterproof the cellar walls. Even an ordinary thick film is suitable for this, the joints of which are well taped. If the room is very humid, it is better to purchase special waterproofing materials. For high-quality protection, at least two layers are used, in the middle of which there is the insulation itself.

Main nuances of the work:

- It is necessary to provide free space between the lining sheet and the insulation for the necessary ventilation of the room. This will ensure a long service life of the structure.

- If you plan to install shelves or racks with wall mounting in the cellar, the frame must be strengthened at the installation sites. This is done using beams of larger cross-section. Be sure to measure the distance so as not to drill into the wall “blindly”.

- For lathing, you can use special metal guide profiles. This will increase the cost of insulation, but this option is very resistant to corrosion (galvanized steel is used), and also gives proper strength to the structure with a relatively low weight.

- Wooden sheathing is much cheaper, because you can use material that was not useful in construction, as well as all available wooden pieces. However, before installation they must be impregnated with special compounds. They “preserve” the wood from damage and also make it less flammable.

Installation of the sheathing can be done using different methods; the easiest way is to do it according to a pre-marked diagram. It must be completed in any case, because before purchasing materials this will have priority. It is necessary to calculate the material with a small margin, especially if you are performing such work for the first time.

A warm cellar under the garage - is it possible?

To organize a warm cellar, it is not necessary to install a heating system there. It is enough to increase the thermal resistance of its enclosing structures and ceilings. How and how to insulate a cellar in a garage? Insulation work can be carried out outside if the building is still under construction. In a ready-made cellar, only internal work is possible. As insulation, it is most convenient to use slab material with a low moisture absorption coefficient and high strength. Polystyrene foam and extruded polystyrene foam fit these requirements. They are mounted on basement walls and under wet floor screed.

To reduce heat loss through the basement ceiling, the concrete floor in the garage is insulated using joists. Here, the thermal insulation material can be expanded clay (subject to its additional waterproofing), mineral wool, or polystyrene foam. More details about the organization of the insulating layer on the garage floor are described in the video:

Insulation of facility space

Sometimes a viewing hole is used as a basement. In principle, the rules are similar to insulating cellars. However, there are some nuances. The inspection hole can be sealed exclusively from the inside using mineral wool insulation.

The basement itself is sealed both from the outside (garage basement) and from the inside. When sealing the internal space, the same mineral wool insulation is used. You can use polystyrene foam or polystyrene foam if necessary.

As a final operation, the owner must insulate the cellar lid. It is through it that a fairly large amount of heat comes out during the winter season. In addition, such a cover helps maintain a special microclimate inside the basement.

It can be installed on a special frame using hinges. The main material for it is wood. Mineral wool insulation and tin stuffed onto the lid help reduce heat loss.

Advantages and disadvantages

The work performed to improve cellars, as a rule, has a number of positive qualities, as well as some disadvantages:

- An optimal atmosphere for storing canned goods and vegetables will be constantly maintained inside the storage facility.

- You can protect the structure from freezing, which negatively affects the structural elements of the extension.

- Subsequently, it is possible to use the premises not only as storage, but also for other purposes.

- Thermal insulation will avoid periodic heating of the cellar space.

- After the insulation work is completed, there will be no increased humidity inside the storage facility.

- Thermal insulation will protect the storage from the penetration of rodents and other pests.

However, despite the positive aspects, there are also a number of disadvantages: the cost of comprehensive insulation is quite high, and a higher temperature will be regularly maintained inside the cellar. In addition, when performing cladding, the usable area inside the storage facility will be significantly reduced.

Important. Before proceeding with thermal protection of the basement, it is necessary to understand the feasibility, since if the structural elements do not freeze at excessively negative temperatures, then performing this work will be impractical.

Protecting the basement from moisture

When insulating a basement, the first thing you should do is protect it from moisture. This is especially important when it is located in an area with high humidity. The fact is that water and condensation can significantly accelerate the destruction of garage and basement structures.

Thermal insulation is impossible without ventilation. High humidity is the reason why the greatest amount of heat is lost from the basement room located in the garage. Properly installed ventilation allows you to remove excess moisture from it, thereby maintaining a constant temperature and creating a special microclimate inside the structure.

Additionally, special attention should be paid to such a technological operation in the process of equipping a basement in a garage, such as waterproofing the cellar. If work on protection from moisture and its base is carried out poorly, water can penetrate into both rooms. Therefore, if there is wet soil at the construction site, it makes sense to erect this building using monolithic concrete. If the ground is dry, the walls and basement of the garage where the cellar will be located can be built from slate sheets, fastening the joints between them with bitumen.

Thus, their high-quality waterproofing is created.

Common mistakes and useful tips

Before insulating the basement in the garage, it is necessary to carefully level the surfaces of the walls, floor and ceiling. Some people neglect this process and make a big mistake. After all, most coatings are applied to a hard, flat surface using anchors or adhesive mixtures.

Leveling walls with plaster

For leveling, plastering is most often used, with the help of which:

- the durability of the installation is ensured;

- all inaccuracies in the structure are eliminated;

- surfaces acquire the necessary hardness.

Another common mistake is poorly thought out electrical wiring. Before plastering, it is imperative to lay a cable or wire for further installation of switching devices and lamps. The open installation method, even in corrugated plastic or metal pipes, is still undesirable due to the fact that the room has high humidity.

Important advice! A dark and damp basement is perfect for the growth of various types of fungi. Before insulating the walls and ceiling in the garage cellar, they need to be primed.

Nowadays there are many different materials on sale for this purpose with antibiological additives that inhibit the development of mold and bacteria. In addition, primers contribute to the non-flowability of the plaster and its long-term preservation.

If the basement has just begun to be built, then insulation is carried out from the inside and outside. This process is complex and costly in time and effort, but necessary. The cellar is dug around the perimeter and a layer of roofing material or bitumen-based material is laid.

We insulate the floor in the cellar

Answering the question of how to insulate a basement in a garage, we go directly to the insulation process and start with insulating the floor covering.

Rigid polystyrene foam is effective for thermal insulation of floors

To insulate the floor, you will need to perform preparatory operations:

- we deepen the floor, digging a hole about 30 centimeters deep around the entire perimeter, and level the entire surface of the floor;

- we add fine crushed stone about 10 centimeters deep along the entire perimeter of the floor;

- Next, apply a layer of sand approximately 5 centimeters thick (this will avoid the formation of moisture on the floor);

- apply a layer of insulation - it is best to choose extruded polystyrene foam, at least 5 centimeters thick;

- We reinforce the floor with mesh and fill it with concrete screed.

Recommendation! You should not use sawdust or wooden platforms made from boards to insulate the floor, as wood tends to absorb moisture. Within a short time, an unpleasant odor will appear and the wood will begin to rot, which will require replacement of the floor covering, and as a result, additional costs.

Arrangement of the cellar

It must be said right away that a good basement can be built only if it reaches a depth of about two meters, has a side exhaust and a vertical entrance - this is the main difference from ordinary classic basements. Excavation work may be hampered by stone boulders or groundwater.

Before construction, you need to find out the depth of the water layers in the area where you live. There are special instructions for this, which can be found on the World Wide Web. If the foundation of your basement gradually erodes, it will not last long. .

Important. If you have a lot of moisture around your basement, then you need to make a water drainage system around its perimeter. Otherwise, water will flow into the middle of the room.

A variant of the movement of air masses into the cellars by vertical descent

In most cases, the basement is made rectangular; it can be located either under the entire garage or under part of it.

Sequence of steps when building cellars:

- They dig a trench under the foundation;

- They make formwork to pour the foundation;

- Concrete is poured for the foundation, before that we make a sand cushion at the bottom of the trench itself;

- The walls are made of reinforced concrete blocks;

- It is necessary to think through holes for vertical ventilation passages so that moisture can escape;

- The last step is to insulate the cellar in the garage.

Foundation insulation

In this part we will talk about how to insulate a cellar from the inside and start with the foundation. Since the walls are made of concrete, they, like this material, have high thermal conductivity. In the summer months it warms up, and in the winter it freezes.

From such temperature changes, the wall begins to collapse. Through the foundation walls located in the frozen ground, cold and moisture enter the cellar.

- To ensure that the foundation does not come into contact with the ground, they are plastered on the outside;

- To achieve maximum insulation, you need to put roofing felt.

Floor insulation

To prevent moisture and cold from entering our room through the floor, we need to make the following design:

- It is necessary to deepen the floor by thirty centimeters and level it;

- A layer of crushed stone ten centimeters thick is poured;

- Pour sand onto the crushed stone to make a cushion of about five centimeters;

- We compact the materials well;

- Fill the resulting mixture with hot bitumen;

- We make a concrete screed and reinforce it with reinforced mesh.

Components for wall insulation

Wall insulation

Insulating a loggia and insulating garage walls are similar in many ways. Their main similarities are the materials used and the progress of work.

This part is also suitable for those people who have a question: how to insulate a cellar in a private house? Because the work is the same. First, you need to pay attention to the presence of moisture, which will require insulating the electrical wiring, because faulty wiring is a big fire hazard.

If the wires come into contact with the insulation, the fire will spread very quickly, so they need to be hidden in special boxes. How to insulate a cellar in a garage? These can be a variety of thermal insulation materials: mineral wool, glass wool, polystyrene foam and others.

You can read more about them in a special article on our website.

External wall insulation

Important. Before the thermal insulation is installed, it is necessary to treat the walls with antifungal solutions. Copper sulfate or quicklime can help you with this.

The top of the insulation can be sheathed with decorative materials, for example, sheets of plastic. Such a plastic insulated cellar will look modern and beautiful.

But what to do if moisture accumulates in the basement, how to insulate it? This is where vapor-proof materials come in handy. For example, ordinary polyethylene is suitable for the floor; it needs to be rolled out over the entire floor area and left ten centimeters at the walls, here it will be pressed against the bricks.

If such simple protection is not enough for you, then you can build the following structure:

- Fill the ceiling with bitumen;

- Place a layer of sawdust on top;

- Laying a wooden floor.

To create thermal insulation, we will use charcoal, straw, peat or expanded clay.

If external insulation is not enough, then the cellar floor is insulated from the garage side. How to insulate the cellar from the outside in this case? To do this, a suspended ceiling is constructed, inside of which a heat insulator is placed.

- Pipes with a cross-section of one inch are attached to the floor slabs;

- A chain-link mesh is attached to the pipes;

- Everything is painted with waterproof paint;

- Plastic bags filled with straw or moss are placed under the mesh.

The price of this type of insulation will be much less if you use store-bought insulation. The efficiency of this design is high if there are no gaps or voids.

If you are interested in how to insulate a cellar on the street, then this is done in the same way as insulating the walls of residential buildings.

But if the cellar freezes, then you need to insulate it from the inside with foam plastic, for this:

- Wooden blocks (lathing) are attached to the walls;

- Polystyrene foam is placed tightly between the bars;

- Using dowels, the insulation is attached to the wall;

- All voids and joints must be blown out with foam;

- We plaster the walls;

- We insulate the lid. If you do not know how to insulate a cellar lid, then carry out this work according to the example written for walls, but without the plastering step.

Conclusion

The basement, even if it is in the garage, is not just an unnecessary room for storing crops and all sorts of rubbish. This is free space that can be useful.

In order for the garage cellar to function normally, it must be insulated, as well as have working ventilation so that it cleans the air of gases and toxic substances emanating from the garage. Then you can even convert a simple cellar into a gym or a beautiful workshop. Moreover, everything can be done with your own hands.

Selecting material for the cover

You can make a lid for the cellar from metal or wood:

- If you choose metal, then you should remember that such a cover will need to be additionally insulated.

- Wood itself is a good thermal insulation material, but the cover made from it will need to be further strengthened and treated with water-repellent materials and insecticide.

Advice. If the point of thermal insulation is not important to you (for example, the hatch is not in a living room, or non-food products are stored in the basement), then it is not necessary to insulate the lid.

It is also necessary to consider what loads the cellar lid must withstand. If people will constantly walk on it, then it is best to make it out of metal.

Functional features of the basement

The basement serves several functions:

- It maintains certain conditions, practically independent of the outside world, which allows you to store food in it.