Technical features of the device

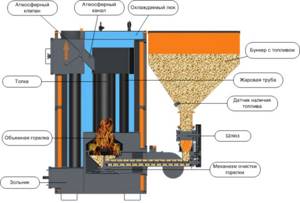

A pellet boiler is a stationary unit, for installation of which a house basement, an extension or a specially equipped room can be used. The power of the unit is selected depending on the installation method of the device, the area of the facility, the level of its thermal insulation, and the number of family members.

For heating in capital buildings, a unit is used that contains in its design:

- - frame

- – burner

- - firebox

- – heat exchanger

- – bunker

- - chimney.

In its standard version, the unit is equipped with a container that can hold fuel for a week. To ignite pellets, the combustion chamber is equipped with an electric heating element, and air is supplied to the combustion chamber by a built-in fan. Heating a house using pellets is not limited to using a strictly defined type of energy resource. The equipment, which has a removable grate and a replaceable burner, can operate on granulated sawdust, firewood, and peat briquettes.

Power and consumption of a pellet boiler

A simple table for calculating the power of heating equipment.

The most decisive factor is the power of the pellet boiler, which is calculated based on the area of the private house. For every 10 sq. m of living space we need 1 kW of thermal energy . If the area of your private house is 100 sq. m, you will need a 10 kW pellet boiler. We add here a margin of 10-20% - we get the equipment power of 11-12 kW.

Next, we calculate the approximate costs of heating a private home. Pellet fuel has good heat release - 1 kg of pellets releases 5 kW of thermal energy. For the above house heated by a 10 kW pellet boiler, the pellet consumption will be 2 kg per hour. Daily consumption will be about 48 kg. In order to reduce fuel costs, it is necessary to purchase it in bulk, in large quantities at once. It is also recommended to deal with heat losses.

To eliminate heat losses, pay attention to the design of windows, the presence of insulation of walls, floors and attic space. It is also recommended to reduce the window area and install normal insulated doors in a private house.

Heating a house 100 m²

Really, honestly, really

| Heating a house 100 m² from | RUR 49,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 10 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 25,000 rub. |

| Radiator pipe routing | 12,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 49,500 |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 100 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 120,000 rubles

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

House heating

Disadvantages of pellet boilers

Speaking about the advantages of this type of solid fuel boilers, it is worth mentioning their disadvantages.

- despite the fact that pellets are made from wood waste, a unit of heat generated will cost more when compared with boiler equipment that runs on wood;

- It is necessary to store pellets in a dry room , since under the influence of humidity they begin to swell and fall apart, causing the augers to become clogged

- to operate autonomously in remote suburban areas, you will need to purchase a generator and additional equipment, which can make purchasing a pellet boiler an expensive pleasure;

- The consumption of granules per month can be about 1 ton . Knowing the price of pellets in your region, it is not difficult to calculate how much it will cost you to heat a country house in the winter. As practice shows, your costs will be comparable to using electric boilers and will exceed costs if you use natural gas as fuel.

Heating a house 150 m² - 52,500 rub.

Really, honestly, really

| Heating of a house 150 m² from | RUB 52,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 10 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 25,000 rub. |

| Radiator pipe routing | 15,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 52,500 |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 150 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 200,000 rubles

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

House heating

Factors influencing choice

When choosing a high-quality, reliable unit, pay attention to the following characteristics:

- For power. Household appliances have relatively low power. To provide heat to a living space, 15 kW is enough. For 10 sq. m. accounts for 1 kW. A boiler with this power can heat a house measuring 150 square meters. m.

- On the efficiency factor. For pellet boilers, efficiency varies from 80 to 95%. The high rate is achieved due to the quality of the granules and the design features of the device.

- By burner type. There are retort and stoker burners. The first ones have smoke directed upwards. They are unpretentious to fuel quality and operate for a long time without cleaning. The efficient operation of the stoker burner is achieved due to the high quality of the loaded granules. The main disadvantage of such a device is that it often gets clogged.

- To the level of process automation. Some pellet boilers can operate without human intervention. Such devices are controlled remotely using a mobile phone. A special program allows you to turn the device on and off and adjust the temperature from a distance. In the event of a malfunction, information about failures is sent instantly to the mobile device.

- On the design of the heat exchanger. They are horizontal and vertical, flat and tubular. Experts recommend choosing vertical heat exchangers with turbulators, which spend most of the energy on heating the coolant and do not allow ash to settle in large quantities.

Heating a house 200 m² - 72,500 rub.

Really, honestly, really

| Heating a house 200 m² from | RUB 72,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 15 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 35,000 rub. |

| Radiator pipe routing | 25,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 72,500. |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 200 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 250,000 rubles

Detailed estimate for installation of heating system

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

What are pellets?

Pellets are waste from the woodworking and agricultural industries compressed into granules. Since the granules are produced without chemical additives, these products are hypoallergenic and environmentally friendly. Pellet heating is a relatively new phenomenon in our country. Due to the fact that prices for diesel fuel and electricity have increased significantly, the population began to look for alternative and economical sources of heating. So, pellets came to us from Europe.

New pellet manufacturers have appeared, they have become more accessible and cheaper. And if initially the pellets were wood or coal, later they began to be made from agricultural waste - husks, straw, corn.

Pellet classification

Due to the increased demand for alternative fuel, more and more new varieties of pellets are appearing. Depending on the raw material, granules are:

- woody;

- peat;

- granules from solid household waste;

- coal

- from husks.

Depending on the degree of purification, granules come in three grades:

- higher (household or white pellets);

- standard (industrial pellets);

- economy (agropellets).

Household pellets

Household pellets are a premium fuel. This is the optimal choice for heating frame houses. Granules are made from sawdust. Soft and hard wood is used as raw material. They have extremely low ash content - less than 0.5%. This means that the boiler needs to be cleaned no more than once a month. Heat transfer is high, 17.2 MJ/kg. Household granules are white. This effect is achieved by debarking the wood, which is carried out before crushing and granulating. And this means higher fuel efficiency. Household pellets are suitable for any type of boiler.

Industrial pellets

Industrial pellets have a slightly lighter color than agropellets. They are made primarily from unbarked wood. The heat transfer of this category is 17.2 MJ/kg, ash content – from 0.7%. The frequency of cleaning the boiler surface when using such granules depends on how high their ash content is.

Agropellets

Agropellets belong to the economical fuel class. This type of fuel is the cheapest. Sunflower seeds and buckwheat hulls are added to the granules. Since these pellets are not debarked, their color is very dark. The ash content is from 3%, and the heat transfer is 15 MJ/kg. Typically used in large industrial boilers. If automatic cleaning is not provided, the inside of the boiler must be cleaned every day.

Pellet burning

Any fuel produces heat when burned. This process occurs gradually and is divided into four stages: evaporation of water, gasification and combustion of pyrolysis gas (the main process) and combustion of charcoal. In order for these processes to take place with the greatest heat transfer, a sufficient volume of oxygen must be provided in the combustion chamber.

How often do you need to add pellets to your boiler or stove? There is no single recommendation for this issue; it all depends on your equipment – its consumption and the volume of pellet bins. There are different types of bunkers: some of them can be filled with fuel several times a year, and some of them once every few days. The amount of fuel consumed also depends on the size of the house.

Pellet combustion process

Pellet consumption

What is the consumption of a pellet boiler or how many pellets are needed for heating? Consumption directly depends on the design of the heating system, as well as on how insulated the room is. For every 100 m2 of living space per year, approximately 2000 m3 of gas or 4.3 tons of pellets are needed.

What power should be set on a pellet boiler? There are two types of power selection: precise and primitive. An accurate assessment will require an audit of the premises.

A primitive calculation should be made based on the fact that for every 10 m2 with a height of up to 3 m, 1 kW of power will be required. Thus, for a frame house with an area of 150 m2, a 15 kW boiler is needed.

One full load of the boiler with pellets can last for 4-5 days!

How to choose quality pellets?

When choosing granules, you should be guided by the following signs:

- Smell. A sign of good quality is the slightly sweet smell of glue. The granules should not smell like spruce.

- Length. Pellet length is limited to 50 mm for suction systems. However, it should not be too short.

- Diameter. Most often, the diameter of the granule is 8 and 6 mm, much less often 10 and 4 mm. The diameter determines how the boiler or furnace operates for efficient heating. If the diameter is larger or smaller, this means that the production of fuel pellets is not the manufacturer’s core business.

- Color. Pellets can be dark or light in color, but not gray. This is a sign that the raw materials have been in a damp place for too long and fungus has appeared.

- Surface. The smoother the surface, the stronger the granule. There should be no swelling or cracks.

- Dust. A large amount of dust is a sign of poor quality and rapid abrasion. This can also lead to raw materials being claimed. If you store the granules in a closed bag, there will be much less dust.

Heating a house 250 m² - 87,500 rub.

Really, honestly, really

| Heating of a house 250 m² from | RUB 87,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 20 pcs)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 45,000 rub. |

| Radiator pipe routing | 30,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | 87,500 rub. |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 250 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 300,000 rubles

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

Heating a house 250 m²

Strapping schemes

The piping scheme depends on the principle of movement of the coolant through the pipes. The systems use natural or forced circulation.

Features of natural circulation

The coolant naturally moves through the pipes. This heating system does not have a pump. Here circulation occurs solely according to the laws of physics: a colder medium squeezes out a hotter and less dense one.

Photo 2. Piping diagram for a pellet boiler with natural circulation. For its proper operation, a certain slope of the system is required.

Advantages of a natural circulation heating

- low cost of the boiler and ease of installation;

- cheap service;

- quick restoration of work in case of breakdown or failure.

Flaws:

- This piping scheme is used only in a single-circuit system.

- The harness is suitable for small rooms.

With forced circulation

A circulation pump in a heating system makes it possible to heat houses and industrial premises of any size . This heating system has its disadvantages:

- Expensive installation.

- Complex scheme. It consists of a large number of elements, so an ignorant person will not be able to understand all the details.

- The elements of the home heating system must be aligned with each other.

- Dependence on the availability of electricity. The circulation pump will only work when current is supplied to it.

The cost of installing heating systems

Heating system installation

| Heating radiator installation | PC | from 2,000 ₽ |

| Installation of a floor-mounted convector | PC | from 4,500 ₽ |

| Installation of a heating radiator ( non-standard size, cast iron, design) | PC | from 4,500 ₽ |

| Installation of distribution heating cabinet | PC | 4 500 ₽ |

| A set of works for installing a heating system for a house up to 100 m² | from | 49 500 |

| A set of works for installing a heating system for a house up to 150 m² | from | 52 500 |

| A set of works for installing a heating system for a house up to 200 m² | from | 72 500 |

| A set of works for installing a heating system for a house up to 250 m² | from | 87 500 |

| Please call for exact cost | 84957446774 |

The cost of installing heating systems . Price adjusted as of May 05, 2021 Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Installation of an underfloor heating system (warm floor)

| Water heated floor | m² | from 500 ₽ |

| Distribution manifold cabinet for underfloor heating (external) | PC | 4 500 ₽ |

| Heated floor temperature control device | PC | from 2 000 ₽ |

| Heated floor temperature control groups (thermostatic valve, thermostat with clamp-on sensor, bypass valve, starter) | PC | 3 750 ₽ |

| Main pipes heating system and pipe insulation (cross-linked polyethylene, metal-plastic) up to 20 mm | m/linear | 100 ₽ |

| Main pipes heating system and insulation with pipe insulation (cross-linked polyethylene, metal-plastic) up to 32 mm | m/linear | 230 ₽ |

| The exact cost is calculated after check-out | engineer |

The cost of installing heating systems . Price adjusted as of May 05, 2021 Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Installation of heating systems for warehouses, hangars, workshops, car service centers

| Installation of a fan heater , with pipes, fastening to a concrete wall | PC | from 15 000 ₽ |

| Installation of automatic fan heater control | PC | from 4 500 ₽ |

| Pressure testing, commissioning, filling with coolant | m2 | from 100 ₽ |

| Register mounting, thread | PC | from 6 750 ₽ |

| Register installation, welding | PC | from 15 000 ₽ |

| The exact cost is calculated after check-out | _engineer_ |

The cost of installing heating systems . Price adjusted as of May 05, 2021 Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Construction of stoves and fireplaces

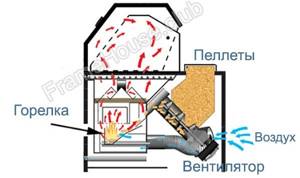

Units (stoves) using wood pellets as solid fuel consist of the following elements:

- housing made of high-quality heat-resistant stainless steel;

- firebox;

- burner;

- chimney;

- heat exchanger;

- fuel bunker;

- fan.

After the pellets from the bunker automatically enter the firebox, they form gas during the combustion process. This flammable gas subsequently enters the heat exchanger. It is there that the heat is released, and to distribute it throughout the living space, the unit is equipped with a fan.

In addition, the fan performs the function of extracting smoke gases. Pellet stoves are also equipped with a thermostat with a control unit to regulate the pellet feed rate.

It is optimal to purchase stoves that use a type of solid fuel such as pellets, which are additionally equipped with a heat exchanger - this way, in addition to air, the unit will also heat water.

Production of pellets in a factory

At the enterprise, the production of pellets from sawdust will require compliance with the step-by-step implementation of all processes:

Production technology

Grinding the product to small sizes: length up to 25 mm, diameter 2-4 mm. This process simplifies the operation of the pellet press. It is necessary that the sawdust be as fine as possible. Quality directly depends on this. The material is crushed using a crusher. The process can be repeated several times. The sawdust goes into the mixer and then into the drying drum. Drying sawdust is a very important stage, since the percentage of moisture in pellets should not be less than 8% and more than 12%. Deviation from the norm will cause poor adhesion of components and deterioration in the quality of combustion in the boiler

It is important to dry the sawdust to a certain percentage of moisture. The waste fractions in the process of separating sawdust and air enter the pellet boiler. Grinding raw materials to flour. It is then sent to cyclones, which separate the wood from the air. Flour is transported via conveyors to the hopper of the production granulator, and from there to the mixer. The mixer uses water and steam to adjust the desired humidity percentage. Separation into granules in an industrial granulator

At a temperature (250-300 degrees above 0) and through a selected matrix, the raw material is converted into pellets of the required size. Cut with a fixed knife. Cooling of pellets using a special fan and packaging.

Production of straw pellets

First, the straw is chopped into pieces 4 mm long. Then crushing to a finer state in a mill crusher. Then the raw materials are dried in a drying drum. Next, the product must undergo humidity control (using water and steam). After several grinding procedures, the straw flour is transferred to the granulator. There, pressing and division into granules of the required circumference and length takes place. At the end, the granules are cooled and packaged.

Ring Die Granulator

This type of matrix is used in large factories for the production of pellets: the design allows the processing of 300-500 tons of raw materials.

The principle of operation is this: soft sawdust is pressed through a hole in a metal plate. This is how the pellets are formed and then cut with a knife to the required length.

Main characteristics of pellets

In fact, pellets are waste from the wood processing industry, as well as peat, coal, and other products of plant origin. We will consider the technology of their production, as well as the features of determining quality, a little later, but we can talk about the general parameters now.

In short, these are capsules that are obtained by pressing organic matter at high pressure (about 300 atmospheres) and temperature. In this case, the material itself, passed through certain forms, is squeezed out into capsules or granules, the particles of which are glued/soldered together. What is typical is that no chemicals or adhesives are used in this case. The diameter of these granules ranges from 0.6-1 centimeters, and the length is about 2-3 centimeters.

What makes fuel pellets so special? First of all, when burned, they release much more thermal energy than other types of fuel. Using a ton of pellets, you can get as much heat as comes out from the combustion of 0.5 tons of diesel fuel, 480 m3 of gas or 1.6 tons of firewood.

Note! Thanks to this, pellet heating can easily compete with wood heating. And the cost is not as high as that of diesel fuel or gas

That is why the number of houses that are heated with pellets is growing every year.

Depending on the type of raw materials used in the manufacturing process, granules can be of the following types:

- made of wood, bark;

- from coal;

- from sunflower or buckwheat seeds;

- from peat;

- from municipal solid waste.

Pellet heating boilers

Previously, we talked about how pellet boilers are designed. We advise you to read this guide in addition to this article.