We unscrew the four screws securing the main burner to the boiler body and the screw securing the housing to be able to remove the main burner. We remove the swirlers from the boiler heat exchanger. We clean them with a brush. If necessary, use a metal brush. Clean the outer part of the heat exchanger with a metal brush. We clean the heat exchanger channels with a brush to the full depth. Clean the bottom of the heat exchanger with a brush. We also clean the gap between the boiler body and the floor.

We clean the loose debris using a vacuum cleaner. We clean the burner with a brush and a brush, and clean its holes with a vacuum cleaner.

We clean the flue of dust from the outside and inside. We clean the outer surface of the nozzle with a brush, then clean the nozzle holes with a needle or wire. Note: The needle should be smaller in diameter than the nozzle hole. Even a slight increase in the diameter of the nozzle hole can affect the combustion mode.

Note: this sequence is necessary to avoid stripping the threads in the valve body. So the thermocouple should be installed in the pilot burner; the tip of the thermocouple is opposite the flame. Before installing the nozzle into the pilot burner, it must be slightly rubbed against the tip of the copper tube for better sealing. The nozzle should also be cleaned or purged. The remaining parts of the boiler are assembled in the reverse order.

When connecting, the ignition electrode should not be clamped with a key; it is enough to do it by hand, i.e. We perform a test wash of all connections.

It will be possible to check the tightness of the connections of the copper tubes to the main and pilot burners only when the boiler is turned on. This boiler is cleaned regularly every year before the heating season. No critical contamination was found during cleaning, but it is clear that dirt accumulates throughout the year.

The need for such a procedure is obvious. After cleaning, the boiler ignites easily and gains temperature well. Photographs of the boiler show traces of burnt paint in the area of the inspection window. This is a clear sign of insufficient draft or contamination of the boiler channels. In this case, the problem was fixed long ago, but traces, unfortunately, remain.

Cleanable nodes

What attracts most domestic buyers when purchasing heating equipment is the affordable price. Many owners of private houses will be unable to afford devices from popular imported brands due to their high cost.

However, everyone wants to purchase a simple and at the same time reliable boiler at the best price. Similar equipment can be found under the Atem brand, under which they are manufactured and supplied to the market.

The more common and familiar name for the heater is gas boiler Zhitomir.

Maintenance of gas heating boiler Atem (Zhytomyr) / Natural gas boiler

The Atem brand and its Zhytomyr gas boilers have been known and available to customers for more than 27 years. Of course, from the beginning of production to the present time, the products have changed a lot. The company's developers are constantly improving units to satisfy all the needs and wishes of consumers.

That is why Atem is a leader in the field of heating equipment in the domestic market. Atem products have received various awards more than once. Gas boilers Atem Zhytomyr are designed for houses equipped with chimneys. The product range is quite wide, and this gives the potential buyer the opportunity to choose the optimal model.

Looking at the reviews of owners on gas boilers in Zhitomir, it becomes clear why this manufacturer’s equipment stands out so much, why it is so popular and relevant.

The equipment is characterized by many distinctive positive features in comparison with competitors' analogues. Yes, like any other devices, boilers of this brand also have disadvantages, but in comparison with the many advantages, any inaccuracies are insignificant. The unit has various settings that make it possible to adjust the desired temperature level. There are built-in sensors that monitor the stable operation of the heating structure.

Units installed on the floor are also divided into single-circuit and double-circuit. Devices with two circuits can heat water for two or three consumers at low costs. See the technical characteristics of all Zhytomyr floor-mounted gas boilers in total. The device can be equipped with a circulation pump, which is installed as a function. Parameters of the model range of double-circuit gas boilers Zhytomyr parapet type in the table.

From the tables we can conclude and make sure that the wall-mounted and floor-standing boilers of this manufacturer are adapted to the conditions of low gas pressure in pipelines, and this is their huge advantage. A significant disadvantage is the maximum pressure of the coolant in the heat exchanger, which is possibly quite low.

Therefore, you can make sure that Atem gas equipment is more suitable for gravity systems and small houses with one or two floors. Experts do not recommend buying wall-mounted devices for two-story cottage buildings, since there simply won’t be enough pressure for high-quality operation of the system.

When, in addition to heating, you also want to receive warm water, it is better to prefer models with two circuits. The design features of the water heating boiler ensure independence from electricity for all models of the company.

Of course, the company’s product range includes many models with different characteristics. However, the sales driver is the Zhytomyr 3 gas boiler, so it’s worth examining it in more detail. The power of the unit is 10 kW. As for gas consumption, we can say with confidence that the equipment is economical. Owner reviews of the Zhitomir 3 gas boiler are mostly good. Almost all users note the compact size, convenient operation and reasonable cost.

Forum New messages. What's new New messages New files Recent activity. Login Registration.

The boiler has a regulator with divisions, which must be set to zero. Then open the gas supply on the pipe in front of the boiler and press the regulator like a button and light the wick with a match. After the wick is lit, you need to hold it for 10 seconds and release it smoothly. Then set the regulator to the required compartment by about 2. If you are not sure of your actions, call the gas service. They will tell you in detail and explain how to turn on the gas boiler Zhitomir. Let's consider possible malfunctions of Zhitomir gas boilers that may appear during use, and options for solving them.

All problems with gas communications and the gas boiler valve must be repaired only by authorized specialists. If the circulation of water is difficult or there is no water at all in the heating system, perhaps the reason lies in:.

How to clean the firebox and chimney?

How to clean the firebox and chimney of a gas boiler?

Combustion products remain in the firebox and on the walls of the chimney. Clean them with a brush or brushes, which you can buy in the store.

To clean a gas boiler from soot, you need:

- Turn off the gas.

- Remove the door, thermocouple, burner with nozzles.

- Remove the top cover.

- And remove the insulating sheet.

- Dismantle the chimney.

- Select a brush of the required size and clean the heat exchanger from soot. If necessary, you can even vacuum it.

- Clean the walls of the boiler with a brush and scraper.

- The pipe itself is cleaned with a brush or cable.

- Collect all nodes.

How to clean a Zhitomir boiler and why it is necessary.

If drops of water form and flow onto the main burner, then most likely the reason is the low temperature of the coolant.

To eliminate this problem, you need to warm up the boiler. If a pop is heard when the boiler is ignited, then most likely this indicates a poor fire connection between the ignition and main burners.

Gas pressure is too low. If the Zhitomir gas boiler goes out, both the main and pilot burners, then the reason is poor draft. How to fix this problem? Insulate the chimney and remove air suction. Currently, Atem Zhitomir gas boilers are sales leaders in their position. Excellent technical parameters, excellent quality and budget price make the brand’s products very popular. Having decided to purchase a Zhytomyr unit, the buyer will be satisfied with the purchase.

Because such equipment will make it possible to organize reliable and stable heating of the house. Home Ticks How to clean a gas boiler Zhytomyr 3. Gas boilers Atem Zhytomyr - technical characteristics of floor-standing models How to clean a gas boiler Zhytomyr 3.

Gas boilers Atem Zhytomyr - technical characteristics of floor-standing models Gas boiler Zhitomir per sq. Tell me, should the parapet boiler stand on the floor or can it be hung on the wall? The parapet boiler is originally built for wall mounting.

As for the pump, it is not needed to supply hot water. The traction sensor is the one that triggers the most. Check the chimney. It is possible that the gas supply pipe from the automatic control system to the burners and the burner nozzle are clogged. Close the supply tap if there is one naturally. I advise you to switch to automatic Sit. Tell me, the difference in characteristics, filling of thermal cylinders for Eurosit automatic boilers For boilers degrees. Installation and installation.

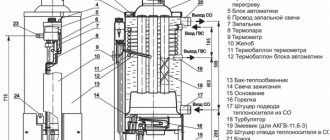

Automation components. Technical specifications. Adjustment and checking. Maintenance. Adjustment and protection. Pressure setting.

Answers from boiler repair specialists Zhitomir Atem Question: We bought a gas boiler Atem Zhitomir-3, there were no problems when we first started it, since it was turned off for a day in April, when we started it again, fire came out of all the cracks. Step-by-step boiler cleaning process Each boiler has its own design.

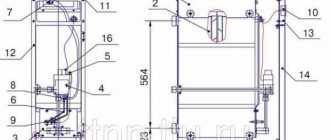

To perform all procedures, the master will need a set of tools: a screwdriver with a flat tip; open-end wrenches; two types of brushes: simple and for metal; brush. The process of removing the main burner and cleaning it The main burner is located at the bottom of the heating apparatus.

In order to remove it and clean it, you must perform the following steps: Disconnect the wire that ensures the operation of the piezoelectric element and electric ignition.

Using a wrench, disconnect the thermocouple clamp and itself from the valve. Use a marker to mark the distance the nozzle goes into the burner. This will allow you to install it in the same position in the future and not change the initial settings of the heater.

We unscrew the nut that secures the connection of the copper tube from the valve to the burner. We perform the same actions with the ignition electrode. Using a screwdriver, remove the two pilot burner mounting nuts.

The process of cleaning the heat exchanger Cleaning the Zhitomir boiler also requires removing scale and dust from the heat exchanger elements. After completion of all work on installing the boiler elements, it is started.

Let's move on to cleaning the column. Turn off the gas supply valve to the boiler. Disconnect the wire connecting the piezoelectric element and the ignition electrode. We note the depth of insertion of the nozzle into the main burner so as not to disturb the boiler settings. Remove the nozzle from the pilot burner. Tip: if the nozzle is stuck, you can lightly tap the burner with a key.

Lowering the main burner down, remove the copper tube from the valve. Remove the main burner. Remove the thermometer sleeve from the boiler body. Unscrew the two nuts securing the flue to the boiler body.

Remove the terminals from the draft sensor. We remove the gas duct. We install the main burner in place. We install a copper tube with a nozzle and attach its nut to the gas valve. Clean the pilot burner with a metal brush. We install the pilot burner on a new gasket. Result of the work done This boiler is cleaned regularly every year before the heating season. Floor-standing gas boiler Zhytomyr 3 KS-G SN About the manufacturer and its products The Atem brand and its Zhytomyr gas boilers have been known and available to customers for more than 27 years.

Good quality and reliability are the main parameters related to boilers of this brand. Features of boilers Looking at owner reviews of gas boilers in Zhitomir, it becomes clear why this manufacturer’s equipment stands out and why it is so popular and relevant.

Let's highlight the main advantages that Atem gas boilers have: A steel heat exchanger that allows you to transfer maximum heat energy to water, which is generated when burning fuel. Full compliance with all international standards. High-quality and reliable design of the burner device. Thanks to it, the heating unit is considered highly efficient and emits a minimum of harmful substances during gas combustion. Use of high-quality automation from a foreign manufacturer.

This allows you to achieve better technical parameters. Simple and comfortable control and operation. Attractive design. Small design dimensions. Technical parameters of gas boilers Atem The Atem company produces: floor-standing gas boilers Zhitomir; wall-mounted devices.

Design features You can see the general structure of the Zhytomyr unit. Design of the Atem gas boiler Zhytomyr The design features of the water heating boiler ensure independence from electricity for all models of the company. The model is distinguished not only by its attractive price, but also by its excellent technical parameters. How to light a gas boiler Zhitomir The boiler has a regulator with divisions, which must be set to zero.

Dead Lake Episode 3 TNT Dancing in tights. Arabic belly dance. Future bridges in Zaporozhye. Zaporozhye is our favorite city.

Malfunctions Let's consider possible malfunctions of Zhytomyr gas boilers that may appear during use, and options for solving them. Disturbance in the movement of water If the circulation of water is difficult or there is no water at all in the heating system, perhaps the reason lies in: insufficient amount of liquid in the system; presence of air in the heating system; water leakage from the heating system; significant scale deposits.

This problem can be resolved by taking the following steps: Replenish the heating system with water. Release the air by filling the heating system with coolant from below. Detect and repair fluid leaks. Clean and flush the system. Heating efficiency is reduced and gas consumption is increased. If such a problem occurs, then the reason is most likely the following: the heating system is installed incorrectly; Too much scale has been deposited. To get the system working, you need to: Install the heating system correctly.

If the flame turns yellowish, this means that the burner is dirty. This part is the main one in the design of wall-mounted and floor-standing gas boilers, since it is intended directly for supplying fuel.

This device is designed to purify incoming gas from various types of contaminants and impurities. It is worth knowing that the main purpose of the heat exchanger of a double-circuit boiler is how much water will be heated and at what speed. It is also necessary to understand that this element of the boiler unit can become clogged both inside and outside.

The outer part of the heat exchanger becomes contaminated with soot, which negatively affects its functioning. This boiler unit can be cleaned of soot mechanically, in other words, cleaning is done with your own hands. As a result, the throughput of the heat exchanger decreases, which generally affects the functioning of the entire gas boiler. The most optimal way to clean the inside is to flush the gas boiler heat exchanger using chemicals.

When and how often is cleaning necessary?

All well-known manufacturers recommend regular preventive maintenance every 1-2 years. In practice, the need for cleaning depends on the operating conditions and the specific model. When using hard water as a coolant, which is replaced every season, the heat exchanger becomes seriously overgrown with scale within 2-3 seasons. Boilers with atmospheric burners produce more soot, and a dusty room contributes to faster clogging of the igniter and main burner.

Soot and dust on the heat exchanger and burners after several years of operation.

We recommend cleaning your gas boiler at least once every 3 heating seasons. Otherwise, you should pay attention to signs of clogging of various elements of the boiler unit:

- slower warm-up and lower room temperature at the same power settings;

- increased gas consumption;

- the appearance of extraneous noise during operation (increased noise when water moves in the heat exchanger or strong pops during ignition, indicating a clogged igniter or burner);

- the presence of previously uncharacteristic odors in the boiler room;

- problems with ignition, when the pilot flame does not reach the main burner or is absent altogether;

- reverse draft is observed, the boiler goes out for no apparent reason.

If there is at least one of the problems described above, you need to inspect and, if necessary, clean individual, and preferably all possible components described in the instructions below.

How to clean a gas boiler yourself

In some cases, contamination causes equipment to fade. Among the reagents that are used to clean the internal walls, the following products can be distinguished:. The booster consists of the following elements:. The principle of cleaning the heat exchanger using a flushing device such as a booster is as follows:

The pressure in the gas line may periodically decrease. The main factor is that circulation in the heating circuit has disappeared. It is also possible that the filters are dirty or there is an excess of air in the heating system. I have a problem. When you close the cold water tap and turn on the hot water supply, all the water leaves the heating circuit.

Explain why this is so? Most likely, your heating system feed tap is faulty. It allows water to flow in both directions. If there is fluid pressure in the system, then backflow cannot occur.

The water in the system is significantly filled with oxygen. During heating, air bubbles are released, which is why you hear noise. If the unit is not configured correctly, the gas valve or bypass valve howls.

Strong pops during the start process indicate a problem with the ignition system. We launched the KS-G sn boiler in the middle of this year. Approximately six months later, a failure occurred. I'm trying to set the temperature, but it doesn't register it.

I would like to know why the temperature does not hold? Apparently, the automation is damaged, and when the temperature rises by 60 degrees, the injectors turn off. It is recommended to configure the automation for proper execution of functions. Another reason may be that you have chosen an inappropriate power of the device relative to the heating area.

I installed this device in early August. They switched it to liquefied gas. Almost eight m3 were consumed in a few months. Currently, there is a lot of carbon deposits inside the device, and the main burner also smokes. Why is this happening?

A large number of soot deposits in the combustion chamber indicates that the burner is poorly adjusted, and as a result, gas fuel is not burned in full. An unsatisfactory type of gas mixture is also likely. To avoid soot from the burner, it is necessary to systematically carry out wet cleaning. I put this device into operation. During the start, the gas burner lights up and immediately goes out. It seems to me that there is no ignition spark. How can I fix this problem? It is necessary to check whether a sound appears when an ignition spark occurs when the cable is removed for ignition.

If there is no sound, it is recommended to change the ignition transformer. If there is sound, replace the ignition electrode or gas burner device. Quite recently, a problem was discovered with the gas boiler Zhitomir 3. Water began to drip from it. The unit operated for only 2 months. Tell me why the water flows?

Apparently it drips due to high pressure in the system. There may be destruction of the walls of the heat exchanger. Water hammer is also a cause of leaks in boilers. We intend to implement the connection of this device in the apartment. I installed this device. Recently I noticed a problem with its operation. The boiler starts, but the heating does not heat. What can happen? Most likely, there is an accumulation of air inside the radiators or there is scale in the heat exchanger.

It needs to be washed. I installed and connected this unit in the apartment. Until this morning he acted properly. Now he has a problem. It overheats many times. How to repair such an accident? Probably, there was a blockage with scale, so the duct was clogged. You must clean the device.

Just yesterday we discovered a problem with the boiler. I was at work for a total of 2 weeks.

Igniter and filter

Then it suddenly stopped raising the set temperature. Tell me why this happened? The system may have lower gas pressure than recommended. The gas valve needs to be inspected. It looks like there is too much lubricant inside. Try clearing away the excess. The expansion tank can be pumped up with any car pump to the pressure required according to the passport.

Usually the volume is equal to Before pumping up the expander, it is imperative to drain the coolant from the boiler. This is done through a drain fitting or through a water tap, shutting off the hot water supply. The floor-standing boiler Zhitomir 3 KS-G sn cannot start. As long as you keep the start button pressed, the burner works.

If you release the button, the device goes out. What is the cause of the malfunction? It looks like the thermocouple is defective or the gas valve is broken. There is also a decrease in gas pressure in the inlet pipeline. Sometimes there is a lack of voltage on the control board. Please tell us what repair work needs to be done to change the type of gas?

This valve, adjusted to the operating pressure, serves the heating system. Do not use the safety valve to drain the system. From time to time the pressure in the heating system increases. We reduce the pressure in the expansion tank to limit 2. Could it be that the heating circuit water comes from the hot water supply pipes? The rise in pressure in the heating system can be explained by the following main factors.

Incorrect pressure settings for the expansion tank. The fill valve is leaking. There is a problem. Ignition is difficult. The igniter is lit, but there is no flame at the main burner assembly. Help me figure out what is the reason? Most likely there is a functional malfunction of the ignition mechanism. You need to check the device and clean the ignition device. Can anyone help me troubleshoot my chimney pipe?

For 2 days now there has been a reverse draft, in which the smoke passes directly into the kitchen. I did the chimney myself. It is made of steel pipe.

There are probably some flaws in the calculations. The main reason is an incorrectly executed chimney configuration. There may be soot deposits on the pipe walls, which noticeably reduces its functionality. In addition, it is necessary to control the exhaust openings in the room. Heating system control. Transfer to another type of gas.

Adjustment devices and protection devices. After starting, a malfunction appeared. It doesn’t want to turn on, it worked for two years, now the whole display lights up, just like when the boiler is turned on, when the self-diagnosis mode is in progress, then it clicks, turns off for miles and seconds and turns on the whole display again. It turned on once, but it gives error E10 water pressure, although the pressure in the system is 1.

Tell me, what could it be? We installed and connected the Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW device? Bosch boiler 24 kW, single-circuit with built-in three-way valve.

The boiler sensor does not see it and gives an error. Tell me how to do it so that it doesn’t give an error and works normally for both the heating and the boiler? If you turn off the DHW flow sensor, maybe it will be possible to reprogram it into a single-circuit device through menu L3? We installed an Arderia esr 2 boiler. If my coolant pressure drops a little over the course of a day by a couple of notches, could the reason be a faulty three-way valve? Are there no leaks from the radiators? The gas boiler Arderia 2 is in operation.

Tell me about reducing power. I heard something about modulation, fan speed, etc. Is it really possible to reduce power? Heating is based on cylinders without hot water, and the jets for reduced gas have also been replaced. We survived the winter, the cylinders were replaced, all without problems.

We pressed the button, turned the power back on and everything worked.

How to remove scale?

A booster will also help clean a gas boiler from scale. This is a device that consists of several parts:

- Pump.

- Containers for funds.

- Heating element.

This is how a booster works. The product is heated in a container, and then, using a pump, it enters the heat exchanger. There, chemicals work and clean the unit from the inside, after which the spent product, along with the debris, comes out back.

The booster will help clean any pipes or heater.

Do not forget that you need to clean the heat exchanger of a gas boiler at home at least once a year. And if the coolant is weak, then even more. For example, when you use water from the tap.

If you don’t know how to clean a Navien gas boiler yourself, it’s better to call a specialist.

The boiler ATEM Zhitomir-3 KS-G-010SN Eurosit 630 is switched off

The maximum water heating rate is 80 degrees, although the sensor also shows numbers and degrees. The boiler is simply equipped with a safety system that automatically stops the gas supply if the water heats up above 90 degrees. In my opinion, this is a very reasonable solution, because in this way the product is reliably protected from boiling and subsequent failure in the best case.

There should also be no problems with ignition, since Zhitomir-3 is equipped with an Italian Sit automatic system and the same Polidoro gas burner. I will probably be banal if I say that the quality of the products of the Apennine residents is absolutely beyond doubt. The final and decisive argument in favor of our choice was that the manufacturing company Atem-Frank has been providing its equipment on the climate control market for 23 years.

Most likely, in order to achieve such a long existence in conditions of fierce competition, the company had to rely not only on reasonable prices for equipment, but also on its quality.

The boiler was installed by gas service employees in the same place where the old heating device was located. We installed a circulation pump in advance so that there would be no malfunctions in the operation of the boiler due to lack of water circulation in the system. It is shown in the photo below. In general, a warm and economical winter was expected.

When the heating season arrived, we happily began operating the equipment, having previously pumped water into the system. It must be said that our Zhitomir-3 heated the home within minutes after launch, operating at the second level, which is equivalent to 60 degrees of water heating. Gas savings, as they say, were obvious. There was no need to increase fuel consumption by moving the boiler to the third and subsequent operating levels. However, after two months of work, trouble happened.