Criteria for choosing insulation

In the construction industry, penoplex, mineral wool, natural analogues, polyurethane foam, foam glass, and penofol are used for this purpose. Considering the difficult operating conditions, the first option is more appropriate as it is the most resistant to natural manifestations and easy to install.

Penoplex

The work should involve a type of product designed specifically for thermal insulation of a screw foundation. The tile material is able to quickly and efficiently cover the base and protect the underground space from the penetration of cold, dampness and wind. The solution is useful not only from the point of view of insulation, it protects against the penetration of groundwater, precipitation, and moisture. The lightweight material does not create additional load on the foundation, retains its performance properties over a wide temperature range, is budget-friendly and is in demand in all regions.

Polyurethane foam

When applied, it evenly covers the entire area and forms a dense layer. Compared to other materials, it has superior heat-retaining properties and has optimal sizes of bubbles and cells in the structure. Polyurethane foam exhibits high adhesion, is compatible with any base surface materials, and efficiently envelops areas with complex configurations. The only difficulty in use is the need for special equipment for application.

Foam glass

A controversial solution, as it is characterized by labor-intensive installation and high cost. Fixation is carried out using dowels, which must be inserted extremely carefully so that cracks do not form in the fragile material.

If the installation technology is followed, the solution is durable, does not burn, and exhibits excellent waterproofing properties, which is important for the safety of the metal base of the structure

Penofol

Available in rolls, it is in demand among builders due to its high thermal insulation properties. The material is made using thin aluminum foil, lays flat on surfaces and covers large areas. Protects against heat loss and moisture penetration, absorbs sounds, and is not afraid of temperature changes. The presence of foil prohibits the use of finishing in the form of paint and putty.

Mineral wool

It is easy to style and exhibits high heat retention capabilities. Since the material is vulnerable to moisture, high-quality waterproofing will be required, which increases the cost. This solution is short-lived and, if neglected at the installation stage, quickly becomes deformed.

Mineral wool - insulation for insulating screw foundations

Natural materials

Tow, plywood residues, and sawdust can be used as insulation materials; their advantages include breathability and environmental safety. But this solution is not enough if year-round use of the structure is planned. The attractiveness of such natural materials to insects and rodents is also considered a potential problem.

When choosing the optimal insulation, you should also focus on the essence of the planned work - internal, external, combined. The grillage needs special attention: its joints should be waterproofed, since these areas serve as places for moisture to penetrate. As a result, condensation may form inside, causing metal corrosion and mold formation.

Problems in the absence of insulation

Whatever the design features of the piles, the option and technology of their installation, this type of foundation has many disadvantages:

Cold underground, causing significant heat loss during frosts through open space.- When the grillage is reinforced concrete, it forms a significant cold storage tank. If you do not constantly heat the room, it is not easy to restore a comfortable microclimate in it.

- Freezing of pipelines laid underground is possible.

- Piles anchored in the frost layer can be pushed out. They are an excellent conductor of cold. When insulation measures are not carried out, concrete or metal pillars become the cause of local heaving.

- If some piles are located at points with low soil density, uneven shrinkage of the building occurs.

- Aesthetically, an undecorated foundation of this type looks unattractive.

- The underground space will certainly become littered, so it has to be cleaned periodically.

What types of insulation are best to use?

The greatest efficiency is achieved with comprehensive insulation both inside and outside the base.

Suitable types include:

- extruded polystyrene foam (penoplex);

- mineral wool;

- Styrofoam.

The latter type is often chosen due to its low price, but the service life of such thermal insulation material is limited. Polystyrene foam has low strength, is not resistant to moisture, and is interesting to rodents.

To reliably insulate the foundation of a wooden house, you need to use penoplex. It has a thermal conductivity of 0.029 W/mK. This material is not afraid of moisture, rodents, and is durable. Its only drawback is the high price. For a detailed description of the sequence of work, read the article: “Technology for insulating the foundation with penoplex.”

Mineral wool, namely basalt or stone, is not inferior in characteristics. However, a waterproofing layer must be laid under such insulation.

Read more about other types of insulation, their technical characteristics, pros and cons: “How to insulate the foundation of a house from the outside.”

Photo: thermal insulation of the internal space of the base of the house

Range of potential insulation materials

The following materials may be suitable for insulating the base:

- Styrofoam. It has the most attractive price, which also has a downside - if you compare it with other insulation materials, its thermal conductivity is quite high. Its durability also leaves much to be desired. The region in which the house is located also plays a role. For northern latitudes, the thickness of the slabs should be at least 150 mm, for middle latitudes - 100, and for southern latitudes - up to 50 mm.

- Mineral wool is a popular option, but it will require a waterproofing layer, which could be roofing felt.

- Penoplex, unlike the first on this list, boasts low thermal conductivity and sufficient strength, which has already brought many fans to its camp. In addition, rodents do not like penoplex, and its moisture resistance is excellent. These advantages made it an “expensive thing”, but it will serve for a long time.

- Polyurethane foam is fourth on this list, but in reality it is the winner, since its seamlessness speeds up the work significantly. There are also some drawbacks: polyurethane foam urgently requires expensive equipment.

To determine the required thickness of the material, a thermal engineering calculation is needed to help determine the intensity of cold penetration into residential premises.

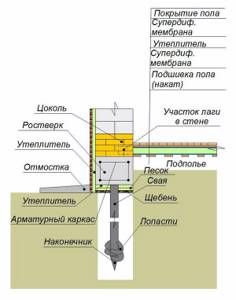

Insulation of a pile-grillage foundation with a low grillage level

Insulation of a strip-pile foundation can be carried out according to the same principle as a conventional strip foundation

due to the fact that it is also buried in the ground and made of reinforced concrete. This means that you can use either sheet insulation for a pile foundation or loose insulation, and additionally insulate the structure using a warm blind area.

Insulation of the grillage of a pile foundation should begin by marking and preparing a trench with a width slightly greater than the thickness of the insulation, and a depth of 5-10 cm below the location of the support area of the piles located under the foundation.

At the next stage, it is necessary to clean the base surface and install insulation against moisture penetration, after which you can begin installing the insulation. To do this, you will need to have fasteners, polyurethane foam or other adhesive composition. Dowels for insulating materials, or in installer slang, “mushrooms,” are optimally suited as fasteners.

Do-it-yourself insulation and finishing of a pile foundation

If it is necessary to simultaneously improve the appearance of the base, you can apply insulation technology using bulk materials, together with base thermal panels.

The algorithm for this type of insulation is as follows:

- A trench is prepared with a depth just below the support pad of the piles and a width of 0.5 to 1 meter.

- Sand filling is being made.

- The trench is filled with insulation, slightly below the ground level, 5-10 cm is enough.

- Thermal panels are installed; they need to be slightly deeper into the loose insulation and secured with dowels.

- The blind area is being poured.

Protection of insulation from moisture

Foundation waterproofing.

Even in the dry climate of the construction region, there will definitely be some water in the soil. Adding to this the condensation that occurs during any significant temperature changes, we get a constant effect of water on the structure.

And with long-term exposure it can destroy even the most resistant materials, both insulation and the foundation itself.

Waterproofing is carried out using rolled, sprayed, sheet and coating materials.

Their combination will be even more effective:

- Rolled materials are laid with an overlap of 10-15 cm, the joints are melted with a torch or coated with bitumen mastic.

- Coating and spraying types are applied to a previously thoroughly cleaned surface in a layer of the required thickness.

- Sheet waterproofing materials are firmly attached joint to joint. The seams are sealed with some kind of spray or coating agent.

Materials used for the construction of the fence

When choosing building materials, you must not forget that this part of the building must be practical and beautiful. If you do not organize the removal of the pile-screw foundation, then the facade of the house will lose its attractiveness, in addition, air will begin to circulate under the floor, so any heating systems will not be able to heat the building.

When installing the intake, you must not forget about the passage of various communication systems through this element. To install them, leave the required number of holes. You also need to organize a ventilation system using air windows that are closed in the winter. The fence should not be firmly attached to the piles. It requires a little “freedom”, this will help preserve the structure from possible deformations during heaving of the earth.

Pick-up dimensions:

- for brick structures, it is recommended to install a fence with a thickness of at least 130 mm;

- for rubble structures (cobblestones of irregular shape are laid), the thickness must be 210 mm;

- for the concrete version, the thickness is chosen to be at least 100 mm.

You can build a fence for a pile foundation in various ways. It depends on the building materials at hand, or the financial capabilities of the owner of the house.

Most often, the fence is made of boards. The design can be made either with mounting in a horizontal or vertical position. In this case, the underground part is made in the form of backfill, which is characterized by its thermal insulation properties; ordinary slag can be used.

This method of organizing collection is the most economical. But the structure can also be made from a variety of materials.

Stone, brick

A layer of sand is poured into a pre-dug trench, and a cushion of concrete mortar (7-15 cm thick) and reinforcement is made on top of it. As reinforcement, you can choose rods with a cross section of 7-9 mm. Then, when the cement mixture dries, brick or stone is laid.

Siding

The backing for a pile foundation made of siding is cheaper and easier to implement. For this arrangement it is necessary to build a frame from timber. The frame must be treated with special compounds to protect against fire, fungus, mold and other negative factors.

First, prepare the blind area. It is required to drain water from the foundation that flows from the roof of the house. The frame is then secured to the support pillars and to the bottom of the building. Siding is attached on top of it.

Today there is a large selection of different types of siding on the market. This material is highly resistant to the negative effects of the external environment, in particular to ultraviolet radiation. It can have a different palette of colors, and even imitate natural materials, for example, granite, stone, wood.

The service life of siding is more than 35 years. But it has one drawback - it does not protect well enough from severe frosts, so mandatory insulation is required.

A rather economical solution in this case is a multilayer material for thermal insulation. This is, by and large, ordinary foam plastic with a layer of decorative material glued on top. The decor can be inexpensive plastic or more expensive plates of granite or marble.

Concrete

Picking up in this manufacturing option is more difficult to perform. But the high aesthetic and thermal insulation properties are worth it. Why do you need to dig a small trench around the perimeter of the house, measuring 40x40 cm.

A sand cushion is poured into the bottom of the ditch. Water is poured on top of the well-compacted sand, and then filled with cement mortar with a layer of approximately 30 cm. It is not recommended to connect the foundation supports with the screed, as this will subsequently lead to the appearance of cracks on the base.

DSP

Cement particle boards cut to size are secured to the base using bars. The main disadvantage of this design is the poor thermal insulation characteristics of the material. Mandatory insulation is required inside.

Sheet materials

Profiled flooring is most often used as sheet material. The sheets are attached to a frame base, which is made of galvanized profiles or beams.

The sheathing is constructed in several stages:

- The guides are set taking into account the vertical and horizontal levels.

- The selected material for thermal insulation is laid and fixed, and the sheathing is attached on top.

- Low tides are installed.

- At a height of approximately 25 cm from the ground level, holes are made for ventilation and closed with special plugs.

The profiled flooring must first be cut into pieces of the required sizes.

Recommendation: Taking asbestos sheets is a more economical method of arrangement, but this design is usually used in the construction of ordinary country houses.

Pile foundation insulation technology

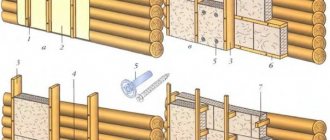

The entire process of insulating a screw pile foundation for a wooden house can be divided into the following work:

- performing waterproofing;

- construction of a frame mesh for the base;

- installation of insulation on the frame;

- external finishing with insulation;

- internal insulation of the foundation.

Performing waterproofing

Regardless of what material the piles are made of, they require proper protection. If the installation of waterproofing under the insulation layer depends on the selected material, then the main structures of the foundation must be protected from the aggressive action of moisture.

Metal piles are coated with a primer, wooden piles are impregnated with special antiseptics

It is important to carefully treat all exposed surfaces to prevent early destruction.

Construction of a frame mesh for the plinth

The frame mesh is made of wood or metal. These structures also need to be protected from moisture.

The operating principle is simple. A sheathing is created for the selected insulation so that the cells are smaller than the insulation boards. This will make it possible to attach the insulation to the frame.

An improvised basement is being built throughout the outside of the house, which will retain heat inside. For strength, the metal frame is welded and sunk slightly into the ground.

It is necessary to ensure the strength of the structure so that it can withstand significant wind loads and not collapse in bad weather. To further strengthen the frame, concrete is sometimes poured onto the base of the frame around the perimeter of the building.

The second version of the base is built of brick. The process is more labor-intensive, but the result is a truly durable structure that you don’t have to worry about during operation.

We insulate the pile foundation with brickwork

You definitely need to build your own for such a base. Then half a brick is laid, followed by insulation.

Installation of insulation on the frame

If the frame is built correctly, installing the insulation will not cause problems. The insulation boards are laid and pressed tightly against the frame. Additional fastening can be done using retaining bolts.

All resulting joints should be carefully sealed. Polyurethane foam is well suited for this.

If you use a material that is afraid of moisture, it is necessary to apply a layer of waterproofing. This will protect the insulation from rodent attacks.

In this regard, it is not recommended to use polystyrene foam, which is a favorite material for mice and rats. Over time, they find how to get into this warm place and create entire labyrinths there, weakening the effect and effectiveness of the insulation.

External finishing with insulation

Any available façade system is suitable for exterior finishing. Most often, siding or decorative PVC panels are used that imitate brick or natural stone.

Basement siding "burnt brick"

You can also choose external protective panels that look like wood. This will make a wooden house stylish.

Installation of any external system is carried out taking into account the requirements specified by manufacturers. Work should start from the very bottom, installing the guide profile. Then the rest of the planks are laid on it, which are closed with a snap.

When choosing exterior finishing, you need to look for not only a beautiful material, but also one that is sufficiently durable and moisture-resistant.

Internal insulation of a pile-screw foundation

The interior of the foundation is insulated using expanded clay bedding. It is necessary to dig a small trench near the piles along the entire perimeter of the house, fill it with expanded clay and, if possible, pour a small layer of concrete on top to prevent contamination of this strip of insulation with soil and plant impurities, which over time destroy the effect of using expanded clay.

It is important to make ventilation holes in the formed base that will ventilate the subfloor. This will prevent the appearance of fungus, rot and early destruction of structures. The openings must be covered with a grill to prevent rodents and other pests from getting inside.

In winter, the ventilation is usually completely closed. In some cases, additional care must be taken to install hoods to prevent the appearance of moisture in the underground

The holes must be covered with a grill to prevent rodents and other pests from getting inside. In winter, the ventilation is usually completely closed. In some cases, additional care must be taken to install hoods to prevent the appearance of moisture in the underground.

Installation of a plinth using decorative panels

Installing a panel plinth requires much less time and is much simpler than erecting a brick wall. If everything is done correctly, then this type of base will last quite a long time and reliably.

The first thing that needs to be done to arrange a slab base is to provide a frame on which the decorative panels will be attached. For this purpose, a metal profile must be attached to the screw piles on all sides of the structure. Fastening is best done by welding. The number of longitudinal profiles is determined depending on the height of the base. As a rule, 2-3 directions are sufficient. In addition to the metal profile, a wooden beam can serve as a material for creating the frame. In order for it to last a long time, it must be treated with a special antiseptic solution. This is necessary to protect the wood from rotting.

Next, slabs of thermal insulation material are attached to the finished frame. Typically, penoplex or polystyrene is used for such cases, as they are stronger and more reliable.

It is important to consider the thickness of the insulation boards. They should not be wider than the grillage, since decorative panels will also be attached to them. After installing the insulation on the grillage of the house, a decorative fence is attached using glue

The panel must be selected so that its top is securely fastened and provides good fixation of the entire plinth structure, and the lower part should be buried several centimeters into the soil. For this purpose, you first need to dig a small trench

After installing the insulation on the grillage of the house, a decorative fence is attached using glue. The panel must be selected so that its top is securely fastened and provides good fixation of the entire plinth structure, and the lower part should be buried several centimeters into the soil. For this purpose, you first need to dig a small trench.

Below, in the place where the soil and insulation come into contact, you need to make a cushion of expanded clay sand. The thickness of such a layer can be at least 10 centimeters. This is necessary to protect thermal insulation and decorative materials from the effects of moisture coming from the soil. In addition, expanded clay sand has low thermal conductivity, which will ensure less freezing of the foundation during the cold season.

If the homeowner decides to provide thermal insulation to the base on screw piles using isospan, he will need to ensure the necessary conditions, in particular, the presence of natural ventilation.

Do-it-yourself insulation work

The correct sequence and accurate execution of all work will help achieve maximum results.

To understand how to insulate a pile foundation yourself, you will need to carefully study all stages of the work and prepare the tools:

- A spatula or brush for applying a protective layer to wooden structural elements.

- Hacksaw. Required when cutting the required size and amount of material.

- Drill or hammer drill for installing insulation.

- Level for measuring the angle of inclination of a surface.

- Insulation material.

After all the preparations, you can begin installing the insulation. All work is carried out according to the following scheme:

- First, the joints of the grillage are waterproofed, since it is through them that moisture most often penetrates. Because of this, condensation forms inside, which promotes the development of mold and metal corrosion.

- Exposed metal areas are insulated with liquid bitumen, wooden areas are coated with an antiseptic to protect against mold.

- Next, a protective structure is constructed. It can be made from a single-row brick wall, which is insulated on the outside with foam plastic and decorated with finishing material.

- A sheathing for rolled or tile materials is mounted on the base.

- Insulation is placed between the guides. For a better fit, leave the distance between them 1 cm less than the size of the insulation.

- Longitudinal guides are mounted at an equidistant distance from the central part of the pile.

- Wooden guides are attached to the prepared frame with self-tapping screws in increments of the size of the insulation plate.

- After laying the insulation, the joints between the plates are sealed with polyurethane foam.

- Final work is carried out using finishing materials. The cladding is attached to the top of the insulation, screwed into wooden guides with self-tapping screws.

When you think about how to insulate a pile-screw foundation yourself, you can try the option of constructing a base from warm decorative panels.

Creating a false base from panels is much easier than laying bricks. First, you should take care of the structure on which the panels will be attached. To do this, a metal frame with wooden guides is created around the entire perimeter. The distance between the guides is calculated according to the height of the foundation. All wooden elements are treated with an antiseptic.

Insulation is installed to the erected structure. It should not protrude beyond the grillage.

A decorative fence is attached to the structure using special glue. The fixed panel is connected to the grillage with its upper part, while the lower part should enter the ground 4-5 cm. At the point of their contact, it is necessary to remove the soil and sprinkle it with expanded clay or sand.

Since the panels have zero air permeability, you will need to create ventilation holes to provide air access. 4 vents are enough, one on each side. With the onset of cold weather, they are covered with a regular rag.

To drain rain and melt water, make a drainage system, then the soil around the house will remain dry.

What materials will be needed

Insulation products on the construction market are presented in such a wide range that many consumers have difficulty choosing materials.

In fact, the most optimal options for insulation products are the following:

- Styrofoam

- Foam glass

- Expanded polystyrene

- Penoplex

- Polyurethane foam

Sheets of insulating material are glued to the surface of the base. The seams between them are rubbed and sealed using polyurethane foam. Then be sure to apply a layer of waterproofing material (for example, mastic or roofing felt).

Ruberoid insulation of the foundation

Thermal insulation from the street side

To insulate a pile foundation from the outside, slab polystyrene foam or penoplex (the so-called extruded type of polystyrene foam) is most often used. The latter option has a smaller thickness (30 mm versus 50), and contains special fire-fighting additives.

External insulation of the base with penoplex Source stroyfora.ru

What materials can be used for thermal insulation?

When answering the question of how to use screw piles, the first thing that arises is the need to select a thermal insulation material. It should be noted that the building's base itself, as well as the grillage, is involved in the insulation process. The screw piles themselves do not need to be insulated, since they are located deep in the ground and do not affect the freezing of the foundation in any way. Accordingly, materials need to be selected only for the base itself.

For thermal insulation of the foundation of a house, the most suitable option is considered to be materials made in the form of polystyrene slabs:

- Penoplex. The second name of the material is extruded polystyrene foam;

- Styrofoam.

The specified thermal insulation materials provide a good effect, as well as convenience during installation of thermal insulation. Most professional builders prefer to insulate the foundation of a wooden structure using penoplex. This material has low thermal conductivity, can serve for a long time and is very durable.

Types of socles

Let's look at the most common types of bases:

- Level - on the outside of the building it is flush with the walls. Usually this option is preferred by the owners themselves, but from the point of view of specialists it is not the best

- Protruding - when the thickness of the wall is less than the thickness of the base and the latter protrudes outward in the form of a step. Such a base retains heat well under the floor and is most often installed under wooden houses. To protect it from precipitation, a low tide is installed in its upper part.

- Recessed - when the wall is thicker than the base and its surface is slightly “recessed” in relation to the plane of the wall. This option is most conducive to increasing the service life of the base, because it is protected from the effects of precipitation by the walls of the house.

See also:

- SNiP requirements for driving piles

- Foundation with grillage on piles

Pickup - what is it?

A pile foundation has one drawback, unlike a strip foundation: the space between the piles, as well as the soil and ceiling of the basement floor, does not have insulation. This is exactly why the fence is installed. By properly constructing this element, heat losses in winter can be reduced. It is also insulated from precipitation.

Methods for installing the fence are calculated for each specific case. The choice depends on many factors. The parameters may also differ, but there are generally accepted requirements: for example, the height of the fence must be at least 50 cm from the ground level. When constructed correctly, the fence is both an element of thermal insulation and an excellent aesthetic solution.

The pile foundation must have a blind area, which is required to drain water. This structure is made 80 cm wide, extending 25 cm beyond the cornice. This will ensure that water drains from the roof directly onto the blind area, which will protect the ground near the foundation from washing away.

The higher the flowability of the soil, the more organization of the blind area is required. Most often, its slope is done in a ratio of 1:5. It is also necessary to organize a moisture-proof layer. Instead of vegetation, which is removed before construction, a layer of clay is poured and compacted.

The blind area of any house on a pile foundation must be accompanied by a channel for drainage of water; its organization guarantees a long service life of the structure.

What is a blind area and why is it needed?

A blind area is a special waterproofing of the outer surface of the foundation, designed to drain rainwater from the base towards the drainage system. It is made of sand, expanded clay and clay, the top ball is concreted with a slight slope to the side. As a rule, the blind area has both the characteristics of waterproofing and insulation, and also has a decorative purpose. It is not surprising that it can be found near the basements of old houses, where rainwater drainage plays a key role.

The blind area is also used as insulation, only granulated expanded clay is used inside, which acts as a backfill near the outer surface of the strip grillage.

How and how to insulate a pile-screw foundation

How to choose insulation? First of all, it must be moisture resistant. Hydrophobic synthetic materials are well suited: polystyrene foam, EPS, polyethylene foam, etc. Of the mineral insulation materials, only foam glass is suitable, mineral (basalt and glass) wool - in no case. No organic-based thermal insulation materials are suitable. The final choice of thermal insulation material depends on where it is located.

How to insulate a pile foundation along a frame, where to place the insulation? It is clear that from inside the underground, but there are options here too:

Placing a thermal insulation layer behind the sheathing frame

At first glance, the easiest way is to first fasten the base sheathing directly to the frame, and then lay the insulation behind the frame. It is behind the frame, and not between its elements. So that there are no cold bridges. But in this case, the question arises about its reliable fixation. You can, of course, attach sheets of thermal insulation to the back of the frame. But it will be inconvenient to carry out such installation with a low base. Access from the reverse side is difficult, but you need to secure the fixing elements and fill the cracks with construction foam.

And, most likely, the thermal insulation will not fit in the locations of the steel piles or its layer will be thinner. These are the disadvantages of this method. Pros: you can use any insulation, in particular inexpensive and easy-to-cut polystyrene foam of the lowest density. Due to the low price, you can increase its thickness. And screw piles can be additionally thermally insulated on three sides from the inside of the subfloor.

made of foamed polyethylene

Insulation of the base on piles

Thermal insulation of the base on stilts is mandatory, since in this case an empty space is formed under the first floor of the house, in which cold wind can easily blow. This impact greatly affects the temperature in the house. To insulate the base of a house on a pile foundation, it is necessary to first carry out a number of works:

- arrange the basement;

- attach thermal insulation materials both inside and outside the base;

- insulate the flooring on the first floor.

In addition, you can insulate a pile foundation using special decorative panels. In this case, a frame is made of a metal profile or timber along the perimeter of the building. Already on this frame, first the heat-insulating material is attached, and then the decorative plates

At the same time, it is important to equip a special expanded clay cushion so that moisture and cold do not pass through the soil. It is done quite simply; under the casing you need to dig a small groove into which expanded clay sand is poured, which is then covered with a layer of earth so that there is no free space between the soil and the foundation casing.

It is recommended to insulate the foundation on stilts from the inside and outside in order to more effectively protect the house from the effects of cold. How to insulate a pile foundation in a wooden house can be seen in the video.

The following are used as thermal insulation materials for foundations on piles:

- polystyrene foam boards;

- Styrofoam;

- foam glass blocks;

- urea foam.

In most cases, the first two material options are used because they are cheaper and easier to install. Foam glass is an expensive material and it is not profitable to use it for a private building. As for urea foam, its installation requires special equipment, which only professional builders possess. Paying for their work also costs a decent amount.

What insulation to use

Insulation for the floor of a frame building on a pile foundation, in addition to the ability to retain heat well, must be light, easy to install and have excellent moisture resistance.

Styrofoam

Fairly good insulation, widely used due to its low cost

However, it should be taken into account that freezing of moisture-saturated foam provokes its gradual destruction. As a result, its thermal insulation characteristics drop sharply, and the cold gains direct access to the room

The use of polystyrene foam is permitted only in combination with reliable moisture protection.

Penoplex

Extruded polystyrene foam is a more expensive modification of polystyrene foam. It is characterized by excellent strength qualities and an almost complete absence of water absorption. This allows the material to withstand low temperatures in conditions of constant humidity. To impart fire-resistant qualities to penoplex, fire retardants are introduced into its composition.

Mineral wool

An excellent option for installing heated floors in a frame house. This material is characterized by high thermal insulation characteristics and absolute non-flammability. Mineral wool is not afraid of any biological influences.

Builders prefer to use mineral wool as insulation. Source krutopol.com

Weaknesses of the material:

- Poor moisture tolerance. Contact with water on the surface of the insulation provokes its subsidence and a decrease in thermal insulation characteristics.

- Expensive. To purchase mineral wool you will have to pay an order of magnitude more money than for penoplex.

This material is produced in the form of plates and rolls. The first option is more convenient for thermal insulation of the floor in a building on a pile foundation. The slabs have the advantage of rigidity and resistance to mechanical stress.

Expanded clay

In houses on screw piles, this insulation is used quite rarely, which is explained by its low thermal insulation characteristics. To achieve the desired insulating effect, you have to pour a layer of decent thickness: this conceals the living space and adds to the overall weight of the structure. Those who still decide to use expanded clay to insulate floors on stilts are attracted by the significant simplicity of its installation.

Recommendations for choosing thermal insulation material

Screw piles, which act as metal posts immersed in the soil, do not require any insulation. Only the false base and trim need to be insulated: these elements are in direct contact with the floor surface of the home. Their freezing causes cooling of the floors in the house.

The following materials are usually used for these purposes

- Extruded polystyrene foam

(penoplex). It has good thermal insulation characteristics and is characterized by increased moisture resistance. Both a solid base and lathing are suitable for installation. - Liquid penoizol

. It is applied by spraying over a frame sheathed with plywood, which significantly simplifies the insulation procedure. - Block foam glass

It is allowed to insulate walls with polystyrene foam, the joints of which are closed with adhesive foam Source drive2.ru As for such popular and inexpensive insulation materials as ordinary polystyrene foam and mineral wool, in this case it is not recommended to use them. Mineral wool, due to its hygroscopicity, quickly gets wet and loses its characteristics. Polystyrene foam is also prone to moisture accumulation between the styrene beads, which causes it to collapse when it freezes.

We insulate the floor

If you decide to insulate not only the base, but also the floor, you should decide on the technology. It is recommended to install the subfloor on joists with internal insulation if the base is made of sheet material over lathing. Having a capital insulated base made of piece materials, you can get by with simpler internal insulation. If the height of the underground part allows, insulate the floor from below so as not to subtract a few centimeters from the height of the premises on the first floor.

To insulate the floor along the joists, you need:

- fill the joists with skull blocks and lay the subfloor;

- lay a continuous sheet of waterproofing and a heat insulator (foam plastic, mineral wool) between the joists;

- lay a layer of vapor barrier and fill the counter-lattice;

- install a covering of boards or plywood for finishing.

Insulating the floor from the room side involves laying a layer of dense polymer heat insulation between the base of the floor and the sheathing. You can choose a vapor- and moisture-proof material or additionally use an appropriate membrane so that moisture does not damage the floor structure.

If it is necessary to insulate the floor from the basement side, a sheathing is placed on the ceiling, waterproofing is attached and sheet insulation is installed - mineral wool mats are inserted by surprise, the gaps between the sheathing and sheets of foamed polymer are filled with polyurethane foam. A vapor barrier film is attached over the structure, and if necessary, the ceiling of the subfloor or basement of a house on a pile foundation is sheathed with a suitable material.

How to insulate a floor

Floor insulation is done in several ways:

- Creating a backfill layer of insulation between the bottom flooring and the subfloor.

- Continuous backfilling of the underground with arrangement of the floor on the ground.

- Construction of a deck with insulation and pouring of a heated floor system.

The choice of the optimal option is made based on existing conditions, configuration and availability of communications in the underground. The most common options include creating a layer of insulation between the bottom and subfloor and pouring a heated floor system.

The procedure in both options starts the same:

- Logs are installed . They must ensure the immobility and strength of the floor; ideally, they rest on the surface of the piles.

- Planks are attached to the lower edges of the joists, which will serve as sides for laying the flooring boards.

- The plank flooring is being laid . Edged boards are used, laid transversely between the joists.

- A heat insulator is laid on top of the boards . You can use polystyrene foam, penoplex. If the thickness is sufficient, expanded clay is used, but for effective service a layer of at least 30 cm is required, which is not always possible.

- A layer of waterproofing is laid.

After this, either subfloor materials are laid and the finishing coating is laid, or underfloor heating pipes are laid, all connections are made, functionality is checked, and then a layer of screed is poured (about 10 cm).

This option is gaining more and more supporters, as it allows you to heat the room economically and efficiently.

Internal insulation

It is more convenient to lay thermal insulation on the internal walls of the false base even before the main structural elements located above the zero mark have been installed. Direct fastening of the insulation is carried out in exactly the same way as when insulating from the street side.

It is better to carry out internal insulation before creating the external wall Source opsar.ru

Since the inner surface is not visually visible, it is possible not to use plaster or decorative cladding to decorate it.

To protect the insulation from rodents, a metal mesh is stretched over it. Additional thermal insulation is provided by a layer of earth or expanded clay sprinkled around the perimeter of the fence. Date: September 25, 2021

Errors and tips

Perhaps the main mistake is to remember the need for insulation after construction. In this case, it will turn out to be much less effective, most likely more expensive and labor-intensive. There is also a chance of damage to the foundation structure, which can lead to problems in the operation of the house or even its destruction.

Despite the fact that many insulation materials themselves are quite resistant to water, are not destroyed by it, and sometimes do not leak at all, this does not mean that traditional waterproofing should be neglected. Protecting the foundation from moisture is the key to its long and safe operation.

Exterior finishing of the foundation

The lower part of the building can be considered completed only after all work has been completed, including exterior finishing. The outer side of the base must be lined with a material that will create a unified appearance with the overall decoration of the building. In this case, special attention will be required at the junction of the external finishes of the wall and the base. It must be made either solid or overlapped downwards. There are many ways to make the base part protected from external influences and, at the same time, attractive in appearance:

- Plaster on a mesh with cement-sand mortar. This method is the oldest, inexpensive, tested over the years, but labor-intensive and associated with “wet” processes, which is not always convenient. This finish retains heat well and does not get wet, but requires fairly frequent repairs.

- Facing with piece materials, such as clinker tiles, natural and artificial stones, facing bricks. This category also includes flexible products based on bitumen or synthetic resins, which are attached to the wall with special glue. All of them will wonderfully decorate both a wooden and brick house. and will also serve as good protection for the main structure.

- Covering with siding or plastic panels. The method is modern and quite effective in all respects. The products are endowed with immunity to atmospheric influences, high strength, and long service life. In addition, manufacturers produce siding in various colors and textures, so it can be matched to any style and maintain the decorative appearance of the house as a whole.

- Use of curtain façade systems. This solution is very useful, as it creates additional insulation for the foundation on screw piles, is easy to install and lasts a very long time. The appearance of the curtain wall may vary depending on the finishing layer. It is very easy to replace the facing panel of the hinged system with a new one without disassembling the main structure.

Another element of insulation of the pile foundation is the blind area. It should not be neglected under any circumstances. And it needs to be made of high-quality concrete, preferably with reinforcement. Be sure to maintain a slope from the wall - outward. It is the blind area that helps drain rainwater away from the house, preventing it from penetrating under the foundation and base.

A set of works on insulating a pile foundation, carried out efficiently and responsibly, will serve as excellent protection not only for the foundation, but also for the entire building from many troubles. This includes increased thermal insulation of premises and resistance to seasonal weather conditions. In addition, insulation procedures will have a positive effect on the strength characteristics of the foundation as a whole. By the way, with some skills and a great desire, all work on insulating the base can be done with your own hands.

Insulation materials with moisture-proof properties

If you turn your attention in time to insulation materials that can repel water, you can save a lot on foundation insulation. Waterproof materials include:

- Airgel;

- Foam glass;

- Extruded foam (polystyrene).

By covering the base of the house with such insulation in a timely manner, you can not only save money, but also avoid unpleasant surprises in the form of corrosion on the foundation structure or gradual destruction of the building.

Insulation of a pile-grillage foundation is not only the comfort and coziness of your home, but, above all, the health of you and your family. As follows from the laws of physics, all the heat of the house always accumulates under the ceiling, therefore, the floor is already always cold, not to mention the foundation made of screw piles. By approaching the construction and insulation of your home more seriously, you will not only preserve your health, but also extend the life of all its inhabitants.

The grillage is the most important detail. Its functions include distributing the weight of the building onto the base and onto the land as a whole. In this way, maximum stability of the pile foundation is achieved. The base element must be made in accordance with technological standards, and in addition, it is necessary to select the correct insulation for a foundation made using this technology.

A properly executed foundation of a house is a tax on reliability and comfort. The first ensures the stability of the structure. But comfort is achieved due to the fact that the base is an additional insulator of the structure from low temperatures. The roof and walls protect the house from wind and rain, and the foundation becomes an obstacle to the cold coming from the ground.

In fact, it is simply impossible to build a house without a foundation. The simplest insulation option is to insulate the foundation with expanded clay and sand. This is a universal remedy. They can be used to insulate a strip foundation or to insulate a grillage type foundation. The latter is often insulated with polyurethane foam, but expanded clay should not be discounted.