Disclaimer

It’s worth mentioning right away: the author is not an experienced stove maker.

The purpose of writing this article is to introduce the owners of country houses to a new concept, a way to dramatically increase the efficiency of a conventional Shvedka-type heating and cooking stove and make their home warmer at minimal cost. Judging by the information dug up during the writing of the article, these are very friendly and helpful people, which is not typical for the RuNet. You can receive an accurate and comprehensive answer to a specific question asked in the forum.

They will be happy to tell you the details of how heating panels are installed - the order, the size of the panel specifically for your home, the recommended type of panel and the thickness of its walls. The reason that discussion of any topic does not turn into throwing banana peels at each other is simple: stove makers are mature, experienced people. Finding out which of them is wiser and more experienced is simply not interesting to them.

Participants in furnace forums are, as a rule, middle-aged and sensible people who willingly share their knowledge.

What devices is the shield used for?

The two most common situations are:

- Purchase of a metal stove, which is also a fireplace.

- Using a brick cooker.

Also, a brick panel is in demand among residents of country houses in which Swedish Zhirnov stoves are installed. Outwardly, they resemble a fireplace, but structurally they consist of a firebox and a hob: most of the heat is spent on heating, a small part - on cooking.

Fehringer ovens are also in most cases equipped with a brick wall, which increases their productivity.

If the heating panel for a metal stove or brick stove is not used, then the heat obtained from the combustion of fuel literally flies out into the chimney. And if it is present, the heat is retained, which allows you to warm the room.

Stove with panel for space heating

The heat shield, which looks like a thick brick wall, can be compared to a gas-air heat exchanger, which is attached to any furnace in order to increase its operating efficiency. Gas flows, under the influence of chimney draft, move through vertical and horizontal channels inside the wall.

The operating principle of this device is based on heat extraction from flue gases. As a result, the brick structure heats itself and then heats the air in the room. Due to the heat capacity of the material, the wall cools down for a long time and continues to give off heat after the fuel burns out.

As a rule, the shield is not equipped with its own combustion chamber, playing the role of only an additional element. But sometimes the design provides for the presence of a firebox.

Conclusion

The role played by the brick shield is very important. This device allows you to increase the efficiency of stove heating when operating stoves of various types:

- iron stove-fireplace;

- stone oven;

- a simple potbelly stove, the efficiency of which usually does not exceed 30-40%.

When using a brick wall with air ducts inside, you have the opportunity to reduce wood consumption several times, ensuring proper heating in the room.

Metal cooking and heating stoves have one undoubted advantage - compactness. Such a unit will not take up much space in your home or country house. To increase the efficiency of steel and cast iron stoves, a brick heating panel is used.

Requirements for the arrangement of shields

It is important to remember the strength of the foundation and its high-quality waterproofing (for example, with a layer of roofing felt). This will prevent moisture from getting on the shield. It is also necessary to strictly take into account all fire safety requirements

It is also necessary to strictly take into account all fire safety requirements.

To prevent the formation of excessive condensed moisture and reduce draft, it is necessary to control the maximum temperature of the exhaust smoke, which should be no more than 120 degrees.

Features of materials

It is better to build the chimney wall from smooth and chip-free brick. All joints between rows, all seams must be properly and evenly sealed with mortar. The solution that has fallen down the unit should be removed from there through special openings to clean the oven.

The ideal size for laying the shield is considered to be half a brick in size, which prevents it from cooling quickly.

To build the shield, it is permissible to use ordinary brick. The only condition is that it should not be hollow. It is better to seal the seams between layers of brick not with cement mortar, which is not adapted to the influence of high temperatures, but with a clay mass.

A correctly folded heating shield increases the efficiency of the stove from 30% to approximately 65%.

Selection of materials

If you decide to build a shield with your own hands, then it is best to do it from high-quality ordinary brick. It is advisable to use smooth material without chips. The wall thickness, ideally, should be half a brick. This size is considered the most optimal and efficient when using a stove, since this thickness ensures the fastest heating and fastest cooling of the shield. The brick must be hollow. It should be noted that correctly laid brick increases the efficiency of the furnace by 35 percent!

Laying a heating shield with your own hands

Tools

In order to fold a brick stove panel yourself, you need to use the following tools:

- Trowel - it is used to apply and level the mortar;

- Roulette - used for marking;

- Cord;

- Level - to control the horizontal and vertical when laying;

- Plumb;

- Hammer drill;

- Screwdriver;

- Angle grinder;

- Diamond blade for cutting;

- Containers for water and mixtures;

- Seam cutting tool.

Materials

To fold a brick stove panel, you will need the following materials:

- Fireproof brick - the quantity is calculated based on the size of the structure;

- Sand, clay for preparing masonry mixture.

- You can buy dry mixture:

- Chimney damper;

- Cleanout doors;

- Roofing felt for waterproofing; Grates for ventilation

Order

Laying recommendations:

- Do not use cement mortar, it should only be clay-based;

- Immediately remove any remaining masonry mixture from the inside;

- The construction of the shield begins with laying the foundation. It should not be connected to the foundation of the building. It is necessary to waterproof it using roofing felt. There are many schemes for independently constructing panels for iron stoves; we present one of the options for constructing a heating panel made of bricks for an iron stove.

- Laying out should be done especially carefully, because the evenness of the entire riser depends on it. First, lay out the brick dry. It is necessary to measure all dimensions (check the horizontality, verticality of the masonry, diagonal).

- After checking all the parameters, install it on the solution. It is necessary to make fireproof cutting. If there is a wooden wall adjacent to the shield, it will be brick. With a non-combustible partition - half a brick. The optimal thickness of the seam in the masonry is 7 mm. With such a seam, the riser will look more aesthetically pleasing and will be easier to maintain in the future.

- To limit the draft of smoke and close the smoke hole, install a gate valve (or view) in the upper part of the shield.

- In accordance with the requirements of fire safety rules, the first 2 rows are blind, that is, without smoke ducts. Placed in compliance with dressing.

Recommendations for masonry

For laying the shield, only medium-fat clay with admixtures of sand is used

To fold a brick panel for a metal stove in a bathhouse or house, you need to follow the recommendations:

- The solution should only be clay-based. Cement cannot be used.

- During laying, you must immediately remove any remaining mixture from the inside of the structure.

- Construction must begin with the installation of the foundation. It must be separate, not connected to the foundation of the house. First, the brick is laid dry to check the horizontal position. After checking all the parameters, the foundation is secured with mortar.

- To limit the draft of smoke, you need to install a gate valve at the top of the structure.

The first two rows are laid out blank, there are no smoke channels in them. This is necessary in accordance with fire safety requirements.

Order

Doors should be installed on the brick panel for cleaning the channels from soot

The order of the bell-type heating shield is as follows:

- Rows from the first to the third are laid out in the standard way. In the third row, it is necessary to leave an empty space in which the fire door will be installed.

- On the fourth and fifth rows, a vent and a door for cleaning are mounted, and two plugs are installed here.

- In the sixth row, they begin to gradually reduce the number of channels, and a heating tank is installed.

- The seventh row is intended for mounting the grille. In order for it to be securely fixed, you need to cut off all the bricks that may interfere. The channel is closed to allow two further branches to be made.

- The eighth row is designed for installing two doors.

- On the ninth and tenth, a steel strip tab is placed.

- The next stage is the execution of door overlaps. On top they should be lubricated with a clay solution.

- A cast iron stove is installed on the twelfth row.

- On the sixteenth tier, you need to cut off the bricks in the area of the right corner, and on the nineteenth, a valve is installed.

- The twenty-second row is reserved for mounting the shield and samovar.

- To expand on the thirty-first row, the bricks are cut together, and at the next stage a ventilation grill is installed.

The order in all cases is individual, but is based on the same principles.

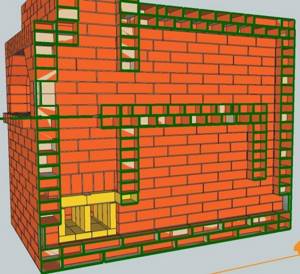

Brick heating panel.

The scheme is as follows. As you can see in the figure, smoke valves are made in the upper part of the shield. The second valve is responsible for the summer flow of gases. The third is the winter mode (it is open, and the gases go into the smoke circuits of the shield, the second valve is closed). While the gases pass through the channels, they cool, giving up part of their heat to the shield, and in a cooled state they go into the pipe. .

The dimensions of our thick-walled heating panel are 89 x 38 x 224 cm. Weight - 1.2 tons. Heat transfer: one good firebox - 430 kcal/h; two fireboxes respectively - 600 kcal/h. As a rule, the panels are plastered or laid directly from beautiful refractory bricks. Three smoke dampers make it possible to regulate the movement of gases. The operating modes are as follows.

Shield operating modes.

- In winter, the winter valve is closed, the first and second valves are open. Going along all the passages of the shield, the gases lose their heat, giving off their heat to the shield.

- In summer, valves 1 and 3 are open, the second is closed. Gases, bypassing the chimney of the shield, go directly through the pipe. For better ventilation of the room, a special channel is installed in the mounted pipe. It opens with a grille having louvers (valves). Their presence allows the ventilation system to be operated in 3 modes: open, half open and closed. Next we will see the laying of the heating shield.

Material for laying the heating shield:

- refractory brick - 400 pcs.;

- river sand - three to four bags;

- clay mixture - three bags;

- roofing felt for waterproofing - 1-2 m.

- cast iron valves 13 x 13 cm -3 pcs.;

- ventilation draught with valve (15-20 cm);

- cast iron doors 14 x 13 cm - 3 pcs.

When laying the foundation under the shield, it is not brought up to the level of the finished floor by two rows in height. One row of brick is placed on top of the foundation, waterproofing is laid over it, after which the shape of the stove is marked out. Next, the second row is laid, with its upper surface reaching the level of the finished floor. After this, you can start laying out the shield.

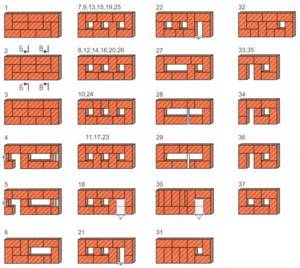

- 1st row - made of solid brick.

- 2nd and 3rd rows - according to the picture.

- 4th row - during the laying process, a window is left for entry to the furnace panel and 2 cleanings are installed.

- The 5th row is similar to the fourth, the ligation of the seams is exactly as in Fig.

- 7th row and next. odd, up to the 25th - according to the figure with the formation of three channels.

- 8th row and next. even numbers up to and including the 26th - according to the order in the picture.

- Rows 10, 11, 17, 23 and 24 are similar to the previous ones. However, for the purpose of better reliability, ligation of sutures occurs differently.

The 18th row is placed similarly to the 10th and 24th. A valve is installed in the channel on the right wall. The 21st and 22nd rows are placed with the installation of a samovar. 27th row - during the laying process, the two left channels converge into one and overlap. samovar. 28th row - a cast iron valve is installed during the laying process. 29th row - according to the order

Pay attention to the dressing. 30th row - during masonry, a valve is placed on the right side of the shield, an overlap on the left. channel. In the 31st and 32nd rows we bandage the seams differently. Top of the shield - overlap in three rows

This can be seen in the figure. This scheme is completely made according to fire safety requirements. 33, 34 and 35th rows - according to Fig. 36th row - during masonry we make a ventilation and smoke passage

The top of the shield will be covered in three rows. This can be seen in the figure. This scheme is completely made according to fire safety requirements. 33, 34 and 35th rows - according to Fig. 36th row - during masonry we make a ventilation and smoke passage

In kitchen wood stoves, most of the heat energy literally goes up the chimney, and only a small amount of heat is used to heat the stove. To trap hot gases and use them to heat your home, you need a heating panel - a brick wall with smoke circulation channels inside. A heating and cooking stove with a shield is ideal for a summer house and summer kitchen - it does not take up much space, effectively heats the room and can operate in winter and summer modes.

Stages of work

Before starting work, you must purchase a pick, plumb lines, a ruler, a level, a tape measure and a square, a cord, a hammer and a combination trowel, which is used to remove excess mortar.

The material for constructing a standard heating panel and fittings will require fire bricks (about 310 pieces), about 6 buckets of clay and about 4 buckets of sand, 1.5 meters of waterproofing roofing felt, 3 special cleaning doors, a 20-centimeter grille for ventilation and 3 pieces of valves (smoke) measuring 13x13 cm.

As mentioned above, the shields are erected on the foundation. Therefore, the process begins with the arrangement and waterproofing of the base.

Construction of the foundation

The solution in the foundation is leveled using a level, without reaching approximately 10 cm from the floor. A brick is placed on the dried layer, the base of the structure is treated with waterproofing material, and the outline of the unit is outlined. Then a second layer of brick is laid, finally comparing it with the floor level.

Don't miss: Which thermal device to choose?

The basic algorithm for laying the foundation is the same for arranging a heating panel of any configuration.

Laying a shield without an autonomous firebox

- Row 1 – completely lined with bricks.

- The 2nd and 3rd rows are laid following the order.

- At the level of the 4th row, 2 clearings are installed and a window is left among the bricks for further connection with the shield.

- On the 5th row, the same work is done, but attention is also paid to bandaging the seams of the stove. The 6th row is placed, not forgetting to leave 2 channels.

- Starting from the 7th, including all remaining odd rows (up to the 25th), lay out the bricks in order, leaving 3 channels.

- Starting from the 8th and including all even rows, they act strictly according to the order scheme.

- At the level of the 10th, 11th, 17th, 23rd and 24th rows, a different masonry is used, which ensures a stronger connection of seams.

- In the 10th, 18th and 24th rows, do not forget to put the valve on the right.

- At the level of the 21st and 22nd layers, a samovar is installed, which will be blocked on the 27th row, which combines the 2 left channels into one common one.

- A reliable latch is placed on the 28th layer, and the 29th is laid out in accordance with the order, not forgetting about the dressing.

- On the 30th row, the channel on the left is blocked, and the valve is reinstalled.

- The 31st and 32nd rows should provide ligation of seams and overlap with a thickness of 3 rows.

- The levels of the 33rd, 34th and 35th layers are laid based on the order, and on the final - 36th row, care must be taken to leave channels (ventilation with smoke).

Arrangement of the shield with an autonomous firebox

This scheme is more complex and provides for the possibility of separate combustion of the shield and the stove. Here you will also need much more material than with a simplified version of the shield.

After the foundation is securely installed, the first two layers are laid, following the ordering pattern. 3rd row - similar, but with an ash pan, which is needed for the firebox.

- The 4th layer is quite important: 2 valves are installed here (for winter and summer), as well as doors (blowing and cleaning) in the amount of 4 pieces. Similarly on the 5th row, but here they additionally bandage the seams.

- On the 6th level they install an oven with a water-heating box, and also reduce the size of the channels and block the doors.

- On the 8th layer, doors are installed: a large one for the stove and a small one for the shield.

- The 9th and 10th rows are laid according to the diagram, but on the 10th row a steel seal is laid over the oven structure.

- On the 11th row, the upper edge of the oven is smeared with clay, and the doors are also blocked.

- The final row is the 12th, serves to strengthen the frame and install cast iron flooring.

The need to heat rooms around the clock prompted the creation, instead of a standard potbelly stove, of a highly efficient heating panel that has excellent heat capacity and guarantees comfort both when preparing food and when staying in the room.

Types of heating panels

The design is classified according to various criteria.

By wall thickness:

- half a brick (thick walls, the best option if you plan to regularly operate the stove for a long time, and also as protection against potential fire);

- a quarter of a brick (thin walls that heat up faster, but at the same time cool down faster, while masonry in this option requires more careful compliance with fire safety rules, as well as laying the shield on a waterproofed foundation and indispensably equipping the furnace with a metal casing).

According to design features and installation features:

bell type - one or two brick surfaces connected by channels. In each cap, the inlet and outlet of the chimney are placed below its upper plane. The reason is that hot air tends upward, so that, having heated up and entered the hood, it will remain there until it cools down, and then, being displaced by hotter gas, it will go higher up the smoke exhaust pipe.

In this sense, a two-hood heating shield is more profitable - it will take more heat from the furnace gases than a design with one hood.

channel type - involves the installation of a spiral chimney channel, which has the same diameter in all sections of the pipe. Such a chimney can be vertical or horizontal, but, in any case, partitions are installed in it. This type also involves the installation of jumpers - in summer they prevent unnecessary heating of the entire surface, focusing heat exclusively on the stove.

Important! There is no need to install jumpers if a duct-type heating panel is “attached” to the fireplace, since the main task of the fireplace is to heat the room.

By configuration:

- straight – the most common form of the shield;

- corner - less common, but it saves space in the room and provides more heat due to its larger area.

Important! In order to separate kitchen worries and heating issues, experts recommend equipping the panel with a combustion chamber.

Classification

Thermal shields are divided according to several features:

- Wall thickness;

- Design or installation features;

- Configurations

Each of the above features divides the design into several more types. For example, the thickness of the walls can be either half a brick or a quarter. The first method is perfect for those who want to work with the stove for a long time and not be afraid of fire during prolonged use. In structures with thin quarter-brick walls, the main feature is that they cool much faster.

It is important! Creating this type of heating panel requires caution, compliance with fire prevention rules, and, most importantly, additional costs for a metal casing and a waterproofing system for the foundation.

Design and installation features also have their own divisions. There are two main types of structures: bell and channel types. In the first case, one or two surfaces are combined according to the cap principle using channels. The operating principle of this design is simple. The hot air will remain in the upper part of the structure until it begins to cool. After the air in the hood cools, other hot air will take its place.

Don't miss: Do-it-yourself chimney cleaning in a bathhouse: the best methods + prevention of soot deposits

Bell-type structures are characterized by low flammability

The channel type is simpler than the bell type. This case implies the same diameter in the pipe and the presence of jumpers in certain places of the structure, which allow you to regulate the heating or cooling of the surface.

The configuration of the shield is divided into straight and angular. Each configuration has its own advantages and disadvantages that affect the functionality of the shield. However, it has been noted that the corner design is used much less frequently than the straight type. This may be due to the fact that the corner structure is more difficult to construct. At the same time, it can save space, which will be an excellent solution if the room in which the shield is located is small.

Types and designs of shields

According to the internal structure, these structures are of 2 types:

- channel: in the body of the shield there is a developed network of gas ducts, which consists of several vertical channels connected to each other. Before exiting, the gases make a tortuous path along these passages, intensely giving off heat;

- bell-shaped: such a shield for a cast-iron stove or stove has one or two chambers with horizontal arches, where hot gases are retained until they cool down. Only after this can they enter the vertical channel and go down the chimney.

Duct-type heaters are structurally simpler, and therefore easier to fold. Bell shields are more efficient in terms of heat removal, but their design is much more complicated. It is not recommended for beginners to undertake their construction; the hand of a master is needed here. For independent construction, we present you with drawings and sections of a simple duct-type heating panel with three vertical gas ducts:

In order for our heating and cooking stove to be used in the summer for cooking, the design provides for switching the smoke circulation to the summer mode. The transition is carried out using three valves built into the gas ducts. In addition, in the upper part of the structure there is an exhaust ventilation shaft to organize air exchange in the room. To avoid the draft tipping over in strong winds, a grate with a check valve is installed at the shaft exit.

The following diagram shown below shows a metal cooktop with a bell-type heating hood. As you can see, here the gases, after leaving the furnace firebox, enter a chamber with a vault, from which 2 channels lead.

Since the only way to move from the chamber is downward, high-temperature combustion products are retained under the roof until they cool down. Then they become heavier and, according to the law of convection, leave the chamber space. In this case, to increase efficiency, the furnace with a heating shield is equipped with tubular heaters located inside the flues.

Since it is assumed that most interested people have little experience in the stove business, a simple channel design is proposed for self-construction, presented in the first drawing of the previous section. Unlike a master, an ignorant person will need the order of the heating panel for construction, which we will show in the diagram:

To build a channel panel according to this procedure, you will need the following materials and fittings:

- solid red ceramic brick – 309 pcs.;

- valve 130 x 130 mm – 3 pcs.;

- cleaning door 130 x 140 mm – 3 pcs.;

- exhaust grille with valve 150 x 200 mm;

- clay - 6 buckets;

- sand - 4 buckets;

- roofing felt – 2 m2.

It should be noted that the heating panel is laid according to all the rules of stove art. First, it is necessary to build a concrete foundation that is not connected to the base of the building. Its top should be 150 mm below floor level. Having laid a waterproofing layer of roofing felt on the foundation, they begin laying in accordance with the order. The masonry mortar must be thoroughly mixed from pre-soaked and filtered clay and sifted sand.

To correctly fold a brick shield with your own hands, you need to maintain a seam thickness of 3 mm, the maximum permissible layer is 5 mm. After laying the stones, each row must be checked for compliance with the horizontal and vertical using a building level and plumb line. Excess mortar protruding from the seams must be removed, and the inner surface of the flues must also be wiped with a damp cloth after laying 3-4 rows.

A do-it-yourself shield for a potbelly stove or any other heating and cooking stove must dry thoroughly. Small cracks that form should be carefully sealed with clay. After this, you can heat the stove, starting with a small pile of firewood and gradually increasing the temperature.

Types of shields

All types of shields for brick kilns are divided into 2 types of structures:

- channel;

- bell-shaped

Heating panel diagram.

Duct shields have a developed network of gas ducts in their design. It consists of separate vertical channels that are connected to each other. Gases can come to the surface when they overcome a complex maze of pipes. In the process of moving, they actively transfer their heat to the shield.

The construction of bell-type structures is more complex. The design includes 1-2 chambers with horizontal arches. Heated gases are kept in these chambers until their temperature reaches the minimum possible. Only at this moment will the gases be able to flow through the vertical channel into the chimney.

Despite the complexity of the design, bell shields remove heat much more efficiently. This completely compensates for the difficulties encountered during the installation process. Experts recommend assembling bell shields only to those who have minimal experience in such work. Beginners are unlikely to be able to cope with the task.

In the conditions of a country house, the easiest way to equip it with your own hands is a simple heating panel of a duct structure, which has 3 vertically located flues. Modern man highly values the functionality of buildings

It is important to arrange the structure in such a way that in the summer it can be used for cooking

This means that combustion products can leave the chamber only after cooling. As soon as their temperature begins to drop, the gases become heavier and gradually sink to the bottom of the chamber. To give the furnace maximum efficiency, additional tubular heaters are placed in the flue ducts.

Most often, heating panels for a brick kiln act as simple heat exchangers and are not equipped with their own combustion chamber. In more complex designs you can see a small firebox.

Bell shield

The bell-type heating shield consists of one or two flat surfaces that are connected by channels (three-channel). Warm air rises upward. Getting into the bell part, the air remains in it until it cools completely and is displaced by warmer gas, going higher. Therefore, the chimney is mounted below the upper plane.

It is important to note that the presence of two bell elements in order does not affect financial costs and the purchase of more material. The bell shield has some features that distinguish the brick structure from each other:

The bell shield has some features that distinguish the brick structure from each other:

- The ordering is possible straight and angular. The efficiency of its operation is the same, it only allows you to save territory.

- creating a combustion chamber allows you to separate the structure from the furnace, making it independent.

How to make a heating shield with your own hands

Making a heating shield is a very real task even for a person who does not have much experience in construction before. At first glance, some may think that the design is too complex, while others will consider this type of heating element simple. However, do not forget that each process has its own nuances that must be taken into account and must be known in advance, before the laying out of the material begins.

First masonry option

The first step is to pour concrete; it is important that the foundation is not connected to the base of the house structure. After the concrete has dried, it is necessary to lay roofing felt

It will serve as excellent waterproofing. For clarity, see the figure below.

Let's look at two simple basic methods of ordering.

In the first case, the parameters of the future shield will be 89x38x224 cm. To lay out such a structure, you will need the following tools:

- Trowel;

- Hammer with a small pickaxe;

- Plumb;

- Tape measure, ruler, square, level.

You will also need piping and lace. These simple tools, in most cases, almost every person has them, otherwise acquiring them will not be difficult.

The materials that will be needed to lay out the shield are also familiar to many and are sold in hardware stores. You will need 309 bricks, about four buckets of clean sand, at least 6 buckets of clay cleared of debris. You will also need 1.5 m of roofing material, 3 smoke valves, 3 small doors for clearing soot and a grate up to 20 cm in size.

Preparatory work

The foundation should be below floor level, the first layer of brick should be laid on it, and then roofing material should be laid. Another brick layer is placed on the roofing felt, and it should be at the level of the floor surface. This is the best and safest option to start laying the future shield.

Process

All actions must be performed according to the instructions:

- After laying the foundation, the first layer of bricks is laid. From rows 2 to 3, bricks should be laid depending on the order that is preferable.

- The fourth and fifth rows will require cleaning as well as the window in order for the connection to the shield to be successful.

- In the sixth row you will need to leave 2 channels.

- From the seventh to twenty-fifth rows, it is enough to follow the chosen order and leave three channels. In this case, the masonry will be in odd numbers of rows.

- From the eighth to 26th rows, it is enough to follow the order.

- On the eighteenth row you will need to install a valve. The twenty-first and twenty-second rows are laid together with the samovar. On the 27th row, after the samovar is blocked, it is necessary to combine both channels on the left side.

- On the 30th row on the right, a valve is installed. For row 36 you need to follow the order. Row 36 is the last, but requires no less attention, since it is necessary to leave ventilation and smoke ducts in it.

Second masonry option

Materials:

- Bricks will be needed here in the amount of 680 pieces;

- Purified sand and clay - at least 22 buckets of each;

- Steel corners 4 m;

- Door;

- Steel strip about 55 cm;

- Steel sheet no less than 0.5×0.7 m;

- Cast iron stove, preferably with 2 burners;

- Door for firebox, vent, cleaning;

- Valves;

- Box for water heating.

Preparation

Preparation in this case will not differ from the first option. A high-quality foundation that complies with all rules is required. The parameters of the future shield are as follows: 1.40x1.02x2.17 m. This design will be larger than the previous one, will require more effort and materials, but it will be durable and more heat-intensive than the previous version.

How to lay out a panel with an autonomous firebox

What does it look like

The shield can work in both summer and winter smoke circulation systems, allowing you to heat either the stove or the shield separately.

Important! Before starting the main masonry, you should build a strong, high-quality foundation with waterproofing (you can use roofing felt).

Features of masonry

The arrangement of the heating panel in this design has its own characteristics (the diagram can be found on the Internet by asking the appropriate request). In general terms the process looks like this:

- The 1st and 2nd rows are laid out in accordance with the order.

- In the 3rd row it is necessary to leave an ash pan under the firebox.

- 4th row: two valves are installed (one for summer operation, the other for winter) and four doors (two blower doors + two cleanout doors with brick linings inside).

- Row 5 is similar to the fourth (bandaging the seams is observed).

- Row 6: all channels are reduced, all doors overlap. An oven and a hot water box are installed.

- In the 7th row, two grates are laid (one for the firebox of the stove, the other for the firebox of the panel). The bricks on both sides of the gratings are crowded together. The long channel on the left overlaps to create two short channels.

- In the 8th row (placed in order) firebox doors are installed (one smaller for the firebox of the shield, the other larger for the firebox of the stove).

- The 9th row is placed according to the scheme, as well as the 10th, but in it a steel strip is placed above the oven.

- Row 11: the doors overlap, the top of the oven is greased with clay solution. To the right of the water-heating box, the channel is closed with a brick, to the left it remains unblocked.

- In the 12th row, cast iron flooring is laid, and a frame of steel corners is strengthened around the slab. This row is the final one in laying the slab.

Other orders are the laying of the shield (see diagram).

- In the 16th row it is necessary to cut off the brick on the right at the second channel.

- At 19, a valve is installed that closes the pipe (from this to row 25 inclusive, five are formed from the three existing channels).

- In the 22nd row a samovar is placed, then in subsequent rows there remains one channel - a pipe, and the shield is covered with masonry in three rows.

- In the 31st row, the pipe channel is widened by cutting off the brick.

- A ventilation grille is installed in rows 32 and 33 (a separate channel is created for this).

Important! Watch the thickness of the seams - it should not exceed 3-5 mm.

Dimensions to consider:

- Length – 1400 mm.

- Width – 1020 mm.

- Height - 2170 mm.

- Weight - 2800 kg.

- The length of the steel strip above the oven is 550 mm.

Device designs

The designs of heating panels are divided into two large categories: they can be thick or thin-walled.

About wall thickness

- Thick-walled panels are laid in half a brick. They must be warmed up well beforehand. When a hob with a heating shield is used constantly, such a device is advisable. Among other things, thick-walled structures are preferable from a fire safety point of view.

- A thin-walled heating shield is placed in a quarter of a brick. To meet fire safety requirements, such structures are often covered with metal casings.

- The surface of the walls can be plastered, tiled with tiles, or, after opening the joints, left unfinished. The fireplace stove with heating panel should be covered during its installation.

- The devices can operate in two operating modes – winter and summer. In the first of them the structure is heated completely, in the second it is partially heated.

Basic operating diagrams

Based on the principle of operation, there are two types of devices.

Duct shields

- Inside such a device there is a kind of labyrinth of chimneys, which have the same cross-section.

- When such heating panels are installed, they can be arranged in both horizontal and vertical partitions.

- The combustion products release thermal energy to the walls during their uniform movement along the entire length of the channels.

- In duct type devices, jumpers are often installed that bypass the chimney. They are fenced off with partitions. This is necessary so that in the summer the cooking stove does not heat the room.

In fireplace stoves, jumpers are not needed, because they are equipped with shields for greater heat transfer. A device for a powerful metal unit, for example, for Bavaria (thermal power 14 kW), should not be made without such a jumper. (See also the article Biofuel for fireplaces: features.)

Bell devices

A bell-type heating shield consists of one or more cavities that are connected by chimneys. The exit and entrance of the channel in all caps is made much lower than the top of its plane.

Why is this necessary? Heated air and furnace gases always flow upward. Having penetrated the bell, the gases will be located there until they cool. When they give up their heat, they will be displaced by a new portion of heated combustion products, and they will flow down the chimney into the street.

Features of the implementation of the shield scheme

- In addition to rectangular devices, when there is little space in the room, a corner shield is often installed. In addition to the fact that this design saves useful volume, due to the larger heat exchange area, it releases more energy.

- If you equip the shield with a separate firebox, it will be transformed from an additional element of the stove into a full-fledged heating equipment.

- You need your own fuel chamber so that you don’t need to heat up the cooking stove. (See also the article Heating a private house with wood: features.)

https://youtube.com/watch?v=YiJRfgw9s90

Disadvantages of metal cooking stoves and how to fix them

- The compact dimensions of metal stoves also have a drawback - the air heat exchange surface is too small.

- In addition, gaseous combustion products have a very high temperature - from +300° degrees or more. Therefore, you have to think about fire safety and thermally insulate the chimney.

- As is known, the efficiency of stoves is inversely proportional to the temperature of the exhaust combustion waste. To prepare food, cooking units do not use all the generated thermal energy.

- In addition, such stoves usually have short chimney ducts. Therefore, they also absorb some heat.

Note! Based on all this, the instructions note that the maximum heat loss of the units occurs in the chimney, through which combustion products are discharged into the atmosphere. That is, in fact, cooking stoves spend a large percentage of the heat from the fuel used to “heat the street.”

- Such heat losses are irrational from any point of view. There is a need to minimize them. One of the most common ways to reduce the energy losses of a furnace is to equip the unit with a heating panel yourself.

What is the device

- The shield is a small brick wall attached to the stove, inside of which there is a developed chimney system.

- Such devices are almost never made with a firebox . The shield heats up thanks to the gases removed from the stove. Structurally, the wall is not capable of releasing much heat into the environment.

- There are more complex and convenient designs, the price of which is higher . They are equipped with their own small fireboxes. You can make them independent of the hob and attach them, for example, to stoves with a fireplace.

- Brick has good thermal conductivity, and most importantly, high heat capacity . Warming up when lighting the stove or cooking, it gives off heat to the room for several hours. This way you can get an analogue of a brick stove. Only simpler in design and for less money.

Note! A heating and cooking stove with a shield is capable of having a thermal power of 7/14 kW. When the fuel burns out, the wall releases approximately 1 kW of heat into the environment for a long time. This is not enough to warm up the room on your own, but this amount of energy is enough to prevent it from getting cold quickly.

Arrangement of the shield

The order of the heating panel.

For self-construction, craftsmen recommend choosing a simple channel-type structure. A person who does not have experience in carrying out such work will additionally need order. Experts usually do without it. In addition to the arrangement for arranging the stove panel, you will need to prepare:

- brick;

- 3 valves;

- 3 cleaning doors;

- exhaust grille with valve;

- clay;

- sand;

- roofing felt

The laying of heating panels is carried out in accordance with all standards of stove craftsmanship. The first step is to build a concrete foundation that will not be connected to the base of the building itself. Check that its upper part is located 15 cm below floor level. A waterproofing layer is placed on the foundation, which is created from roofing felt. The laying is carried out according to the order.

To achieve high quality work, the thickness of the seams is left at 3-5 mm. Each laid row of stones is checked for horizontalness and verticality.

A brick stove will not be able to effectively heat the air in the room if it is not equipped with a shield. The heat transfer of the furnace depends on how well it is installed.

//www.youtube.com/watch?v=LcV5QrGrVkM

When arranging a shield yourself, you should realistically assess your own strengths and choose the design that you can recreate without outside help.

Installation safety rules

a sheet of waterproofing material on it , this will protect the shield from getting wet (as a rule, roofing felt is used, since it is the best option in terms of price and quality). The foundation must be strong. When installing the shield itself, it is necessary to take into account all fire safety requirements. All joints and seams must be carefully sealed and smoothed with a special mortar or masonry mixture. It is also recommended to cover the seams between horizontal rows of bricks not with standard cement mortar, but with a clay mass (the clay must have a certain percentage of fat content)