Internal breakdowns

Now let's see what undesirable phenomena can occur inside the column itself:

Water circuit

Most often you encounter the following problems:

- The “original” filters included in some speakers are clogged.

- The flow area has decreased due to scale deposits.

Solid deposits, commonly referred to as scale, are formed by magnesium and calcium salts dissolved in water. The higher the water temperature, the higher the rate of scale formation, so the heat exchanger is the first to suffer from this problem. Its thin tubes clog very easily, resulting in a drop in pressure with all the consequences described above.

Today, a number of effective products are produced to clean the pipeline from scale. If a special composition for geysers is used, the heat exchanger does not need to be dismantled. It is enough to disconnect the supply pipe from it and drain the water by opening the hot water tap on the mixer.

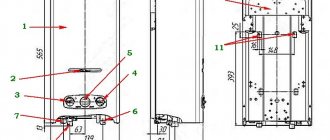

Gas water heater water circuits

Then a rubber hose is secured to the inlet pipe of the heat exchanger using a clamp, into which the reagent is poured through a watering can. You need to pour it slowly, otherwise the product will splash out due to a violent reaction.

Descaling products contain very aggressive components, for example, hydrochloric acid. When working with them, you must carefully follow safety rules and use protective equipment - gloves and goggles.

After a 2-hour soak, the supply pipe is again connected to the heat exchanger, the root valve is opened and a certain amount of water is driven through the column.

If you couldn’t get a special product for speakers, you can use any, but then the heat exchanger will need to be removed and washed separately. Otherwise, an important element of the column - the aluminum gearbox - may be damaged.

If for some reason you cannot purchase a factory-made reagent, use a folk remedy - a solution of 100 g of citric acid per 0.5 liter of water.

Ignition system

In some columns, the spark to ignite the burner is generated by batteries - this is the so-called. electronic ignition.

The reason for the “strike” declared by the water heater can be very simple - the batteries are dead and need to be replaced.

The igniter may go out due to the fact that the ignition button was not held down long enough (less than 20 seconds) - the bimetallic plate did not have time to heat up.

Smoke removal system

Soot build-ups can form not only in the chimney, but also inside the column - on the heat exchanger. It needs to be cleaned periodically.

In turbocharged engines, the cause of poor draft may be a malfunctioning fan.

Modern instantaneous water heaters are very different from outdated models, so before purchasing you need to study the main characteristics of the equipment. : recommendations from experts and review of models.

We will consider the technology for pumping a well after drilling in the article. And also read useful tips on choosing equipment.

Automation

The most common type of automatic equipment that fails is the rubber membrane in contact with water. It may become deformed or crack. This element needs to be replaced.

When choosing a new membrane, give preference to silicone-based products - they are the most reliable and durable.

The traction sensor also fails relatively often. To check its functionality, you need to measure its resistance by connecting a tester to the terminals. The device should show “infinity”.

Scale on the heat exchanger - how to fix it

The need to clean the heat exchanger is usually caused by the following reasons.

- The water takes a long time to heat up.

- Poor water pressure.

- The overheating sensor is triggered and the column turns off.

If the above happens to the column, this means that it is necessary to clean the heat exchanger, since a large amount of scale has formed in it.

Step-by-step instruction

Cleaning the heat exchanger consists of the following steps.

- It is necessary to shut off the water supply to the heater with the valve and dismantle the heat exchanger, disconnecting it from the water pipes. If cleaning is carried out infrequently, it is recommended to use a lubricating spray for dismantling, which makes it easier to unscrew the oxidized nuts. After treating the nuts with a spray, you need to wait 15-20 minutes and start unscrewing them.

- After dismantling the heat exchanger, you can begin cleaning it. To clean scale, you can use a solution prepared at the rate of 100 grams. citric acid per half liter of hot water. Using a watering can, the solution is poured into the heat exchanger and left there for 12 hours.

- Afterwards, you need to drain the solution and rinse the part thoroughly with clean water. It is necessary to thoroughly clean the heat exchanger from any remaining scale, as it can clog the tubes, blocking the flow of water. This can be done using pressurized water or compressed air.

- The final stage at which it is necessary to install the heat exchanger in place in the heater after first changing the sealing washers.

Equipment disassembly

- shut off the water supply;

- shut off the gas supply;

- remove the speaker from the wall.

Before removing the speaker from its rightful place, be sure to disconnect it from all communications. First, open the “hot” tap at the nearest water tap and drain the remaining water in the heat exchanger. Then close this faucet. Disconnect the water pipes, then the gas pipes. Don't forget about the chimney pipe.

Go ahead. Disassembly is carried out in several stages.

- Removing the handles. We are talking about regulators that are located on the main panel of the device. They are installed on the same principle as the handles on a regular stove. You can remove them either by simply pulling them towards you, or by prying them with a long flat-head screwdriver and, again, pulling.

- Removing the casing. The front panel is usually secured with screws. Their location depends on the specific speaker model - they can be at the top and bottom, or on the rear panel. In any case, they need to be found and unscrewed. After this you can remove the front panel. Sometimes it is additionally secured with hooks. In this case, you need to lift the lid a little and only then pull it towards you. Do not make sudden movements, since wires are attached to the control panel from the internal elements of the speaker. They need to be disconnected and only then completely remove the casing.

- Removing the heat exchanger. As a rule, it is attached to the fume hood and to the gas burner using screws. They need to be unscrewed and pulled out, and then the element itself must be removed, being careful not to damage the wires and contacts. You can watch the video for a detailed description of removing the heat exchanger:

For all these operations you only need a set of screwdrivers. Be careful: place all removed screws in some container so that they do not get lost later. When it comes to removing the heat exchanger, we recommend photographing the location of the structural elements before each subsequent step. This way you can later easily restore their original position and connect everything correctly.

After the equipment is completely disassembled, you can begin preventive or repair procedures.

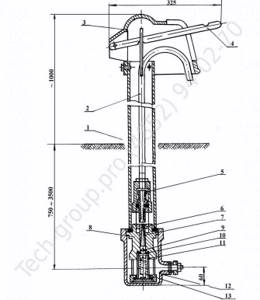

How the column works

When pressed down all the way, the lever (4) presses through the pipe and the tip of the riser (2) onto the ejector with valve (9), the spring (13) is compressed and the lower part of the ejector (7) with the holes falls below the socket. The water that is constantly in the receiver is filtered through a mesh (11), enters the ejector and then along the riser (2) to the consumer. After the end of water collection, the lever under the action of the spring rises to its original position, the valve with a rubber gasket (10) is pressed against the inner end of the ejector and closes the access of water to the ejector. The water remaining in the riser is drained through the window in the middle part of the ejector (6) into the pipe (1), where it remains until the next water draw. A normally operating ejector ensures complete suction of water during subsequent water withdrawal and guarantees uninterrupted operation of the column.

Fig.1

Types of instantaneous water heater malfunctions

A gas instantaneous water heater is a complex piece of equipment that, if operating rules are followed and properly maintained, will last a long time. As a rule, the installation fails due to lack of annual maintenance, poor quality of water and gas, improper installation, and wear of parts.

Speaker malfunctions include:

- equipment overheating;

- spontaneous shutdown of equipment;

- the occurrence of extraneous sounds;

- problems with ignition, etc.

Regular maintenance of the installation will reveal possible malfunctions in the operation of the equipment. Service activities are performed by service center employees in accordance with the manufacturer’s recommendations.

How to check draft in a gas water heater: practical recommendations

Before starting the dispenser, it is imperative to check the draft, since the quality of the equipment’s operation will depend on the speed of movement of the exhaust gases in the chimney. In addition, this procedure is carried out to eliminate the possibility of carbon monoxide poisoning. To check the intensity of draft, gas service representatives use an anemometer. You can also use a fire flame brought to the ventilation shaft. To do this, you need to light a sheet of paper or hold a match to it: if the flame quickly rushes into the chimney, it means the draft is good and you can use the column.

Checking the draft in the ventilation shaft

Important! Weak draft of instantaneous water heaters can be formed due to blockages in the structural elements of the columns. This is easy to see if there is an uncharacteristic (deep orange or green) color of the flame in the burner. To remove soot, you need to clean the ventilation shaft and remove dirt from the device components.

Maintenance intervals

For trouble-free operation of the water heater, the manufacturer recommends servicing geysers twice a year. Maintenance includes a visual inspection of equipment, replacement of consumables, elimination of minor failures, cleaning of the burner, checking gas pressure. Timely maintenance of the speakers will help avoid emergency situations and guarantee stable operation of the installation. When concluding an annual contract for regular service, equipment maintenance costs are reduced.

Benefits of turning to professionals

Our service center offers diagnostics, preventive maintenance and repair of gas water heaters of any complexity. Vast experience allows us to accurately determine the malfunction and repair speakers with piezo ignition, manual or electric ignition. The price of services depends on the complexity of the work and the condition of the unit.

5 reasons to contact us:

- free consultation with a qualified specialist;

- We carry out urgent repair work;

- calling a technician to the site;

- affordable prices;

- warranty for service and repair work.

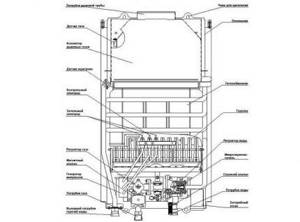

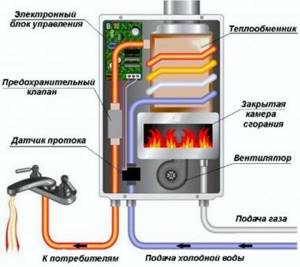

Construction of gas water heaters

To repair any equipment, you need to know its design features.

For municipal and domestic needs, gas water heaters of 3 main types are used:

- accumulative;

- flow-through;

- combined.

The most popular are gas instantaneous water heaters. Abbreviated as GPVN. GOST defines them as instantaneous water heaters. In such devices, water is heated only when the tap is turned on.

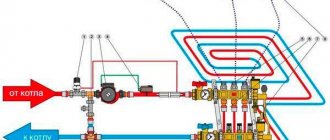

The standard HPGV circuit includes many elements grouped depending on the functions performed: gas path, combustion path, water circuit, etc. For example, burners belong to the gas path, and the heat exchanger belongs to the combustion path

Technical requirements for household instantaneous gas water heaters equipped with atmospheric burners are established by GOST R 51847-2009. Their classification is also given there.

OUR PRICES

| Visit of the master | For free |

| Diagnostics (examination) of a water heater | 1390 RUR | |

| Travel outside of Kaluga | 30 rub/km | |

| Flushing the heat exchanger | from 1900 rub. | |

| Replacing the water regulator | from 1750 rub. | |

| Replacing the electronic unit | from 990 RUR | |

| Gas valve lubrication | from 570 RUR | |

| Water heater service | from 3900 rub. |

If your water heater is broken, we are ready to offer urgent repair of a gas water heater in Moscow, St. Petersburg, Kaluga. To call a specialist, just call by phone or fill out a request on the website.

Contact our service center - we will competently determine the cause of the dispenser failure and restore the functionality of the water heating equipment!

Checking for correct connection

So, the device has been tested for functionality, it works, delighting with rich sound, but the computer does not play anything. The next thing to do is check that the device is connected correctly.

I remind those who forgot: the speaker system is always connected to the green slot on the computer or the jack marked with the image of the speaker on the laptop.

If you have a sophisticated stereo system with many satellites and subwoofers, the sockets are marked with the following colors:

- Orange – central monitor or subwoofer;

- Black – rear speakers;

- Gray – side satellites;

- Green – front satellites.

The red jack is always used to connect a microphone. Blue is the line input to which all other external sound sources are connected.

I also remind you that the detachable RCA cable to the speaker system should always be connected according to the color of the socket and plug: red to red, white to white.

WE ARE THE OFFICIAL SERVICE SERVICE

Geyser is often installed in apartments and houses due to its cost-effectiveness, performance and efficiency. Despite this, there are a number of reasons why equipment fails. It is not recommended to restore the operation of the water heater on your own due to the explosive hazard of the gas. In this case, repairing the speakers by qualified craftsmen will help.

Our company will provide high-level maintenance and repair of geysers of various modifications. The store's assortment is represented by a huge list of original spare parts for instantaneous water heaters Baxi, Ariston, Radiant, Electrolux, etc. Column service operates around the clock.

If the traction is weak

The thrust of the device weakens, the thrust indicator reacts, and the gas is automatically blocked. All this happens when the chimney becomes clogged. These may be soot formations or accidentally falling objects, as well as cracks.

In this case, the wick of the gas water heater usually does not light.

You can even conduct a draft test: open a window, lean a paper sheet against the chimney opening, or hold a flaming match.

If there is traction, the piece of paper will be attracted, and the match flame will tilt to the side.

If the traction is weak, this will not happen. Then it is necessary to clean the chimney. You should not do this on your own. After all, you need to work from the roof of the house.

Where to go if the gas water heater does not work for this reason? This is where your local property management company can help. Contact them and they will send you chimney cleaning specialists.

You can contact a private licensed company.

Analysis of the scope of work is free of charge. And the cleaning itself takes place in three stages:

- Vacuum equipment is used. A special vacuum cleaner removes dirt.

- Mechanical cleaning. A special cable with a ruff at the end is used.

- Repetition of point 1.

Cost / Prices for repair of geysers

| № | Name of work | Cost of work (rub.) |

| Call a technician within the Moscow Ring Road | 300 | |

| The technician will travel 1 km outside the Moscow Ring Road. | 40 | |

| 1 | Diagnostics of electronically controlled devices* | 800 |

| 2 | Diagnostics of devices with piezo ignition* | 400 |

| 3 | Repair category 1 (minor repairs without disassembling the product) | 1100 |

| 4 | Repair category 2 (repair with disassembly or partial disassembly or replacement of spare parts) | 1500 |

| 5 | Repair category 3 (repair with disassembly and replacement of two or more spare parts in different instrument units) | 2000 |

| 6 | Major repairs (complete disassembly, cleaning, assembly, inspection) | 3000 |

| 7 | Gas instantaneous water heater maintenance | 1900 |

| 8 | Commissioning of a gas water heater | 2200 |

*If the customer refuses repairs, diagnostics are paid in the amount of 1000 rubles.

Oven repair at home

Oven not baking? Does it smell like gas? Grill won't turn on? Electric ignition not working? Do not attempt to repair it yourself! Leave this work to our specialists, they will help resolve and eliminate the breakdown. The most efficient, reliable and fastest oven repair for Ardo, Gorenje, Gefest, Indesit, Miele, Smeg, Siemens, Hansa, Zanussi, Electrolux, Whirlpool, Beko, Kaiser, Darina in Moscow. We will repair your oven in no time! Our engineers are experienced, honest, reliable. If you have ordered a repair, you should prepare it for an initial analysis. Turn off the power to the oven, open the door and empty the cabinet of dishes and baking sheets.

Read more…

Cleaning the geyser from scale and rust

Why did the gas water heater stop lighting up? Possible causes of failure.

When operating a gas water heater for quite a long time under conditions of high lime content in the water, it is necessary to take into account the factor that accelerates the wear of the heat exchanger and shortens the established service life of the water heater - scale. Scale deposits on the walls of the radiator significantly reduces heat transfer, reduces the water heating coefficient, throughput, and is considered a malfunction.

It is useless to fight scale, but its formation can be reduced to a minimum by increasing the speed of water flow. You should take a shower or wash dishes without adding cold water. Cold water wedges into the hot flow, diluting and delaying. Temperature adjustment should be made using the adjustment selector on the column itself.

Cleaning a geyser from scale depends on the degree and thickness of the formed layer, structure and chemical composition. The heat exchanger is dismantled from the main structure and freed from residual water. Pour in a folk remedy for cleaning the column - vinegar. Leave for 6–8 hours

Features of diagnostics and repair

Manufacturers usually indicate in the accompanying documentation that repairs to the main air pump should only be performed by service company employees.

In accordance with labor safety requirements, such work is performed by adults who have undergone professional training and have a license from Gospromnadzor.

If you nevertheless decide to eliminate minor defects yourself, you should remember the explosion hazard and suffocating effect of liquefied and natural gas, be prepared for emergency situations, and be able to use fire protection equipment.

Please note that the same problem in equipment operation can be caused by different reasons. For example, you open a hot water tap, but the gas water heater does not turn on. This may be due to dirty filters, breakdown of controls and about a dozen other reasons.

Both home craftsmen and representatives of service companies face diagnostic difficulties. But gas workers have experience and professional equipment, which makes solving the problem much easier and faster. The home handyman is often armed only with a screwdriver and an adjustable wrench.

Before you begin self-repair, adequately assess your resources and weigh the pros and cons. This will help save time and avoid risks.

Do not forget that all repair operations that require removing the front panel of the housing or completely removing it must be carried out by gas technicians from the organization with which an agreement has been concluded for the service and supply of gaseous fuel. In case of independent intervention, the manufacturer's warranty is void.

If the warranty period has long expired, you can perform the simplest steps to restore the functionality of the gas water heater yourself. When identifying the causes of malfunctions, there is no need to immediately dismantle and disassemble the device.

Proceed from simple to complex, first check:

- are the water and gas shut-off valves open?

- is there gas in the cylinder (if the dispenser runs on liquefied fuel);

- whether the batteries are installed correctly in the battery compartment and whether there is a charge.

This principle works for most common faults. In the future, we will not return to it, believing that you have already carried out the initial diagnosis, but were unable to get by with a little bloodshed.

Why doesn't water heat up well?

Over time, the burner channels accumulate dust, and soot is deposited on the fins of the heat exchanger. As a result, the actual heating output drops and barely warm water flows from the tap. Related problems: the column does not turn on, the burners smoke and go out spontaneously.

The water entering the heat exchanger from a well or water supply contains magnesium and calcium salts. When heated, they settle on the internal surfaces of the heat exchanger in the form of scale.

The thermal conductivity of stainless steel and copper, from which the heat exchangers are made, is 45 and 401 W/m2×K, respectively. These indicators vary slightly depending on the grade of metal. The thermal conductivity of scale is much lower - only about 0.2 W/m2×K.

This means that even a small deposit on the walls of the heat exchanger leads to a decrease in heat transfer. As a result, the water heating time increases. Deposits reduce the diameter of the flow area, which reduces the flow of water.

How to clean the heat exchanger?

At home, the chemical method is mainly used. It is universal and suitable for both collapsible and welded/brazed heat exchangers. Special detergents are used that do not react with metal, but dissolve carbonate deposits.

Before cleaning you must:

- shut off the gas and water supply;

- drain the remaining water by turning on the tap;

- remove the protective cover;

- disconnect the supply pipes and wires;

- remove the heat exchanger.

Pour warm water with some dishwashing detergent into a deep basin. Place the heat exchanger and gas burner unit in the basin. Use a soft brush to clean soot from the radiator grille, rinse the parts with a stream of clean water, not forgetting about the channels through which gas is supplied to the burner.

To remove scale, install the heat exchanger in a basin upside down (down with the radiator and up with the inlet and outlet of the tube). Pour anti-scale agent into the tube. After the scale has dissolved, drain the liquid and thoroughly rinse the heat exchanger. Reinstall and connect

The plate heat exchanger can be carefully disassembled before cleaning. At the same time, do not miss the opportunity to inspect it and assess its condition. If the wear of the plates is significant, it is better to replace them immediately. If there is a small layer of scale, instead of special liquids, you can use ordinary table vinegar or a solution of citric acid.

The washing time varies from 30 minutes to a day or more, depending on the properties of the detergent and the thickness of the deposits. After removing contaminants, the thermal performance indicators of the column must correspond to those specified in the passport.

Preventing scale formation

Using mixers in a water supply system involves mixing cold and hot water. This method leads to accelerated scale formation. It is recommended to use a separate tap for hot water, and a gas flow regulator will help to increase or decrease its temperature.

If, when heating water, its temperature often rises above 60 degrees, scale forms faster. Do not fill the bathtub with boiling water and then dilute it with cold water. Set up the device correctly, and water at a comfortable temperature will flow straight from the tap. The recommended temperature for baths and showers is between 37-42 degrees.

The rapid accumulation of soot is caused by prolonged heating of water at maximum burner flame, poor chimney draft, incomplete combustion of gas and the presence of impurities in it.

What to do if the speaker does not turn on?

Have you opened the hot water tap, but there is no spark and the instantaneous gas water heater does not ignite? It is possible that carbon deposits have formed on the electrodes of the spark plugs. In many models, these parts can be cleaned through the viewing window using a long-handled brush.

Sometimes water heaters do not work due to low water pressure. Check the filter and, if necessary, clean it or replace it, rinse the heat exchanger. Open the shut-off valve completely. If the pressure remains weak, contact the management company (housing and communal services).

Difficulties in igniting a gas water heater are often caused by damage to the elastic membrane located at the beginning of the water circuit. When the tap is opened, a pressure difference occurs, which causes the membrane to bend and act on the gas valve through the rod. As a result, gas flows to the burners.

With repeated bending, the membrane wears out, stretches, tears and no longer performs its functions properly. Losing elasticity or integrity, it is not able to press on the rod with sufficient force. The gas valve does not open or does not open completely.

Due to lack of fuel, the water heater does not work. The membrane replacement algorithm is as follows:

- shutting off the water and gas supply;

- removing the casing;

- disconnecting pipes and wires;

- removing and replacing the membrane;

- reverse assembly.

Upon completion of work, use a soap solution to check the tightness of the detachable joints.

The burner goes out spontaneously

A water heater with an open combustion chamber turns on normally, but during operation its nozzles go out. This problem may be due to a lack of air, which is taken directly from the room where the device is located.

When plastic windows are tightly closed, air exchange with the street is difficult, which leads to the protection system being activated and the burner flame going out.

The operation of a gas water heater may be blocked due to poor removal of flue gases. A common cause of this problem is a clogged chimney pipe.

Open the window slightly, wait about 10 minutes and turn on the speaker. If it goes out again, check the combustion products path. For water heaters with atmospheric burners, these are ordinary chimneys with natural draft.

Gas workers check draft using an anemometer. The device allows you to determine the volume of air passing through the chimney. Home craftsmen use thin paper, which must be cut into strips about 2 cm wide and about 20 cm long and brought to the chimney inlet at a distance of 5 cm.

You must first turn off the column, remove the gas exhaust pipe and open the window. If the paper strips are not carried away by the air flow and do not touch the chimney inlet, then it is time to clean it.

The ignition device does not work if the gas supply is interrupted or the spark plug is clogged or smoked. Other reasons include a breakdown of the ignition device transformer or a disruption of the electrical circuit connected to it.

Please note that in case of leaks, gas accumulates in the outlet shafts. Therefore, you should not tempt fate by testing your traction with a burning match, candle or lighter.

The burner operates with the tap closed

Have you turned off the hot water tap but the burner won't go off? Most likely, the gas or water circuit rod is jammed. This is the case when you cannot do without specialists.

But first of all, it is necessary to block the access of gas to the device by closing the shut-off valve on the gas main, and only then call the service department.

Leakage through detachable connections

The shut-off valve is installed on the cold water supply pipe using a union threaded nut. The pipe through which hot water enters the plumbing system is connected to the heat exchanger pipe in a similar way.

All detachable connections of the water circuit are sealed with gaskets made of non-asbestos paronite, Teflon or oil and petrol resistant rubber. Wear of gaskets leads to failure of sealing of joints and leaks

Before replacing the gasket, the column is turned off, the water in the water supply system is turned off, the nuts are unscrewed, the worn gaskets are removed and new ones are installed in their place.

The water heater is very noisy

Serviceable gas equipment operates very quietly and this is one of its advantages.

Gas water heaters with a closed combustion chamber are equipped with fans that pump in the air required for combustion and remove flue gases

Increased noise levels indicate excessive water flow in the heat exchanger or overheating.

Measure the water temperature in the tap and, depending on the result, adjust the water or gas flow downward.

Security issues

To ensure that gas pumps meet safety requirements, manufacturers equip them with a variety of sensors. If the burner goes out for some reason and gas continues to flow, the gas-air mixture may explode.

This development of the situation helps to prevent the presence of a flame sensor. Ionization currents arise between its control electrode and the burner flame, on the basis of which discrete signals are generated. If there is no flame, the shut-off valves are activated and the gas supply is stopped.

If the sensor is installed in such a way that the electrode touches the burner parts or is located too far from the flame, its correct operation becomes impossible. This causes the speaker to turn off. To solve the problem, it is enough to change the location of the electrode.

To control the water temperature, an overheating sensor is installed on the heat exchanger tube. Usually it is a thermal relay with bimetallic temperature-sensitive elements.

When the water temperature approaches the boiling point (85°C), the shape of the temperature-sensitive elements changes, which opens the electrical power circuit of the electronic unit and the column turns off.

A breakdown of the overheating sensor or a break in the electrical circuit lead to premature shutdown of the column, even if the water has not had time to heat up.

Having ruled out other possible causes of the malfunction, use a multimeter to check the integrity of the current-carrying conductors of the electrical circuit. If there are no breaks, check the sensor and, if necessary, replace it with a serviceable one.

To do this, disconnect both wires from the sensor and unscrew the mounting screws that secure the device to the heat exchanger. Now all that remains is to remove the old sensor and install the new one.

Pressure testing of the water circuit

After repairing a gas water heater with disassembling the water circuit, you need to check the tightness of the pipes and joints. The most effective method is crimping. Fill the circuit with water, the temperature of which is from 5°C to 25°C. The air temperature in the room should be above 0°C.

Using a manual or electric pump, raise the pressure in the circuit to the test value. Hold for at least 5 minutes, monitoring the pressure using two pressure gauges pre-installed at two points in the system.

If the pressure has not dropped by more than 10%, the water circuit is considered tight. Otherwise, the faults are diagnosed again, and after they are eliminated, a leak test is repeated.

The test pressure is 1.5-2 times higher than the working pressure specified in the water heater passport. The exact values for different types of columns can be easily found in GOST R 51847-2009. They cannot be exceeded, therefore during pressure testing it is necessary to carefully monitor the operation of the pumping equipment.

Full disassembly service

Do not be afraid to disassemble the water heating installation, the procedure is not that complicated. You will need the most common tools - screwdrivers, pliers, standard wrenches. What to do before starting work:

- Close the taps of the cold water, hot water and gas supply pipelines. Unplug the turbocharged dispenser from the outlet.

- Substituting the container, unscrew the union nuts (American) on the connection of the water pipes. Disconnect the connections from the unit without losing the rubber gaskets.

- For convenience, it is recommended to remove the gas heater from the wall. It is not easy to disassemble and clean a unit that is hung too high or installed in a narrow niche.

- To dismantle the water heater, disconnect the gas line and the chimney pipe. Remove the unit from the hooks.

Lay the hot water column on a horizontal surface and proceed to further work, the order of which is outlined in our instructions.

How to remove the heat exchanger and column burner

We will show the disassembly sequence using the example of a cheap Chinese Novatek water heater. We present step-by-step instructions with photos:

- Remove the control handles mounted on the front panel. Unscrew 2 screws (or 2 plastic clips) and remove the device casing.

- The next step is to remove the smoke collector. To do this, disconnect the wires from the draft sensor and unscrew the screws holding the diffuser box.

- Disconnect the heat exchanger tube from the water unit by disassembling the connection with the union nut. The second pipe must be freed from the lock washer, pressed with 2 screws.

- Disconnect the burner from the gas valve by unscrewing the 2 screws on the flange. Having moved the radiator upward, carefully remove the burner device (pull towards you) and move it to the side.

- Unscrew all screws connecting the heat exchanger to the rear panel of the water heating unit.

- Pull out the radiator completely and remove the burner, disconnecting the wires along with the ignition electrodes.

Disassembly of geysers from other manufacturers may differ, but not fundamentally. The order of work remains unchanged. Let's list some important points:

- in a chimneyless turbo column, the fan will have to be removed;

- in units of the Italian brands Ariston (Ariston) and some others, the pipes are connected not with nuts, but with self-clamps;

- If the water heater is equipped with an igniter, then before removing the burner it is necessary to disconnect the gas tube connected to the wick.

Our expert plumber will demonstrate the above process in detail in his video:

Watch this video on YouTube

Flushing procedure

This operation is very simple compared to disassembly - cleaning the gas water heater begins by immersing the heat exchanger in a container with washing liquid. The procedure is as follows:

- Take a bucket or deep basin, fill it with water and prepare a cleaning solution according to the recipe on the package. The concentration of citric acid is 50-70 grams per 1 liter of liquid.

- Immerse the heat exchanger in the container with the radiator down and the pipes up.

- Using a watering can, fill the coil with detergent. Rinse it periodically by adding new solution.

- Flush the heat exchanger until clean liquid comes out of the tubes without scale flakes. Then run tap water through the coil to remove any remaining product or impurities.

The removed burner can be cleaned from the outside and purged or washed with a solution of citric acid (no more than 50 grams per liter of water). Finally, rinse the element with running water, blow with compressed air and dry thoroughly.

Do not ignore other parts of the gas water heater - mesh filter, smoke collector and combustion chamber, remove soot and other contaminants from them

After washing and drying, put the heat exchanger back in place, connect the burner and follow the remaining steps to reassemble the water heater

It is important to achieve tight connections: when installing old gaskets, treat them with high-temperature sealant. Check joints for tightness using water pressure (4-6 bar)

It wouldn’t hurt to blow out the inside of the burner with compressed air at a pressure of 4-6 bar

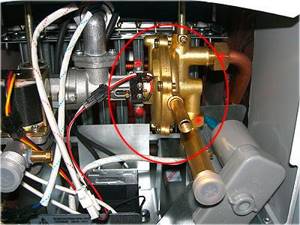

Purpose of the water node

Regardless of the complexity of the design, geysers used to heat water in houses where there is no hot water supply (DHW) operate according to the general principle. The water passing through the heat exchanger is heated by gas, which is supplied to the burner when liquid flow appears through the water unit and is shut off when the hot water tap is closed.

The water unit is the first automatically operating block of the geyser on the path of cold water.

The water unit (A) is located at the very beginning of the journey made by water along the water “main” of the gas water column, so it is easily detected after removing the housing. Structurally, the block is connected to the gas unit (B) and the heat exchanger

The main task of the water block is to send a signal to turn on or off the gas unit working in tandem with it, regulate the gas supply to the burner and the water supply to the heat exchanger coil (ensuring normal operation of the column).

Thanks to the original internal device, when you open a hot water tap, the water reducer gives a signal:

- to open the gas, provided that the flow of heated water is not lower than specified;

- to stopping the gas supply when the tap is turned off or the hot water pressure is insufficient.

At the same time, the water reducer (also known as a frog, or water regulator) is one of the safety devices of the water heater, since with low water pressure it prevents overheating of the heat exchanger, which fails due to regular overheating. We talked about repairing the heat exchanger in our other article.

Repair of gas hobs

If you have any questions about using a gas hob, please contact us. We will always come to the rescue, we will help eliminate such troubles as: turning off the burners, jamming the tap, we will adjust the ignition process, we will adjust the gas combustion, we will change the frying table, glass, we will clean the garland of buttons, we will clean the grease from the mechanisms. All this breaks, and we fix it all in due time. Call. Repair of gas hobs is carried out with the installation of original spare parts. We are ready to cooperate with all clients, regardless of the brand of hob manufacturer, whether domestic or imported, its cost and service life.

Read more…

Repair of Bosch geysers in Moscow

Our service workers can repair a Bosch gas water heater on the same day the client contacts us. There is no charge for urgent work, except on holidays. All repair work and regulated annual maintenance are supported by a warranty document indicating the work performed. The cost of calling a technician outside the Moscow Ring Road is negotiated separately by phone, on average 30 rubles = 1 km.

| DIAGNOSTICS We diagnose a Bosch geyser over the phone, so the cost of this service for you is 0 RUBLES |

| CALL We will charge 500 rubles for the call if the repair is refused, but this service costs 0 RUBLES |

| REPAIR The cost of the repair work performed without the cost of the required spare parts in our company varies from 900 RUBLES |

| GUARANTEE Before leaving, our employees will issue a guarantee from our company for the work done for a period of up to 12 MONTHS |

| Every user of a gas water heater must remember and not forget to undergo scheduled maintenance. An inattentive approach and neglect of annual inspection leads to unexpected breakdowns or complete failure of the device. Before each cold season, you should undergo general cleaning of the column, regardless of the frequency of its use. In the future, this will help avoid emergency shutdown due to contamination of the heat exchanger. With the right approach to cleaning, not only the efficiency of the column increases, but also its service life is extended. Checking all moving parts will save you from searching for a repairman in the future, this is especially true if you live far from Moscow. Timely submission of an application to call a specialist will extend the life of the heating device for several more years. Often, a call to the service center occurs only after the gas water heater has stopped turning on and does not respond to any function, that is, it has stopped completely. For the correct operation of the Bosch geyser, it is necessary to carry out regular inspections for contamination by combustion products. This work must be carried out by qualified specialists; independent intervention will not give a good result. | |

|

|

How to order a service?

Dear visitors, if you encounter problems or complete failure of the Bosch Gas Heater, then dial the phone number of our Service Workshop. Gas Service specialists will help solve any problems.

List of main problems and ways to solve them

First, it’s worth mentioning what to do if the gas water heater breaks under warranty. In this case, everything is simple - you must contact the service department of the store where you bought the device. It should be repaired free of charge. If the warranty has expired, you will have to pay for repairs. Its cost depends on the manufacturer of the water heater and the type of breakdown.

Let's look at the most common problems that arise during the operation of the device.

Lack of traction

If there is a lack of traction, the corresponding sensor is triggered, which blocks the gas supply. This happens if the chimney or ventilation becomes clogged. Debris, leaves, or a sooty layer can build up there. Another symptom of a clogged chimney is the inability to light the device’s pilot light. You can also test using a lit match or piece of paper.

You can improve traction by cleaning the pipe. To do this, contact the housing and communal services or management company. They should send a drain cleaner. You can also contact a commercial company specializing in this type of activity.

The chimney is cleaned as follows:

- vacuum equipment is used to extract dirt;

- Mechanical cleaning is performed using a special cable with a brush at the end.

For serious blockages, chemical cleaning methods are used, which involve treating the pipe walls with special preparations.

Discharge of power elements

If your gas water heater is ignited using batteries, then in about a year they will run out. Therefore, if the water heater does not light up, the first thing to do is check the battery charge.

If this does not help, then we check the device for other breakdowns.

Read here how to properly flush a gas water heater

Lack of water pressure

If the gas water heater does not have enough water pressure, it will not start. Therefore, it is important to test it and open the cold water tap. If it flows out in a thin stream, you need to contact the city water utility or housing and communal services. A plumber will arrive and determine the water pressure, and also find the reason for the decrease in its pressure.

If the cold water pressure is fine, you should look for a clog that is reducing the water pressure. The problem is often caused by:

- strainer clogged;

- stretching of the gasket in the water unit;

- scale build-up in the heat exchanger;

- clogged hot water pipe;

- leakage in the radiator.

There are two ways to clean the filter, pipes or heat exchanger - yourself or with the help of a specialist. If a leak appears in the circuit, the part should be replaced with a whole one.

Gas burner contamination

During operation, the burner device becomes clogged with soot and soot. As a result, the fire has an unnatural red or yellow color, sparks, or does not ignite at all. To clean the burner, it is not necessary to call a service center specialist; you can solve this problem yourself. If desired, the burner is removed and disassembled, and all contaminated elements are cleaned in a special solution.

Adjusting the geyser

Adjusting the burner flame height - the closer to the maximum, the hotter the water. Adjusting the water flow - the closer to the maximum, the greater the flow, therefore, the colder the water. Winter/Summer - mode of using the speaker at different times of the year. In winter the power is greater than in summer.

Not all craftsmen know how to properly set up a gas water heater and simply do not do it, leaving it as it is (by default). But we do not recommend leaving the settings at the factory settings and making adjustments yourself.

Temperature setting

- Set the gas and water supply knob on the heater to minimum.

- Open the gas and water supply valves on the pipelines.

- Open the hot water tap and adjust the water pressure you need using the handle on the gas water heater.

- Wait 1-2 minutes and measure the temperature. Using the gas supply knob on the column, increase the flame, thereby increasing the water temperature to the desired temperature.

- When the water temperature is comfortable, you can leave all adjustments alone and use the water.

In the future, you can adjust the temperature using another knob (supplying heated water).

Pressure setting

This is a membrane in a gas water heater; if it fails, the unit stops responding to water pressure.

When adjusting the column, sometimes unpleasant moments arise. The new column either turns on at very low pressure, or does not want to start at all. This depends on increased or decreased water pressure in the pipeline and is eliminated in the following ways.

| System pressure | Solution |

| Increased | Change the inlet valve. Install a pressure regulator. |

| Downgraded | Change the membrane; it may be leaky or clogged. |

Gas is not supplied

When the device is functioning normally, a certain sound is heard when it starts up. If there is no sound when turned on, then gas does not flow into the geyser.

If you have gas in the house and have such a dilemma, call a gas technician.

The column will be diagnosed (400-500 rubles). Checked:

- Opening angle of the gas shut-off valve. It must be straight.

- The quality of the connection of the device to the gas pipeline. A special tee is used for this. If a flexible hose is used to carry fuel, the technician analyzes the tightness of the contacts and looks to see if the hose has kinks. If there are these shortcomings, he corrects them.

Device structure

In order to be able to diagnose device malfunctions without the help of a geyser technician, you need to have a general understanding of their structure, because this is what determines how the repair work will be carried out. There is no need to delve into the intricacies of assembling many different models, because... most of them are similar. Therefore, we can limit ourselves to only familiarizing ourselves with the general principles of operation of such devices.

By historical standards, hot water supply appeared in homes not so long ago. Water was heated using various methods, but the easiest way to do this was using a solid fuel heater. Usually it was heated with coal, less often wood or fuel oil was used. In order to have enough hot water to take a bath, you had to spend quite a lot of time heating it up - from 2 hours or more. Of course, this is not entirely convenient, and geysers were created to solve the problem.

You can see the design of a gas water heater in this video:

This device is designed to increase the temperature of water using gas from the city mains. To speed up the heating process, heat exchangers were built into the equipment - it is in them that moisture is distributed through a system of thin tubes located above the gas burner. Due to this feature, the column is able to heat water quite quickly and does not require filling a large tank.

Geyser - equipment that allows you to heat water using gas

This is the main principle of operation of all gas appliances; the rest of the technical filling is designed to ignite, maintain the flame, regulate the heating temperature, and also ensure safety during operation. Ignition of the main component - the burner - can occur:

- From the igniter. It is lit manually using a match, a special lighter, or turned on with a button (automatic or mechanical). The first options are considered outdated, so such speakers are unlikely to be found on sale.

- Without igniter (piezo ignition).

- Using electronics. This method works the same way as igniting cars.

The security system blocks the flow of gas to the burner if water gets inside

Most modern speakers are equipped with a mechanical security system. Even devices with electronic filling have this type of protection, located between the membrane in the device for receiving water and the valve of the gas pipe. The system works on the following principle: the valve stops interfering with the flow of natural fuel into the device only if the water pressure presses on the membrane with the required force. Everything can be explained even simpler: gas is not supplied to the burner if water does not enter the column.

Kinds

Today, the gas appliance market offers a wide selection of different models of gas burners. Generally speaking, all gas heaters operate on the same principle and differ from each other in the following characteristics.

Power. The greater the power of the heater, the more water it can heat in a short period of time.

Among the most common types of power, the following three can be noted:

- Heater with a power of 28 kW.

- Heater with a power of 26 kW.

- Heater with a power of 17 kW.

The latter type has a low cost, but at the same time cannot provide hot water to the bathroom and kitchen at the same time. As a rule, most users choose the second type, as it has an optimal price-performance ratio.

Safe operation of the device. It is one of the main criteria when choosing a heater. Despite advanced technologies, there are still cases when water or gas is turned off and in order to prevent leakage of fuel or combustion products, the dispensers are equipped with the following sensors.

- Gas shut-off sensor in case the flame goes out.

- Flame sensor. It is redundant and also turns off the gas supply if the flame goes out and the first sensor does not work.

- Water pressure relief valve. Prevents water pipes from bursting in the event of high pressure in the system.

- Sensor for opening and closing a water tap. Performs the function of turning the heater on and off when the tap is opened.

- Traction sensor. Prevents the column from turning on in the absence of traction, while avoiding carbon monoxide poisoning.

- Water pressure sensor. Prevents the heater from turning on in case of low pressure in the water supply.

- Thermostat. Ensures that water heating is turned off when the temperature has reached the desired level.

This is the main list of protective sensors that a modern geyser should be equipped with. If one of them is missing, such a device is highly not recommended for use from a safety point of view.

Type of arson. Arson can be carried out in one of two types.

- Piezo is a mechanical type, which means you have to burn it manually.

- Auto-ignition operates using batteries and is automatic. The principle of operation is the same as in piezo arson only without human intervention. Automatic ignition also includes hydroturbine ignition, powered by an electric generator.

Additional features. These functions include the presence of an LCD display that displays various information, additional settings, etc.

This is the main list of differences that distinguishes the types of geysers from each other; they also have differences in color, shape and design, which is no longer so significant when choosing and does not in any way affect the technical characteristics.

The water heater is leaking

If you see similar stains on your column, then be sure that it is leaking and needs repair.

This malfunction can occur mainly in geysers that have been operating for a long time. The two main reasons for the leak are:

The radiator is leaking.

Tubes (bends) or gaskets in connections are cracked. Replacing the radiator or taps is quite expensive. Therefore, there is a reason to repair the geyser on your own. For repairs you need:

- screwdrivers (cross and regular);

- open-end wrenches (set);

- solder with rosin;

- vacuum cleaner;

- solvent;

- "skin".

Sealing holes

Due to harsh operating conditions, the radiator or taps may burn out and holes may appear on them. If you have determined where the leak is, you can repair the small hole with a regular soldering iron.

Preparing a gas water heater for repair

- Drain all liquid from the system - open only the hot water tap, unscrew the nut on the cold water inlet pipe, and most of the water will flow out;

- Remove the radiator completely;

- Inspect the entire tube. - if you see “green”, clean and inspect these places for cracks.

Soldering a heat exchanger does not always give good results; a lot depends on your skill. If the soldering is bad, the heat exchanger will quickly leak again.

When you have found leaks, you need to do the following:

- clean the holes found with sandpaper and immediately wipe with a cloth with solvent (this will remove any remaining grease, carbon deposits and dirt);

- using rosin with solder, tin this place with a 100-watt hoop (if you don’t have rosin, use aspirin);

- Fill the crack or hole with solder, and after it cools, add more tin (the layer should be 1-2 mm).

Attention! In some cases, with holes of about 5 cm, craftsmen apply a “temporary” overlay made of a copper or aluminum plate, securing it with thick wire or metal tape

But as a rule, such a “temporary” solution remains for a long time. We recommend replacing the radiator completely and forgetting about its leaks

Faulty gaskets and tubes

Replacing flexible hoses of this type does not require special skills; anyone can do it with a wrench.

Very often, leaks form at the points where the taps are connected to the heater externally or to the internal components of the column. All connections are made “American” with gaskets inside.

Due to constant heating/cooling, rubberized liners either melt or lose their properties and harden. Cracks appear in them, through which water flows. If you notice a gas column leak in such connections, replace the gaskets. Using a wrench (usually 24), unscrew the nut and replace it.

It also happens that the flanges on the tubes crack over time - in this case, you need to replace the entire tubes.

The heat exchanger is clogged with scale

With our water quality, heat exchangers in geysers become clogged with scale quite quickly and very heavily, which reduces their thermal conductivity and increases gas consumption.

The longest process in terms of time is cleaning the main tube (radiator) from deposits that arise when heating tap water. If you turn the gas knob all the way, and the water coming out is barely warm, then this indicates that the heat exchanger is clogged with ordinary scale, which does not transfer heat well.

This happens quite often if the gas water heater does not have automatic ignition (with a igniter). Scale also forms if you set the water heating temperature too high. The unit overheats, the tube (radiator) heats up to 80-850, which contributes to the rapid (a little more than an hour) formation of scale. Isn't it better to just turn off the speaker in time? Then there will be no problems, because 40-600 is enough for all washing and washing processes.

Before starting work on the heat exchanger, check the inlet tap or valve. Maybe the whole reason is that they are clogged. But if they are working properly, it is necessary to get rid of deposits in the tube.

There are two ways to solve the scale issue. We will consider both options.

Auto

The Cillit KalkEx cleaning system does its job quite well. With its help you can quickly descale any boilers. Unfortunately, it is not very accessible to ordinary users of geysers.

This is an expensive method using a special device (Cillit KalkEx) and a set of special preparations for washing. Your speaker doesn't even need to be removed from the wall. You just need to disconnect the water hoses (inlet/outlet).

The purification device is connected to the column, and it circulates the heated reagents in a closed cycle (in a circle). The scale decomposes under their influence, is washed out and drained.

Manual

Cheap, but long and labor-intensive process. To do this, it is necessary to disassemble the water heater almost completely and then wash it manually.

The following materials and tools will help us with this:

- open-end wrenches (set);

- screwdrivers (phillips and regular);

- paronite gaskets (set);

- rubber hose;

- vinegar essence or anti-scale agent.

Disassembling the gas apparatus

To remove the heat exchanger, proceed in the following order:

- First, we block the access to cold water;

- then we remove external elements that prevent disassembly (switch handles, regulators);

- remove the casing, and to do this, unscrew the screws located on the rear wall of the unit, lift and remove the cover;

- open the “hot” tap;

- unscrew the supply tube from the heat exchanger and move it aside;

Flushing the system

After the water has completely drained, we put the hose on the heat exchanger tube and raise it above the level of the column. Slowly pour the solution we prepared into the hose and leave the column for 4-6 hours.

Next, you need to open the water supply tap a little and watch the water that will come out of the column; if you see a lot of scale, then our work was not in vain - we got rid of it. If there is no scale in the outlet water, then we repeat the whole process again.