Vadim

5490 0 0

Vadim August 27, 2016

I have heard more than once from friends that ecowool insulation is a relatively inexpensive, fast and very reliable method. As you know, our people won’t pay attention until they come across it, so for me, until my neighbors did such insulation, I wasn’t interested in it. To be honest, I liked the insulation, but as a person who is not inclined to believe intrusive advertising, I found out everything in detail. In this article I will tell you in what cases this material is suitable, how to use it, and most importantly, what advertisers are not telling.

This is what ecowool looks like.

How to insulate an attic?

Experts advise using mineral wool based on basalt, glass particles or slag. What are their differences? Basalt wool is obtained by melting a certain rock, which is then mixed with clay, limestone compounds, and dolomites. The adhesive substance is usually replaced by formaldehyde. The resinous structure of the chemically active substance binds the ingredients, resulting in a finished product.

Slag analogues are obtained in the same way. Industrial waste from the production of cast iron, zinc, and copper alloys is placed in the melting tank. The high degree of toxicity does not allow the use of slag wool in the treatment of buildings for residential use. Glass wool is a product of processing limestone, sand, borax, and soda. Mineral wool is a natural insulation material with a fibrous structure.

Advantages and disadvantages of attic insulation with ecowool

Experienced craftsmen are well aware of the advantages of bulk mass. Users appreciate it for the following advantages:

- Ecowool has excellent soundproofing properties. After insulating the floors, the house will become quieter.

- The elastic and resilient material does not shrink in a vertical position, which is important if you have a sloping roof.

- Does not react with metal roof coverings.

- The heat insulator retains its qualities for a long time thanks to wood fibers having a capillary structure.

- After application, a monolithic layer without voids is formed, filling the surface of any shape. The trimmings can be reused - ecowool production is waste-free.

- The raw materials contain antiseptics that prevent mold and mildew from growing. Mice do not live in its thickness.

- The coating performs its main functions at a humidity of 20%, which is ideal for use in cold attics. A vapor barrier membrane is not necessary to form an insulating layer.

- Ecowool reliably fills hard-to-reach spaces between beams, sheathing and complex floor surfaces. If the technological process is followed, the substance forms a monolithic coating without cold bridges.

- The process of creating an insulating layer can be mechanized. Special devices allow you to process large areas in the shortest possible time.

When insulating an attic, disadvantages of ecowool appear, which the user should be aware of:

- To thermally insulate inclined surfaces (roofs, slopes), it is necessary to create closed cavities into which the mass is blown. They take a lot of time to make.

- Raw materials for the production of insulation are cheap, but the processing technology requires special devices, so the finished product is quite expensive.

- The material smolders under the influence of high temperature, although there is no open fire. It should not be laid near chimneys.

- During dry application a lot of dust is generated.

Methods for laying ecowool

There are two ways to insulate an attic with your own hands:

- dry;

- wet (using glue).

Dry styling

The work must be carried out following simple instructions.

- The material is unpacked at the work site. Therefore, bags with insulation are carried into the attic and opened there.

- Ecowool is fluffed using a mixing attachment on a drill or a construction mixer. It is better to carry out this work in a barrel or box, initially filling their volume by 1/3; the volume of insulation should increase approximately 2.5-3 times.

Floor insulation is carried out in the following order:

- Waterproofing is laid on the floor between the joists. There must be a dry and hard surface underneath. Without the use of waterproofing, the insulation will get wet and quickly lose its properties.

- Ecowool is placed in the space between the joists and lightly compacted. The density of the material in the floor covering should be 35 kg/cub.m. The layer thickness should be 100-150 mm. Visually, the density of the finished insulation should be approximately half the density of the factory packaging.

- The finished layer must be lightly sprayed with water from a spray bottle. A thin crust forms on the surface of the insulation, preventing its possible movement.

- The resulting insulation is covered with a vapor barrier film with an overlap between the sheets and on the walls.

- Next, the resulting structure can be covered with floors.

The insulation is laid on a layer of waterproofing

Attention! Work with insulation must be carried out while providing eye and lung protection - wearing construction glasses and a respirator. Clothing should prevent contact of ecowool with exposed skin. Cotton wool is not poisonous, but the borax it contains can cause redness and itching.

Next, you can start insulating the walls:

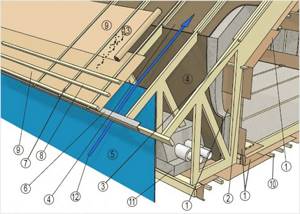

- A gap of 3-5 cm must be left between the roof covering and the insulation to ensure ventilation and prevent condensation.

- A layer of waterproofing is fixed to the rafters, which will prevent the ecowool from getting wet on top. In order for the insulation to remain on the inclined surface, it must be poured into boxes that are mounted on the rafters.

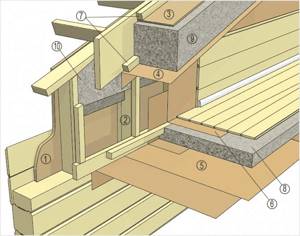

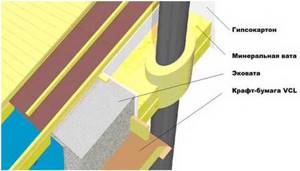

- To create boxes, GVL or OSB boards are gradually hemmed to the rafters, starting from the floor. In one step, a slab of such a height is attached that it is convenient to fill the resulting pocket with ecowool. A vapor barrier film is attached between the slab and the space for insulation. The result should be the following “pie”: waterproofing-ecowool-vapor barrier-slab.

- As the pockets are filled, they are gradually hemmed up to the roof ridge.

Let's talk about competitors or what advertising doesn't say

My story would not be complete without a little critical analysis of the material. I visited several major forums dedicated to this topic and found out that people are most interested in the question of what is better ecowool or basalt insulation.

Technological window in vapor barrier.

- Let's start with its direct purpose, that is, the ability to insulate. In particular, it is stated that ecowool has almost the lowest thermal conductivity. Although upon closer examination it turns out that mineral insulation and the same polystyrene foam are practically not inferior to it. A difference of a few hundredths is important for laboratory studies, but in practice it does not matter;

This is how the dried insulation is trimmed.

- Now let’s move on to the “sore” point of all cotton insulation – moisture absorption. Here our material is seriously ahead of the competition. When the humidity of a basalt mat increases by 1%, its thermal insulation properties drop by approximately 8–9%. While cellulose, even when wet at 25%, loses no more than 5% of its characteristics. Plus, as I already said, cellulose insulation can both gain and release moisture without loss of properties, of course, within reason. Basalt wool simply gets wet, and it takes several times longer to dry than ecowool;

- The fact that cellulose insulation is installed without seams, of course, does it credit. On my own behalf, I can add that with proper installation, it will not be difficult to tightly cover the surface with basalt mats. So here they are equal;

- We often hear about the high soundproofing properties of cellulose. But this is only true when the material density is high. Only wet ecowool with adhesive application can “beat” basalt mats in this field. Other arrangement methods have the same or even lower noise insulation characteristics;

Installation methods

You can insulate a house with ecowool using several methods. It is quite possible to carry out this procedure at home with your own hands, but the end result will be significantly inferior in quality to the option using special equipment, regardless of personal skills in carrying out such work.

Subtleties of hand-made insulation and its features

The procedure for insulating an attic with ecowool with your own hands is not difficult, so there is no need to describe it in detail.

Having opened the bag with insulation, you need to pour the required amount of material into a separate container or directly onto the installation site, fluffing the wool using a construction mixer or drill using the appropriate attachment. This completes the insulation process, but it is equally important to decide in which cases this work should be performed.

Often, ecowool is used to fill the floor and roof attic of a house, but there are some nuances that must be observed. In each case, the insulation is poured, fluffed up and slightly compacted between the lags, so there must be a dry and strong base below.

The attic is ideal for this material, since moisture is unlikely to be present on the surface of its ceiling, and atmospheric humidity is practically incapable of harming the cellulose. Because of this feature, the need for vapor barrier is eliminated.

In houses built of wood, the attic and ceilings between floors are covered with paper to prevent cellulose dust from penetrating through the ceiling. If it is completely lined with 2 layers of sheet materials like plywood, then there is no need for additional paper covering.

Important! During operation, ecowool is not capable of harming human health, however, when laying dry material with your own hands, a huge amount of dust arises, from which it is recommended to protect your eyes and respiratory organs by wearing glasses and a respirator.

One of the main advantages of this material is the effect of moisture condensation, which is also inherent in natural wood. Thanks to this, when excessive moisture occurs, ecowool can absorb it. In the same way, when the moisture level decreases to a minimum, the material is able to release the accumulated moisture back.

When insulating the floor on the first floor with your own hands, you should also take into account a number of certain subtleties. For example, on the base of a wooden or frame house, there must be a layer of high-quality waterproofing under ecowool, which will prevent the material from getting wet in the event of flooding. At a minimum, technical polyethylene should be used as a protective material, which is also suitable for laying expanded clay and foam plastic.

Note! When used in a dry attic, between floors and partitions, ecowool does not actually need a vapor barrier layer, but where there is a constantly high level of humidity, it cannot be avoided, since the insulation will quickly become saturated with liquid and lose its positive properties.

Dry installation method using specialized equipment

Compared to the manual method of insulation, the dry machine method is many times more effective, allowing work to be done more quickly and efficiently. The equipment itself is a unit consisting of a hopper in which fluffing and mixing of the material is carried out, an air compressor of enormous power and a system of hoses supplying ecowool.

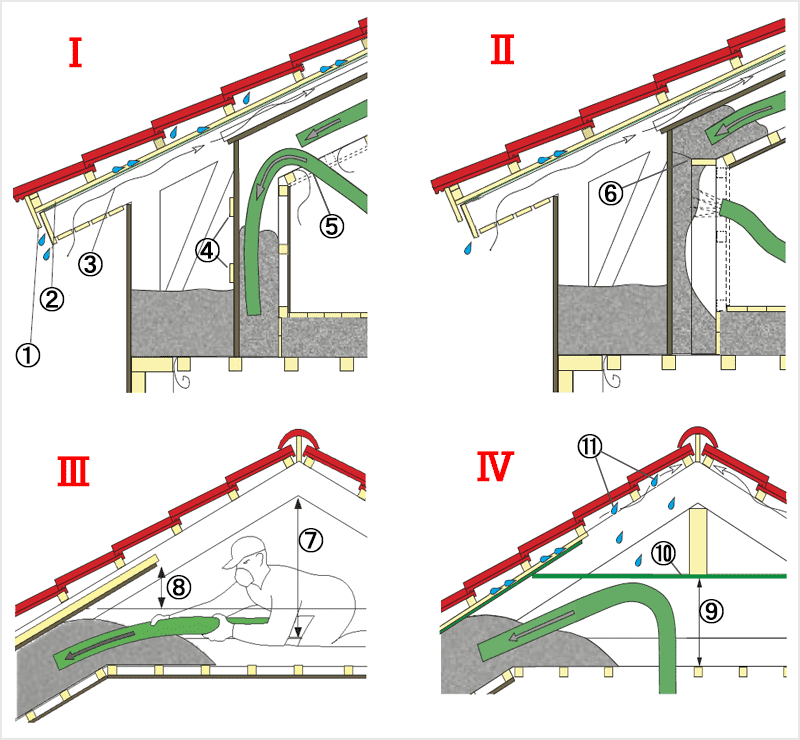

In most cases, insulation of the attic with ecowool is carried out precisely using such special equipment, which makes it possible to easily fill a broken roof with a fairly significant angle of inclination with a cellulose-based mixture. During the work, it fills the free space between the sheathing packed horizontally on the rafters. If the procedure is carried out manually, shrinkage of the ecowool will occur and significant voids will subsequently appear along most of the length of the roof.

Features of the use of other materials

Extruded polystyrene foam is a good, but more expensive replacement for polystyrene foam. It is available in the form of slabs. You can purchase elements with a stepped end, which will provide an exceptionally tight connection.

Extruded polystyrene foam boards are not placed between the rafters, but mounted on top of them. The material is fixed using various adhesives or self-tapping screws with an enlarged telescopic cap.

Simple installation helps reduce the time required to complete the work, but you should remember the flammability of polystyrene foam when installing electrical wiring.

Ecowool is an environmentally friendly heat insulator with decent characteristics. It is made from paper, which brings the quality of this material closer to natural wood.

Glass wool installation technology is similar to mineral wool insulation. But working with such material is more difficult, since you will need protective clothing to protect your skin from the irritating effects of glass fiber. You will also need a protective face mask; contact of glass wool with mucous membranes is undesirable.

Ecowool is an interesting option for insulation. This is a safe and effective material that is applied to the space between the rafters. But the work will be quite expensive.

Polyurethane foam provides exceptional insulation. It is applied in a continuous layer without seams. But it is difficult to carry out such work on your own, since this requires equipment and trained personnel.

Insulation of the attic with ecowool

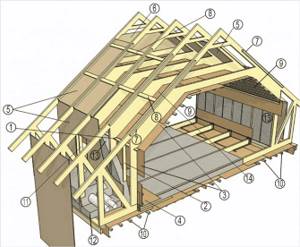

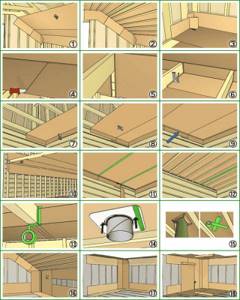

Approximate diagram of the attic floor - optimal solutions when preparing the attic for insulation with ecowool using slab “breathing” windproof materials:

Approximate diagram of the overhang element of a pitched roof of an attic - optimal solutions when preparing an attic for insulation with ecowool using slab “breathing” windproof materials and a diffusion under-roof membrane (protection from under-roof condensation of the attic’s heat-insulating contour):

An approximate diagram of the element of the connection zone of an insulated pitched roof, an insulated pediment and an insulated interfloor ceiling - using a windproof slab and internal vapor barrier material:

Options for carrying out installation work and options for manipulating the installation hose from blowing equipment during mechanical insulation of an eco-wool pitched attic roof:

Approximate illustration of preparation for insulation of ecowool country house - Description of work on INTERNAL filing with rolled vapor barrier materials:

Options for insulating wooden ceilings with ecowool

The owner can choose the option of laying insulation inside and outside the room. Most often, the substance is scattered over the surface of the attic floor, insulating the floors. From the inside, materials are laid out only through technological holes in a continuous filing.

Display methods:

- Wet. Option using water or glue. The wet substance clogs all cracks and holes and is evenly distributed over the surface.

- Dry. A simple and quick option for insulating ceilings. Spraying is done with a nozzle - this makes it more convenient to cover the surface and fill voids. After application, the material is covered with a film or compacted.

- The mechanical option involves the use of a compressor. Supply of porous structure to 150 m length and 30 m height, compressor power up to 6 kW. A strong film is first stretched over the base, then a hose is inserted into the hole and the covering is filled.

Before choosing a technology, you need to evaluate the size of the room and the skills of the master. Mechanical laying is used to insulate large areas. In everyday life, the manual method with compaction or the use of a water-adhesive mixture is sufficient.

Scheme of arrangement of ceilings with ecowool insulation

If we consider an insulated ceiling in cross-section, it looks like a multi-layer structure with layers of steam and waterproofing material and insulation. After finishing, the surface is hemmed with the selected finish.

Important! After laying out in the attic, ecowool does not need to be protected from steam, but only from excess moisture. Any roll or membrane waterproofing insulators will do.

Selecting layer thickness

When calculating what layer of mineral wool is needed to insulate ceilings, one must rely on average indicators:

- Dry option. The layer on the attic side is 300–400 mm. From inside the room from 150–200 mm.

- Wet method. In low-rise buildings the layer is up to 100 mm, in multi-storey buildings up to 150 mm.

Material consumption is determined as follows: the volume of the cavity is multiplied by the density of ecowool. Density for manual laying is 30–35 kg/m3, mechanical 40–45 kg/m3.

Comparative table of two insulation materials

In order to make a choice, it is recommended to familiarize yourself with the technical characteristics of the materials. This will help you decide which is more profitable: mineral wool or ecowool.

| Characteristics | Mineral wool "TeploKnauf" (loose) | Ecowool |

| Thermal conductivity (W/m*K) | 0.038 | 0,032-0,041 |

| Moisture absorption (%) | 0.5 | According to GOST 17177.5 for 72 hours - 16% (a block with heat-insulating material is placed over a container of water and kept for 3 days, after which it is weighed) |

| Density (kg/m3) | 11 | 30-55 |

| Vapor permeability (mg/(m*h*Pa)) | 0.3 | 0.67 |

| Flammability group | NG (non-flammable) | G2 (moderately flammable) |

| Density of connection to the structure | With voids | Absolute |

| Linear shrinkage | Interslab voids form | Absent |

When the humidity level of ecowool reaches 20%, processes begin to develop in it, leading to the appearance of mold. But at the same time, the material loses its thermal insulation properties by only 2-4%. The situation with mineral wool is sadder. With 1% moisture (by weight), it loses its thermal insulation properties by 8%.

The cost of insulating ceilings with ecowool

If installing insulation on the ceiling on your own is impossible, professionals will come to the rescue. The price of work starts from $25 (1,700 rubles) per 1 m2. If there are additional actions - stretching the fabric and strengthening it, processing the floors, the estimate will increase.

Important! Before insulation, the wooden ceiling must be treated with an antiseptic, fire retardant, and dried. A deep penetration primer provides good protection against bugs.

Interior decoration Density of mineral wool and ceiling insulation technique in a private house Read more

Conclusion

Insulating a house with ecowool is a new thing in our country. At the moment, this convenient material is just making its way.

But judging by the trend, cellulose insulation has serious prospects, you just need to use it correctly. The photos and videos in this article contain material on the topic of cotton wool. If you have any questions or can add anything, welcome to the comments, I’ll be glad to chat.

In many cases of individual house construction, it is possible and advisable to also build an attic. You may need it, for example, for your office, creative workshop, and in the summer your guests can relax in the attic. The cost of construction will not increase much, but the advantages are obvious.

Therefore, let's talk about how to insulate the attic, because this is the coldest part of the house in winter, and the hottest in summer.

The main mistakes made in the process of insulating the attic

The final result of the work, which is done by hand, directly depends on how accurately the technology and all the prescribed rules are followed. It is worth paying particular attention to the procedure for laying the waterproofing layer, since materials that are capable of absorbing moisture subsequently dry out, which often causes cold in the room.

Here are some recommendations from experts that can be used to minimize the negative consequences:

- if the roof slope does not exceed 13°, this will cause precipitation to remain on the surface. The result is rust and leaks. All this can negatively affect the condition of the insulation, so it is important to make sure that the angle of inclination is large enough before starting work;

- installation of thermal insulation material on the walls and roof is not all the necessary work. It is also necessary to take care of insulating windows (using Swedish technology). To do this, it is best to invite specialists to ensure that leaks are avoided. Especially if it is necessary to install windows at an angle;

Installation of thermal insulation material on walls and ceilings can be done independently or with the help of specialists

- in order to provide the thermal insulation material with ventilation and the ability to dry out if it gets wet, it is advisable to leave a gap of approximately 2-3 cm between the material and the roof;

- it is strictly forbidden to skip at least one of the necessary layers of vapor or waterproofing materials;

- If the thermal insulation material is thicker than the rafters, then their height can be increased by filling additional slats yourself.

These simple recommendations can help in the work process, significantly improving the quality of insulation. However, if for any reason there are doubts about the strength and experience, it would be better to invite a specialist. Of course, you will have to pay for this, but in this case you will not have to redo everything twice.

Insulating the attic gable from the inside is far from the most difficult task that a home owner may face. Often, owners want to place a balcony on the top floor, the insulation technology of which also has its own characteristics.

As with walls, a wide variety of materials can be used to insulate the ceiling on a balcony, although it is worth noting that loggia insulation technology is often used here, which has not been mentioned before. The step-by-step instructions “Insulating a balcony from the inside with your own hands” will help you understand in detail the features of this process.

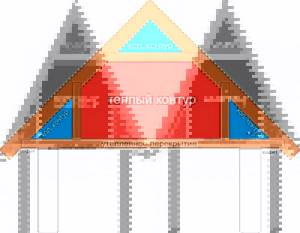

Diagram of attic temperature contours

Recommendations from professionals ↑

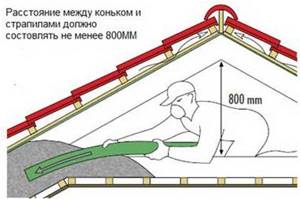

- If the distance between the ridge and the attic ceiling is more than 80 cm, this allows work to be carried out through the attic room.

- Insulation can also be applied from the ceiling side, using technological holes in the inner lining.

- If the distance between the ridge and the attic ceiling is too small to carry out the work, installation is carried out using technological holes in the inner lining, from the ceiling side.

- The chimney exit to the roof is carried out taking into account the fact that ecowool will begin to smolder at high temperatures.

© 2021 stylekrov.ru