In buildings that are not equipped or connected to a central heating system, a gas gun is often used to heat the premises. This mobile and easy-to-use device with a thermostat is able to quickly heat the air in the room and maintain a comfortable microclimate at a given level. Therefore, many owners of country and private houses, as well as industrial premises, prefer gas guns to their diesel counterparts.

Design and operating principle

Heating equipment of this class is used as a permanent or temporary heat source. In essence, a gas gun is a regular fan heater, but powered by gas, which, due to its design features, has a high level of efficiency and expanded functionality. The device releases warm air into the room, which is formed during the combustion of fuel.

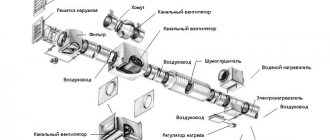

The device is placed in a metal case, which has outlet openings designed to allow hot air to escape. Inside the body the heat gun contains:

- fan;

- burner;

- control device;

- heat exchanger;

- ignition device;

- thermostat.

In addition, additional elements can be placed inside the case, depending on the type of model and design features.

How does a gas gun work:

- A burner is placed in the combustion chamber, where gas is supplied.

- The device that provides ignition ignites the fuel, due to which the heat exchanger heats up.

- The fan draws in cold air and directs it back through the heat exchanger structure.

- Equipment protection from overheating and malfunctions is provided by a thermostat.

- When the air in the room warms up to the set point, the thermostat is activated and the switch breaks the electrical circuit, causing the gun to stop working. When the temperature drops a few degrees, the device turns on again.

This principle of operation of a gas heating device allows you to maintain an optimal microclimate in the room.

Gas-powered heat guns have a number of advantages. Among the most significant advantages are the mobility of the units, simple operation, as well as the affordable cost of units that operate with bottled gas. In addition, this type of heating device has a high efficiency rate with minimal electrical energy consumption.

Basic device and principle of operation

A heat gun is a mobile air heater for premises for various purposes. The unit is primarily used for two purposes. The first task is to organize local heating of exhibition halls, trading floors, warehouses, garages and pavilions.

The second purpose is to quickly dry individual elements during technological operations, for example, fastening French ceilings or performing interior decoration in winter.

The fan heater has a simple device. The main structural parts of the device: a fan, a heating element, a thermostat for off-line operation and a thermostat that prevents the gun from overheating

All components are assembled into a durable metal case, equipped with grilles for cold air intake and hot air exhaust. A heating element, an open spiral or a fuel tank with a heat exchanger is used as a heat-generating unit.

Operating principle of the fan heater:

- The “gun” captures air currents and passes them through the heater.

- Hot masses are pushed out through the nozzle, distributed throughout the room.

The operation of the mechanism is similar to a regular fan. The only difference is the parallel connection of heating elements supplying warm air.

Types of gas heat guns

Gas heating guns come in two types, depending on the fuel consumed. Some operate only on liquefied gas, which is in a cylinder - propane or butane. The second type of device is universal and can operate on any type of gas, because their body contains an element that ensures pressure stabilization. The presence of this component allows you to connect the device directly to the gas main.

Depending on the type of fuel consumed by the device, it may have certain characteristics. The gas pressure in the general network varies between 0.015-0.02 MPa, so the devices are designed for different inlet pressures. But at the output, the reducer installed on the gas cylinder has an indicator of 0.036 MPa.

The differences between these types of units also affect the nozzles, which may have different nozzle diameters, because the calorie content of natural and liquefied gas is significantly different. Bottled gas is three times more calorific than main gas, so if the functions of the gun do not include the use of main fuel, then you should not connect to it a heater designed only for bottled liquefied fuel.

Attention! During the operation of a heat gun, oxygen is necessarily burned out. Therefore, these devices are not recommended for use in rooms without a ventilation system. This is life-threatening!

Based on the type of construction, there are only two types of these devices: gas gun of indirect heating and direct. Let's look at the features of each variety.

Direct heating device

The design of a direct-heating gas gun is not equipped with the function of purifying air flows from burning, so in residential areas they can poison oxygen. This is the only but very significant drawback of these devices, which forces consumers to make a choice that is not in their favor.

At the same time, direct heating units have an efficiency of 100% and during their operation consume a minimum amount of fuel and electricity.

The design of direct heating equipment is quite simple: a fan and a burner are placed inside the housing, heating cold air currents, and the fan blows them into the space, creating a powerful stream of air.

Indirect heating device

A gas heat gun with indirect heating uses a ring-type heat exchanger as a heating element. The working process of these devices differs from direct models in that fuel is first burned inside the housing, and then toxic products that are released as a result of the combustion process. Therefore, this type of guns is considered environmentally friendly and absolutely harmless to human health.

For obvious reasons, devices with indirect heating are popular among consumers for heating homes. Installation of such guns is allowed even in rooms with poor ventilation systems.

However, this design also has one, but very significant drawback - the presence of a chimney pipe in the body, which reduces the mobility of the device and creates difficulties in its transportation.

Note! Compact models of guns powered by natural gas are very economical. The unit consumption is only 1 l/h.

Gas cylinder for the dacha: advantages and disadvantages

When a person moves into a private house that is not connected to a gas pipeline, he is faced with a choice: use an electric stove, or is it possible to connect a gas stove to a cylinder? Both solutions have both advantages and disadvantages. The benefits are as follows:

- A gas burner heats up much faster. Cooking time is shorter, which means more free time.

- The cost of refueling is lower than the price of electricity. The exception is the use of electricity at a reduced rate. For example, for village residents. There is also a discount on utility bills for low-income people.

- In some regions, the rate of electricity consumption per person is limited to 50 kW per month. Once the limit is reached, the price increases significantly.

The disadvantages include:

- Fare. Gas stations are less common than gasoline stations.

- Inability to accurately determine how much fuel was filled into the cylinder.

- Installing a gas stove in a room not equipped with ventilation is prohibited.

Areas of application of gas guns

The popularity of gas heat guns is determined by their safety, practicality and wide range of applications. These devices are used not only for heating living rooms, but also for domestic needs: drying objects with large dimensions, as well as for ventilation of rooms.

Operating a gas gun in a garage will create conditions for normal starting of the car, as well as performing repair work. In addition, the gas gun is in demand not only in domestic conditions, but also in production. This equipment is used for high-quality and economical heating of greenhouses, greenhouses where vegetables, seedlings and flowers are grown.

A gas gun is an autonomous heating device, but it can also become a structural element of an entire installation, which is designed to maintain the necessary microclimate in the room. Structures that run on natural gas can be used to heat automotive, agricultural and specialized equipment.

The capabilities of this device are often used during repairs, when it is necessary to quickly dry walls after puttying. In addition, this type of equipment is used when installing suspended ceilings, since the fan built into the structure speeds up these processes.

In addition, the functionality of a gas heat gun will be useful in large areas, the size of which exceeds 25 m².

Compact guns

The guns of the two models described above are stationary products. In addition to them, compact guns are widely used. They are designed to operate with power from one or through special adapters from several gas cylinders simultaneously. For ease of movement, these models are equipped with handles and wheels. Compact guns are considered high-risk products. The battery life of such devices directly depends on the capacity of the gas cylinders from which they are powered. Gas consumption can be 0.6 – 7.8 kg/hour. The gas cylinder for the heat gun can be refilled at any gas filling station.

The most economical models are considered to be heat guns that have thermostats that allow you to automatically turn off the devices when the air temperature in the heated object reaches the specified parameters. At the same time, heating large rooms using gas guns allows minimizing heating costs.

Permanently installed gas guns, operating from a centralized gas supply system, are often mounted on the ceiling. This minimizes the time it takes to warm up the room, but technically it is a rather complex solution, because These models have high power and have significant dimensions and weight.

How to choose a gas heater?

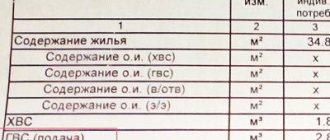

To select a device with suitable parameters, the following characteristics must be taken into account:

- the material from which the building is constructed (brick, stone or metal);

- quality of thermal insulation (types and features of internal and external insulation);

- the absence or presence of electrical wiring in the room (the gun will not be able to work without electricity);

- features of the ventilation system;

- total area of the room;

- operations that take place indoors.

- manufacturer and level of product quality;

- gas gun body shape;

- heating method (direct or indirect);

- unit power level;

- dimensions of the device.

In addition, it would be a good idea to read reviews from other consumers who have already purchased and used the device.

Conclusions and useful video on the topic

Detailed video instructions for choosing a heat generator. Features of the operation of different types of guns, comparison of the main technical parameters:

The primary criterion for choosing a heat gun is the type of energy carrier. The power of the device and the specifics of its application depend on the heating method.

In everyday life it is better to use safe electric models, for production purposes - diesel, gas and multi-fuel units. Water cannons can act as a secondary source of heat.

Share with readers your experience of using heat guns. Tell us what the choice of unit was based on, and whether you are satisfied with the purchase. Please leave comments on the article, ask questions and participate in discussions. The contact form is located below.

Frequent breakdowns and their elimination

Common problems with gas guns and possible causes:

- If the flame goes out when the forced fuel supply button is released, this may indicate a breakdown of the safety sensor.

- There is no ignition when gas is supplied - there may be no spark in the design, so adjustment of the piezoelectric element may be required.

- The fan operates without fuel supply - this sign indicates a malfunction of the solenoid valve.

- It is not possible to adjust the fuel supply while the device is operating - most likely, the gas line is clogged.

- During operation, a strong smell of carbon monoxide appears - the device requires cleaning and adjustment of the gas pipeline on the heat generator. You must immediately turn off the equipment and under no circumstances continue to use it.

Important! It is better not to risk trying to repair the device yourself. All repair work should be performed by a professional.

How to make a gas gun with your own hands?

If your knowledge and experience allow you to make such a complex heating device yourself, then you can make an indirect heating gas gun with your own hands.

To make the device you will need:

- two pipes 1 m long and with a diameter of 18 cm (body) and 8 cm (combustion chamber);

- pipe with a diameter of 8 cm and a length of 30 cm (outlet pipe);

- axial type fan with round flange;

- gas burner equipped with a piezoelectric element.

Before you start creating a device, you should carefully study the diagram, which will become a guide during the work process.

Do-it-yourself gas heat gun manufacturing technology:

- First you need to take a pipe with a large diameter and make a couple of holes. The size of one of them is 8 cm. An outlet pipe for heated air will be attached to this hole. The size of the second is 1 cm. This hole will be used to fix the gas hose. You need to make a combustion chamber from a pipe with a diameter of 8 cm.

- Then you need to assemble the plug. It can be cut from a sheet of metal. This part must cover the gap between the housing part and the combustion chamber. In this case, it is very important not to block access so that it is possible to connect the structure to the chimney.

- After this, all the elements come together. To do this, you will need a welding machine and skills in handling it. The combustion chamber along with stiffeners is welded inside a large pipe. A pipe and a plug are fixed from the outside. Through this element, heated air will enter the room. All that remains is to install the gas burner and fan. All elements must be firmly fixed.

Helpful advice! To keep the combustion chamber firmly in the central part of the housing, it is better to use plates that are welded to the pipe.

The process of assembling a direct fired gun is much simpler. Such a device consists of a pipe, at one end of which a fan and burner are attached. Combustion products and hot air flows will come out from the opposite side.

How to avoid accidents

The use of gas equipment is a hazardous activity. To prevent trouble, you must follow several rules:

- Do not leave the burners on for long periods of time unattended, especially at night.

- Do not place cookware on burners without grates.

- You cannot bring fully filled cylinders from a cold place into a warm room. Expanded gas can rupture the container.

- Do not illuminate the meter with a lit match when checking.

- Do not tie ropes to clothes drying pipes.

- Do not allow young children to turn the stove on and off.

Safety precautions when operating a gas gun

A gas heat gun is very simple to use. If you follow the rules of its operation, the equipment will not pose any danger to human life or health.

Basic safety rules when operating a gas heat gun:

- Do not dry shoes, clothes and other items on the device body, as well as any actions during which the air duct or air collector may be blocked.

- The device housing and fan must be protected from moisture.

- It is imperative to use wiring with a power corresponding to the technical parameters of the device.

- Do not operate the unit in a dirty room with a high concentration of dust.

- In a building where a direct heating gun is used, it is necessary to organize good ventilation.

- Do not place hazardous or flammable substances close to the device.

- The area where the gas hose is attached to the fuel cylinder must be checked for complete leaks. Leaks are not allowed.

- The gas is much heavier than air, so it can accumulate at the bottom of the room, creating an explosive situation. Therefore, it is prohibited to operate gas guns in rooms that are below ground level.

Before turning on the device, you need to read the operating instructions, which describe all the nuances of connecting and using the device.

Thus, a gas gun for heating rooms is an economical, safe and compact device with high efficiency, therefore these devices are considered the best way to heat air in buildings with different areas and large volumes. Such units can become an alternative to the standard heating method.

Review of popular models

Analyzing information on thematic forums, we can identify the following popular gas burners among Russian consumers:

- MASTER BLP 17M . Ideal for heating a garage. Reliable and durable equipment, the reducer is “unpretentious” to the quality of the supplied gas. There is a power regulator from 10 to 16 kW, so it is suitable for garages up to 150 m2. The only negative is manual ignition, although because of this the device almost never breaks down; the manufacturer generally gives a 3-year warranty. The average cost is 9 thousand rubles.

- SPECIAL IGE-15 . Russian-made gun. It is small in size and suitable for use when installing suspended ceilings or for drying walls after painting. Power is 15 kW, but the flow is narrowly targeted. It has 2 heating stages, the kit includes a hose for connecting to the cylinder (with adapters). The average price is 5.2 thousand rubles.

- Caliber TPG-10 . Also made in Russia, power up to 10 kW, suitable for small spaces. The gearbox is collapsible, the manufacturer has provided for its complete replacement with an analogue one. The fan is also serviceable and not pressed into a bearing. But the functionality is minimal. But the cost is only 4 thousand rubles.

- Kroll P 10 . Popular model of foreign production. It works when connected to cylinders, there is a piezo ignition, a safety thermostat and a pressure sensor. The productivity is small - up to 300 m3 per hour, but the flow of heated air is not narrowly targeted, as in other models. The average price is 9.5 thousand rubles.

- Profteplo KG-57 . Industrial type heat gun with a capacity of up to 1400 m3 per hour. Available in two versions - with connection to 220V and 380V. The latter is noisy in operation, but it is not suitable for small spaces. There is flame control, as well as a sensor that turns off the gun when it detects movement in front of it (it can be forcibly turned off). The average price is 11 thousand rubles.

MASTER BLP 17M, one of the best selling models

We recommend our article on the topic - Heating boilers for a private home, where we examined the principle of their operation and how to start the heating system step by step.

In summary, a gas gun is an excellent option for quickly warming up non-residential premises. For residential use this is not the best option, as it requires connection to a chimney. But you can make a cannon yourself; all this will require only 2–3 thousand rubles (for all materials).