Where to buy a boiler

In order to choose a Protherm gas boiler, you need to go to the official online store page: protherm.ru.

On the website you can find the nearest sales and service points of Protherm Gepard models, for example for Moscow:

- "GK PROJECT"

- .

- UniEnergoTech Trade LLC.

- LLC "ThermoStream"

- LLC "Incomplex"

- LLC "Comfort-Eco"

- LLC "Levada"

- STI Service LLC.

- LLC "Energobyt Service"

- LEX plus LLC.

In addition, on the website you can get acquainted with all the new boilers, their technical characteristics and production instructions.

The site’s specialists will help you choose the Protherm Gepard model that best suits the thermal loads of a heating supply facility.

Main models

The Skat model range is quite wide due to the different boiler capacities. Such a spread is necessary to fully meet the heating needs of any premises: from small rooms to large industrial premises.

Wall-mounted options are mainly single-circuit devices (but there are also double-circuit ones with the possibility of supplying hot water), created for heating apartments and residential buildings. They are simple and easy to use and install.

Important! Power ranges from 6 to 24 kW. Wall mounting eliminates the need to equip an additional room for a heating system

Scat 6 kW

A boiler with a production capacity of 6 kW, with proper configuration and a well-thought-out heating system, is capable of heating a house with an area of up to 60 square meters. The power is divided between two blocks of heating elements of 3 kW each. The multi-stage adjustment step is 1 kW. The mass of the modification is 34 kilograms. This makes it possible to install the boiler directly on the wall. Operating voltage 220 or 380 V (works from three-phase and single-phase networks). The equipment has its own simple software, which makes it possible to independently regulate the heating of the coolant.

Electric boiler skat 9 kW

In terms of power supply, this model is also universal: it can be powered from a single-phase network with a voltage of 220 V or from a three-phase network of 380 V. The power of 9 kW between two blocks of heating elements is not divided into equal parts: one of them is 6 kW, the second takes on the remaining 3 kW .

In proportion to the power, the possible area for heating also increases - for this modification it is already 90 square meters. A display is installed on the boiler panel. Which displays basic data about the system and the condition of the coolant.

12 kW

This option operates exclusively on power from a three-phase 380 V network and has two separate blocks of heating elements, each 6 kW.

This boiler provides heating for a home up to 120 square meters. Despite its fairly high power, it is a wall-mounted model.

24 kW

Power mode - from a network with a voltage of 380 V. Heating is provided by four blocks of heating elements of 6 kW each. The largest heating area is 240 square meters. Equipped with a display on the front panel, which displays detailed data on the status of the heating system and the environment. The boiler is also equipped with sensitive step-by-step power adjustment. This allows you not only to select the appropriate temperature regime, but also to ensure significant energy savings.

It is possible to connect an additional circuit for heating DHW to devices of any power and model. For equipment of any modification, the manufacturer provides a warranty period of one year.

Important! To save money on electricity bills, it is recommended to purchase two electric meters for night and day tariffs (if separate payment is provided)

Data transmission unit VR 920

The question of remote control of the boiler and temperature in the house arises not only in the case when the house or cottage is unattended most of the time, but also in any permanent residence. Since information about the main parameters of your boiler and its operating mode in your phone, it simplifies control of the equipment and allows you to save energy resources if the remote control device operates in thermostat mode.

A feature of most Protherm and Vaillant boilers is the presence of an eBus digital bus, connection to which makes it possible to obtain more information about the operation of the boiler. Vaillant offers the VR 920 Data Communication Unit, which provides remote access to heating, cooling and ventilation system controls. This unit only works when used with the multiMATIC VRC 700/x system controller. As a result, the cost of a remote monitoring and control system is comparable to the cost of a mid-range boiler.

Therefore, at most facilities and for sale, our company uses already proven and easy-to-use thermostats and controllers from Microline - Zont and others.

Installation Features

The kit includes instructions that describe the process of connecting and setting up the unit step by step

Before installing Proterm Skat heating equipment, it is necessary to coordinate all work with electrical distribution services.

Proterm Skat electric boilers with a power of 9 kW can be connected to a conventional 220V power supply. Installation of such heating equipment is carried out using a mounting strip. Such a unit has no certain restrictions on the choice of installation location. Of course, there are some requirements - you need free access for service, maintenance, adjustment and repair of heating equipment.

How to install

The Proterm Skat electric boiler is connected to the pipe system using pipes. The heating device is connected in such a way that the coolant can be easily drained in case of failures during operation without affecting the entire system. Additional valves allow you to fill the system with coolant and drain it. Also, in order to prevent freezing of water in houses with seasonal residence during cold periods, experts recommend removing the coolant completely from the system before temperatures drop.

The Proterm Skat boiler is connected to the electrical network through a power line supplied separately. The network cable is connected to the terminals, which are located in the lower corner of the case. All screws on the connectors must be carefully tightened. A boiler with a power of 9 kW can be connected to a single-phase network.

Brief operating instructions

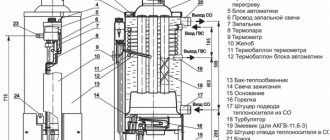

Proper adjustment of Protherm gas boilers ensures optimal temperature conditions in rooms of different purposes and sizes. Among other things, the regulation of the automation of such equipment helps to increase the efficiency of the unit, and also makes its operation reliable and safe. Modern automation solves problems:

- opening and closing valves in the gas supply system;

- the process of starting the unit in automatic mode;

- established or emergency shutdown of boiler equipment;

- adjusting the flame level in the burner using a temperature sensor;

- display on the screen of air temperature, coolant heating level and other parameters.

Instructions for setting up a gas boiler:

- connecting a thermostat to a temperature sensor recorded in the room and setting the required values allows you to obtain a comfortable heating temperature;

- installation of a thermostatic valve on supply pipes in front of heating radiators helps to change the cross-sectional area of the pipe and easily carry out the process of regulating the temperature of the coolant;

- the first start of the system at the maximum temperature allows the coolant used to freely enter the tank, which contributes to its maximum filling;

- Increased efficiency is facilitated by timely removal of scale and soot, as well as monitoring the lack of air in the system and installing a draft limiter;

- regulation of pressure indicators is carried out using special valve regulators, and in order to increase the pressure, a circulation pump is installed;

- reducing the power of the boiler burner is carried out automatically through the service menu, and increasing power is controlled by installing additional radiators or replacing existing ones with the most powerful models;

- many units are characterized by full operation at a pressure of 1.5 atm., and normally this value is 0.3 atm. lower than the indicators in the heating system;

- a slight decrease in the pressure level in the unit is restored during a standard restart;

- automatic selection of the operating mode of the gas boiler helps maintain the desired temperature level even in the absence of consumers in the room for a long time.

The process of turning on the boiler for the first time is accompanied by its short and vigorous operation after the unit is fully connected to the heating system, making it easy to check the correct installation of the boiler equipment and the full functioning of the heating.

Connection and operation instructions

When installing and connecting equipment, you must use protective equipment and follow safety regulations

When choosing an installation location, pay attention to:

- For the dryness of a specific place and the room as a whole.

- Structures that could easily catch fire should be kept away.

- Devices must not be installed in such a way that they interfere with access to emergency exits.

- Large household electrical appliances cannot be located nearby. This is especially true for air conditioners.

- Installation is strictly prohibited where there is a possibility of water and other liquids getting into the boiler.

You must also follow the rules:

- To protect the boiler and users, grounding must be done.

- It is necessary to take into account the weight of the equipment and select appropriate fastenings when installing wall structures.

- When installing additional modules, you must strictly follow the attached instructions.

- When installing the wiring on the electrical panel, separate circuit breakers are installed to power the boiler.

- Heating pipes must be laid so that there are no distortions.

Advantages and disadvantages

For a single-circuit boiler, a hot water boiler is connected

Electric boiler Skat 12 kW Protherm and other modifications of this brand have advantages and disadvantages. The advantages include:

- large selection of power models;

- reliable security system;

- Efficiency 99.5%;

- high-quality assembly of elements;

- modern design;

- possibility of connecting additional equipment;

- reliability during operation.

Among the disadvantages we note the following:

- there are no models with a boiler for heating water for domestic consumption;

- no thermostat included;

- It is unacceptable to use non-freezing liquids as a coolant.

The disadvantages are not significant; they can be ignored in accordance with the positive qualities.

Advantages and disadvantages of Proterm Skat boilers

Most of these disadvantages and advantages are inherent in most boilers operating on electricity.

Pros of Protherm Skat boilers

- High efficiency

- Easy to install

- Unpretentious in maintenance

- Eco-friendly

- Doesn't require much space

- Silent operation

Disadvantages of Skat series boilers

- High cost of electricity

- Dependence on power outages

Sometimes electric boilers are credited with shortcomings that are no longer relevant or were obviously incorrect; let’s look at some of them:

The boiler power is not enough to heat a house larger than 300 m2

This statement is incorrect, due to the fact that Skat boilers can be connected in a cascade to increase the heated area, if there is a shortage of 28 kW.

Frequent replacement of the heating element

Due to the fact that the heating medium is heated using a heating element, many believe that such a heating element will not last long, but you need to take into account the quality of the heating element itself and do not forget that it is not water that circulates in the system, but a coolant.

Electric boiler Protherm (Proterm) SKAT 21K

Electric boilers Protherm SKAT (Slovakia) are wall-mounted single-circuit electric heating boilers used in systems with forced water circulation. Protherm SKAT electric boilers have eight power modifications, from 6 to 28 kW (6 kW, 9, 12, 15, 18, 21, 24 and 28 kW).

Single-circuit wall-mounted electric heating boilers are intended mainly for use in residential premises. Therefore, not only technical stability and excellent performance are important to them, but also design. Protherm electric boilers are boilers with increased comfort, are easy to use and maintain, and create almost no noise.

All boilers can operate from a 380 V network, and models 6K and 9K can be connected to a network voltage of both 220 V and 380 V.

This version of the SKAT v.13 boiler has a liquid crystal display for indicating temperature, operating modes and other parameters, as well as displaying fault codes.

| Boiler | Heating elements, kW | Individual power stages, kW | |||||||||||

| Protherm 6K | 3+3 | 1 | 2 | 3 | 4 | 5 | 6 | ||||||

| Protherm 9K | 6+3 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

| Protherm 12K | 6+6 | 2 | 4 | 6 | 8 | 10 | 12 | ||||||

| Protherm 14K | 7+7 | 2,3 | 4,7 | 7 | 9,3 | 11,7 | 14 | ||||||

| Protherm 18K | 6+6+6 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | |||

| Protherm 21K | 7+7+7 | 2,3 | 4,7 | 7 | 9,3 | 11,7 | 14 | 16,3 | 18,7 | 21 | |||

| Protherm 24K | 6+6+6+6 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Protherm 28K | 7+7+7+7 | 2,3 | 4,7 | 7 | 9,3 | 11,7 | 14 | 16,3 | 18,7 | 21 | 23,3 | 25,7 | 28 |

- Single-circuit electric boilers;

- 8 power modifications from 6.0 to 28.0 kW;

- Possibility of setting up to 4 power levels;

- Stepped power switching with a time delay to protect against sudden power surges in the network;

- Overvoltage control;

- Possibility of working with weather-dependent automation;

- Pump run-out;

- Possibility of cascade connection of boilers;

- Built-in 10-liter expansion tank;

- Built-in circulation pump with automatic air vent;

- Possibility of working in a 220V network (models 6K and 9K).

Specifications:

Electrical voltage 3 x 230 V / 400 V, 50 Hz., 220 V (only Skat 6K and Skat 9K); Maximum operating pressure - 3 atm; Minimum operating pressure - 0.8 atm; Recommended operating pressure - 1-2 atm.; Efficiency 99.5% Maximum operating coolant temperature - 85ºC; The maximum pressure of the circulation pump is 50 kPa; Degree el. protection IP 40; Supply/return connection - ¾", drain - ½"

Documentation

The price of the product is indicated at a discount

The manufacturing company reserves the right to change the configuration and place of production of the product without notifying dealers!

The information provided is not a public offer

Components for boilers Proterm Skat

When purchasing a boiler, in addition to it, the manufacturer offers various accessories to expand the functionality.

Thermostats

For boilers Skat, Proterm suggests using three types of room regulators: Exabasic (article 6195), Exacontrol (article 0020159367) and Exacontrol 7 (article 0020170571).

Room thermostats for boilers Protherm Skat

The simplest Exabasic model has only a rotary switch for setting the temperature, Exacontrol is already equipped with a display and has mechanical controls. Modification number 7 - has a weekly programming function.

Connection diagram of the thermostat to the Protherm Skat boiler

Temperature sensors

To adjust the operation of the boiler relative to the temperature outside the window, you should purchase an outdoor temperature sensor (article 0020040797).

External temperature sensor for Protherm boilers SKAT

In the retail network, its cost varies around 2,000 rubles (38 euros).

Advantages and disadvantages of equipment

The only disadvantages of such heaters include the high cost of electricity consumed as the main energy carrier. Such boilers have many more positive properties:

- Full automation of all processes, which does not require human intervention during the work according to a given program.

Absolute noiselessness during operation, the only element creating a barely noticeable background noise is the circulation pump.

Electric boilers Proterm Skat have a high efficiency of up to 99%.

They do not require installation or connection to the chimney.

They depend only on the power supply.

Electrical equipment is environmentally friendly, given that during operation no fuel combustion is used and there are no emissions into the atmosphere.

Advantages and disadvantages of electric boilers Protherm Skat

Proterm Skat has a number of advantages over other types of heating:

- does not produce harmful emissions into the atmosphere, since it has no combustion products, so this type of heating can be called environmentally friendly;

- An electric boiler is an affordable type of heating. It is used where it is not possible to connect to mains gas or can become an alternative form of heating;

- does not require systematic maintenance, unlike, for example, gas or solid fuel models;

- silent operation;

- there is a heat level regulator;

- able to adapt to domestic water of poor quality;

- resistant to voltage surges;

- equipped with several types of protection.

Along with the advantages, there are some disadvantages:

- electric boiler Protherm Skat needs to be connected through a stabilizer;

- is unable to perform its work during a power outage.

Technical characteristics of electric boilers Proterm Skat

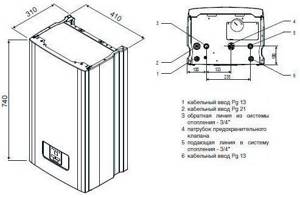

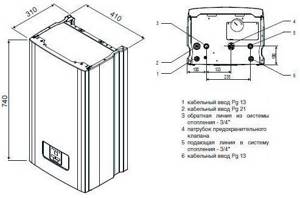

The main products of this company are boilers of the Proterm Skat model of various capacities. They all have similar technical characteristics. Overall dimensions are: height - 74 cm, width - 41 cm, depth - 31 cm. The device operates from both three-phase and single-phase networks. The maximum permissible current in them is 50 amperes. The highest pressure in the system is up to three atmospheres, the coolant temperature is about 85 degrees.

Important! When connecting heating systems to the network, their power consumption must be taken into account and suitable wires must be used. This will protect them from melting and burning out, increasing their service life and ensuring safety.

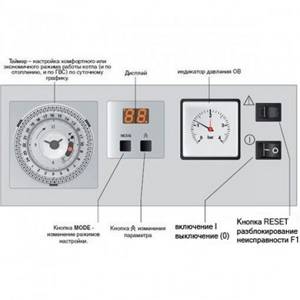

Heating modes Proterm Cheetah

The gas boiler Proterm Cheetah can operate in several modes:

- “Heating” - you need to press the MODE button once, and the display will show the “radiator” symbol with the current pressure value in the heating system. While in this mode, the unit works only to produce heating, while the hot water supply is turned off.

- “Summer” - activated by pressing MODE twice. The pressure indicator in the heating system will appear on the screen along with the “tap with a drop of water” symbol. In this mode, the boiler only works to supply hot water.

- “Vacation” - press the MODE button three times, and the OFF symbol with a pressure reading appears on the screen. In this mode, heating and domestic hot water do not work, but all protective functions of the device are active.

The desired heating or hot water temperature can be adjusted using the “+” and “-” buttons. The setting is carried out as follows:

- The DHW temperature is adjusted as follows: after pressing the “+” or “-” button, the “tap with a drop of water” and “ºC” symbol starts flashing. The required temperature value is set in the range from 38ºC to 60ºC.

- The heating temperature is also set using the “+” and “-” keys. After pressing one of them, click on the MODE button, a flashing “radiator” and “ºC” symbol appears. Then use the “+” and “-” keys to set the optimal coolant value in the range of 38-85ºC.

The operation of the Proterm Gepard gas boiler without thermostats is not very economical. To achieve maximum savings, it is recommended to purchase a room thermostat.

Advantages

The Proterm electric boiler has a number of positive features that distinguish it from devices from other manufacturers:

- High quality components and good assembly.

- Reliable and durable design.

- A wide range with different power options for units for any room.

- Reliable security system.

- High efficiency (up to 99%).

- The ability to be equipped with additional modules, acquiring new options and the ability to perform new tasks.

- The manufacturer has a good reputation among Russian users.

The Protherm electric boiler also has some negative properties:

- Quite a high price (starts from 35,000 rubles).*

- Antifreeze liquid is prohibited for use as a heating system filler.

- The device does not include a compact thermostat for use in a room.

- Despite the wide range of models, there is no factory modification that would provide for heating water for household purposes using a boiler method.

Protherm electric heating boilers and their features

The range of devices operating on electric fuel is represented by the Skat line. The model is designed for heating an apartment, private house, cottage or small office - in a word, any room where it is possible to connect the device to the electrical network. Such a boiler can be used not only as the main one, but also as a backup heat source, which will help out in case of interruptions in the fuel supply or malfunction of the main (solid fuel, gas or diesel) device.

One of the most important advantages of this product is the price of the Protherm electric boiler. You will not need to save money for several years to purchase it or take out a bank loan and pay huge interest rates for it. For a very affordable price, you get a convenient and reliable heating device with a 2-year warranty.

The numerous advantages of the proposed devices include:

- the presence in the Skat line of eight modifications with different rated power - from 6 to 28 kW. Devices with a power of 6 and 9 kW can operate from a network voltage of 220 or 380V. More powerful devices require a voltage of 380V;

- The Protherm electric boiler is equipped with a power step switch with a maximum step of up to 7 kW. To avoid too sudden power surges, a delay in its switching is provided for a certain period of time;

- very high efficiency - 99.5%. This is achieved thanks to an improved design, as well as due to the unique properties of electric fuel, which does not produce any waste. Therefore, there is no loss of produced heat with removed combustion products, while devices operating on hydrocarbon fuels cannot completely get rid of such losses;

- The Protherm electric heating boiler is equipped, in addition to the heating element and heat exchanger, with an expansion membrane tank (its capacity is 7 l), a circulation pump with an automatic air vent and an electronic control unit. There is a thermostat for protection against overheating and a coolant flow sensor;

- To control the functions, an automatic electronic unit with a liquid crystal display is included in the design of the device. The interface of this device is intuitive, so no special theoretical knowledge or training in practical skills is required to use this heating device;

- You can buy a Protherm electric boiler together with a room temperature controller, the power source for which is ordinary batteries. It is connected via a wire to the control unit of the heating device and helps to constantly maintain thermal comfort in the house. The manufacturer offers several options for regulators that are adapted to the manufactured models. Among them there are devices with a modulation function, as well as the ability to program the heating mode for a day or a week. There is also a program to protect the device from freezing;

- The Skat series of heating devices includes only single-circuit models intended for heating. To organize hot water supply, the design has the ability to connect an indirect storage boiler. The water heating rate is about 15.3 l/min;

- Protherm compact wall-mounted electric boilers take up very little space, so they are convenient even for a small cottage. To save usable space, the boiler can be placed under the boiler or choose a model that is hung on the wall next to it. The company produces water heaters of various sizes, the design of which is made in the same style as heating devices. The boiler body can be cylindrical or rectangular;

- With the proposed heating devices, you can use weather-dependent automation (of course, prices for Protherm electric boilers with outdoor sensors and an intelligent control system will be slightly higher). The microprocessor, which receives information from the sensors, performs flexible adjustment of the heating mode according to the “vags” of the weather. This allows the owner to save significant money, since electricity is not wasted.

Technical characteristics and appearance

The Proterm electric boiler will fit into any interior due to its small size and wall placement.

- Circulation pump;

- Automatic air vent;

- Expansion tank 7 liters.

There is no need to worry about installing the piping - just connect the pipes and radiators, fill the system with coolant, after which you can start testing.

Models with a power of 6 kW and 9 kW can operate from both single-phase and three-phase networks. More powerful ones are three-phase. The equipment is not afraid of power surges and does not cause overloads on the network - a stepwise increase in power is provided here. The maximum current in the circuit when the heating elements are operating is up to 50 A. The maximum coolant pressure in the system is 3 atm, the temperature is up to +85 degrees.

When connecting Protherm electric heating boilers to the electrical network, you must ensure that the cross-section of the wires corresponds to the power consumption.

Layout of inlets for Proterm electric boilers, as well as their dimensions.

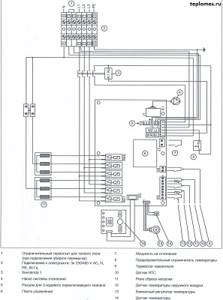

Protherm electric boilers are equipped with convenient control panels. They contain LED indicators and liquid crystal displays. Self-diagnosis systems are provided - error codes are displayed on built-in screens. Thermostats are used to create a comfortable atmosphere. Safety systems include an overheating sensor, frost protection, a pressure sensor, a safety valve and an anti-blocking system for the circulation pump.

An interesting functionality is the ability to connect external storage boilers, which are purchased separately.

Installation of Proterm Skat boilers in a cascade

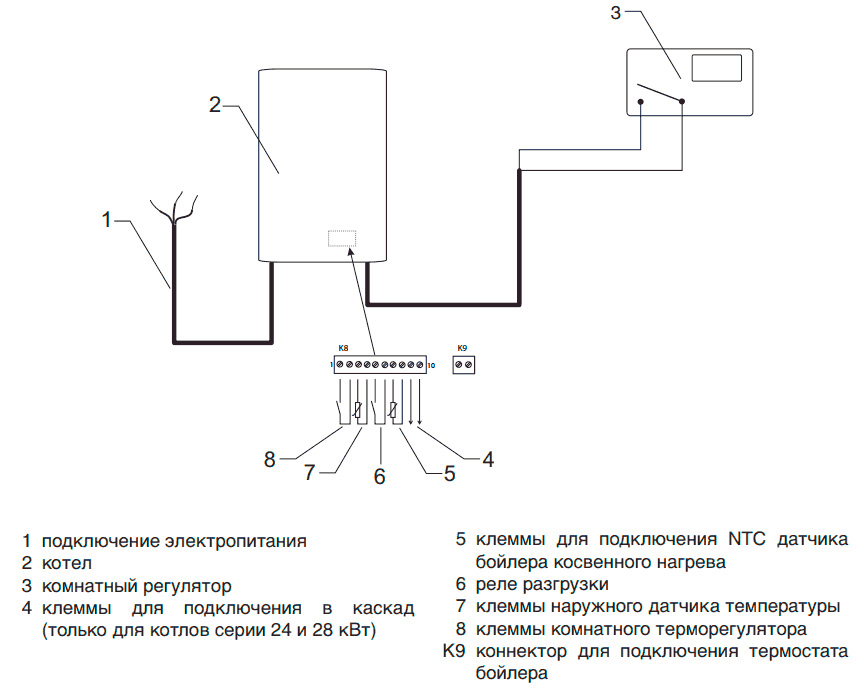

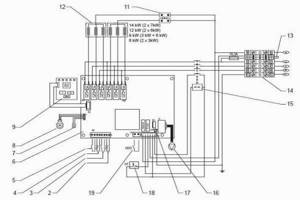

If a 28 kW boiler is not enough to heat the house, it is possible to install the Slopes in a cascade to increase the coverage of the heating area. When two boilers are connected in a cascade, the second boiler is controlled using a room thermostat, which is connected to the first boiler. This diagram will look like this:

The contacts of the room thermostat are connected to terminals 1 and 2 located on connector K8 of the main boiler, and terminals 9 and 10 of the main boiler are connected to terminals 1 and 2 of the slave boiler.

Setting up a gas boiler Proterm Medved

The floor-standing gas boiler Proterm Bear has a simple design. There are models on sale that can only provide heating, and there are also those that produce hot water. Depending on the characteristics, the Proterm Bear gas boiler is configured as follows:

- DHW temperature - press the MODE button, the light in the upper left corner will blink, and another diode will light up in the lower right. Using a button with two arrows pointing upward, set the required temperature in the boiler in the range of 40-70ºC. Confirm the selected temperature by pressing the MODE button.

- Coolant temperature – in the heating temperature setting mode, the light blinks in the upper left corner. Using the button with two arrows pointing up, set the required coolant temperature in the range of 45-85ºC. To activate the selected value, press the MODE button.

In the list of temperatures there is a parameter -. When selected, the gas boiler switches to operating in summer mode, when the heating is turned off and the hot water supply mode is running.

When connecting an equithermal temperature controller to the boiler, additional settings are made.

The Protherm gas boiler is produced by the famous company Protherm, founded in Slovakia more than a quarter of a century ago. The model range of this manufacturer is characterized by a successful combination of heating power levels and energy efficiency indicators.

Connection and operation instructions

When installing and connecting equipment, you must use protective equipment and follow safety regulations

When choosing an installation location, pay attention to:

- For the dryness of a specific place and the room as a whole.

- Structures that could easily catch fire should be kept away.

- Devices must not be installed in such a way that they interfere with access to emergency exits.

- Large household electrical appliances cannot be located nearby. This is especially true for air conditioners.

- Installation is strictly prohibited where there is a possibility of water and other liquids getting into the boiler.

You must also follow the rules:

- To protect the boiler and users, grounding must be done.

- It is necessary to take into account the weight of the equipment and select appropriate fastenings when installing wall structures.

- When installing additional modules, you must strictly follow the attached instructions.

- When installing the wiring on the electrical panel, separate circuit breakers are installed to power the boiler.

- Heating pipes must be laid so that there are no distortions.

Device

There are especially good reviews for the Proterm Skat 6 kW electric boiler, which can provide a small office with heat and hot water. Thus, the Protherm Skat 9k electric boiler, like other models in the company’s line of electric boilers, is fully automated; an LCD display is installed on the front surface of the body, which reflects the set readings.

Thus, low-power single-phase devices have one single-phase heating element, while powerful three-phase units are equipped with three single-phase heating elements. The required temperature of the heating system, when connecting a boiler - water supply circuit, and power is set by the consumer himself. Three-phase ones consist of three single-phase ones. Moscow, Kyiv highway, no.

If a forced circulation circuit is used, the boiler unit should be installed at the highest point of the heating system. Everything here is already provided by the manufacturer and is located inside the case. Protherm boiler power levels Skat Warranty The warranty period for these boilers is 2 years. Any malfunctions are indicated on the display by an error code.

For example, the price of a Proterm Skat 9 kW wall-mounted double-circuit boiler is comparable to the price of a boiler of similar power, but single-circuit. Electric boilers are superior to both solid and liquid fuels in terms of comfort. F86 indicates that the coolant in the storage boiler intended for hot water supply has frozen, or its temperature has dropped below three degrees. When purchasing an additional heating boiler, it can be integrated into the hot water supply network.

When installing several boilers in a room, it is necessary to use a parallel connection. Thus, the Protherm Skat 9k electric boiler, like other models in the company’s line of electric boilers, is fully automated; an LCD display is installed on the front surface of the body, which reflects the set readings

This is a simple, convenient, compact and, importantly, safe solution - there is no open flame, there is nothing to explode or burn, there are no harmful emissions or unpleasant odors

It is very difficult to get to the pump; only the top cover where the electrical wires are connected is accessible. The electric boiler is installed by a specialist in accordance with the design documentation. Protherm electric boilers allow you to quickly and efficiently solve the heating problem and organize hot water supply, using a minimum of labor and money. Includes intermediate relay, fuses, terminal clamps, power supply, etc.

Electric boiler Proterm: photo The main difference between electric boilers of this model range is their rated power, which can be 6 or 9 kW, 12, 14 or 18 kW, 24 and 28 kW. For the first few days, it is necessary to monitor the settings and thermal conditions throughout the entire heating system of the building in order to identify possible problems with air pockets, etc. INSTALLING, CONNECTING AND STARTING THE ELECTRIC BOILER! Protherm SKAT

How to connect and configure

Basic conditions for installing gas heating equipment from:

- installation of the boiler and the necessary auxiliary equipment is carried out in accordance with the design documentation, taking into account the requirements of SNiP and the manufacturer’s recommendations;

- installation of equipment is carried out in a room specially designed for these purposes, and in case of special modification of the unit - exclusively in well-ventilated outbuildings;

- the installation and commissioning process is carried out by specialists who have completed a training course in the installation and maintenance of gas equipment;

- any boiler malfunctions are repaired by a service organization authorized by the manufacturer of heating and water heating equipment;

- independent installation work entails deprivation of the consumer's warranty on the unit and its repair;

- When unpacking heating equipment, the supplied boiler must be checked for completeness and compliance with the type of fuel used.

Before proceeding with installation, you must carefully read the instructions supplied with the gas boiler, and during the installation process all recommendations given in the accompanying documents must be followed. Markings on equipment must not be damaged or removed.

Standard technology for connecting and setting up a gas boiler:

- the unit is fixed to the wall using screws with appropriate spacers;

- connection pipes should not be loaded with a pipe heating system, hot water supply system or gas supply elements;

- the installation size of the tube connections, including their height and the required distance from inlet to outlet, must be strictly observed;

- the hydraulic group is placed on the lower part of the gas equipment, and the system is necessarily equipped with a filler valve and safety relief valves;

- when the maximum pressure inside the system is exceeded, steam or water is released from the safety valve;

- connecting the unit to the heating system presupposes the ability to carry out the full scope of maintenance and repair work;

- water is delivered to the heating system via a filling valve, and a drain device is used to reduce pressure or partially drain the coolant;

- special outlets installed in designated areas of the heating system have full drain and fill functions;

- the pressure of hot water supply to the equipment must exceed similar indicators in the heating system;

- in the “Filling” tap position (hydraulic group), the operation of the system must be monitored using a boiler pressure gauge;

- The valve opens counterclockwise and closes strictly clockwise.

Boiler equipment maintenance items covered by the warranty do not include activities such as deaeration and adjustment of the expansion tank.

Video: Connecting the Proterm boiler

Video: Setting up Protherm equipment

Installation and startup of Protherm equipment

Due to the fact that electric boilers do not require a smoke exhaust system to operate, they can be installed in almost any convenient place. The main condition is the availability of a power supply of 220 or 380 volts and the possibility of organizing grounding.

https://youtube.com/watch?v=1_SniMbfpiY

Tips for startup and maintenance:

- Only a qualified specialist should install and perform an initial check of the operation of Protherm devices. Before start-up, equipment owners must be instructed on the principles of boiler operation.

- After installing the unit in the chosen location, it is connected to the network, the taps on the heating circuit are opened and the pressure in the system is checked, which should be 1 or 2 bar.

- After the display shows the settings, you must select the required power, the temperature of the heating system and, if a boiler is connected, the temperature of the water supply circuit.

- If the “bar” light flashes on the display, it means that the pressure in the structure has decreased and you need to add water.

- When stopping equipment for a long time, it is necessary to turn off all taps and disconnect it from the network.

It should be borne in mind that if the device breaks down, parts of the Protherm boiler can only be replaced with original spare parts.

Efficient, reliable and high-tech electric boilers Proterm are well adapted to the weather conditions of the unpredictable Russian climate, therefore they are widely used for heating apartments, cottages and private houses.

How to put the Protherm Skat boiler into operation

To start the boiler, you must follow the instructions below.

- The electric boiler is installed by a specialist in accordance with the design documentation.

- Before starting the equipment, a professional provides instructions on the principles of operation of the electric boiler.

- Before turning on the boiler, you should connect to the network , open the taps on the heating circuit and note the pressure level (1 or 2 bar).

- The display shows the settings options.

- The required temperature of the heating system, when connecting a boiler - water supply circuit, and power is set by the consumer himself.

When the pressure is low, the “bar” light starts flashing on the display. To correct the situation, add water to the system. If in this case the pressure decreases, then you need to contact a specialist.

If you need to stop the operation of the Protherm boiler for a long time, you need to disconnect it from the power supply and turn off the taps. If shutdown is necessary in winter, the system must be drained to prevent freezing.

How to care for a Protherm electric boiler? Do not use abrasives or chemicals. It is better to wipe the surface of the case with a damp cloth, and then dry the surface.

Any malfunctions are indicated on the display by an error code. The code numbers are located and deciphered in the product passport.

If serious problems occur, for example, the heat exchanger is frozen or water is dripping from it, the electric boiler must not be connected to the power supply. You need to wait for a specialist who will diagnose and carry out high-quality repairs. Replacement of parts is carried out only using original spare parts.

So, dear readers, you have become acquainted with the alternative type of heating Protherm Skat. When gas and solid fuel are out of reach or you are a stickler for cleanliness, an electric boiler can be a good help.

Solid fuel boiler Protherm Beaver DLO

It has an efficiency of about 80%, which is ensured by a large heating surface area. This area is achieved through the use of a two-pass cast iron heat exchanger. Thanks to this, the coolant heats up in the shortest possible time and allows you to achieve the result stated above.

In addition, the Beaver boiler, like all solid fuel boilers, is easy to use, reliable and has a long service life.

Solid fuel boiler Protherm Beaver

If you connect a boiler to the boiler, you can prepare hot water in it. The power of the Beaver series boilers varies from 18 to 48 kW; the boiler power can be adjusted by changing the air supply force. The cast iron heat exchanger is protected from condensation, the boiler itself is protected against overheating due to the presence of a cooling circuit.

The middle cast iron sections of the boiler can be replaced; the number of sections in the boilers in the series varies from 4 to 10. The combustion chamber of the boiler is open. The boilers do not depend on power supply; no network connection is required.

We remind you that there should be no flammable materials or substances - paints, varnishes, paper, oils, etc. - in the same room as the solid fuel boiler.