Gas stove for a sauna or bath?

Time does not stand still: more and more lovers of steam baths understand not only the significant difference between the national baths of neighboring peoples, but also that the conditions of these baths are demanding in terms of heating equipment, room design and other components.

Hence the question: in which bathhouse would a gas stove be appropriate? And is it really contraindicated for someone else?

The answer to this is quite simple: gas is just fuel , and the material from which this stove is made will be of real importance for your bathhouse.

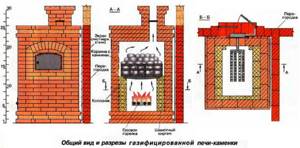

After all, it won’t be a big discovery for you that a gas burner can be placed not only in a metal oven, but also in a brick oven?

And a brick stove is the most optimal unit for a real Russian bath .

But not every brick stove is suitable for gas. What are the restrictions?

- The combustion part should not be too large, but the torch from the burner should not touch the stove material .

- A stove without a smoke circulation system is not suitable. A Dutch or Swedish design is suitable .

- Bell-type stoves are also not an option for switching to gas, because the gas combustion product will not be retained under the hood, it will be carried out into the chimney, and the hood’s task is to catch the heat. In this case, he won’t have time .

The least suitable for a Russian bath would be a metal stove without shielding . But with a good-quality brick screen, this is also a completely acceptable option.

As for the sauna , it requires fast and strong convection . Consequently, the best stoves will be those that have nothing stopping them from freely heating fresh air flowing through the ventilation from the street - this is either a metal stove without external decoration with an open heater, or the same stove in a mesh casing.

Gas as a fuel behaves quite controllably and predictably, if you do not violate the operating instructions. Therefore, you can get the specified conditions without surprises.

And for a better understanding, let's look at this:

Video

We invite you to watch videos about some models of such stoves.

An interesting Salekhard stove, designed specifically to operate on gas, unlike other stoves that are designed to operate on wood and are equipped with burners.

Another review of the stove from Izistim. A separate article is devoted to the Yalta 25 stove.

And here is the opinion of a specialist from the bath association.

***

Here is a brief overview of the most significant issues related to a gas sauna stove. More information, as already mentioned, can be found in our other article.

Information about wood-burning and electric stoves is collected in separate publications. Obtaining complete information about the types of units will allow you to decide which sauna stove is better.

Main advantages

Traditional wood-burning stoves installed in a bathhouse are good, especially if there is free access to fuel. In any other situations, an economical gas stove for a bathhouse can be an excellent alternative to a solid fuel boiler. Its installation is not difficult. The main thing is to follow all the necessary rules and precautions.

According to statistics, gas bath boilers are the best sellers among all types of heating devices installed in steam rooms. This is due to the fact that their advantages are undeniable:

- Compactness. Gas stoves for saunas and baths do not have a volumetric firebox or a compartment for collecting ash, so they take up minimal space in the room.

- Optimal temperature. A gas sauna stove allows you to regulate the temperature level. All you need is to set the optimal mode.

- Easy to use. A gas sauna stove does not require special care. Its operation does not imply cleaning the ash pan and monitoring the combustion of fuel.

The main disadvantage can be considered the rather high frequency of emergency situations. They are caused by the installation of uncertified equipment and violation of operating standards.

If you choose the stove wisely and do not violate safety precautions, the gas burners will last in normal mode for decades.

What to look for when choosing a gas stove for a sauna

If you decide to purchase a gas stove for a bathhouse, you need to focus on several basic selection criteria. And the main thing, of course, will be the required thermal power.

How to determine the power of a gas sauna stove

The stove must, according to its characteristics, be able to cope with its direct task - creating and maintaining the required temperature in the steam room. That is, we are talking about the thermal power of the purchased unit.

It is usually accepted as an axiom that for one cubic meter of steam room volume, about one kilowatt of furnace power is required, regardless of the type of fuel used. It would seem that everything is simple: multiply the linear dimensions of the room by height, length and width - and the desired value is “in your pocket”. However, this issue also has its own nuances.

This approach is justified only if the steam room has complete thermal insulation, carried out in accordance with all the rules and based on thermal engineering calculations, including with the recommended reflective vapor-proof material such as penofol. Then the internal lining made of natural wood will not require additional heat.

Insulating a steam room is a task of special responsibility!

High-quality thermal insulation of this room is necessary for obvious reasons - it is necessary to maintain a high temperature there, without leading to a senseless waste of fuel or electricity. In addition, thermal insulation must be able to withstand the “pressure” of high concentrations of water vapor. The optimal solution: the use of foil insulation for baths - read about this in a special article on our portal.

But in practice, there are areas in the steam room, and sometimes very significant ones, that become “gaps” in the thermal insulation. They must also be taken into account by making appropriate adjustments.

- If there is a window in the steam room, then in any case it contributes to heat loss. In this case, you need to add 3 kW (or 3 m³ to the volume of the room, as is convenient for you) for each m² of window if it has one glass, and 1.5 kW if the window is double-glazed or double-glazed.

The presence of a window in the steam room requires increasing the power of the sauna stove

- Brick (stone) sections of walls, or surfaces lined with ceramic tiles, have a high heat capacity, and for each m² of such a section another 1.2 kW is added.

- Log walls (or walls made of timber) have a very high heat capacity, but in order for the desired microclimate to be created and maintained in the bathhouse, they must be heated. If a bathhouse in a log house does not have internal thermal insulation lining, then the nominal volume of the steam room (that is, the power of the stove) should be increased by one and a half times.

The log walls of the steam room will require a very significant amount of heat to fully warm up.

- An uninsulated door (thin wooden plank or even a newfangled glass door) will require an increase of another 1.5 kW.

- When the fuel window is located in an adjacent room, heat loss through this “bridge” is inevitable. Therefore, it is necessary to make an adjustment for this circumstance, on the order of an additional 10 percent.

In total, a very significant increase in volume can occur. And when choosing a stove, it is recommended to consider models such that the calculated total value is approximately in the middle of the power range (or steam room volume) indicated in their passport.

And one more nuance: there may be one stove model, but it can be equipped with burners of different power - this is also worth paying attention to.

Prices for Ermak sauna stoves

Sauna stove Ermak Uralochka

To make it easier for the reader to carry out the necessary calculations, below is an online calculator for calculating the required power of a gas furnace for a bath.

Calculator for calculating the power of a gas sauna stove

Go to calculations

Other criteria for choosing a gas furnace

- Steam rooms, as a rule, do not have a large area. And in order not to reduce the already cramped space, it is worth choosing a stove of proportionate dimensions so that its presence does not restrict the free movement of people.

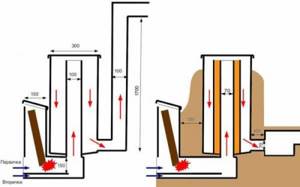

- The best option would be a stove with an extended, remote fuel channel. That is, all control actions will not be carried out in the steam room, gas equipment will not “steal” space, the safety of operating the stove and taking bath procedures will increase sharply. Most modern models have exactly this layout.

- The data sheets of many models indicate approximate gas consumption. Of course, the lower it is, the better, the more efficiently the device works, that is, the higher its efficiency.

- Be sure to focus on what type of gas is acceptable for the stove. The fact is that some gas burners that are equipped with furnaces are designed exclusively for natural network gas, while others allow the gearbox to be reconfigured and the nozzles to be changed for liquefied bottled gas. Don't lose sight of this to avoid getting into an unpleasant situation.

- As already mentioned, many stoves have versatility - they can also work with wood when changing the fuel block. This can be beneficial in cases where gas has not yet been supplied to the house, but such an opportunity is visible in the near future. So that the bathhouse does not sit idle in vain, and in order to avoid unnecessary costs, such a model will be just a godsend - over time, it will be possible to simply install a gas burner instead of the loading window.

- You should probably think in advance about how the water in the bath will be heated, and purchase the appropriate tank that matches the model you choose. Well, if you want to save as much space as possible in the steam room, then it is better to take the container into the washing room, and for the steam room, purchase, at a little extra cost, a modification of the stove with a built-in heat exchanger.

- Be sure to carefully check all the documentation of the purchased stove - the store manager is required to present quality and safety certificates, the manufacturer's passport of the product with marks of technical control upon request. If there is some confusion with the documents, or there are none at all, then you should refrain from purchasing.

- It is never a bad idea to carefully inspect the device for external damage. Anything can happen during transportation, loading and unloading - but you need a quality stove!

- Important - as a rule, stoves are not equipped with stone filling, but the passport always states how many stones the baskets are designed for. These are not empty numbers, since the rated capacity of the furnace is designed specifically for the specified amount of minerals. And making your own adjustments to this issue is not recommended.

- You should not rush to cheap models from completely unfamiliar brands. There are cases where such accessibility is achieved by completely unacceptable savings from unscrupulous manufacturers on quality materials. This will then certainly affect the operation of the device, and in the worst case, the safety of operation.

Prices for the Ermak Uralochka stove

Ermak uralochka

It is best to purchase gas stoves from proven, completely trusted manufacturers. By the way, this is precisely the case when there is no need to chase imported equipment. Russian companies produce excellent gas stoves - these are the already mentioned above, Teplodar, KUTKIN, Ermak. Many of them use components for gas automation from the world's leading brands.

Gas stoves made in Europe are also very good, but their cost is usually significantly higher than domestic ones, with essentially equal characteristics and functionality.

Types of gas boilers for baths

All equipment operating on blue fuel is divided into:

- single-circuit - installed in small rooms;

- double-circuit - in addition to heating, they will provide hot sanitary water;

- three-circuit - additionally heat pools or heated floors.

In order to not only heat the bathhouse, but also ensure the supply of hot water, you should choose a double-circuit boiler with a power of 20-30 kW. This power is enough for an area of 200-250 square meters. Water heating rate is 10-14 l/s.

Heats the heating circuit and hot water supply

Boilers can operate both on main gas and bottled liquefied gas. Not all holiday villages are gasified, so the latter type of boiler is optimal for a private bathhouse. Some models are equipped with replaceable nozzles, which allows the equipment to operate on liquefied and main fuel.

Classification of gas boilers:

- by material - metal, stone, brick;

- depending on the fuel used;

- equipped with different tanks for heating water;

- have different types of burners.

Compared to metal stoves, brick and stone stoves take longer to heat up, but they can retain heat longer. A metal boiler is chosen due to its compact size, after which it is lined with brick.

The burners used are atmospheric and inflatable. The atmospheric burner does not require electricity to operate, so it is more economical and at the same time completely silent. It functions due to the air entering the ash pan. The main requirement for boilers with an atmospheric burner is proper ventilation.

The amount of oxygen supplied can be increased by increasing the size of the slot

An inflatable burner is different in that it requires a fan that is powered by electricity to operate. The operating principle is the same: gas is mixed with air to heat it. To make the operation of such a model safer, you need to take care of installing an emergency power source.

What types of gas devices are there?

There are several types of gas stoves, they are classified according to the following principle:

- What type of burner is used;

- What material is the body made of?

- What device is installed to heat water?

- Power parameters.

Depending on these criteria, there are many models of gas furnaces, which complicates the task of choosing. Therefore, before purchasing equipment, you should study all the important nuances.

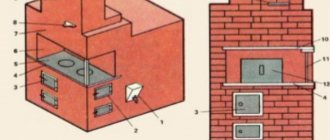

Stone and brick stoves

A sauna stove with a gas burner, which is made of brick or stone, is an analogue of a Russian stove with a firebox for logs. The layout of a bathhouse with gas stoves will not be affected in any way due to the material in which the body of the device is made. Stone or brick structures fit into any interior.

The only drawback of this material is the duration of heating. Stone conducts heat better than brick, so it will heat up faster. In models made of brick and stone, behind the firebox door there is a heater, which is heated by radiation of energy from the burned fuel.

The heater is located above the gas burner. A gas sauna stove with a closed heater does not require additional ventilated operation, unlike an open heater. In many models, the heater is open, so if this issue is fundamental, it is worth taking this nuance into account.

Metal stoves

Metal stoves are cheaper than brick and stone stoves, and they are easier to install. The compact design of the metal device allows it to be installed even in small bathhouses. Other benefits include:

- Fast heating, as the metal structure is very thin;

- The ability to select a furnace of the required power, so you can save on energy resources.

The presence of a metal structure presupposes the presence of mandatory thermal insulation. It is necessary to make thermal insulation of the equipment body from the floor covering (for example, with a brick layer), thermal insulation from the walls and chimney. If this is not done, there is a high chance of a fire.

If the bathhouse is planned to be heated from time to time, and not constantly, then it is better to choose a metal structure; its minimum weight is 45 kg, while a brick or stone structure weighs from 750 kg.

Furnace equipment

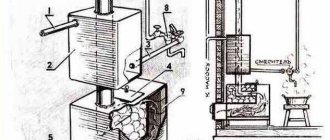

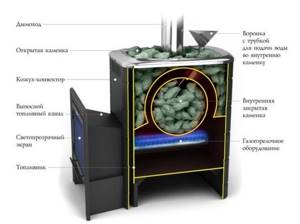

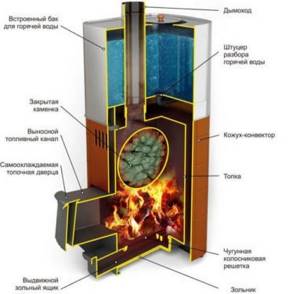

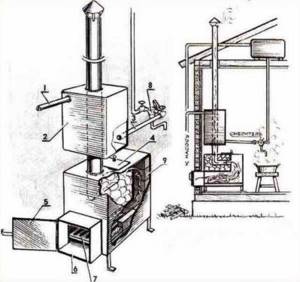

Gas sauna stoves have a fairly simple structure:

- a burner is installed in the housing, to which a gas pipe is hermetically connected;

- above the burner there is a water tank, which is an integral part of the heat exchange and heating system;

- A tray for the heater is installed on top of the body. It is worth understanding that the performance indicators of gas and wood stoves differ significantly, so for the heater you need to use cobblestones from the river or seabed. Thanks to the combustion of gas, the heater can heat up to 200 degrees. This, coupled with water getting on it, can lead to rapid failure of the heater. River and sea stones, unlike others, are able to withstand such impacts;

- In addition to the tray for the heater, there is an outlet on top of the body of the gas stove; a chimney is connected to it;

- Gas sauna stoves with a water tank and models that do not have this element of the heat exchange system have a fuse in the design, which is responsible for automatically turning off the gas supply when the fire goes out.

Having studied the design of the device, you can understand that a gas stove for a bath with your own hands is a reality. You can assemble it yourself. The exception is burners, which must be purchased from a trusted manufacturer.

Kutkin stove - reviews

Artem Sagdeev, 46 years old, Ufa

I bought a Kutkin stove for the occasion, I was flattered by the advertising and the fresh look of polished stainless steel. During transportation, the box was accidentally dropped on its side. As a result, two welding points flew off; this became clear during installation. I barely found a welder and grabbed the seam with a semi-automatic welding machine. In general, the stove is normal, but if it is not made carefully, you will be tortured to repair it.

Petr Mikhailovich Lunev, 72 years old, Stavropol

I’ve been using the Kutkin stove for over a year now, it works well, but I need to select the mode for myself. Otherwise you won’t have enough wood. The chimney heats up to a crimson color, so you need to change the standard 5-liter tank to a larger container, and always with running water. Otherwise, the chimney will burn out in just a few months.

Recommended Posts

Door to the steam room: do-it-yourself installation

Bathhouse on screw piles

Bathhouse with utility block: with toilet, woodshed

Do-it-yourself wood concrete bathhouse

Finnish sauna - what is it?

Heat exchanger for sauna stove

Gas furnace device

What was said above already seemed to hint that a gas stove is not much different from a wood stove. And indeed: if you wish, you can remake your existing wood stove by installing a gas burner in it.

For your information! There are limitations, for example, it is better to install a micro-torch burner so that the metal does not burn out, you must ensure that the flame does not touch the walls and top.

An internal heater can also become a source of problems - flow-through or closed, it is not designed for a torch temperature of 1600 degrees.

Keep in mind! Even when the gas burns entirely in air, problems remain. After all, all the heat goes up, but the lower part does not heat up . Therefore, the steam room heats up unevenly, which means it takes longer.

By the way, the dimensions of the fuel compartment in an initially gas stove will still be smaller than in a wood stove, but this is understandable - firewood is voluminous, so additional space in the firebox was allocated for it. But gas doesn’t need that much space. He only needs air.

IMPORTANT! But this is a really important point: for complete combustion, gas needs an influx of fresh, oxygen-saturated air . Because any combustion is oxidation, interaction with oxygen. If there is not enough of it, combustion will be incomplete, and incomplete products are dangerous for humans!

To better understand this issue, let's look at the structure of the main part of a gas sauna stove:

Gas burner device

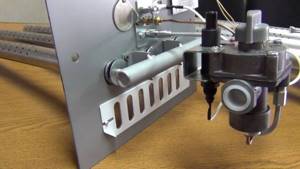

Today there are two types of burners:

- atmospheric;

- supercharged.

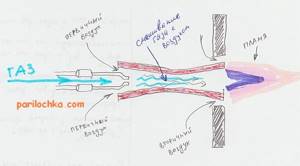

Atmospheric

A cheap type of gas burner because it is designed quite simply. It is a tube or tubes through which one or another natural gas flows under pressure. Before it burns, it must be mixed with air, and the air in this type of burner is supplied only by draft. And if there is no proper ventilation, then it is better not to experiment with such burners.

Well, if you are sure that your ventilation is good, the draft will work properly, then the atmospheric burner will be good - it is silent and does not depend on electricity.

True, it depends on the movement of air in the room itself - this makes changes in the proportions of mixing gas and air. The result is uneven heating. And the efficiency suffers - a lot of heat literally goes into the pipe. In addition, gas combustion is often incomplete.

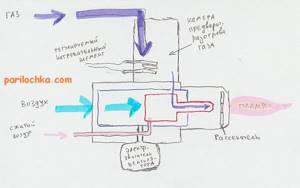

Supercharged

The second type differs significantly from the first in design. The point of the differences is to make the thrust uniform . This requires a fan, and therefore electricity.

As in an atmospheric burner, in a forced-air burner the gas must first be mixed with air. The fan is adjusted so that the ratio is optimal. When this is achieved, the dependence on air movement in the steam room disappears , and with it the unevenness in the formation of the mixture and its combustion.

It’s worth mentioning right away the advantages and disadvantages of blower or fans (yes, these are also options that are structurally the same thing). It is clear that dependence on electricity is difficult to classify as an advantage.

IMPORTANT! If someone has problems with electricity, then it is better to secure the gas furnace fan with an emergency power source.

The second, less important drawback is noise. The third is the cost, which is 2-3 times higher than the cost of an atmospheric burner. As for the latter, it’s worth calculating how quickly the choice will pay off, because a supercharged burner also has a big advantage: it is twice (!) more economical than an atmospheric one.

In addition, forced-air burners are normally installed in wood-burning stoves. But it’s up to the owner to decide, because converting a wood-burning stove to gas can significantly shorten its service life due to metal burnout.

One more advantage is worth mentioning: the ability to customize power.

operate from both main gas and liquefied gas . At the same time, the transition from one type to another is quite simple.

Video

For a better idea of the subject, watch the video, which clearly demonstrates the operation of a forced-air burner installed in a metal sauna stove.

As you can see, not everything is as simple with a gas stove as sellers say. Therefore, it is worth comparing the advantages of all existing types of stoves.

What are the advantages of using gas sauna stoves?

Compared to their wood-burning “brothers,” gas sauna stoves have a number of significant advantages:

Almost all models have a thermostatic control system. This means that in the process of taking bath procedures there is no need to be distracted by maintaining the required temperature - adding firewood, changing the position of the blower window, etc. It is enough to set the required heating level in the steam room in advance - the automatic operation control system will take care of the rest.

The thermostatic control system for gas burners allows you to set the desired temperature - and no longer be distracted by this matter while taking bath procedures

- Modern gas furnaces are extremely easy to use. They are equipped with all the necessary levels of control and security.

- Wood-burning stoves have to be cleaned of accumulated ash literally after every kindling. There is no such problem in gas installations. Prevention is certainly necessary, but its frequency, as a rule, does not exceed twice a year. By the way, this also applies to a chimney for a bathhouse - there are incomparably more solid combustion products in wood smoke than when burning gas.

- When using natural network gas, there are no issues with organizing the storage of fuel or its delivery to the bathhouse. Just open the tap and you can light the heater. If you use liquefied gas in cylinders, then this is a little more complicated. But for cylinders, you can also organize a compact gear cabinet once at the outer wall of the bathhouse, extend the hoses on an ongoing basis, and not experience any serious problems in the future.

If you plan to use bottled gas, you can mount a special cabinet near the wall of the bathhouse.

- In terms of speed of heating a steam room, gas stoves are in no way inferior to wood or electric ones, but at the same time their operation will be much cheaper, thanks to the quite affordable cost of “blue fuel”.

- Modern models of gas sauna stoves are distinguished by their enviable durability, and the manufacturer gives them a very good factory warranty.

- Many models of gas stoves for baths are already given the appropriate appearance in advance, which does not require any modifications. However, there are also those that require obligatory brick lining or complete covering on all sides with a heater.

- It is also important for traditionally cramped bath conditions that gas stoves are usually compact.

Prices for gas stoves

gas oven

There is only one significant disadvantage of such furnaces. As with any other gas equipment, they require approval of the installation by the relevant organization and the connection of the main line. This means that you will have to order the preparation of a project, and then have it approved by authorities, which is always accompanied by a loss of time, nerves, and additional material costs. But the advantages of gas stoves still outweigh this “minus”.

New quality of gas fuel boiler

From an economic point of view, it is advisable to use gas in cylinders for small and tiny steam rooms, for example, for a bathhouse on a trailer or a sauna in a fishing house.

Using a gas boiler for a sauna or bathhouse allows you to solve several serious problems:

- Get rid of the fumes and the smell of scale that accompany almost all wood-burning stoves. Gas fuel combustion products consist of 99% harmless carbon dioxide and water;

- To ensure smooth and accurate heating of the air in the bathhouse, in many modern gas boilers for saunas the automation is able to maintain the temperature even more accurately than in the case of electric heaters;

- Get the desired compactness of gas equipment. A modern gas boiler is only slightly larger in size than an electric heater.

For your information! The temperature of the combustion front of methane fuel in the gas furnace of a boiler is only 850°C, while the intensive formation of deadly carbon monoxide and the release of fine soot begin at 1000-1100°C. For comparison, when burning firewood produces a flame 150-200°C higher than in the case of gas fuel.

This means that a branded gas boiler is much safer than any wood-burning stove. If you do not interfere with the operation of burners and control equipment installed by a specialized specialist, the chimney will remain sterile clean, and the risk of fire or poisoning is practically zero.

DIY pipe boiler

An iron boiler welded from a metal pipe has a very simple structure. Preparatory work in this case is limited only to the study of several drawings of these devices, as well as the acquisition of all required consumables.

Almost always, such boilers are made from a metal pipe of fairly large diameter. It is most convenient to take a diameter of approximately 500 mm; a length of no more than one meter would be quite suitable. Due to this, you can get a device that can create a comfortable temperature in a room, the volume of which is about 15 cubic meters or approximately 9 square meters.

To produce such a boiler it will not be possible to do without the following tools:

- Inverter or electric welding machine;

- Angle grinder or grinder;

- Metal cutting wheels for grinders.

Construction of a solid fuel boiler for a bathhouse

First prepare the pipe:

- At the first stage, three supports are made that will stand parallel to the surface of the earth at three different levels. To do this, you need to take three pieces of reinforcement, the diameter of which should be 14 mm and the length 3 cm. The first level is required in order to install the stove. The second one is placed depending on where the blower door will be located. The third is installed 20 cm from the top edge of the pipe;

- The bottom is a circle of the required dimensions, which is cut from a steel sheet whose thickness is at least 5 mm;

- For the grate, through which combustion products will fall, as well as the oxygen required to maintain combustion, a circle of sheet metal will be required. An already perforated sheet is taken or slots are made in it;

- The furnace lid acts as a support for the stones, so it is also made of sheet steel with a thickness of 5 mm. In the central part you need to cut a hole into which the chimney pipe is inserted;

- A slot is made in the lower part of the future boiler to install the door;

- Instead of a door, in some cases a box is installed through which fuel will be supplied to the boiler.

The entire structure is assembled at its final location following the following sequence of actions:

- At the first stage, a box is welded into the structure. If this work is already carried out directly in the bathhouse, then the box is placed in the boiler in such a way that it goes either into the dressing room or onto the street;

- A chimney pipe is welded into a pre-prepared hole. This work should be given as much attention as possible, since if even the slightest hole is left, combustion products will pass through it into the steam room and accumulate there. This can have a very negative impact on a person’s health;

- The structure is quite heavy, so it is necessary to build a foundation for it. The easiest way is to make a reinforced concrete slab. Instead, a concrete or reinforced concrete screed is suitable. Moreover, it is poured onto crushed stone, the layer of which must be at least 15 cm;

- The structure is placed on a prepared base, and stones are placed on the lid.

In principle, instead of a metal pipe, craftsmen often use a barrel of suitable sizes. Moreover, this structure can be built without the use of any power tools, except for a welding machine - all holes are cut out with a chisel or an ax. All other actions will be exactly the same as when working with a piece of pipe.

Boilers for saunas made of pipes with heaters

Costs for a gas boiler for a bath

Installing a gas fuel boiler in a home bath is always more difficult than a wood-burning or electric version of a heater stove:

- It will be necessary to complete a project for pipe routing and installation of heating equipment;

- Buy only certified equipment, and the power and design of the gas boiler must exactly match the parameters of the steam room and bath;

- Conclude an agreement and pay for the work of UGH or any other office with a license to install and start up a gas boiler in the bathhouse.

It turns out to be expensive and troublesome, but if the installation is carried out in good faith and all service conditions are met, the gas boiler can work in a bathhouse for a couple of decades. Wood stoves and fireboxes burn through to holes during this time. The best part is that after 2-3 years of operation, switching to gas will show savings in the cost of maintaining the bathhouse.

It’s easy to calculate; heating a bathhouse requires 270-280 kcal for every 0.5 m3 of room volume. To place a steam room less than 10 m2 with a gas sauna boiler, you will need about 1-1.1 m3/h of methane fuel; according to tariffs for private households, this will be only 6-7 rubles per hour. For an electric boiler in a bathhouse of a similar design, you will need to spend 3-6 kW/h, which is approximately 20-25 rubles/hour, the difference is obvious. That is, the more the boiler works in the bathhouse, the faster the investment will pay off.

Choosing a Finnish wood-burning stove for a sauna

Stoves from Finnish manufacturers can be considered synonymous with quality. These units combine traditional solutions and the latest technologies. The production uses metal that has good thermal conductivity. The stoves produce soft heat that lasts for a long time. This increases the efficiency of the equipment and its cost-effectiveness.

Stoves provide gentle heat

The equipment is characterized by a long service life. Their minimum service life (if used correctly) is at least 10 years. Among other things, Finnish equipment has an attractive appearance.

Original design of a Finnish stove

The operating principle of a Finnish stove (most models) looks like this.

- The combustion chamber is made of heat-resistant steel (cast iron fireboxes are not often found in Finnish stoves) with a thickness of 4...10 mm. For stoves from Finland, it is located in the lower part of the body. Firewood is placed in it and ignited. Above this compartment there is a blower. The firebox door is usually made of heat-resistant glass, which makes it possible to observe the combustion. Burning wood produces heat.

- Thermal energy rushes upward. Typically, Finnish units are equipped with two independent fuel combustion channels. Stones placed in a heater that holds 20...110 kg are heated.

- The chimney, located in the center of the stove, additionally heats the stones.

- Water is poured into the heater through a special funnel.

- The steam, passing through a pile of stones, dries and enters the steam room in the form familiar to a Russian bath.

- To be able to splash herbal infusion on the stones, the heater usually has a door.

- Some models are equipped with a tank for heating water, which is mounted on the chimney or on the side of the unit. Often the firebox is remote, then the steam room is heated from the next room.

Not all models have a water tank. Some models of Narvi stoves

When deciding to purchase products from Finnish manufacturers, it is useful to have an idea of the important characteristics that you need to pay attention to. What are the benefits of modern metal stoves?

What are the benefits of modern metal stoves?

- The thermal power of the devices is of decisive importance. For wood-burning equipment, it depends on the capacity of the heater (the mass of stones placed there determines the amount of heat and steam released). There is a simple rule: for heating 1 cubic meter. m steam room requires about 1 kW of power. You should not purchase a unit with a large performance margin. This is fraught not only with unnecessary costs, but also with possible deformations of the cladding. A unit that is less powerful than required will not last long (you will have to increase the load, constantly maintaining the fire) and will not be able to provide the conditions necessary for staying in the steam room. Typically, manufacturers indicate the performance of the furnace when operating under ideal conditions (the room must be well insulated, heat loss must be minimized). However, as a rule, a small reserve of power should be provided in case not all the heat remains in the steam room.

- Preference should be given to products from a company whose quality has been tested by time.

- The presence of a water tank allows you to obtain hot water for the needs of those in the bathhouse.

- A remote firebox helps save space in the steam room and create comfortable conditions in the adjacent room.

- The grate, which protects the bottoms from temperature influences and is necessary for removing ash, must be made of heat-resistant steel or cast iron.

How to choose a Finnish sauna stove

The products of Finnish stove makers are distinguished by their performance properties and attractive design. Despite the fact that domestic manufacturers try to develop analogues, they do not always manage to achieve similar characteristics.

How to choose the right gas stove?

The stove is the most important element of the steam room. It determines how comfortable and useful a visit to the bathhouse will be, and how much it will cost.

The design of a gas stove is not the last selection criterion. The volume of stones is also important; by splashing water on which you can adjust the steam hardness and other vaping characteristics.

When choosing a stove, take into account the requirements for gas baths, which relate primarily to operational safety. The manufacturer or seller must have official documents confirming that a particular model has been tested and meets government standards.

As for technical parameters, the main ones are:

- area of the steam room;

- rated power;

- firebox type;

- material of manufacture;

- control method;

- installation features;

- design.

If the power of the stove is too large for the volume of the steam room, the air will heat up quickly, and the stones will not have time to warm up. This means that getting decent steam will be problematic.

At low power, the oven will operate at the limit of its capabilities, which will lead to rapid wear and deformation. As a result, you will have to spend money on expensive repairs or even buy a new unit.

Therefore, it is necessary to determine the volume of the steam room and add to it the volume of adjacent rooms if they are also planned to be heated using the same stove. You can add 20-25% to the obtained value and, based on this data, select a model based on other criteria.

Facing a gas stove with bricks or slabs of natural stone significantly increases the heat transfer of the unit and protects bathhouse lovers from direct exposure to high and ultra-high temperatures

It is important to pay attention to the firebox, which must be made of steel grades that can withstand high temperatures and their significant differences.

It is desirable that the stove has thermal inertia, that is, it can retain heat after being turned off. This will not only save fuel during bathing, but also dry the bathhouse after completing all procedures.

If the stove will also heat water for the shower room, which is located outside the steam room, you should choose a model with a remote tank. Those who like wet steam need to buy a stove with an open heater. For connoisseurs of dry heat, you will need a unit with a closed heater, in which the heating of the stones reaches 500°C.

Multi-mode models will help you not to limit yourself to one thing and, depending on your mood, steam in either a Russian steam room or a Finnish sauna. Some stoves are capable of providing the conditions of an oriental hammam and an infrared sauna.

Additional equipment will allow you to control the unit from a distance and prepare the bathhouse for your arrival, being hundreds of kilometers away. All that remains is to wish you a successful purchase and easy steaming!

Gas pressure is an important criterion when choosing a boiler for a sauna

It should be taken into account that when supplying gas to the boiler from the central line, or even more so from a cylinder, it is necessary to monitor the pressure. When purchasing a boiler, the pressure in the network is one of the criteria for its selection, since manufacturers warn that a disruption in the energy supply is not safe for operating the device.

Preparing the bathhouse for installation of equipment

What kind of stove should I install? This is one of the first questions that the owner asks himself when he has the desire to build and install a gas stove for his favorite bathhouse with his own hands.

Any normal owner wants to ensure safe and comfortable operation of the devices they use. You can assemble a stove from a variety of materials: both expensive and cheaper.

Gas-fired sauna stoves are in direct competition with wood-burning stoves. This is due to ease of use, lack of need for constant maintenance, and cost-effectiveness. Such a device can be warmed up and ready for operation much faster than a solid fuel unit

Most often, metal, stone or brick structures are assembled. This is due to high reliability, low financial costs for purchasing the necessary parts, ease of assembly and installation. At first it may seem like assembly is a complicated process, but in reality it is not.

Before gasifying the bathhouse, you need to make sure that it holds heat well. The room must be completely thermally insulated and insulated both outside and inside. Only in this case will heat loss be minimal, and the stove will perform its functions as efficiently as possible.

Choosing a location for installing a gas furnace

If the bathhouse has already been built and all that remains is to choose a convenient heating method, then you should choose a suitable gas stove design. On the other hand, you can choose the appropriate device option and slightly adjust the bath room during the installation process.

That is, it is advisable to initially select the future heating option and build the building in accordance with this choice.

The process of installing a homemade gas stove is quite simple. You just need to follow the basic safety rules. A well-made stove, if repairs are carried out in a timely manner, can serve the owner for five decades or more.

Installation and installation of a gas sauna stove is usually carried out in a steam room, in an adjacent washing room or partially in a relaxation room. The main task of the stove is to ensure complete heating of the entire bath structure and maintain a constant temperature.

To reduce heat loss, it is best to place a homemade gas stove in the center of the bathhouse. It has been established that if the heat source is not in direct contact with the walls, then there is a significant reduction in heat loss due to the thermal cap. Heat does not escape from the building through the walls.

Warm air circulates throughout the steam room. It rises from the center of the room to the ceiling, where it is reflected from the vapor barrier with a reflective layer and spreads over the entire area of the steam room.

This way you can steam indoors for as long as possible. However, it is not always convenient to install a gas stove directly in the center of the steam room.

Brick and stone stoves have a long heating time. So, if you want to take a steam bath, you need to start heating the oven about 8 hours before visiting the steam room. However, such stoves retain heat many times longer than metal ones.

Choosing a furnace installation location from various options has its own advantages and disadvantages. If you install a homemade gas stove in a steam room, you will need to install an additional ventilation system.

This is due to accelerated oxygen consumption. The advantages of this installation method include the ability to regulate the temperature without leaving the steam room.

Installing a gas stove in a bathhouse with your own hands in a relaxation room provides the following advantages:

- There is no accelerated burning of oxygen, therefore, there is no need for increased ventilation of the room.

- The steam room does not occupy any useful space for visitors, therefore it can accommodate more people.

- The steam room will not be contaminated with fumes and other waste associated with the operation of the stove.

- A gas stove installed in an adjacent washing room or in a relaxation room usually heats not only the steam room, but also all other rooms.

This type of installation will require additional manipulations such as creating holes in the wall leading to the steam room. However, if you plan for this type of installation in advance, you will not have to carry out any additional work.

Ensuring fire safety

In order to avoid negative consequences after installing a gas furnace, you should take care of fire safety.

All flammable and flammable materials or objects must be placed at some distance from the device. A half-meter distance will be enough. You should also maintain a distance of the stove from the wall in the range from 5 to 15 centimeters.

Installation of a sauna stove requires a serious approach and compliance with safety measures. In particular, the distances between flammable objects and the oven must be maintained. The burner must be equipped with a fuse

In the place where the homemade gas sauna stove is placed and installed, you should also lay out insulating sheets of refractory material or make brickwork.

It is also necessary to protect the ceiling with fire-resistant sheets with basalt cardboard or other material. It should be taken into account that the protection area should be approximately thirty percent larger than the dimensions of the oven.

It is recommended to position the structure in such a way that the door providing access to the burner opens towards the doorway, and the heater door opens towards the wall. In a room heated by gas, there must be a means to quickly extinguish the fire in case of fire. The dressing room should have at least one small window.

The construction of a stone or brick sauna gas stove is carried out according to a pre-developed scheme. This scheme assumes a certain logic and sequence of actions when laying the next row of refractory bricks and installing additional elements

When building the walls of a sauna stove, it is worth using refractory bricks, and for laying the combustion chamber, bricks made from fireclay clay.

The masonry mortar is mixed from clay with the addition of sifted sand. For the foundation of the stove and the outer part of the chimney, cement is used in the solution instead of clay. To strengthen the base of the future furnace, you need to reinforce the foundation with reinforcement and use galvanized sheet to protect the floor in front of the door of the combustion chamber and the closed heater.

To equip a brick stove, you will need to purchase a grate, a combustion door and a blower door. Also, if you plan to install a gas-burning stove, then you should take care of the place where the solid fuel will be located so that moisture does not get on it.

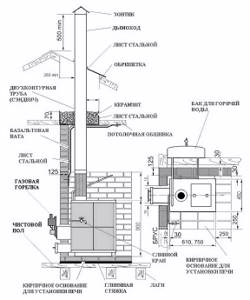

To ensure that the chimney from a gas stove lasts a long time, asbestos-cement or stainless steel pipes are used for its installation. The chimney height is usually planned at five meters above the burner level.

The installation of a chimney should be approached with special responsibility. There should be no holes, cracks or crevices either in the stove body or in the chimney pipe. Their presence can lead to carbon monoxide entering the room and poisoning people.

You will also need to provide water and gas supplies. Water can be supplied by connecting a water supply or from containers using a compressor. All options are used for gas supply: from connecting to the gas main and using a gas holder or cylinders.

Safety and Installation Requirements

Since gas is used for operation, you should be as careful as possible during operation.

Necessary:

- monitor the wear of all equipment parts;

- regularly check the readings of the gas analyzer and other devices;

- Only trust a specialist to replace parts.

Savings when purchasing, installing and operating gas equipment can lead to dire consequences.

Requirements for the room where gas equipment is planned to be installed: no high humidity, no accumulation of dust, limited access for children.

Before a gas boiler room is installed in a sauna or bathhouse, you need to study the rules for safe installation:

- the height of the room must be at least 2.2 m;

- All doors must be opened outwards;

- It is necessary to have a window and exhaust ventilation;

- absence of flammable structures near the equipment (minimum distance - 0.5 m);

- if the walls of the room are made of fire-hazardous material, when installing the equipment, an indentation of at least half a meter should be made (the use of a fire-resistant barrier or heat-resistant screen is allowed);

- a hole for a rectangular burner (height - 48-55 cm, width - 35-45 cm);

- to prevent gas leakage, it is recommended to install a special sensor that will operate when the burner goes out;

- the smoke exhaust pipe should not pass through living rooms;

- the stove must have a metal base that will protrude at least 10 cm;

- To prevent the occurrence of condensation, the chimney must be made of stainless steel.

If the site is not gasified, then forced removal of combustion products should be organized. To maintain high temperatures, high-quality thermal insulation of the room is necessary.

The optimal solution would be to use foil insulation. It should be noted that heat loss increases in the presence of windows and uninsulated doors.

Wiring requirements for an electric furnace in a bathhouse

Consider the following points:

- For a single-phase network, use a three-core cable, for a three-phase network, use a five-core cable.

- A prerequisite for wires is the presence of a grounding wire.

- Attach the wires to the wall using conventional cable ducts.

- The cable between the control panel and the oven must be in special rubber insulation. Sometimes this cable is supplied with the oven.

- Reinforced insulation wires are expensive, so it is recommended to reduce their length. To do this, install a metal mounting box near the stove (no closer than 1 m), on the wall. Between the box and the remote control, covertly lay ordinary wires in vinyl insulation, and from the box to the oven - wires with reinforced insulation. Pull the heat-resistant wires through a metal hose or pipe, which you ground.

- Under high temperature conditions, strands of copper and aluminum wires oxidize, so all wires in the building must be copper.

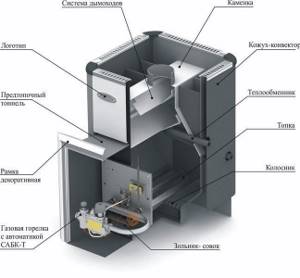

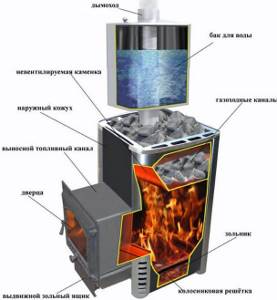

Gas boiler-heaters in standard version

In appearance, standard models of gas boilers for baths, photo, are practically indistinguishable from wood-burning versions. The same high rectangular metal body, a filling heater in the upper part of the structure and a side tunnel for supplying air and fuel.

Modern models of domestically produced gas equipment copy well-known Finnish and Italian brands in shape and design.

A gas appliance is always easily recognizable by its automatic control unit. Where a wood-burning stove has a door or hatch for loading firewood, gas boilers for a bathhouse have a panel with nozzles, a fire front sensor and an ignition device.

The outer walls are made of thin sheet steel, which provides reliable protection from the hot combustion chamber. Its shape and dimensions are much smaller than a wood firebox, almost always made of heat-resistant alloy steel.

Inside the firebox there is a package of two or three nozzles. The dimensions and shape of the combustion chamber of a gas boiler are carefully selected and calculated during the production process. Therefore, you cannot simply take and install a gas burner into the combustion chamber of a wood stove. The firebox will burn out within a few months of use.

There are gas-wood models of heaters for baths. In this case, the dimensions of the combustion chamber are made such that they can burn wood with a very small combustion front and gas with a high flame height. But even in such designs, only the gas burner that comes with the boiler can be converted and installed; the use of a burner device of any model leads to burnout of the chamber walls and outlet channels.

In a classic gas boiler, tubular heat exchangers are always installed to heat water. To heat the bathhouse, the registers are connected to a storage tank and a pump that pumps hot coolant through radiators or underfloor heating pipes.

In low-power boiler systems, instead of a built-in heat exchanger, mounted water tanks are used, similar to tanks in wood-burning stoves. In powerful gas boilers, double-circuit coaxial heat exchangers can be installed to heat the bath. Essentially, these are two pipes, one inside the other. Water flows through the inner tube, which is heated to spray the heater; the coolant of the heating system usually flows in the space between the walls.

Burner selection

Burners are:

- Atmospheric.

- Supercharged.

For a homemade design, you can only use forced-air burners. They are more complex than atmospheric ones, but much safer.

The devices are equipped with automatic valves that will shut off the gas if the flame goes out, or the stove overheats, or if there is a leak. There are models with automatic ignition.

You need to purchase a burner in advance, before stocking up on all the materials. The fact is that burners come in different sizes and shapes - drawings and diagrams will be developed based on this.

Metal is a material that is easy to process. You can make a do-it-yourself sauna stove from metal very quickly, and the design will be mobile.

For models of long-burning stoves for the home, see this review.

Gas heaters

Using natural gas as a fuel for heating a bath provides one undeniable advantage. Low-power household boilers are made without a combustion product exhaust system; heated gases partially pass through a backfill of stones, partially through side windows and channels for heating water containers.

The absence of a chimney above the heater greatly simplifies the process of temperature control; there is no particular need to monitor air humidity, since most of the water is constantly evaporated by the flow of exhaust gases.

Of course, the thermal power of a gas heater is less than that of a standard heating boiler for a bath; it usually does not exceed 3 kW. Since some of the gases enter the steam room atmosphere, when installing the boiler it is necessary to use special exhaust ventilation and an alarm system with a sensor for the presence of CO in the air.

Many natural gas heaters do not have a built-in boiling water tank, so you must use a metal ladle and a grate placed on top of the backfill to obtain boiling water.

Features of operation

When operating gas-powered furnace equipment, a number of rules must be observed:

- After each heating, check whether the gas valve is closed.

- If there is a smell of gas in the bathhouses, it is necessary to put out the fire, open the windows and doors. Wait until the gas dissipates.

- Use long matches to ignite the gas burner.

- Check the integrity of the gas pipeline connection once every two weeks.

It is advisable to have one or two fire extinguishers in the bathhouse.

Gas sauna stoves are becoming more popular. They are cheaper than brick structures, heat up quickly, and are economical to operate. When installing gas equipment, you must follow a number of rules. Any mistake can lead to dangerous consequences.

Similar articles

Basic recommendations for cleaning a chimney

Why do you need a spark arrester for a chimney for a bathhouse and is its absence dangerous?

Principles for choosing a water tank for a bath

Principles of making a stove from car disks for a bath

Disadvantages of gas boilers

Imported models of gas boilers for baths are always made with a reserve of mechanical strength of the body walls. Many domestically produced models are more similar in design to Chinese boilers due to the minimal thickness of the combustion chamber walls and design. As a result, when the internal heat exchanger is turned off, the firebox often overheats and becomes deformed.

One of the most common types of problems is the burner turning off spontaneously. In boiler apparatus from well-known manufacturers, gas automation is installed in a box protected from heat and water vapor. In cheaper boilers, the burner operation control board can simply be placed in an aluminum box. As a result of oxidation of the contacts in the humid atmosphere of the bathhouse, the flame control sensor is the first to fail. Repairing boiler burner equipment is not difficult, but in any case it must be done by a specialist, otherwise the equipment may be sealed and the owners may be fined.

What materials are used

As mentioned earlier, to make a stove for a gas bath with your own hands, it is recommended to use fireclay (fireproof) brick, metal or stone. Stone stoves take much longer to heat up (4-5 hours), but the temperature is maintained 3-4 hours longer than metal stoves. Brick ones are characterized by similar indicators. In turn, metal units heat up faster (rooms up to 50 sq.m. completely warm up in 2.5-3 hours), but also cool faster.

At the same time, metal stoves are lighter than their brick counterparts and are easier to manufacture, and if the outside is lined with fireclay bricks, then there will be no fundamental difference between the 2 units.

Boiler installation methods

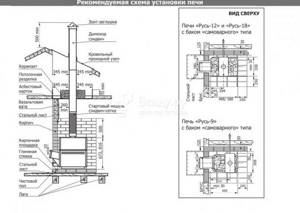

If the structure is equipped with an external tunnel, then the best option would be to install the boiler in the partition opening between the steam room and the dressing room. To control the operation of gas burners, use a remote control panel or control valves on the board. According to the standards for installing boilers and furnaces, the area in front of the tunnel must be illuminated either by an emergency lantern or through a window opening.

Methane heaters are installed mainly under the wall under the exhaust ventilation opening. For low-power models, you can choose a place next to the entrance door of the steam room.

Recommendations

The principle of operation of the device is what you should understand before making the device. You can consider it using the example of a burner for roofing work. How does the burner work?

- The device is connected to the reducers of oxygen and propane cylinders by a system of supply hoses.

- Reducers are placed on the cylinders to create working welding pressure.

- A diagram for gas and oxygen is assembled, the tightness of the connections is checked, the nodes are secured, after which the gas can be opened with valves.

- The gas pressure is set to the operating value and the valve opens.

- The fuel is supplied through hoses to the propane appliance.

- The injector carries out the mixing process to form a gas-air environment.

- A working flame with a temperature reading above 2000 degrees comes out of the device.

When performing any welding work, you must wear personal protective equipment: gloves and goggles, special shoes. You can work with propane cylinders only in a well-ventilated area, and at sub-zero temperatures, any actions with the burner are excluded.

What you should absolutely not do:

- work near open fire;

- keep the cylinder tilted;

- place vessels under the sun;

- carry out work without a gearbox;

- Warm up the gearbox over an open fire.

If you can clearly smell the gas, work with the burner should be stopped by closing the valve on the cylinder. Homemade burners, depending on the purpose of use, can be different: burners with a VK-74 valve, devices converted from an acetylene gas cutter and mini gas burners. It is realistic, profitable, and useful to build every homemade device. Only initially you need to decide on the type of structure and its parameters. The gas burner is also used in private households and for commercial purposes. In plumbing, a metal workpiece is heated with a torch, which ultimately comes out quite hardened.

How to make a gas burner, see below.

Gas-wood boiler

For those who cannot imagine visiting a steam room without the unique smell of burning wood and want to save on the operation of the bathhouse, a gas-wood stove may be the ideal solution.

Such a heating device is a modern universal design that allows the use of various types of fuel: natural and liquefied gas, coal and wood. This is possible due to the fact that such stoves have removable elements necessary for working on solid fuel and gas.

Devices designed for gas combustion consist of burners, filters and various valves. At the same time, to operate a solid fuel stove you need a fuel receiver. Such heating devices are not new on the modern market. They were used back in Soviet times. A striking example of this is the OGV (heating gas water heating) boiler.

The equipment necessary for gas combustion is installed in the ash pan of the furnace. If it is dismantled, the boiler will function properly using solid fuel.

Gas-wood stoves are very popular not only due to their versatility. Their cost is at an acceptable level, which is an important factor for bathhouse owners.

Do-it-yourself gas burner for a sauna stove: how to make a homemade device

The key element of the heating gas unit is the burner nozzle. It creates a mixture of fuel and air that supports combustion. If you make a gas burner for a sauna stove with your own hands, then this fact gives confidence in the reliability of the design. And this, you see, is a fairly compelling argument in favor of making your own.

You can make a nozzle for a sauna stove from scrap materials. Empty gas cylinders, scraps of metal pipes, and parts from old equipment will be used. Before commissioning, the finished product is checked by Rostechnadzor specialists.

We'll tell you how to do everything correctly. We will tell you how to obtain a certificate of suitability for a homemade gas burner. It confirms the safety of the device and allows connection to the heating system of the bathhouse.

Rules for installing gas furnaces

The installation process of gas-fired heating devices must be approached as responsibly as possible. Not only the efficiency of operation, but also the safety of people visiting the bathhouse depends on the correct installation.

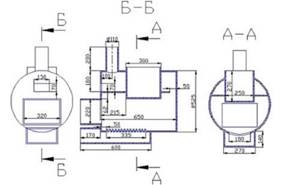

Experienced specialists with extensive experience in this field should work with gas furnaces. Having entrusted the installation of a gas boiler to a professional, the installation process should still be monitored. When carrying out such work, you need to pay attention to the following things:

- the distance from the wall to the stove must be at least 50 mm. In this case, all surfaces parallel to the walls of the boiler are made of non-combustible materials or lined with such;

- the fireproof base of the boiler must protrude at least 100 mm from its edges;

- The height of the burner connector without a lining should vary from 470 to 550 mm, with a lining - from 615 to 680 mm, width - from 350 to 450 mm and from 515 to 665 mm, respectively.

Particular attention should be paid to the chimney. The gas stove is connected to the chimney duct using stainless steel pipes. In this case, the pipe bends must fit into each other by at least half a diameter.

The gas boiler is installed simultaneously in the steam room and the dressing room. The front side with the burners should be placed in the dressing room. This eliminates the possibility of fire extinguishing due to water ingress. A boiler with water and a heater are placed in the steam room.

A prerequisite for operating a gas stove is the presence of a hood and windows with vents in the dressing room. Doors must open outwards. The length of the chimney channel must be at least 5 meters.

If the chimney is made of different materials, for example, stainless steel pipes are connected to the stove, and then the channel is made of brick, then the connection point must be completely sealed. This place in the heating system should be checked as often as possible.

Where to install the stove

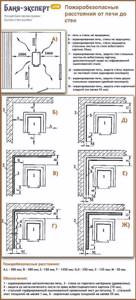

You can’t just put a stove in the middle of the steam room; it’s important to take into account the location of the air ducts, correctly calculate the distances from the walls, and think about protecting the walls of the bathhouse from heat. If you look at the “Appendix to SNiP 41-01-2003”, you will find lines where it is clearly stated that if the walls of the bathhouse are not flammable, that is, they have a fire resistance limit of 60 minutes or more, then a metal stove is allowed to be installed at any distance, but it’s better when there is more than 380 mm of free space between the steel stove and the wall

If you look at the “Appendix to SNiP 41-01-2003”, you will find lines where it is clearly stated that if the walls of the bathhouse are not flammable, that is, they have a fire resistance limit of 60 minutes or more, then a metal stove is allowed to be installed at any distance, but it is better when there is more than 380 mm of free space between the steel stove and the wall.

It is quite difficult to find completely brick or concrete walls in a bathhouse without cladding; often the finishing is done with highly flammable wooden paneling.

It’s another matter if the wall material is wood. In this case, you should adhere to the following rules:

- When purchasing a factory stove, ask for instructions for it and carry out the installation strictly according to the manufacturer’s diagrams. This rule is stated in SNiP 41-01-2010, namely in paragraph 6.6.2.19 (Individual stove heating);

- there should be more than half a meter from the hot walls of the unit to the walls not protected by screens;

- the wall or partition through which the fuel channel is discharged must be made of non-combustible material from the floor itself to a mark of 25 centimeters above the combustion door;

- the thickness of the non-combustible wall through which the fuel channel is routed must be 12.5 cm;

- if the ceiling in the steam room is thermally insulated and protected with plaster over a metal mesh or similar, then the distance from the top of the metal stove to the ceiling should be more than 80 cm;

- in cases where the ceiling is not protected by fireproof materials, the distance from it to the stove should be more than 1.2 m;

- from the fire door to the opposite wall there should be more than 125 centimeters;

- Leave 3 cm between the wall and the front wall of the stove with an external firebox.

Fireproof distances from the stove to the walls

When choosing the best location for your own furnace, take into account the location of such elements as external heat exchangers, wall-mounted heaters, hot water tanks, and pipelines for remote tanks. These elements must be freely accessible for repair and maintenance.

Installing a gas boiler in a bathhouse with your own hands

Before connecting the equipment, it is necessary to obtain the appropriate permits and approve the project with the authorities. Develop a gas supply project in a specialized service, and then send it and accompanying documents for approval, for example, to Gorgaz. You will need papers from the manufacturer: equipment data sheet, instructions, certificate of conformity.

Work with gas equipment is carried out by specialists in accordance with accepted rules and regulations: SNiP 42-01-2002 and II-35-76, set of rules: SP-41-104-2000. They provide a detailed description of how to properly perform this work, and what is strictly prohibited from doing. For example, the diameter of the chimney is selected in accordance with the power of the device using special formulas.

Wall-mounted gas boilers for heating water

Having received the necessary permits, you can begin work: install a gas pipeline and water supply, line the wall with fire-resistant material, make a hole for the chimney.

- Flush the device's pipe systems.

- Attach wall-mounted equipment to the slats.

- Make holes in the wall, secure the planks with anchors or self-tapping screws.

- Secure the boiler to the mounting strips.

- Attach taps and filters to the pipes;

- Connect the taps at the inlet and outlet;

- Install squeegees;

- Connect the heating system;

- Connect the squeegee to the heating;

- Connect the water supply;

- Connect the chimney.

A separate room is allocated for floor equipment. The walls and floor are covered with special fireproof materials. The unit is screwed to the floor. The rest of the connection diagram is identical to the wall-mounted version.

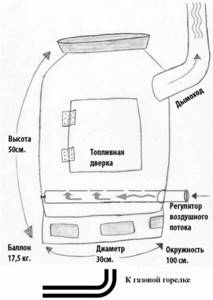

Gas sauna stove from a cylinder

To independently assemble a gas stove for a bath, you will need to collect and purchase the following materials:

- You need to buy an atmospheric burner at the construction market or in a store with gas equipment.

- Find an old but not rusty gas cylinder. A new cylinder, large-diameter pipe or sheet of metal with a thickness of 8 to 16 millimeters will also be suitable.

- For the base of the heater you will need thick metal, for example, a brake disc from a car. It will last for at least several years.

- A gas pipe with a diameter of 5 centimeters and a length of approximately 3 meters.

- A pipe with a diameter of 10 centimeters, which will be used to remove gases.

- Some copper or bronze elements to connect parts.

- Additionally, you will need to acquire the following tools: grinder, welding machine, drill, measuring instruments.

After assembling the complete set of tools, you need to use a grinder to cut off the outer part of the cylinder so that the cut diameter is equal to the external size of the brake disc. Then, using welding or a drill with bolts, you need to attach the disk to the cylinder.

The next step is preparing the air supply pipe. In a pipe with a diameter of 5 centimeters you need to drill about ten 5-mm holes.

A hole with a diameter of approximately 55 millimeters is also made at the bottom of the cylinder. The whole, that is, not drilled, part of the five-centimeter pipe should extend out of the cylinder by about two meters. It must be welded to the cylinder.

First you need to cut the workpieces with a grinder according to the sketch. Then weld all the components using a welding machine. After completing these procedures, you must also grind all welds. The same grinder copes well with this task

The pipe that will supply gas is welded in the same way. An adapter is attached to the second end of this pipe, with which you can connect the device to a gas pipe or gas cylinder.

A hole is cut out on the cylinder for the chimney and the corresponding pipe is welded. Using a grinder, a rectangular hole for the door is also cut. The hinges are welded and the door is hung directly on them. You also need to attach a handle to the door.

In this way, a simple model of a gas oven will be made. Gas is supplied to the burner through the pipe. The combustion process is started, depending on the burner, by piezo ignition or electric pulse.

Features of gasification of a bath

Russian government decree No. 509 of 2008 states that gasification of a bathhouse is allowed. The only condition is that its use for commercial purposes is prohibited.

If the boiler is equipped with an atmospheric burner, the inspector will check the ventilation device and draft

The project should include:

- the presence of a separate entrance (heat-resistant materials are used to make the door);

- availability of fire extinguishing and alarm systems;

- the equipment must be industrially produced and have a quality certificate;

- It is mandatory to have a ventilation system and a carbon monoxide detector.

Practice shows that the chance of obtaining permission to gasify a bathhouse increases if all work is carried out by specialists competently and efficiently. After the building of a bathhouse or sauna is built, it should be registered with the BTI. The next stage is a trip to the city gas supply office, where an application for gasification is written.

When the application is reviewed, an inspector will visit the gasification site. As a result of the inspection, changes may be required (installation of additional ventilation, alteration of the chimney). When permission is received, all that remains is to connect the equipment and insulate the bathhouse building.

After selecting and installing a gas boiler in the bathhouse, you can enjoy the result of your labor. Money and time costs are compensated by maximum comfort and safety. After all, modern equipment allows you to create an optimal balance between temperature and humidity, does not dry out the air and is ideal for lovers of a traditional bath.

Gas sauna - pros and cons

Recently, consumers have increasingly begun to pay attention to gas-fired sauna stoves. The low price of fuel, the compactness of products and the ease of their operation with a fairly high efficiency have become the key to such demand.

However, it is worth warning everyone that gas can become very dangerous in the wrong hands.

In the photo - a gas stove for a bath

Advice: It is better to use time-tested, factory-made stove options rather than homemade ones.

By the way, if you don’t know how to supply gas to a bathhouse, then there are no separate laws or regulations for this. You only need to coordinate the project with the fire inspection service, as well as with other authorities that are related to this.

Constructions

Gas furnaces generally have three main directions, they can be:

Gas sauna stoves are the second type of device (heating). The heating option is more intended for an autonomous heating system in the house and for hot water supply.

They are unable to maintain the required temperature at high humidity. The household class of devices is used for cooking and their main criterion is unpretentiousness and ease of operation, making them an indispensable assistant in the country.

In addition, gas sauna stoves are divided into groups according to the following criteria:

Housing material

A stove for a gas bath can be made of stone or brick, it can also be made of metal. Each of these types of housing has pros and cons.

Stone and brick

Brick sauna stoves, although they take longer to heat up, but, unlike metal ones, retain heat much longer. In this regard, you have to start heating the steam room at night in order to steam to your heart's content during the day.

Gas fired brick stove

The appearance of this design is almost no different from a traditional wood-burning stove. Therefore, it can be built into a classic bathhouse without disturbing its harmony.

Only in this case, the “furnace” door provides access not to the place where firewood is loaded, but to the heater, which is located inside and is heated not only by the heat from gas combustion, but also by radiant energy.

Since it is placed directly above the burner, special requirements are placed on it. Bath stones should be placed in a metal trough, the bottom of which must have sides so that water does not fall on the flame.

Metal heater stoves have very thin body walls, as well as a small load of stones. Thanks to this, they warm up quickly, although they cool down just as quickly. Another advantage of the design is its compactness, which makes it possible to install the structure in any sauna or bathhouse.

Metal stove-heater

Assembling a metal gas furnace is much cheaper. So, if you have the necessary skills and tools, you can make it yourself. Below are instructions for assembling the simplest version of a gas-powered sauna stove from a gas cylinder.

- a used gas cylinder, which can be purchased at a scrap metal collection point for nominal money;

- a used wheel rim, which will become the base of the heater. You can buy it there;

- gas pipes: two Ø 2″ – will be used to supply air and gas to the chamber, one Ø 4″ – for the chimney;

- atmospheric gas burner;

- connecting elements.

- Use a grinder to cut off the top of the gas cylinder so that a wheel rim can be inserted into the hole. It is better to weld them together using electric welding, but they can also be connected with bolts.

- Prepare the air supply pipe. Drill 8-10 holes Ø 5 mm in a 2-inch pipe. Also make a hole at the bottom of the cylinder with a diameter of 52-55 mm. The second, whole part of the pipe, should extend 150-200 mm from the cylinder. Secure it with electric welding.

- Installation of the gas supply pipe is also carried out. At the second end it is necessary to make an adapter to connect the structure to a gas cylinder or gas pipeline.

- Attach the chimney to the top of the cylinder and make a door by cutting out a rectangular hole with a grinder and attaching the hinges and handle to the resulting metal piece.

Scheme of a homemade stove from a gas cylinder

Classification by fuel type

Gas stoves can be either gas-only or combined (gas + wood), which are often called gas-wood stoves. But such versatility comes with additional costs when building a bathhouse, since the latter are large in size.

Therefore, the greatest demand today is for “clean” gas furnaces, which are more compact, lighter and safer to operate.

They can be connected not only to the central gas supply pipeline. The fuel can also be propane-butane, which can be purchased at regular car gas stations.

The latter is almost three times more powerful in terms of calorific value, so its consumption will be correspondingly lower. In addition, transportation and the possibility of storing fuel in liquefied form will facilitate the operation of these devices.

Tip: to save gas when using propane-butane, you need to replace the standard injector, which has a larger hole than necessary.

Flaws

To place gas cylinders, it is necessary to manufacture and install a special metal box in an area located at a safe distance from the bathhouse and the house. You can also place them in a strong container, which you then bury in the ground.

Burner types

There are two types of gas burners for saunas: