Autonomous heating systems based on a gas boiler are becoming the most common option for organizing heating of a private home.

They operate automatically and do not require constant attention and maintenance.

There are a lot of models of gas boilers on sale from different manufacturers, mainly European companies. They demonstrate high performance, but the price and complexity of the design scare off many buyers.

Domestic manufacturers have chosen a different approach to the manufacture of such equipment, based on simplicity and the absence of unnecessary components and parts.

One of these units is the Mimax gas boiler.

Gas boilers from Mimax

Mimax LLC is based in Taganrog. The company has existed since 2002. Initially, the company's activities specialized in the manufacture of automatic burners.

Our own models were designed and tested, demonstrating high performance indicators. Over time, the company updated its technological park and began producing gas boilers.

The company professes the principle common to domestic manufacturers - nothing superfluous, simplicity and reliability combined with low prices.

For the Russian user, the presence of wireless communication modules or electronic control of functions is not important.

He needs the heating system to work in cold weather, despite a power outage .

Mimax engineers took this into account when developing energy-independent and reliable gas boilers.

Rules for filling the system with water before turning on the gas boiler

Before lighting a gas boiler and turning on the heating system, it is first filled with cold coolant, which, after heating, will circulate through the pipes and radiators. During the first launch, everything is carefully checked so that further operation is uninterrupted and the equipment does not require repairs.

The unit body has a special tap located near the pipe to supply coolant to the system. During the filling process, the pressure in the system is monitored thanks to the presence of sensors and pressure gauges. In modern boilers they are already installed and there is no need to purchase them additionally. When the device is filled with water, the mark on the sensor rises. When it reaches the 1.5-2 atmosphere mark, the water supply is shut off and thus completing the filling.

These pressure parameters can be changed as they depend on the manufacturer's requirements for the operating pressure in the heating system. But filling with cold water does not end there, since replenishment will be required after the structure is freed from air pockets.

Kinds

The company's product range consists of two types of gas boilers:

- Floor-standing . Installed directly on the floor or a special fireproof stand. This promotes simplicity and high speed of installation, expands installation possibilities - there is no need to tie to load-bearing or sufficiently strong walls.

- Parapet . These are energy-independent boilers that do not necessarily require a radiator system and are themselves a source of heat. An analogue of such a device is the Russian stove, which heats the house due to its own radiation. Parapet boilers are good for small houses or apartments. They have a closed combustion chamber that does not pollute the atmosphere of the house with combustion products.

According to the set of functions, the company offers:

- Single-circuit boilers . Capable only of heating the coolant for the heating circuit.

- Double-circuit models . They can simultaneously heat the coolant for heating and prepare hot water for domestic needs.

IMPORTANT! At first glance, the best option is a double-circuit boiler, however, it has some disadvantages. The supply of hot water is limited; if the family has high needs for hot water, it is better to choose a single-circuit boiler in conjunction with an external storage boiler.

What types of Mimax boilers are there?

Heating heaters from the Taganrog manufacturer receive positive reviews, mainly due to their compactness and high performance. These devices can operate not only on natural gas: if you change the jets (injectors), you can switch to liquefied gas. According to their intended purpose, Mimax heaters are:

- Single-circuit - they are installed for heating purposes only. They are marked KSG. Next to the letter designation there is a number - this designates the thermal power of the device. The minimum heating capacity for KSG-7 is 7 kW, the maximum for KSG-40 is 40 kW. KSG stands for simply - Steel Gas Boiler. Based on the power, the consumer can judge the heating area. Typically 1000 W per 10 m².

- Double-circuit - they heat the home and provide the supply of domestic hot water. The two circuits have their own separate heat exchangers. Water and coolant do not mix. They are designated KSGV. Power range: 12.5–40 kW.

Any Mimax heater, single-circuit or double-circuit, has a thermometer on the facade indicating the heating temperature - a scale of 0–120 °C.

Advantages

- Low, competitive price. Depending on the power, their cost ranges from 10,000–17,000 rubles.

- Reliability. The equipment is ideally suited to our conditions.

- Availability of a certificate and compliance with all sanitation and fire safety standards.

- Wide power range, easy to find the right option.

How to choose

The gas heater model is selected for heating a specific area. Let's say a consumer decides to purchase a floor-standing boiler. To heat, for example, a private household with an area of 200 m², you will need KSG-20, and if you take it with a reserve, then KSG-25. When choosing, we use the above ratio: for every 10 square meters - 1 kW.

If, in addition to heating, you plan to heat hot water, you need to take a dual-circuit version with a power of 40 kW, no less. This is the main disadvantage of floor-standing devices with two circuits: you have to buy a model with double power.

- 7,000 W. This is the option with the lowest possible power. Suitable for a one-room apartment, a small house, a guard post. Saves fuel.

- 10,000 W. Suitable for a 2-room apartment. For a large apartment this power is not enough.

- 12,500 kW. This is the most popular option. This heating output meets most of the needs of the average home.

- 20,000 W. You can heat penthouses, multi-storey cottages, large offices.

- Versions over 20,000 W are used for heating industrial premises, warehouses, etc.

Series and models

Mimax designers have developed several series of gas boilers:

- VEGA . A line of single- and double-circuit boilers with a power from 7 to 31 kW. All models are equipped with a piezo ignition device and have a built-in gas reducer. In addition, VEGA models are equipped with a flue gas sensor and an overheat sensor that can turn off the boiler when critical situations arise. The heat exchanger is made of cold-rolled steel, which increases its durability. And heating efficiency is enhanced by thermal insulation, which reduces heat loss.

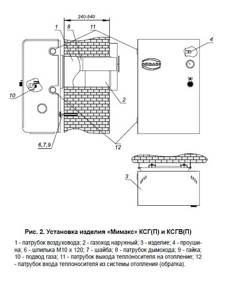

- KSG(P) and KSGV(P) . Single- and double-circuit models of parapet boilers. Can be installed on the floor or wall . Equipped with Italian automatic equipment that regulates the boiler operating mode. They have a rectangular steel heat exchanger that demonstrates high efficiency.

- KSG(IR) and KSG(M) . The model line consists of single- and double-circuit boilers with a power from 7 to 40 kW. IR models are equipped with Italian automatic equipment and Optima atmospheric burners. M models use their own automation developed by Mimax engineers . The secondary heat exchanger is a copper coil, the length of the tube is 12 meters. THIS allows you to use hot water almost without restrictions.

Model range of Mimax equipment

The mimax company offers the consumer the following products of its own production:

- Heating gas boilers Vega KSGV and KSG.

- Parapet boilers KGS (P).

- Solid fuel boiler Titan.

- Gas burners AGU-T-M, AGU-T-E and Optima.

Let's look at the most popular gas models.

VEGA Series

This floor-standing gas boiler is available in two variations:

- With one heating circuit (CHC).

- With an additional water heating circuit for heating water for domestic needs (KSGV).

In addition to the high efficiency of 92% for this type of boiler, the operating instructions contain the following technical characteristics:

- Atmospheric gas burner made of stainless steel.

- Turbulizers are used in the heat exchanger, which will allow for more efficient use of all thermal energy.

- Each boiler in this series is equipped with Italian SIT automatic equipment. This automation is simple, reliable and easy to use.

- The wall thickness of the heat exchanger is 3 mm, it is made of cold-rolled steel sheets.

- Additional thermal insulation of the combustion chamber and the unit body makes it completely safe.

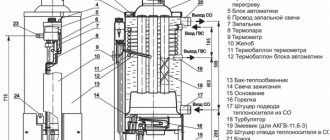

Devices MIMAX KSG and KSGV

In this model of gas heating apparatus, the Mimax company installs open burners of its own production and automatic equipment from the Italian company Optima. The attached instructions contain the following technical characteristics and design features:

- Power from 7 to 40 kW.

- Compact dimensions allow this boiler to be installed in small spaces in compliance with all safety requirements.

- Reliable thermal insulation of the combustion chamber with non-asbestos materials reliably protects the housing from overheating.

Mimax parapet models

The heating boiler of this series has the following features:

- The sealed combustion chamber allows installation of units in rooms that are not equipped with a chimney.

- Exhaust gases are discharged into a coaxial chimney. Air is also taken in through it to support the combustion process.

- Versatility of installation: such a boiler can be mounted on an external wall or installed on the floor.

- The steel heat exchanger ensures high heat transfer and durability.

- Sit automation and additional safety elements: pressure sensor, piezo ignition and thermostat in the heating circuit ensure high reliability and safe operation of the equipment.

All these design features of Mimax parapet boilers have received approval and positive feedback from consumers.

The worthy technical and operational characteristics of gas units of the Mimax brand are deservedly in demand among domestic consumers. A low price with excellent quality, reliability and safety is another advantage of this equipment, which is confirmed by numerous reviews on the manufacturer’s website.

Technical characteristics

Let's look at the technical characteristics of some Mimax models:

| Options | Values | |

| VEGA | KSG | |

| Boiler type | Gas heating | |

| Fuel type | Natural or liquefied gas | |

| Feature Set | Heating and hot water supply | |

| Power | 7-31 kW | 7-40 kW |

| Efficiency | 92 % | 88 % |

| Heating area (max) | 300 m2 | 400 m2 |

| Power supply | Absent | |

| Life time | From 15 years old | |

Model overview

VEGA

Single- and double-circuit floor-standing models with heating output from 7 to 31 kW. Thanks to the well-thought-out design of atmospheric burners, heat exchangers and turbulators, they are characterized by high efficiency - up to 92%. Equipped with SIT automatic equipment (Italy). All Vega heaters have a built-in gas reducer, piezo ignition, a draft sensor and a sensor that prevents the device from overheating. The heat exchanger is durable, as it is made of cold-rolled steel (2.5–3 mm). The use of highly efficient thermal insulation reduces heat losses of the heat exchanger. The body is painted with powder enamel, which gives the product attractiveness and anti-corrosion resistance. Operating water pressure parameters for all modifications are 0.2 MPa. Parameters of VEGA KSGV-31:

- Heating capacity - 31,000 W.

- The maximum heated area is 300 m².

- Efficiency - 92%.

- Fuel consumption - 3.45 m³/h.

- Weight - 131 kg.

- Duration of operation - from 15 years.

KSG(P) and KSGV(P)

These are parapet devices with one and two circuits. Their design provides for a closed firebox. They are used to heat buildings without a chimney. Such devices can be placed both in a house and in an apartment. Oxygen for combustion and smoke removal is carried out through a coaxial chimney crossing the outer wall. Universal connection, easy installation. Non-volatile type SIT automation was used. Sectional Polidoro burners were installed. The heat exchanger is rectangular, this ensures increased heat transfer. Efficiency - 92%.

As an example, we present the characteristics of the single-circuit model KSG(P)-16:

- Heating capacity - 16,000 W.

- Designed to heat 160 m².

- Efficiency - 92%.

- Fuel consumption - 1.7 m³/h.

- Weight - 64 kg.

- Minimum service life is 15 years.

KSG(IR) and KSG(M)

The manufacturer offers single-circuit models KSG(IR) and KSG(M) and their double-circuit analogs KSGV(IR) and KSGV(M). These are steel boilers, compact, with a stylish design. The IR modifications are equipped with automatic equipment made in Italy and OPTIMA atmospheric burners. Modifications of the “M” version are equipped with AGU-T-M automatic equipment, this is our own development. The latest versions are equipped with MAXIMA stainless steel burners.

Versions with domestic hot water are equipped with a copper coil with a diameter of 14 mm. The length of the coil is 12 m. This is 2–3 m more than that of domestic competitors. The large length of the coil ensures increased circuit efficiency and uninterrupted water heating. Thanks to non-asbestos thermal insulation material, heat loss is reduced and efficiency increases. The body is powder coated.

Technical parameters of KSGV(IR)-20:

- Heating capacity - 20,000 W.

- Designed for heating 200 m².

- Efficiency - from 88%.

- Fuel consumption - 2.43 m³/h.

- Weight - 66.5 kg.

- Operation up to 15 years.

Advantages and disadvantages

The advantages of Mimax gas boilers include:

- Reliability, resistance to external loads.

- Simplicity of design, absence of unnecessary parts.

- Ease of control.

- Ability to work with unstable gas and water supply parameters.

- Non-volatility of boilers, which allows you to maintain heating functionality in any situation.

- Durability of the main components, allowing the boilers to be used for many years.

- Attractive appearance, compact.

- Low cost, even compared to domestic analogues.

The disadvantages of boilers are:

- Inconvenient ignition system on some models.

- The absence of a circulation pump reduces the circulation rate of the coolant and requires the organization of a technological slope of the pipelines.

- Frequent contamination of nozzles and other boiler elements.

These disadvantages are common to all energy-independent models of gas boilers, regardless of the manufacturer and country of production.

Basic problems, repairs and adjustments of the Mimax boiler

_______________________________________________________________________________

Tell me how you can get rid of a small problem. A Mimax KSG 10 floor-standing gas boiler equipped with Eurosit 630 automation has been installed. If you ignite, the main burner burns brightly, but after 16-20 seconds it goes out. Repeated procedure does not bring changes. What happened? First of all, look at the draft sensor and thermocouple. Carry out diagnostics of the circuit contacts. Carefully disassemble the pilot burner and clean it. Adjust the pilot burner by reducing the gas pressure. Probably, the draft has become poor, and because of this, the igniter has a lack of air when the main burner device ignites. The flame began to smoke considerably and the burner device burned all the time and did not go out. The temperature cannot rise above the adjusted one, while the torch will burn. There is a lot of soot in the device. Local gas workers said it was bad traction. How can I fix the problem? Most likely, there is a lack of air. Maintenance should be carried out. Remove the burner assembly, blow out and clean the jets and burner. The heat exchanger should be cleaned from the outside. Can you tell me why the boiler smokes? What should I do to resolve this problem? Most likely, it shrank in the firebox. We can recommend cleaning the chimney duct. What should I do, explain to me when the Mimax KSG 12.5 boiler stopped starting? I hold the control handle, press the ignition key, then hold it in this position for about 5 minutes, start pressing, and the device goes out. Apparently the pilot tube is clogged. In this situation, we recommend that you perform maintenance. Another reason is oxidation of the terminals on the draft sensor. Remove the terminals and clean them from oxidation. Malfunction of the KSG 40 boiler with automatic Minisit 710. When you press the ignition button, there is no gas supply to the gas burner device. What could have happened? When this key is pressed, gas fuel is directed only to the ignition burner; there is no flow to the main burner. We installed this device. The process of switching from the wick to the main burner is a little annoying. Three pops are heard all the time. Could this be some kind of problem? Apparently the gas valve needs to be adjusted. We put into operation a unit of the same model equipped with an automatic 710 Minisit; it turns off when heated to approximately seventy degrees. Can anyone help fix the problem? Most likely, the traction sensor is turned on. The chimney needs to be checked. The device of the same model has been in operation for five years. At the beginning of the week, the heating stopped at fifty degrees, but the torch is burning intensely. What could be the reason? It looks like the gas supply pipe from the automation unit on the burner is clogged, as is the burner nozzle. In our house there is a Mimax KSG 16 parapet boiler equipped with Eurosit 630 automation. A week ago it broke down. The device begins to fade as soon as wind blows on the ignition device. I recently changed the thermocouple, but there is no change. What reason? When you turn on the main burner, this causes a decrease in the gas supply to the pilot burner, that is, the automation unit is activated. You must add fuel to the pilot burner. This can often happen as a result of a decrease in pressure in the heating system. In some cases, there may be a weakening of draft in the chimney if it is not designed correctly. Tell me why this model turns off in our house, mainly when there is wind and bad weather outside. How should the issue be resolved? When the igniter is started, the EMC should operate within twenty seconds. When the ignition fuse goes out, the EMC function is interrupted after 10 seconds, at which time you will hear a click. Once upon a time, I installed a KSG 25 boiler in the house. The house is small, about thirty square meters in area. As if the need is small, and the coolant does not heat above 60 degrees. The house has two batteries of twelve sections. I just don’t understand how to increase the heating temperature? To correct the situation, install a circulation pump. Often there is a drop in pressure in the gas pipeline. For what reasons does the boiler systematically overheat during operation? The main source is the circulation in the heating circuit has stopped. It is also possible that the filter is dirty or there is an excessive amount of air in the heating system. Recently there was a problem. When you close the cold water valve and turn on the hot water supply, water comes out of the heating circuit. Tell me the reasons? It appears that the heating circuit make-up valve is not functioning properly. It allows water to flow through both pipelines. When there is water pressure in the system, movement in the opposite direction cannot happen. For what reason does the unit begin to make noise, gurgle, and at times howl loudly and slam loudly? The liquid in the system is fairly saturated with oxygen. During the heating process, air bubbles are released, causing you to hear noise. If the device is not adjusted correctly, the gas valve or bypass may howl. Loud popping noises during startup indicate a problem with the ignition system. At the end of 2014, I installed a Mimax KSG 7 floor-standing gas boiler. About six months later, a failure occurred. I'm trying to adjust the temperature setting, but it won't hold it. Explain what this is? Apparently the automation is faulty, and when the temperature rises by 70 degrees, the injectors turn off. It is recommended to adjust the automation for proper performance of functions. Another reason may be that you have chosen an inappropriate power of the device relative to the heating area. We installed this device in October of that year. They switched it to liquefied gas. Approximately eight cubic meters were spent in 4 months. Currently, there is an excess of soot deposits inside the unit, and the main burner is still smoking. What does this mean? Too much soot in the combustion chamber indicates that the burner is poorly adjusted, and as a result, the gas does not burn completely. Poor-quality composition of the gas mixture is also likely. To prevent the burner from smoking, it is recommended to periodically clean it using water. This unit is in operation. During startup, the burner ignites and suddenly goes out. I believe the igniter is faulty. How can I fix this problem? Check to see if the igniter spark sounds when the ignition wire is disconnected. If not, the ignition transformer must be replaced. If so, replace the ignition electrode or pilot burner. Just yesterday a problem arose with the parapet gas boiler KSG P 10 Mimax. Water began to drip from it. It worked properly for only 3 months. Maybe someone can explain why the leak is happening? It may drip due to increased systemic pressure. There is also probably destruction of the walls of the heat exchanger. Water hammer can also become a source of leaks in boilers. We intend to install this unit for a country house. Explain what is the nominal gas supply pressure (methane/propane) for these devices? In this type of equipment, the declared gas supply pressure for methane/propane is 150.0/300.0 Pascal. This device was put into operation. Recently there was a malfunction. The boiler starts, but does not heat in heating mode. What can happen? Most likely, there is an accumulation of air inside the batteries or there is scale in the heat exchanger. Try washing it. We use this device indoors. It worked well until last night. Currently he has a breakdown. The unit overheats daily. How can I fix this problem? Probably, scale has built up, causing the duct to become clogged. You just need to clean the unit. Just recently we discovered a problem with our heating boiler. Worked for a total of 2 months. After this, it abruptly completed raising the set temperature. Maybe someone can tell me what's going on? In the heating system, the gas pressure is less than required. It is necessary to inspect the gas valve. Looks like there's a lot of lube inside. Just remove the excess. Tell me how to pump up the expansion tank? The expander tank is inflated with a conventional pump to the pressure recommended by the instructions. Usually the approximate range is from 1 to 1.5 bar. Before pumping up the tank, you need to drain the coolant from the boiler unit. This is done through the drain fitting or through the water tap, shutting off the flow of hot water supply. The Mimax KSG 20 floor-standing gas boiler does not start. As long as we press the start button, the burner works normally. As soon as the button is not pressed, the device turns off. What is the cause of the breakdown? Apparently, the thermocouple is damaged or the gas valve is broken. A decrease in gas pressure on the intake manifold may also occur. In some cases, there is a lack of voltage on the electronic board. Remind us what type of service work needs to be carried out in case of changing the type of gas? First you need to replace the nozzles of the main burner device. Then change the modulator supply voltage. Upon completion, adjust the parameters of the highest and lowest pressure. What operating principle does the heating system protection valve have? This valve, adjusted to the required pressure, protects the heating system. The safety valve must not be used to drain water from the system. The pressure of the heating system periodically increases. We reduce the pressure in the expansion tank to 2.1-2.3 atm. Could it be that the heating system water is leaking from the hot water supply pipes? The increase in pressure in the heating system can be explained by the following main reasons. The pressure for the expansion tank is poorly adjusted. The make-up tap is leaking. A problem has been discovered. Starting is difficult. The igniter lights up, but there is no flame on the main gas burner equipment. I just can’t understand what is the reason? It looks like the ignition mechanism is faulty. You need to perform a technical inspection of the boiler and clean the ignition unit. Can someone tell me how to fix the problem with the chimney pipe? For two days now there has been a reverse draft, due to which smoke immediately penetrates into the room. I made the chimney myself. It looks like a metal pipe. There are probably some shortcomings in something. The main factor is an incorrectly designed chimney. Soot contamination is possible, which significantly reduces its performance. In addition, it is advisable to control the hood in residential areas.

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Troubleshooting boilers

- Gas water heaters

- Malfunctions and repairs of geysers

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Troubleshooting electric convectors

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Peculiarities. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and checking. Maintenance.

- BAXI SLIM

Adjustment and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAKSI - REPAIR

After starting, a malfunction appeared. It doesn’t want to turn on, it worked for two years, now the whole display lights up, just like when the boiler is turned on, when the self-diagnosis mode is in progress, then it clicks, turns off for miles and seconds and turns on the whole display again. It turned on once, but it gives error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me, what could it be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler shuts down with error E35 (stray flame). Tell me what to do? First season in operation.

- BAXI - SETTINGS

We installed and connected the Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW device?

- BOSCH - REPAIR

Bosch 6000 24 kW boiler, single-circuit with built-in three-way valve. The boiler sensor does not see it and gives an error. Tell me how to do it so that it doesn’t give an error and works normally for both the heating and the boiler?

- BOSCH - ADJUSTMENTS

If you turn off the DHW flow sensor, maybe it will be possible to reprogram it into a single-circuit device through menu L3?

- ARDERIA - REPAIR

We installed an Arderia esr 2.13 ffcd boiler. If my coolant pressure drops slightly by a couple of notches over 2-3 days, could the reason be a faulty three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia 2.35 is in operation. Tell me about reducing power. I heard something about modulation, fan speed, etc. Is it really possible to reduce power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected the Buderus Logano G234-WS-44 kW boiler, automatic Logomatic 4211. Heating is based on cylinders without hot water, and the jets for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the outside temperature was +16+18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and the red button light on the front wall came on. We pressed the button, turned the power back on and everything worked. This happened several times, then the boiler was turned off completely for the summer, what could be the problem?

- BUDERUS WALL

In the single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is used for DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real/actual differences for the better in the new generation turboTEC plus VU/5-5 compared to /3-5?

- VAILLANT - ADJUSTMENTS

There is a malfunction in the boiler, the green LED (power) is flashing, the instructions say that the thermal protection has tripped, the green indicator is flashing, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is fine.

- DAEWOO

In operation there is a double-circuit gas boiler Daewoo Gasboiler with an electronic panel. When the DHW is turned on, the heating heats up, the operating mode is summer. I removed the three-way valve, there is no dirt or wear. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The Electrolux Basic Xi wall-mounted boiler has been installed and connected. A problem began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts it gave error E1. How can I fix it?

- KOREA STAR

Koreastar boiler malfunction. The heating works perfectly, the hot water comes intermittently, when you turn on the hot water tap, cold water comes out first, then boiling water. After a few seconds it’s cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the Ferroli Domiproject 24 boiler - I set it to 60-70 degrees, it switches to minimum combustion, does not turn on, does not turn off. Restart is unstable. No pattern emerges. What to do?

- JUNKERS

In operation, a Junkers euroline gas boiler, when hot water is turned on, gas ignites, then goes out, and so on several times. If you turn it on while the heating is running, the water heating starts immediately. Tell me, please, what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. It is not possible to adjust the fan run-on. I set it to 30 seconds, but still 2 minutes. spins.

- OASIS

Malfunction of the Oasis ZRT18 boiler. The unit starts, the gas lights up, then goes out. It lights up again and then goes out (this happens three times). Then it lights up and works fine. It doesn't give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the Senor Duval gas boiler - the water pressure sensor shows 0.0, the indicator flashes red, the hot water does not heat up, but the water pressure in the apartment is good. How to fix the problem?

- VIESSMANN

Where should a condensate trap be installed in a coaxial chimney? The boiler wh1d with a closed combustion chamber is located at a distance of 1 m from the wall.

- WESTEN

Problem starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, error E01 after a crackling sound. I moved the fork around.

- BERETTA

The Novella floor-standing gas boiler is blocked - the green lights on the panel are on and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler has been installed and connected, which does not hold pressure at all: while cooling the heated water, the pressure drops to zero, although water is regularly filled. What about the pressure?

- SIME

Metropolis dgt 25 bf boiler malfunction. The hot water supply has stopped working, the heating is working, it does not display an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, whenever you try to turn it on or hot water, displays a GS error.

- WOLF

Wolf boiler in operation. Lately it has begun to behave strangely: during the pause between starts, it turns on the burner for one second five times, and 70 degrees appears on the display. Where to look for a problem?

- ACV

ACV Wester Line works very unstable: it often crashes, makes a characteristic knock and stalls when starting, but at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, the gas supply to the burner stopped. The piezo element clicks, but there is no ignition. There is nothing wrong with the gas stove, there is gas. What is the reason?

- KITURAMI

The Kiturami world boiler is malfunctioning and stops periodically. I clean the flame sensor and the unit works fine for a while, but soon the same thing happens again. He also began to smoke heavily. Maybe the problem is that the chimney is short, and it needs to be lengthened?

_____________________________________________________________

- IMMERGAZ - ERRORS

Errors of Nike Star, Eolo Star/Mini, Mythos boilers. Malfunctions of boilers with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler systematically raises the temperature to 80 degrees in winter mode. I called the repairman three times. He said that many models have this problem and suggested installing a programmer, but it’s not certain that it will help. Tell me how to solve this problem and will this programmer help?

- AOGV

Models 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The AOGV gas boiler was installed and put into operation. Problem with hot water supply. The heat exchanger was washed. Less than a month has passed and the water is not flowing again. We put a filter on the water, but time passed, and again there was no hot water. What kind of breakdown could this be?

- AGV

Installation and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and operating procedure. Automatic adjustments.

- NEVA LUX

The boiler Neva Lux 7023 is malfunctioning. It gives error E7 twice a month. But after reboot it still works. Now it gives error E6. It will work for 15 minutes and turn off. What could it be?

- ROSS

Design and automation unit. Ignition order. Malfunctions and repairs.

- ATEM ZHYTOMYR

Tell me, is it possible that due to low gas pressure the Atem Zhytomyr boiler goes out, a click occurs and goes out. What is the problem? Is it possible to temporarily disable automation and how?

- LEMAX

We installed a Lemax KSG-12.5 Premium gas boiler. After turning off the main burner, a clicking sound occurs after a couple of minutes, what is the reason? Tell me?

- KEBER

A KS-G gas boiler of 250 sq.m. was installed and connected. m. When ignited, it does not turn off, the temperature rises, if I am not mistaken, automatic Arbat 1. The flame is not regulated - it is too large. What to do?

- LIGHTHOUSE

I installed the Mayak gas boiler and connected it. It works fine. But the reason is this. When it works on unit it squeaks a lot, if you turn the knob 2-7 the squeak disappears. Tell me, what could it be?

- DANKO

We installed and connected a Danko gas boiler with automatic Kare, it works great on the igniter, but as soon as you add power to the burner, it goes out completely, yesterday it went out within 5 minutes, today it works for about 20 minutes and goes out completely. Has anyone encountered this problem?

- GAZLUX

The gaseko 18 boiler is in operation. When hot water is turned on, the pressure in the system drops after replenishment, the pressure reaches 3 bar. Have to reset. What's wrong, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, causing it to fail due to overheating. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Rinnai 167 RMF boiler malfunction. Recently I started showing error 14. How can I fix the problem?

- CELTIC

The Celtic DS boiler heats up to 45 degrees and sits all day, does not turn off and does not heat the batteries, sometimes it shows error A3. How can I fix this problem?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

The Seoul gas wall-mounted boiler stopped turning on due to a no-ignition error. How can it be eliminated? What exactly went wrong?

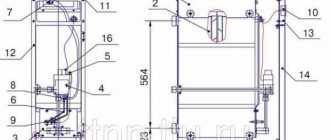

Device

The main elements of a gas boiler are a burner and one or two heat exchangers. The primary heat exchanger performs the function of heating the coolant from the burner flame .

The secondary produces hot water. The gas supply is regulated by gas equipment and an automation unit that can block the operation of the boiler in the event of a critical or emergency situation.

Smoke removal is carried out naturally, using a chimney and stove-type draft.

To enhance circulation and stabilize the operation of the system, an external circulation pump can be used.

Peculiarities

The Mimax KSG(P)-16 model has the following overall dimensions - 600x750x400 mm (WxHxD), while the weight is 65 kg. The parapet installation option involves mounting it on the external wall of the building and removing combustion products through a hole in it.

To obtain the declared power of 16 kW, the natural gas pressure must be at the level of 6.35-17.64 mbar; if this parameter decreases, the thermal power will also drop. ExpertKotel.ru reminds that most often in domestic networks the pressure is 12-20 mbar. The efficiency of the heater, with such indicators, is at a very good level and amounts to 92%.

Operating principle and main parameters.

The convection type of device involves the generation of heat from the combustion of gas fuel, while the boiler operates on natural gas (methane, consumption 1.7 cubic meters per hour).

Non-volatile operating principle

does not require connection to the electrical network and this is a plus, but usually, with this scheme, ignition must be started manually, and the coolant must circulate naturally, without a pump. The main disadvantage of non-volatile boilers is the lack of algorithms and systems for saving electronic fuel, for example weather electronics.

Primary heat exchanger.

In the case of Mimax KSG(P)-16, steel is used, its advantages are budget cost, lightness and tolerance to shocks and deformations, disadvantages are a little more susceptible to corrosion, less durable, an approximate service life of 5-20 years, depending on the intensity operation.

Management and control

The Mimax KSG(P)-16 gas boiler is controlled mechanically, which means that the main parameters can only be adjusted manually and, as a rule, there are few of them; there is no way to save fuel. The advantage is greater reliability than that of an electronic panel and cheaper repairs in case of breakdown.

Thermometer

necessary to control the temperature of the coolant in the boiler.

Protection systems

Gas control

— a useful and necessary function of the burner automatically stops the gas supply if the flame goes out for any reason.

Coolant overheat protection

turns off the burner if an abnormal water temperature value is detected.

Briefly about the operating instructions and setup

The boiler operates automatically. The simplicity of the design allows for long-term operation of the installation, uninterrupted by erroneous messages from sensors, which is typical for most European energy-dependent models.

The setup is done at the factory; when connecting, the technician only makes minor adjustments to the gas and water supply parameters based on local conditions.

The temperature in the rooms is adjusted by the user in operating mode; all other work must be carried out by a specialist from the service center.

Any independent intervention in the boiler design is considered as termination of the warranty agreement at the initiative of the user.

All the Pros and Cons

Among the advantages of Mimax, I would like to highlight its high reliability. High-strength steel of considerable thickness is used for the heat exchanger. The components are durable and designed for long-term service. Timely maintenance allows them to be used for more than 10 years. The heat capacity is high, it is possible to regulate the draft and connect a thermoelectric heater. The cost of the products is quite affordable, much lower than their European counterparts.

- Mimax KSG-7 – from 7900 rubles

- Mimax KSG-10 – from 8700 rubles

- Mimax KSG-12.5 – from 9450 rubles

The numbers 7, 10, 12.5 indicate the rated power of the product

It is also important that the product meets all requirements and standards according to the results of product certification in the city of Rostov-on-Don. In 2012, the Mimax company was awarded the distinction of the European Business Association “EUROPEAN QUALITY AWARD”

Most reviews about the use of such boilers have a “plus” sign. Compact dimensions, attractive design, a wide range of used capacities, and the ability to operate on both natural and liquefied gas are noted. The complaints are related to ignition problems. And this usually depends only on the quality of the gas supplied to consumers.

How to light a boiler

For models with piezo ignition, it is necessary to start using the corresponding button. The thermocouple heats up and ignites the gas, starting the boiler.

For other models, ignition is carried out in stages:

- The regulator is set to zero position.

- Open the gas tap. Press the regulator all the way down and bring the lit paper tow to the wick.

- After it lights up, keep the control pressed for about 10 seconds.

- Set the regulator to the desired position.

Ignition is somewhat complicated; it requires habit and automaticity of actions.

Installation, connection and startup instructions

Installation of the boiler begins with ensuring the removal of flue gases. In the outer wall near which the unit will be installed, a hole with a diameter of 280 mm or 340 mm (for boilers with a power of 16 and 20 kW) must be punched. Then the internal and external chimneys are attached to the boiler and the unit is fixed to the wall using the lugs.

From the street side, the outer part of the chimney is connected and the hole is sealed to ensure an airtight and tight fixation of the pipe.

A deflector is secured to protect the chimney cavity from the penetration of insects or birds and precipitation.

After this, the coolant and gas supply pipelines and water make-up are connected. Check the tightness and tightness of the gas pipeline connection using a soap solution. Then fill the system with water, monitoring the pressure according to the pressure gauge.

Open the gas supply valve and turn the control knob to the “on” position. Press the handle all the way and simultaneously press and hold the piezo igniter button until a flame appears on the pilot burner. After this, hold the control knob for about another minute.

If the flame goes out, try again after 1 minute. The main burner starts when the knob is turned to position 1.

Position 7 corresponds to the maximum power and heating temperature of the coolant. To turn off the burner, turn the knob to the “off” position.

Download instructions for Lemax Patriot boilers.

Why does it go out?

There may be several reasons for the extinguishing of a gas boiler:

- Stopping the gas supply in the main line. In this situation, you should immediately turn off the gas supply valve and contact the gas service.

- The appearance of soot and carbon deposits on the burner nozzles. Requires cleaning.

- Problems with gas equipment - gas valve failure, clogged pipes and other malfunctions. Here, the solution to the issue is available only to specialists from the service center.

- A strong gust of wind outside.

- The occurrence of reverse thrust.

- A draft that prevents normal combustion and disrupts the flame.

External problems - drafts, strong winds or reverse draft - are the most difficult to eliminate. Sometimes it is necessary to move the chimney, change its size and other complex and time-consuming work .

IMPORTANT! Repair of gas equipment can only be entrusted to specialists who have undergone appropriate training and received approval. Independent work with gas installations is prohibited and is subject to administrative prosecution.

Features of operation

Installation, connection, startup, configuration and maintenance must comply with the manufacturer's requirements. Each model comes with detailed instructions for the user to follow. To avoid problems, it is recommended to follow the operating rules:

- Before lighting the wick, the room is ventilated. The firebox is ventilated for 5–10 minutes. The knob that controls the burner must be closed.

- Checking traction: Apply a thin strip of paper to the holes located at the bottom of the front panel. If there is traction, the strips will be pulled into the holes. If there is no draft, lighting the gas burner is strictly prohibited.

- If the draft is sufficient, light the paper tourniquet by pressing the valve button. The flagellum is brought to the wick. When the fire becomes steady, the button is released.

- Smoothly open the control knob and make sure that the fire from the wick lights on the main burner.

- The air supply to the main burner is regulated by appropriate regulators; air must be supplied in the amount necessary to establish a stable blue-blue flame.

- While the equipment is operating, it would be a good idea for the user to periodically monitor the gas and traction. The fuel must burn without leaving soot. The color of the flame is blue-blue. Combustion should not be accompanied by hissing or popping noises.

Why does the boiler go out?

Causes of burner extinguishing and troubleshooting:

Ice build-up on the boiler head

They must be removed extremely carefully; you cannot rush - you can damage the system. Ice frozen inside, on the walls of the tip, blocks the access of air, and the flame goes out.

Defrosting is carried out slowly by removing the head of the device. Then it is brought indoors to allow the ice to thaw. While defrosting is in progress, the equipment can operate without the removed part. The pressure in the gas line has dropped. The gas distribution network or gas meter may be faulty. If the meter is broken, gas does not flow in the required volume - a problem is indicated by sounds that are not characteristic of the meter. The cause of a drop in pressure can also be a breakdown of temperature sensors or a violation of the tightness of connections. When the pressure drops, the automation signals a problem - the system turns off. You may smell gas. To solve the problem, you need to check the tightness of the connections using a damp sponge and soap foam. If there is a leak, bubbles will appear. We urgently need to call the gas workers.

How to remove soot

To clean the boiler from soot, you will need a set of tools:

- a metal brush or brush for cleaning surfaces;

- another brush needs to be purchased to clean the chimney - made of metal or plastic;

- scraper;

- steel cable;

- brush holder;

- hooks

Sequence of work:

- Shut off the fuel supply.

- Remove the door, thermocouple, nozzle, and burner tube.

- Remove the top panel.

- Remove thermal insulation.

- Remove the chimney.

- Clean the heat exchanger with a wire brush.

- To clean the heat exchanger channels you will need a vacuum cleaner.

- Clean the walls of the boiler with a brush and wipe with a rag.

- Clean the chimney with a brush. If it is too long, a steel cable may be needed.

When cleaning is completed, the device components are assembled in the reverse order.

Price range

The cost of Mimax boilers, depending on the design and power of this model, ranges from 10 to 25 thousand rubles, which compares favorably with the prices of boilers from other companies.

When purchasing, you should check the package contents and immediately purchase all additional devices and accessories.

For example, a circulation pump makes the operation of the system controllable and almost doubles the efficiency.

You should not skimp on concluding a warranty agreement. Repairing the boiler yourself can result in serious problems .

Useful tips

To start the boiler, it is necessary to supply power and set the heating regulator to the required operating position. The presence of a weak hum indicates that the circulation pump has started working. Using a screwdriver, lightly unscrew the cover on the detected part. But this must be done before the water begins to flow. If liquid begins to seep out, screw the cap back into place. Such actions are performed several times and after this the air pockets will be completely removed from the system. The gurgling sounds will also disappear and the pump will run quietly.

Boiler types

They are constantly improving:

- thermohydraulic;

- parapet;

- floor-mounted single-circuit or double-circuit;

- solid fuel Titan.

Parapet boiler

It is distinguished by its versatility and ease of installation, and long service life. A special feature is the use of a sealed combustion chamber. Thanks to a special coaxial chimney, maximum safety is ensured. Other features of this type of product: automatic systems for pressure regulation, the presence of overheating sensors, significant burner power, fairly high efficiency, safety.

Solid fuel boiler

It is simple in design, works by using any type of fuel: wood, coal, peat. You can reprogram from working with solid fuel to gas yourself, easily and not for long. This process will take no more than an hour. Advantages in economical fuel consumption due to the ability to regulate gas flow.

In floor-standing boilers, hot water supply is provided using a 12-meter copper pipe. It is longer than that of other manufacturers, which allows for increased efficiency, hot water extraction occurs uninterruptedly, and productivity increases. Special insulating materials Mimax allow you to save fuel. A single-circuit floor-standing boiler is used exclusively for heating. It has a single circuit and fittings for reliable connection of the coolant.

The dual-circuit version, in addition to heating, also includes a hot water supply function. There are two circuits in which the water does not mix.

When choosing a double-circuit option, one cannot ignore the need to use a sufficient amount of warm water. Therefore, the number of kW must be at least twenty.

Conclusion

The Mimax company offers various models of gas boilers for the home in an affordable price segment. When choosing a specific option, take into account its technical characteristics, operating features, type of installation, power and area for which it is suitable.

To create comfortable conditions in homes, including your own, the named heating boilers are well suited. Their practicality and thoroughness evoke a lot of positive feedback, helping to quickly conquer the sales market, improve, and expand areas of use.

Without exaggeration, the Mimax gas boiler produced in Russia can satisfy the needs of customers in full. Created by domestic engineers and designers, prepared for the conditions of any region of our country, it is publicly available, of high quality and easy to use. The control system is automatic. The required fuel is supplied to the combustion chamber autonomously and in regulated quantities. The device comes with accessible instructions.

Internal factors and aspects

The constant extinguishing of your heating boiler is not always due to the influence of external factors. Often the reasons are some malfunction of the heat generator itself or various additional devices.

One of the likely reasons that the gas burner in the boiler goes out may be voltage drops in the electrical network. This situation occurs if you do not have a supply voltage stabilizer installed. Or there is one, but it cannot cope with the load at a given level. It is necessary to select a stabilizer with the appropriate parameters.

Sometimes the electronic control board fails: it needs to be replaced.

If the unit's grounding is faulty, shutdown is also possible. It is necessary to check the potential between “0” and “ground” and, if necessary, install an additional ground loop.

Insufficient gas pressure. This may be due to low pressure in the supply line, faulty fittings, gas meter, etc.

Clogged nozzles also cause the boiler pilot and main burner to go out.

Often, the extinguishing of a gas heating boiler occurs due to a malfunction of the draft sensor. For example, the sensor contacts have oxidized - they need to be cleaned.

The reasons why the wick in the boiler goes out may include other damage and defects:

- thermocouple malfunction (burnt out or heavily dirty). The thermocouple needs to be cleaned or replaced;

- unreliable contacts in the automation unit. It needs to be checked, cleaned and tightened.

In these cases, the automation does not receive a signal from the thermocouple and the safety valve cuts off the gas supply. Its malfunction also entails the extinguishing of the wick or burner of the gas heating boiler.