When constructing any fireplace, it is necessary to ensure its stable position on a rigid foundation. This requirement is ensured

: 1) a foundation special for the fireplace or 2) a rigid interfloor ceiling included in the structure of the house.

In the first option, a foundation is made for the fireplace, which should not be structurally connected to the foundation of the house. Such independence ensures the possibility of independent settlement of the fireplace foundation from the settlement of the entire house.

The second option makes it possible to use rigid structures of reinforced concrete slabs, which are used in the interfloor floors of houses. In cases where interfloor ceilings are made using wooden beams, they can be strengthened with metal structures to carry increased loads. The same approach can be applied to reinforced concrete floors when their load-bearing capacity is insufficient for the loads from the fireplace. In each case, the issue is resolved specifically at the location.

If it is possible to choose from these two options, preference should be given to the second option, and not only for economic reasons. A fireplace placed on a rigid interfloor ceiling is free of its own movements in the overall structure of the building, which significantly distinguishes it from the first option. When choosing a place for a fireplace in a room, preference is usually given to a wall or corner position. This creates certain advantages for installing fireplaces on interfloor floors, since their strength capabilities increase as the load approaches the embedding of the floor into the wall.

Note that when constructing foundations, temptations arise to connect the foundation of the fireplace with the foundation of the house. Such attempts can lead to disastrous results. Due to different settlements of the foundations, the base of the fireplace may deviate from the horizontal position, because The foundation of the fireplace can be supported by the foundation of the house. This will affect, first of all, the fireplace pipe, where the angular deviation in the linear dimension becomes sufficient for the fireplace pipe to be cut off by rigid elements, for example, an interfloor ceiling or the roof of a building.

The final choice from these two options should be made only based on the results of calculating the weight of the fireplace. It ranges from 400 kg to 5-7 tons. Less weight applies to fireplaces whose pipes are built into wall chimneys and fireplaces with metal pipes (for example, a sandwich pipe). Greater weight for fireplaces with brick chimneys.

The weight of the fireplace with chimney is determined by an approximate calculation. Note that the calculation is also necessary for drawing up cost estimates for purchased materials, so we will dwell on it in more detail. For example, consider an open fireplace of a small group, constructed entirely of brick. Portal width – size A = 63 cm (2.5 bricks), portal height – size B = 49 cm (7 rows of masonry), room height – 2.7 m, second floor height – 2.5 m, attic – 1 m, head (pipe above the roof - 1m).

Fireplace perimeter

: width 4.5 bricks (2.5 + 2) – 115 cm, depth – 3 bricks – 75 cm, body height – 18 rows – 126 cm (7 x 18 = 126).

- Two sides – 3 bricks x 2 x 18 = 108 pcs.

- Front side including the portal – 4.5 bricks x 18 – (2.5k x 7) = 63.5 pcs.

- Back side – 4.5 bricks x 18 = 81 pcs.

- Three rows of base (excluding perimeter) – 2 bricks x 3.5 x 3 = 21 pcs.

- Three rows of top filling (excluding the hole in the pipe) – 21 bricks – 1 = 20 pcs.

- Refractory bricks (from experience) – 120 pcs.

- Total – 350 pieces

Fireplace chimney (No. 1) of 5 bricks/row; pipe height 2.7 + 2.5 + 1 + 1 = 7.2 m, with 14 rows/meter of pipe 5 X 14 x 7.2 = 504 bricks.

Total 350 + 504 = 854 bricks.

The calculation does not take into account the consumption of bricks for fluff, “otter” and fireplace cornice, approximately 46 pcs. There are approximately 900 bricks in total

.

On larger fireplaces, for example, a medium group fireplace, with K = 77 cm with pipe No. 2 (6 bricks/row), the consumption of bricks increases to 1200 pieces

. The weight of the brick including the mortar is 4 kg.

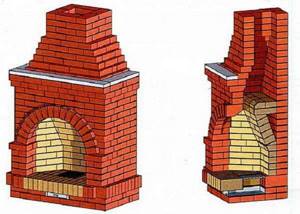

Corner brick fireplaces are especially in demand in small houses, since they do not take up much space and at the same time serve as the main sources of heating for living spaces. A corner fireplace made of brick has another advantage - it can be installed without remodeling or affecting existing structures in any way, which is impossible when choosing a built-in fireplace model. Let's take a closer look at the construction of a corner brick fireplace.

Basic requirements for fireplaces

The main requirements for fireplaces are safety, sufficient heating of the air in the room and aesthetics. Modern fireplaces fulfill all these requirements, and provide enormous opportunities in terms of aesthetic design. Corner fireplaces have a special advantage in this regard: they do not come first in the interior design, but serve as the center and basis for the rest of the decoration and decor.

Briefly about the main thing

In order for a home hearth to effectively heat the room and not smoke, its dimensions must correspond to the area of the room, and the design must not disturb the main load-bearing elements of the house.

Before building a fireplace, a separate foundation is poured for it, which should be slightly larger in area than the area of the hearth itself.

It is recommended to build yourself according to ready-made order schemes, which take into account all the nuances of masonry.

The fireplace is built from ceramic bricks with clay mortar.

Ratings 0

Stages of building a corner brick fireplace with your own hands

The first stage of fireplace construction is a project with dimensions and calculation of the need for materials. The project is linked to specific conditions - the dimensions of the heated room, taking into account the design and material features of the house, as well as its foundation. Fire safety requirements should be the main ones in the creation of the project.

Brick corner fireplace elements

Design elements of a corner fireplace and requirements for them:

- The foundation should not depend on the main foundation of the house and should bear the load completely independently. The foundation is calculated to bear the load from the weight of the fireplace, which depends on the model and dimensions, and can be significant, on the order of a ton or more. Lay the foundation for the fireplace to a depth of 300 - 450 mm.

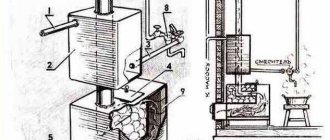

- Furnace department. The optimal volume of the firebox, where wood or other fuel is burned, can be calculated as 1/50 of the volume of the room that the fireplace will heat. The height and width of the firebox section is taken from a ratio of two to three, the depth size is set as 1/3-1/5 of the firebox height, but the specified volume must be maintained. A reflector made of sheet metal can be installed on the back wall of the combustion chamber to ensure that as much thermal energy as possible enters the room. The angle of inclination of the reflector will also change the angle of direction of the heat flow in the desired direction. The material for the reflector is stainless steel. The firebox must be limited by a threshold to prevent burning fuel, ash or coals from falling. Such thresholds are used as additional spectacular decorative elements.

- Chimney pipe. The draft in the fireplace must be strong, for this it is necessary to fulfill several conditions: design the total height of the chimney pipe at least five meters, limit the number of turns of the pipe - a maximum of three turns, the round hole for the exit of flue gases must have a smaller diameter compared to the base of the combustion chamber - 10-15 times less. The pipe material is brick, selected for strength, thermal and chemical resistance. Lining the pipe creates conditions for safe operation of the fireplace and long service life. Combined versions of the chimney also serve a practical purpose: the external brickwork is done in a decorative manner, and the chimney is carried out through a steel pipe inserted inside.

Varieties

After solving all the technical nuances, we will move on to the most enjoyable part of construction - the choice of decorative design. There are few things that can create an atmosphere of comfort and warmth in a home as effectively as wood-burning fireplaces, the dimensions of which we have learned to calculate. There are many alternative offers on the modern market, which have their pros and cons. We will try to introduce you to all the most popular types.

Decorative

If it is important to add zest to the interior without extra costs, a false fireplace will be the best solution.

Built-in

This variety has been especially popular lately. Among the advantages, it is worth noting the saving of usable space, relative lightness and aesthetic appearance. However, when installing in a house with a finished renovation, difficulties may arise with the installation of the chimney.

Electric fireplace

A chic option for an apartment where a classic system with a conventional firebox is not suitable. Installation of the equipment is very simple, and the technology allows you to almost completely recreate the effect of a real flame.

Classical

This is a standard, time-tested fireplace insert, the dimensions of which we determined above. The real effect of a grandiose and status atmosphere will be created only with such a performance. We have considered all the difficulties that may arise at the design stage. Apart from complex and expensive installation, the classic has virtually no drawbacks. Small difficulties are more than compensated by appearance.

Suspension

A real open fire in a modern stylistic solution. Perfect for lovers of exclusivity and non-standard design finds. In addition to the task of decorating the room, this option can also perform the practical function of heating the home. The disadvantages are few, but they are significant:

- High price.

- Difficult to install.

Big

Classic design for large houses under construction. Installation in confined spaces is not recommended.

Average

3*5 bricks at the base - the optimal ratio of size and functionality.

Small

Does not require a foundation, and weighs only up to 100 kg. Installation is possible on the second floor, and in conditions of lack of space.

Bilateral

For effective heating, unusual products with a firebox on two sides can be installed. When located between two rooms, you can easily heat several rooms at once. In the center of a large area, this design will become a real decoration.

Rumfoord

Count Rumfoord created one of the most common and effective models and named the invention in his honor. Strict adherence to regulations and standards allows us to achieve a very high level of efficiency.

Three-tier

A functional and powerful device that can retain heat for many hours after the flame goes out. Each part has its own purpose, and together they create a grandiose and impressive composition. The only limitation is the size of the room and ceilings, which require large sizes.

Dimplex

This brand of electric fireplaces has the highest level of open flame imitation. The effect is created by a steam generator, the steam from which is illuminated by halogen lamps. Almost real flame without the risk of fire.

Cassette

The metal structure of the firebox is covered with glass. Ease of operation and fire safety are the main advantages of this type.

B-B-Q

Two in one. This unit is indispensable for receiving guests at the dacha or in a country house. If you want to impress everyone with a delicious meal cooked on an impressive barbecue fireplace, then be prepared to spend a lot of money to build it.

Metal

You can install it in a completed renovation, and its appearance will allow it to become a central object in the interior. Reliable, simple, stylish and more. Powerful versions can effectively heat even large open spaces.

Mortar for corner brick fireplace

The thickness of the masonry joints is only 3 mm, the solution requirement is approximately 9 liters per hundred pieces. bricks

Mortar for laying a fireplace can be prepared from ready-made dry mixtures, which the construction market offers in abundance. Food is not cooked in the fireplace, and the influence of polymer modifier additives possible in the finished mixture is not relevant. It is also possible to prepare a pure, completely ecological clay solution from red clay and sand. Sand is subject to requirements for grain composition - no more than 1.5 mm and for purity. Organic impurities are not allowed. The sand is sifted through a 1-1.5 mm sieve and washed under running water. The firebox, the fireplace arch with the tooth and the lower sections of the chimney are laid out on a mortar using quarry sand. For the body of the fireplace, you can take any sand of suitable particle size - rounded river or dune.

Clay mortars are related to brick, both red ceramic and fireclay, and provide strength and stability in masonry. The thermal expansion coefficients of clay and brick are almost equal; when heating and cooling, masonry is not subjected to loads that could cause deformation, since the mode of expansion and contraction of brick and mortar is the same.

The fat content of clay is very important for the quality of the solution. Medium clays are preferred; they produce a crack-resistant and durable mortar joint. A small amount of fatty clays is mixed with lean clays, and, on the contrary, more sand is added to fatty clays. There are no exact proportions of the clay solution, since these proportions depend on the fat content of the clay used and are determined empirically. The basic proportion - one part clay to two sand - can be changed to achieve optimal properties of the solution. The base of the fireplace body, bottom, and side surfaces are laid out on a mortar with a small addition of cement - up to 1 kg of cement per 8 liters of mortar.

The process of preparing a clay solution is long; the clay is pre-soaked until completely saturated with water, about 3 days, with periodic stirring. Then the fat content of the clay is determined by visual methods - using a tourniquet or observing how the solution behaves on the mixer blades during kneading. A faster method is to use a ready-made dry mixture for stove and fireplace masonry, which has detailed preparation instructions on the packaging.

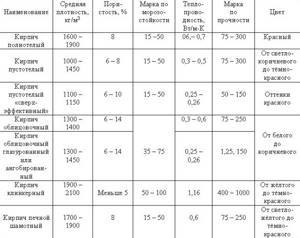

Brick for corner fireplace

The brick for laying the firebox and the lower part of the chimney requires a special one, resistant to the aggression of flue gases, as well as with fire-resistant qualities. External cladding can be made from ordinary clay bricks. Never use silicate, adobe and slip-cast bricks, as well as hollow types of ceramic. Also, you should not use bricks for masonry that show signs of overburning and underburning. The lower supporting rows of bricks, which transfer the load from the fireplace to the foundation, are laid out of brick of a grade strength of at least M100-M150, depending on the weight of the fireplace.

Conditions for normal traction

Everyone has heard of the term cravings. Even without knowing the definition, you can intuitively imagine what it is. There are opinions that this is a pressure difference or temperature difference between the upper and lower points of the chimney.

However, this idea is not entirely correct, because with a small pressure difference, thrust can be increased due to other factors. Therefore, draft should be understood as the speed of movement of air masses through the cross section of the chimney. It may be increased, decreased or normal. The average speed should be 0.25 m/s.

It is impossible to measure the speed of movement of combustion products at home. Before lighting the fireplace, it is recommended to make sure that there is draft. To do this, you should observe the behavior of the flame of a burning piece of paper, and the magnitude of this draft can already be assessed by the behavior of the fireplace itself after kindling.

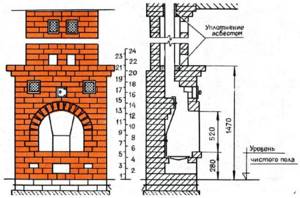

Brick laying scheme

In order not to rely on chance, all factors influencing the amount of thrust are carefully studied. Among them are dynamic (atmospheric pressure, precipitation, wind, damage to the chimney) and statistical, depending on what dimensions of the fireplace were chosen during construction, what its width and height are.

Good to know: Heat-resistant and heat-resistant sealant for fireplaces and stoves

The main stages and features of laying a corner fireplace

Base. The floors in the area for the future fireplace are being dismantled. The foundation is made of monolithic reinforced concrete in formwork. Under the foundation you need a cushion of coarse sand and crushed stone, made with compaction. The design of the foundation is decided individually, since it depends on the soil conditions and groundwater level at the base of the house, and therefore on the existing foundation. If the house is built on a floating slab, then the foundation of the fireplace will rest on the slab, and a strength test will be required, depending on the weight of the fireplace, which can be more than a ton. If there is a strip foundation under the house and there is a basement, place the formwork on a drainage pad of crushed stone, then install a reinforced frame into the formwork and pour concrete to a level below the floor - 100 mm. Concrete care is standard - do not allow stress during the maturation period, as well as avoid drying out the surface. The formwork is removed no earlier than after seven days. The first supporting rows of bricks, which will serve as the base of the fireplace masonry, must be isolated from the leakage of capillary moisture from the concrete foundation. Horizontal waterproofing is made from roll materials on bitumen or bitumen-polymer mastic.

Pouring the foundation

The first thing you need to do is prepare a pit that is (in plan) ten to fifteen centimeters larger than the size of the foundation for the fireplace. The depth of the foundation pit should be about sixty centimeters. The foundation can be either brick or concrete.

In order to decide, you can proceed from the availability of material and prices for it. We fill the bottom of the pit with a layer of crushed stone of ten to fifteen centimeters, which we then compact. We check the horizontalness of the base. Let's proceed to the foundation. For example, we take a concrete foundation, since it is more complex.

We knock down the formwork of the required height from wooden boards (a wooden box without a bottom). The inside walls of the box need to be treated with resin or covered with roofing felt for the purpose of waterproofing. We install the formwork (box) on the base and fill the pre-laid stones with mortar. Composition of the solution: cement - 1 part; sand - 3 parts. Mix sand and cement well in a dry form, then add water and stir until the mixture becomes homogeneous, similar in consistency to thick sour cream. Then we fill it and wait for it to be ready. We level the top of the foundation, carefully smoothing out any unevenness and checking it with a level.

We cover the foundation with polyethylene and wait seven days. Only then can laying begin. It must be borne in mind that the foundation should be six to seven centimeters below the level where the finished floor is located.

Types of loads on various sections of the furnace

To understand which brick can and should be used, you should understand that any fireplace consists of separate modules. Each such module is affected by external factors of a different nature. Therefore, the material needed in each specific case is different. The furnace in its different parts can be influenced by temperatures, mechanical pressure, aggressive environments, and in the upper parts the effect of erosion is inevitable.

The weight of a stove or fireplace made of brick can reach several tons. This design requires a reliable foundation. The foundation is poured with cement mortar, and underneath there are concrete blocks. But the upper layers of the base are lined with brick, so the properties of the brick at the base of the fireplace are subject to certain requirements related to its resistance to mechanical stress.

- The foundation is built under the floor, at a depth of about 60 cm. In this zone, in some houses the temperature in winter reaches negative values. Therefore, the construction of foundations for stoves and fireplaces is made using a durable and frost-resistant type of brick.

- The firebox of modern fireplaces is represented by a metal cassette, which is inserted into the frame. But there are options in which the entire chamber is lined with brick. The temperature inside the combustion chamber reaches several hundred degrees. This is a critical value for most building materials, but not for the special fireclay type, which has increased heat-resistant qualities.

- The area in close proximity to the firebox, where heat is transferred from warm air to the body, is also under the influence of elevated temperature. However, its performance is not so high, but attention is focused on the heat capacity of the material. Heat-resistant ceramic bricks perform the best transfer and accumulation of heat.

- The appearance of the fireplace requires special attention. The portal can be decorated with decorative material, which is presented in a wide variety, but the classic option remains the texture of the brick itself with embroidered seams. In order to leave an aesthetic picture, skill alone is not enough. It is also necessary that the brick be a special facing one, and for decorative finishing it is advisable to choose options with many irregularities for enhanced bonding of the plaster or glue solution.

- What is surprising is that the requirements for the chimney and chimney are not becoming any softer. It would seem that the temperature of the combustion products is no longer the same as in the firebox, the gas has given up a significant part of its energy, and the chimney can be lined with any brick. But it is necessary to take into account the difference in ambient temperature inside the pipe and outside, the constant action of wind and precipitation, and chemical aggression from combustion products. An option to solve this issue is a two-layer masonry made of bricks with different characteristics. Heat-resistant material is used inside, for stoves and fireplaces outside - with low thermal conductivity. This combination will compensate for the destructive effect of temperature differences.

Labeling parameters

In order to select the necessary parameters from numerous options, you need to learn to read them by the brick markings. If the factory does not press the brand onto the surface of the brick, you can find it out in the passport documentation.

- Dimensions. Until recently, everyone believed that each brick had standard dimensions. In most cases, this is a fact, but the number of exceptions is so great that today one cannot neglect such a parameter as dimensions. The same standard brick has a length of 25 cm, a width of 12 cm and a height of 6.5 cm. But there are models with a length of 288 mm, the width can be reduced to 85 mm or increased to 138 mm, and the height comes in two types: 6.5 cm and 8.8 cm.

- Strength indicator. It is more convenient to express strength in the form of pressure that a brick can withstand without damaging its properties. But using the usual system of units is not very convenient. Therefore, the unit of measurement used is kgf/cm2 (kilogram-force per square centimeter). Kilogram-force is the weight of a body weighing 1 kg. This parameter is marked with the letter “M”. It varies from a value of 25 to 500. Typically, bricks for laying stoves and fireplaces are graded M-150 or M-200. Excessively high values of this indicator are unacceptable, since impurities already appear in their composition, which lead to destruction at elevated temperatures.

- Frost resistance indicator. This parameter, which is marked with the letter “F”, determines the maximum number of cycles containing deep freezing and defrosting processes. It cannot be compared with the number of winters, since during one season the temperature can drop to high values several times and overcome the zero threshold. You should look at the frost resistance parameter when constructing a foundation or chimney, since these are the areas that are at risk from low temperatures.

- The degree of thermal conductivity. The thermal conductivity of the material from which the fireplace is made plays a vital role in the function of heating the room. The task of a fireplace or stove is to take away the heat that has been released and transfer it to the air in the room so that it does not have time to escape along with the gases into the chimney. A material with high thermal conductivity can perform this task better. It will absorb a lot of energy in a minimum time and then release all this energy. A high thermal conductivity value indicates that the furnace will have increased efficiency. Unfortunately, we cannot estimate some quantities. These include thermal conductivity. You only need to rely on the comparison procedure. The brand with a relatively large indicator has priority.

- Hygroscopicity. A few words must be said about hygroscopicity. This is the ability of a material to absorb moisture due to its pores. An abundance of moisture is found under the floor in the foundation area and in the chimney, since water is one of the oxidation products. It is in these places that it is necessary to use brick that repels moisture rather than absorbing it. If the material absorbs liquid, this will lead to its destructuring.

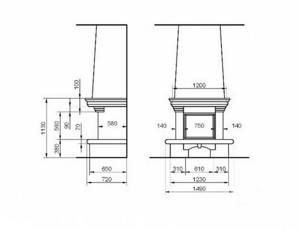

We carry out calculations

The main thing is to make a detailed drawing before starting work. The choice of product scale will depend on the area of the room. It is necessary to strictly adhere to the recommended standards when drawing up a project in order to obtain a high-quality result.

Fire hole

The first step is to determine the dimensions of the firebox. To accurately calculate them, you should measure the area of the room. The proportion of the hole in relation to the room is recommended 1 to 50. Consider a specific example:

- The area of housing where the fireplace will be installed is 40 sq.m.

- We divide this parameter by 50 (40/50 = 0.8 sq.m.).

- The result obtained is 0.8 sq.m or 8000 sq.cm - the required hole area.

This needs to be recorded in the drawing. We will tell you how to determine the aspect ratio below.

Firebox width and height

The proportion by which experts determine the length of the sides is 2 to 3. In our case, it turns out 73 * 109.5 cm. If you want to check the correctness of the calculations, simply multiply 73 and 109.5, the result will be 7993.5 (almost 8000 sq. cm ). This indicator practically coincides with the requirements.

Depth

Correctly chosen, it significantly affects traction, so you cannot make a mistake with this parameter. Inaccuracy may result in smoke and poor heating. Calculating the required value is very simple - it is in proportion to ⅔ to the height. This means: (73/3)*2 = slightly less than 49 cm. If this parameter is exceeded in the finished product, then the heat will simply go into the chimney pipe. If, on the contrary, then smoke will inevitably appear in the room.

Fireplaces: height, width, depth (table to simplify the procedure):

| Room (sq.m) | Portal (mm) | Firebox (mm) | Chimney cross-section (mm*mm) | ||||

| Square | cubic capacity | Width | Height | Depth | Neck | Rear width | |

| 12 | 42 | 500 | 450 | 300 | 120 | 300 | 140*140 |

| 16 | 50 | 600 | 500-520 | 320 | 120 | 400 | 140*270 |

| 22 | 60 | 700 | 560-580 | 350 | 120 | 450 | 140*270 |

| 30 | 80 | 800 | 600-650 | 370-380 | 130 | 500 | 270*270 |

| 35 | 100 | 900 | 700 | 400-420 | 130 | 600 | 270*270 |

| 40 | 120 | 1000 | 750 | 450 | 140 | 700 | 270*270 |

Classification by manufacturing method

The classification of bricks is related to their number. They are all made differently. Some options will initially not be able to perform certain functions. You need to know all this so as not to do unnecessary work when selecting material.

- Sand-lime brick. It is not difficult to distinguish such a brick by appearance. He attracts the eye with his smooth features. The reason for this is that the brick is made from fine sand and lime. Under high pressure, the mass is pressed into a special shape. The resulting building material absorbs moisture and has a low degree of strength and thermal conductivity. It immediately becomes clear that such a brick will not find its use at any stage of fireplace construction.

- Hyperpressed brick. To prepare such bricks, screenings of limestone with the addition of cement are used. Using a certain technology, pressing occurs, as a result of which the strength of the material reaches high levels. But even under this condition, such a brick did not deserve the trust of craftsmen to be used for stove construction. The fact is that it cannot withstand the slightest deformation. If the fireplace begins to settle, the material will immediately collapse. The high density of hyper-pressed brick will lead to the fact that the mass of the fireplace will also become prohibitively large.

- Ceramic brick. Ceramic brick is already close in its performance to the material for fireplaces. It is based on clay, and all its characteristics depend on its breed and on the method of making bricks. In this matter, craftsmen have studied the properties of products from some manufacturers and know which brick to choose. However, they refrain from using this material to cover the hearth core.

- Fireclay brick. The need to use refractory bricks is dictated by high temperatures. The temperature inside the firebox exceeds 1000°C degrees. To finish the firebox, a special fireclay brick is used, which is made from clay with fire-resistant properties. To improve its characteristics, various impurities are added to the composition. As a result, the brick does not crumble even under mechanical stress. A distinctive feature is its flesh color. But it is not used for laying the entire furnace, since it is too expensive in terms of cost. They only finish the inside of the firebox and the beginning of the chimney.

Detailed instructions and order

It is easier to build a fireplace with your own hands if you have a detailed description and photo of each installation stage. There are several stages that are followed during construction. Carrying out the work step by step, you can build a country stove-fireplace with your own hands.

Create a drawing

Regardless of the shape and configuration of the structure, the first thing they do is create a sketch and drawing of the future fireplace. Adhering to the scale on a piece of paper, draw the design, indicating all the elements of the device

It is important at this stage to choose the cladding. For example, if you plan to embroider the outer part, you will need red ceramic brick

And if the cladding will be done with tiles, then choose a more economical option.

What are frame houses and what are they made of?

Preparatory work

When installing a fireplace in a living room, cover all furniture and the floor with plastic wrap in advance. If the premises are not residential, then this is not done, but after construction work, they simply wash and clean everything thoroughly.

The next step is the construction of a foundation, on which the reliability of the structure depends. The foundation is made separate for the fireplace, rather than shared with the house. If the construction is being done in a residential building, then carefully remove the floor in the place where they plan to build a fireplace. It is made 6 cm larger than the structure itself.

They dig a hole 60 cm deep, fill it with 15 cm of crushed stone, fill it and form a base. The foundation is given 7 days to dry. Before building a fireplace, the bricks are first laid out dry without using mortar.

Note! During the process of laying bricks “dry”, each stone is numbered. This will allow you to build the fireplace faster.

Laying out the fireplace

As soon as the foundation has dried, lay out roofing material in two layers. For the first row of masonry, cement is added to the mortar in a ratio of 20% of the total volume of the mortar. The first brick row is laid edgewise. The equality of the diagonals is determined using a tape measure.

Continuous rows are built using a trowel. The chimney and firebox are built manually. The solution is applied to the middle of the brick. If there is excess solution, remove it with a damp cloth immediately before it dries.

After the foundation, a firebox is made. A grate is laid on the bottom, then rows of firebox are erected and the door of the fuel chamber is secured. To securely fix it, the door is placed on a metal mustache and laid between the rows. The blower is built on the fifth row.

The next step is the arch. Regardless of the design of the fireplace, steel corners are used when constructing the arch. Bricks are attached to them, and when facing they are hidden. When building an arch, the bricks are placed in a wedge.

Construction of a chimney

Whether smoke enters the room or not depends on a well-built chimney. If the smoke exhaust duct is round, then the draft is better, but if it is square, it is worse. The walls are made smooth so that soot does not form and smoke easily passes through the pipe. The chimney itself is made vertical, less often at an angle. In this case, the angle of inclination is no more than 30 °C. The size of the pipe depends on the size of the structure and the outlet channel. The minimum cross-section is 14x27 cm. A cap is installed at the top of the chimney, which protects it from precipitation and other parts.

Cladding works

If you build a regular or mini-fireplace with your own hands, then finish it with cladding. Decorate the outer part of the structure in several ways:

- Plaster. First, tighten the mesh and install U-shaped brackets. Drying oil is applied to protect against corrosion. The first layer of 5 mm plaster is applied to the warm wall. The second layer is applied after the first has dried. The thickness of the layer is made thicker than the previous one. The third layer is made with a thickness of up to 15 mm.

- Coloring. Use a chalk or glue solution.

- Drywall. It gives the fireplace a rectangular shape. First, a metal frame is made, and drywall is sewn onto it.

- Decoration.

Note! When painting the outer part of the fireplace white, it is recommended to add blue to the paint. Then the paint will be more snow-white.

806d9bee2ae82c964ba00b857b11994f.jpe

With the help of cladding, flaws that arose during the masonry process are hidden. If the work is done well, you don’t have to do any cladding.

Construction work

Since the masonry of the structure is done with wet bricks, it must be dried before lighting the fireplace. They do this for 6-7 days. Open the combustion door and ash chamber. Then the fireplace is lit to dry, but the temperature is not raised to maximum. During the second week, the structure is heated every day, without raising the temperature to the maximum.

How to choose by appearance

Even if you choose the right brand of brick, you cannot be sure of its quality. In production, there are often deviations from technology standards, so each element must be selected based on appearance.

- The brick is smooth, without curved edges, and corresponds to size.

- When tapped with a hammer it should produce a fairly loud sound.

- The chipped area is durable and does not crumble. The mass is homogeneous, without impurities and voids.

It is impossible not to emphasize the fact that many brick factories have earned their respect for the quality of their products, and therefore are well known among experienced craftsmen. You can also rely on this knowledge when choosing material for fireplaces.