If we compare the heating system with a living organism, then the boiler with the accompanying piping devices is a kind of “heart”. It is from here that the heated coolant is sent for circulation through “arteries” - supply pipes. And here, through the “veins” - the return pipes, the cooled one returns to replenish its thermal energy potential and again go along the circuit. It is clear that the capabilities of this “heart” must be adequate to the power of the entire “organism”. That is, the heating system must cope with its tasks without “suffocating” from the lack of generated heat. But excessive excess thermal energy is absolutely not useful for it.

Setting up a gas boiler yourself

What does this mean? First of all, about the fact that even when choosing a boiler, it is necessary to calculate the required power to fully provide the system with heat in the most unfavorable conditions, at the peak of winter cold. But that is not all. Many modern boilers are capable of operating over a very wide power range. Therefore, you need to be able to organize the operation of the heat generator so that it operates in optimal conditions and with minimal consumption of energy and its motor resource.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

Such adjustments are usually considered the prerogative of local gas industry specialists. But, probably, the inquisitive owner of a house or apartment will be interested in learning how to set up a gas boiler with his own hands.

Why automatically control the heating temperature

In Russia, owners often begin to realize the need for automatic temperature control after the house is built, the heating system is already installed and working, and gas bills begin to arrive.

It turns out that outside the house, the air temperature, direction and strength of the wind are constantly changing. Day or night - the outside air temperature, even during the day, often changes by a good ten degrees. The changeable wind sometimes blows through the house, sometimes it doesn’t, the fickle sun sometimes heats the house, sometimes it doesn’t. Heat loss at home is constantly changing by different amounts.

In addition, heat comes into the house not only from the heating system. Each person in the house serves as a kind of heating radiator with a fairly large surface temperature of 36 ° C. Moreover, the number of such additional radiators in each room of the house is constantly changing.

All the energy consumed in the home by electrical appliances and other devices ultimately turns into heat. Turning each electrical device on and off changes the heat flow into the room.

The sun through the window, the operation of a gas stove or oven - all this creates a constantly changing influx of additional heat into the premises of the house.

Rapid changes in energy flows outside and inside the house lead to constant fluctuations in air temperature in each room. They require the heating system to respond equally quickly to these fluctuations.

In order not to bother with all this leapfrog, the owner of the house manually sets the heating temperature of the heating water on the boiler to a higher temperature, so that the temperature in the house is warmer, with a margin. And at the end of the month, he looks with surprise at the numbers on the gas bill and scratches his “turnips.” Read the comments to the article - there are many such “owners” there.

The owner learns that it is beneficial to keep the temperature lower in rarely visited areas of the house. Building regulations recommend maintaining the air temperature in different rooms of the house during the heating period in the range from +12 to +26 °C. (See the table from GOST with temperature parameters in the premises of the house at the end of the article). In rich EU countries, the room temperature set at night usually does not exceed 16-17 degrees. This is evidenced by a report presented by the German thermostat manufacturer Tado for 2014.

That a change in room temperature of just 1 °C leads to an increase or saving in the amount of gas for heating by approximately 4-5%.

to maintain different temperatures in each room manually, without automation, and with such high accuracy.

The owner learns that in order to equip the house with automatic temperature control, it is necessary to throw out some things, replace and redo the heating system, and install additional equipment. And for this you will have to buy again, drill, chisel, lay, finish, and most importantly, pay for everything. That all this automation would have been much cheaper if it had been installed immediately during the construction of the house.

And having connected a room thermostat to the boiler, the owner is surprised to observe that the temperature in the house remains constant, while the boiler does not turn on for half a day and does not consume gas . The owner is slightly panicked by such savings and asks a question in the comments - why is this?

Watch this video:

Model examples

- Baxi.

The optimal operating mode of this wall-mounted gas boiler is achieved as follows: in small apartments the indicators are set to F08 and F10. The modulation spectrum starts at 40% of the highest power. And the minimum possible operating mode is 9 kW.

Many models of this company are very economical and can operate at low gas pressure. Pressure limits: 9 – 17 mbar. Suitable voltage range: 165 – 240 V.

- Vaillant.

Many devices of this brand work optimally under the following conditions: power - 15 kW. The feed is set at 50-60. The device works for 35 minutes, rests for 20 minutes.

- Ferroli.

The best conditions: 13 kW for heating, 24 kW for water heating.

- Mercury.

Water pressure in the network is maximum 0.1 MPa. The highest temperature indicator at the outlet section is 90 C, the nominal value of the flue gases is at least 110 C. The vacuum behind the apparatus is a maximum of 40 Pa.

- Navien.

Basically, these are two-circuit units. Automation works here. The mode is customizable. The room heating parameter is set. There is a pump that can reduce parameters by 4-5 degrees.

- Ariston.

Automatic setting of modes also works. Often people choose models with the Comfort Plus mode.

- Buderus.

The following values are usually set on the feed: 40 - 82 C. The current parameter is usually reflected on the monitor. The most convenient summer mode is at 75 C.

Room thermostat saves gas

To automatically control the temperature in the house, boiler manufacturers recommend using a room or weather-compensated controller with a continuous principle of controlling the boiler flow temperature.

You can also use a room thermostat of a two-position principle (ON/OFF), but with less efficiency.

Boilers of luxury categories, as a rule, are immediately equipped with a remote control unit. Installed on the wall of the room, such a unit allows you to remotely control and monitor the operation of the boiler, and also serves as a room thermostat.

A room regulator allows you to maintain a constant temperature in a heated room with high accuracy. With manual control, the range of temperature fluctuations is larger and deviations are more often towards higher temperatures. Every extra degree in the room leads to an increase in gas consumption for heating. In addition, using a thermostat, you can program an automatic decrease in the temperature in the house during certain periods (at night...). Refusal of manual control of heating temperature and installation of an automatic regulator to maintain the required temperature in the room can significantly reduce gas consumption for heating .

In addition, to change the boiler settings, the owner does not have to run to the boiler room. Custom boiler settings can be changed right in the house, on the thermostat.

A room thermostat or room temperature sensor is always installed in the largest room of a house or apartment.

Room thermostat saves energy

When the boiler operates without a room thermostat, the circulation pump runs constantly, consuming electricity. The room thermostat controls not only the gas burner, but also the circulation pump. The circulation pump, controlled by the room thermostat, operates intermittently, which saves energy and the life of the pump.

Condensing boiler

This device is similar in structure to the previous unit, but has a higher efficiency, often reaching 96%. This is ensured by a closed heat exchanger; it surrounds the cylindrical burner on all sides. This makes it possible to effectively use the heat from vaporization, which previously was simply lost. At elevated temperatures, water evaporates in the combustion area, steam comes into contact with the heat exchanger and condenses, and the energy obtained from this process is returned back.

A gas condensing boiler is the best heat source for creating a home heating system. However, two conditions must be met - an uninterrupted supply of electricity (or the presence of an electric generator) and the availability of the necessary amount to purchase the device. The cost of this model is quite high, this is due to the modern technical filling. Perhaps this is the main and only drawback of this device, because in terms of its performance it surpasses even similar electrical installations.

Weather temperature control reduces gas consumption

All building structures of a house have the property of thermal inertia. For example, when the air temperature changes outside, the outer walls slowly heat up and do not immediately cool down. That is, a change in outside temperature leads to a change in indoor temperature with some delay.

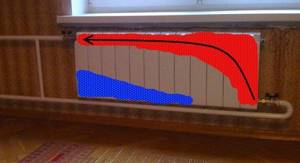

When adjusted using a room thermostat, the temperature of the coolant in the system will not change until it begins, for example, to rise in the room due to warming outside. Only after this the temperature of the coolant will begin to decrease, but, due to the thermal inertia of walls, radiators and other structures, the heat release will continue for some time, and the temperature in the room will always be higher than the set one.

For this reason, the accuracy of maintaining the room temperature using a room thermostat will not be very high. The range of temperature fluctuations in the house will be greater than the value specified by the thermostat hysteresis setting.

If the coolant temperature is changed simultaneously with fluctuations in the outside temperature, the accuracy of indoor air temperature control can be increased, which will increase comfort and reduce gas consumption for heating.

Weather control of indoor air temperature can be done in one of three ways:

- By connecting only the outside air temperature sensor to the boiler, without connecting the room thermostat.

- By connecting a temperature sensor and a two-position thermostat to the boiler.

- By connecting a temperature sensor to the room thermostat, if its design provides for such a possibility.

The best temperature stability, and therefore comfort and energy savings, can be achieved if you use the third method of weather control.

The first option, with only an outside temperature sensor connected to the boiler, provides a minimum of costs - no need to purchase a thermostat.

Connecting an outside temperature sensor and a two-position room thermostat to the boiler is the best option for weather control.

A boiler with an outside temperature sensor will respond to changing weather conditions, and a room thermostat will adjust the temperature of the coolant, depending on the air temperature in the room. The fact is that the temperature in the room depends not only on the heat that comes from the heating system. The temperature in the house changes if, for example, the window is open or the sun is shining through the window, electrical appliances are running, or there are many people in the room. The room thermostat will respond to all this, adjusting the temperature in the heating system.

Protherm gas boiler outdoor temperature sensor

For Protherm boilers, the plant produces an NTC type external temperature sensor with code S010075. The sensor is placed outside, on the facade of the house protected from the sun. The sensor is installed on a bracket, at some distance from the wall, so that the temperature of the wall does not affect the sensor. The sensor is connected to the boiler with a two-core copper wire with a cross-section of at least 0.75 mm2.

Dependence of resistance on temperature for the thermistor of an outdoor gas boiler temperature sensor Protherm. Order number: 0020040797.

There is experience in using an NTC thermistor B57164-K 222-J, 2.2 kOhm, 5%, from Epcos, as an external temperature sensor. You can buy it in the online store. In parallel with the thermistor, you need to connect a regular resistor with a resistance of 2.2 kOhm. This is necessary so that the dependence of the resistance of the external sensor on temperature approximately corresponds to the data indicated in the table.

For weather protection, the thermistor is placed in a suitable box. The cost of such a homemade sensor with a thermistor is significantly lower than a factory sensor.

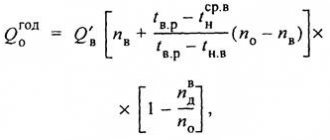

To begin with, you need a reasonable choice of power

Attempts to optimize the operation of the heating system will be completely pointless if the rated power of the boiler is far from the required one. Moreover, it doesn’t matter which way.

- With a clear lack of power from the heating unit, with the onset of cold weather in some rooms, or even in the entire house at once, it will be clearly cool, to say the least. Moreover, it is impossible to eliminate this drawback with any settings - “you can’t jump over your head.” All that remains is to rely on additional electric heaters and plan to replace the boiler with a more powerful one in the foreseeable future.

- With an overly powerful boiler, it would seem that the owners have a trump card on their hands - a solid operational reserve! But this is only at first glance …

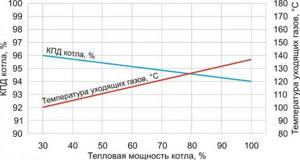

The problem is that thermal equipment is mainly designed and calculated for power close to the upper limit of the rating range. It is under such conditions that the boiler will show all the advantages inherent in it by the designers. A reduction in power is possible (this is what the range is indicated for), but this is inevitably accompanied by a decrease in efficiency.

Range of total (Q) and useful (P) boiler power. Please note that the minimum and not the maximum, but the nominal limits are shown. That is, the optimal mode with maximum efficiency is to operate the boiler at the highest power levels.

By the way, indicate the decrease in efficiency with a decrease in power in the passport or on the product nameplate. This information is usually only available in the service instructions.

For example, the instructions for the “Protherm Gepard 23 MTV” boiler directly state that with a rated power of 23.3 kW, the efficiency indicator (η) reaches 93.2%. And if the equipment operates at the lower end of the power range (8.5 kW), then the efficiency drops to 79.4%. That is, in reality, it turns out that when operating in low power mode there is a significant loss of performance - a considerable part (more than 20%!) of the expended energy simply burns out, without bringing any benefit to the consumer.

I don’t even want to think about the efficiency value if the real demand of the heating system is less than the lower limit of the power range... However, such “curiosities” do occur.

And to avoid them, it is necessary to purchase a boiler with power indicators that are adequate to the real needs of the existing or planned heating system. That is, to carry out preliminary calculations.

For such calculations, a ratio is often proposed: 100 W per square meter of heated area. However, this “algorithm” does not take into account the specific climate of the region of residence and the location of the building on the ground, nor the characteristics of the house itself and each of its premises. And therefore, a considerable mistake in one direction or another is likely.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

Therefore, let me offer you another solution to begin with - a special calculator for determining the required thermal power. It evaluates each room of the house, taking into account many criteria. The sum of all heated rooms will give a very accurate idea of the total thermal power of the system. In addition, the obtained value for the room will allow you to correctly select heat exchange devices for it - radiators, convectors, etc.

Below is an explanation of the calculation procedure.

Calculator for calculating the thermal power of a heating system

Go to calculations

Explanations for calculations

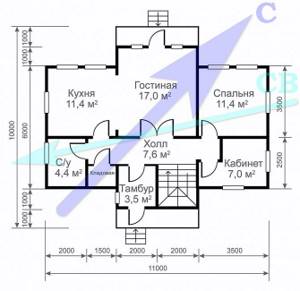

We repeat - the calculation is carried out for each of the premises of the house or apartment individually. The sum will give the total heating power requirement.

To simplify your task and save the results obtained for the future, you can, armed with a plan of your property, draw up a plate in which you can indicate, line by line, all heated premises. And then determine according to the plan and write down all the necessary data for each of the rooms. This will be, perhaps, the most difficult part of the calculations, since the calculator will take care of the rest.

On a copy of the plan, you can indicate the directions of the cardinal points (here the wide blue arrow shows the North) and, if information is available, the predominant direction of cold winter winds (“wind rose” for the winter).

An example of a sign is shown below - it is not tied to the plan taken solely as an example, just as a proposed design option. And now we will briefly go through the requested data.

| Name of the room, its area, ceiling height. Insulation of the floor, which is located above and below | The number of external walls, their orientation to the cardinal points and relative to the winter “wind rose”. Quality of wall insulation. | Number, type and size of windows | The presence of doors to the street or to an unheated room | Required thermal power |

| 1. Hallway. 3.18 m². Ceiling 2.8 m. Floor laid on the ground. Above is an insulated attic. | One, South. Average degree of insulation. Leeward side | No | One | 0.52 kW |

| 2. Hall. 6.2 m². Ceiling 2.9 m. Insulated floor on the ground. Above is an insulated attic | No | No | No | 0.62 kW |

| 3. Kitchen-dining room. 14.9 m². Ceiling 2.9 m. Well-insulated floor on the ground. Upstairs is an insulated attic. | Two. South, west. Average degree of insulation. Leeward side | Two, single-chamber double-glazed windows, 1200 × 900 mm | No | 2.22 kW |

| 4. Children's room. 18.3 m². Ceiling 2.8 m. Well-insulated floor on the ground. Above is an insulated attic | Two, North - West. Full insulation. Windward | Two, double-glazed windows, 1400 × 1000 mm | No | 2.6 kW |

| 5. Bedroom. 13.8 m². Ceiling 2.8 m. Well-insulated floor on the ground. Above is an insulated attic | Two, North, East. Full insulation. Windward side | Single, double-glazed window, 1400 × 1000 mm | No | 1.73 kW |

| 6. Living room. 18.0 m². Ceiling 2.8 m. Well-insulated floor. Above is an insulated attic | Two, East, South. Full insulation. Parallel to the wind direction | Four, double-glazed window, 1500 × 1200 mm | No | 2.59 kW |

| 7. Combined bathroom. 4.12 m². Ceiling 2.8 m. Well-insulated floor. Above is an insulated attic. | One, North. Full insulation. Windward side | One. Wooden frame with double glazing. 400 × 500 mm | No | 0.59 kW |

| TOTAL: | ||||

| Area 78.5 m² | 10.87 kW ≈ 11 kW |

So, for the calculations you will need to clarify and indicate the following data in the calculator for each of the premises:

- What temperature is typical for the region in the coldest decade of winter. It is clear that this indicator will be the same for calculating all rooms - it simply characterizes the climatic features of the area. So there is no point in putting it in the table - you can specify it during the first calculation, and then simply not change it.

Important - this should be a minimum, but normal temperature for your region.

- The area of the room and the height of the ceilings - there is nothing to explain here.

- The number of external walls, that is, the reverse side in contact with the street or a cold unheated room.

- The side of the world towards which the outer wall faces. The idea is that walls in the South or South-West can receive a “solar charge”, unlike their “antipodes” in the North and North-East, which never see the Sun.

- If the direction of the prevailing cold winds in winter is known, then this factor can also be taken into account. If there is no such inflation, leave it at default, but then the calculation will proceed as for the most unfavorable, quickly cooling windward side.

- When assessing the degree of wall insulation, one should proceed from the fact that the thermal insulation that is completed on the basis of thermal engineering calculations is considered complete. If there is no such confidence, then it is better to leave the medium level - this approximately corresponds to brickwork of two bricks (approximately 500 mm) or a log house with a wall thickness of at least 200 mm. Well, the walls of a residential building should not be uninsulated - you will simply go broke on heating!

- Next, you have to choose from the proposed lists the option of insulating the floor or adjacent to the rooms above and below.

- An entire block of fields is dedicated to windows. You have to indicate their quantity and quality - choose from the list of proposed options. In addition, the calculator asks for size. The glazing area is automatically calculated and compared with the area of the room, on the basis of which a correction factor is introduced into the calculation.

- Finally, the number of doors leading from the room to the street or to a cold (unheated) room is indicated. This is understandable: each opening of the door means an influx of a considerable volume of cold air, which requires a certain compensation.

After that, press the calculation button - and the result for a specific room is ready. There is no need to add anything to it - the operational reserve is already included in the fact that the calculation was carried out for the most unfavorable conditions.

The total value for all rooms of a house or apartment is a guideline for purchasing a heating boiler. For example, in the table above it turned out to be 10.87 kW. They select a model that, of course, has slightly more power, but best of all is the closest one in the direction of increase. That is, in this example, let’s say, choosing a boiler with a capacity of 11.6 kW would be appropriate.

* * * * * * *

What to do if, for some reason, a boiler with too much power has already been installed, and its replacement is not planned for the foreseeable future. Is it possible to optimize the operation of the heating system?

It turns out, yes, many modern models allow you to make adjustments, those that, if they do not bring the boiler to the optimal mode, will at least bring it to a level as close as possible to the nominal values.

Thermostatic valve on the radiator reduces gas consumption

Installing a thermostat on a radiator is a mandatory requirement of building regulations. Weather control changes the temperature of the heating water in the heating system depending on the outside temperature.

A room thermostat regulates and adjusts the temperature of heating water depending on the temperature in one room where it is installed.

The room thermostat is always installed in the largest room of the house or apartment. The temperature in other rooms will differ from the one that is necessary, in one direction or another. For example, in order to save gas, it is beneficial to keep the temperature in rarely visited rooms lower.

The temperature in other rooms can be controlled using thermostats installed at the heating water inlet to the radiator. A thermostatic valve or an electronic radiator thermostat is used as radiator thermostats.

The thermostatic valve regulates the flow of heating water through the radiator so that the room temperature remains constant, set on the thermostatic head scale. The control head of the thermostatic valve contains a bellows filled with liquid or gas. When the temperature in the room changes, the temperature of the liquid (gas) changes. As a result of thermal expansion of the liquid (gas), the bellows changes its position and acts on the valve stem on the radiator pipe.

On sale you can find thermostatic valves with a remote temperature sensor . Such devices provide a more stable room temperature, since the influence of a closely located radiator and window is eliminated.

Electronic radiator thermostat

Powered by AA batteries, 2 pcs. Temperature adjustment from 5 °C to 35 °C. Hysteresis ±0.5 °C. LCD display. The electronic radiator thermostat, as well as the thermostatic valve head, is installed on the control valve on the pipe to the radiator. Compared to a thermostatic valve, it has many more control functions.

A radiator thermostat consists of a built-in or remote temperature sensor and a servo drive, which opens and closes the valve valve on the radiator.

An electronic programmable radiator thermostat can provide:

- Indication of room temperature.

- Low battery indication.

- System fault indication.

- Operating mode indication.

- Setting an economical and comfortable temperature regime.

- Setting a schedule for alternating comfortable and economical modes for each day of the week.

- Child lock function.

- Room ventilation function.

- Valve protection against souring.

- System frost protection function.

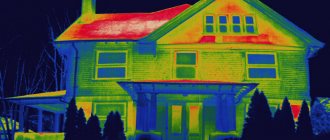

Ways to reduce heat loss

The above information will help to be used to correctly calculate the coolant temperature norm and tell you how to determine situations when you need to use a regulator.

But it is important to remember that the temperature in the room is affected not only by the temperature of the coolant, street air and wind strength. The degree of insulation of the facade, doors and windows in the house should also be taken into account

To reduce heat loss from your home, you need to worry about its maximum thermal insulation. Insulated walls, sealed doors, and metal-plastic windows will help reduce heat loss. This will also reduce heating costs.

Servicing a gas boiler with low performance is expensive. Therefore, anyone who uses such a device wants to find the optimal operating mode for the gas boiler

, at which it will have the highest possible efficiency (efficiency factor) with minimal fuel consumption. This problem becomes especially relevant on the eve of the next heating season.

The performance of a gas boiler is influenced by various factors. If you have not yet purchased this device, but are just planning to purchase it, please note that the main condition for its installation is the presence of a centralized gas supply. Some people think that they can get by with bottled gas, but this will significantly increase costs. In this case, it is better to install electric heating.

Optimal performance

depends on the following criteria:

- Boiler designs - they can be single-circuit, double-circuit, mounted, floor-mounted, etc.

- Efficiency – nominal and real.

- Proper organization of heating in the house: the power of the boiler must correspond to the area of the heated premises.

- Technical condition of the equipment.

- Gas quality.

Now let's take a closer look at how each of the criteria can be optimized to achieve maximum device performance.

Boiler design

Boilers are single-circuit and double-circuit. For the first one, you will have to purchase an indirect heating boiler so that it can heat the water. The double-circuit option is preferable, as it is equipped with everything necessary for producing hot water and heating the house. For ease of use, the priority mode in such a boiler is hot water supply. This means that when the water supply is turned on, the heating stops.

There are wall-mounted and floor-mounted gas boilers. The former have less power and can only heat a room up to 300 m². If your home is larger, you will need to purchase another wall mounted or floor standing boiler.

Nominal and real efficiency

The instructions for any gas boiler indicate the nominal efficiency, usually it is 92-95%, for condensing models it is about 108%. However, the real figure is usually 9-10% lower. It is further reduced by the presence of various types of heat loss:

- Physical underburning - this indicator depends on the volume of excess air present in the unit during gas combustion. It is also affected by the temperature of the flue gases: the higher it is, the lower the efficiency of the boiler.

- Chemical underburning - this indicator fluctuates depending on the volume of carbon monoxide that appears from the combustion of carbon.

- Heat loss that escapes through the walls of the boiler.

You can increase the real efficiency of the device in the following ways:

- Reducing the rate of physical underburning by regularly cleaning soot on the pipeline and removing scale from the water circuit.

- Reducing the amount of excess air by installing a draft limiter on the chimney pipe.

- By adjusting the position of the blower damper so that the maximum coolant temperature is achieved.

- Regular cleaning of soot from the combustion chamber, which increases gas consumption.

Replacing the chimney with a more innovative one will increase the efficiency of a gas boiler. Most traditional outlet pipes are too dependent on weather conditions. They were replaced by a coaxial chimney, which is resistant to temperature changes and can increase efficiency and also save fuel.

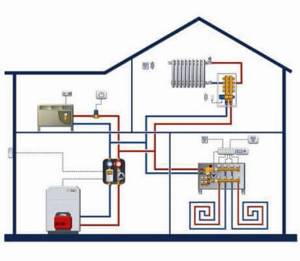

Automatic temperature control in a house with heated floors

As you know, a warm floor can be either “comfortable” or “heating”.

"Comfortable" heated floor

slightly warms the surface and provides a pleasant feeling when a person is on the floor. The main heat supply to the room is provided by radiators. For a comfortable heated floor, it is necessary to maintain a constant temperature of the coolant.

"Heating" heated floor,

In addition to comfort, it provides complete heating of the room.

In the Russian climate, the relatively small thermal power of a heated floor makes it most often suitable only for comfortable heating.

An air temperature sensor in the thermostat housing and a sensor in the floor provide room temperature regulation and protect the floor from overheating

In a house with a comfortable heated floor, it is necessary to have three automatic control systems to control the temperature .

One system that regulates the operation of a warm floor must be controlled by the air temperature in the room until the temperature of the floor surface reaches a comfortable level. That is, in the off-season the house will be heated with the heat of the heated floor.

the automatic radiator control system comes into effect . Radiators will heat the air in the room, adding their heat to the heat that will constantly come from the heated floor.

The heating mode of the coolant by the boiler must be regulated by another automatic weather control system that responds to the outside air temperature .

Considering that the underfloor heating system has a high inertia (it heats up slowly and cools down slowly), it is recommended to use weather automation to control its operation. Then the temperature of the coolant supplied to the system will be adapted to the outside temperature. Due to this, along with changes in outside temperature, the temperature of the coolant circulating in the floor changes.

The mixing unit with circulation pump is on the left. On the right, a manifold of underfloor heating pipes is connected to the mixing unit. Control valves with a servo drive are installed on the manifold. The valve is controlled through a servo drive by a thermostat, which regulates the supply of coolant to the heated floor circuit depending on the temperature of the floor surface and the air temperature in the room.

Each room with a “warm floor” is at least one circuit (one pipe loop). All these circuits must somehow be combined into one and connected to a boiler or other heat source. Both ends of the pipe of each heated floor circuit are connected to the manifold.

To regulate the temperature of the heated floor, it is necessary to select and install a manifold equipped with servo drives on the control valves.

A servo drive is a device that, when electrical current is supplied to it from the thermostat, acts on the valve, opening or closing it. The servo acts as a switch, completely opening or closing the valve. The surface temperature of the heated floor will be maintained with an accuracy of +/- 0.5 - 1 °C.

Frost protection

The most important mode is frost protection. The mode is active when the boiler is switched off or winter mode is switched off. Why is it needed:

- the burner continues to work;

- the boiler was in working order;

- works when the heating is turned off.

Not every boiler has a protection mode. When the boiler turns on when water is supplied, the outlet water temperature is checked. Each boiler has a separate threshold, most have 5 degrees. If the temperature is 5 degrees, the boiler brings it to 15, then turns off.

Thermostats for heated floors

A thermostat is a device that measures the temperature of something, compares this temperature with a predetermined temperature and, depending on the result of the comparison, commands the servo drive to turn the control valve on or off. Thus, by turning on or off the heat supply, the thermostat maintains the temperature of something with minimal deviations from the set value, usually with an accuracy of +\- 0.5 oC.

To measure temperature, the thermostat may have a temperature sensor built into the body of the device. The temperature sensor can also be remote. The remote sensor is connected to the thermostat by wires.

—>

The thermostat always has buttons or wheels with which you set the temperature, the stability of which it must ensure. All thermostats have an indication of the current state - “heating on” or “heating off”.

The thermostat, depending on the method of connection with the actuator, can be wired or wireless.

The lowest budget option is a wired thermostat. The device itself is installed in a room in which it must maintain temperature. A heated floor collector with servo drives can be installed in another place, for example, in a boiler room. These devices are connected to each other by thin wires.

The wireless thermostat transmits a control command to the collector servo drive via a radio channel. To do this, there is a radio transmitter in the thermostat housing, and a radio receiving unit is installed near the collector. Installing a wireless thermostat can be beneficial when automation work is carried out in an already built house - there is no need to lay wires and disturb the finishing of the premises.

Thermostat with the function of regulating room temperature and heated floor temperature. Works with two temperature sensors, one in the device body, the other remote, in the heated floor.

To regulate the air temperature and the temperature of the heated floor in accordance with the algorithm - we regulate the air temperature in the room, but do not allow the floor to heat up above the set temperature, you need a thermostat that has the appropriate functions.

Thermostat for underfloor heating:

- Must work with two temperature sensors: a built-in air temperature sensor and an external heated floor temperature sensor.

- The thermostat should have the ability to set the air temperature and the heated floor temperature separately.

- There must be a control algorithm based on air temperature with a limitation on the surface temperature of the heated floor.

One thermostat can control several actuators installed on one manifold. The thermostat and servo drives are connected through a special unit - a switching module.

Equipment difference

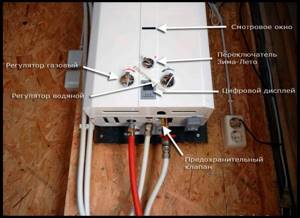

The two boiler options mentioned above (single-circuit and double-circuit) are just enlarged characteristics of a wide range of gas equipment. They are taken as an example due to the fact that the installation of such a gas boiler can be done with your own hands. Other options for gas heating devices will require the involvement of professionals. Fortunately, now it’s not difficult to find a specialist for installation. They will prepare the room and complete the documentation.

Boiler for hot water supply

Such equipment is often called a “water heater”. At their core, they are actually simple in design. There is nothing except the heat exchanger and burner. To work, you need to connect a gas and water hose to it, and also equip a chimney. Nothing more will be needed. Of course, you should not forget about obtaining permits for connecting a gas boiler. Otherwise, there is a risk of receiving a serious fine.

Boiler room for home

Double-circuit gas equipment with automation is produced so well-developed that the installation process is exactly the same as for a simple water heater. The presence of automatic control is due not only to the ease of installation and installation. It is able to control the ambient temperature and adjust according to the necessary settings. During operation of such a boiler, gas consumption can be reduced by up to 70%.

But installing a gas boiler of this type has a significant drawback. If the power supply to the house is interrupted, the boiler will not work. At the same time, the circulating sediment, if present, will also stop working. You will have to take care of additional backup power supply. You can see how to choose the right electric generator here.

Choosing a room thermostat - thermostat

Let's look at the choice of automation devices for controlling the heating system in a private home using the example of the Protherm brand equipment manufacturer.

A room thermostat installed in a room measures the current air temperature and, if the temperature deviates from the value set in the settings, sends a control signal to the boiler.

The room thermostat, which controls the operation of the boiler, is installed in the largest room of the house . Radiators in the room in which the thermostat is installed should not have valves that regulate coolant flow. In other rooms, a thermostatic valve must be installed on each radiator, which regulates the coolant flow through the radiator depending on the temperature in this room.

In heating systems with heated floors and radiators, the automatic air temperature control system is more complex.

Read: “Automatic control of air temperature in a house with heated floors and radiators .

Products for Auto

⇆

The signal from the thermostat to the boiler can go via wires, or maybe via wireless radio. In the latter option, a unit for receiving a radio signal from a wireless thermostat is installed on the boiler.

It is recommended to use thermostats of the same brand to control Protherm boilers. The Protherm brand boiler manufacturer produces several modifications of room thermostats for its gas boilers.

Removing air from the heating system of a solid fuel boiler.

Air in the heating system can cause a number of problems: poor circulation of coolant or its absence, noise during pump operation, corrosion of radiators or heating system elements. To avoid this, it is necessary to bleed the air from the system. There are two ways to do this - the first is manually - we think about installing valves at the highest point of the system and on lifting sections and periodically pass these valves, releasing air. The second way is to install an automatic air release valve. The principle of its operation is simple - when there is no air in the system, the valve is filled with water and the float is located at the top of the valve, and, through a hinged lever, seals the air outlet valve.

When air enters the valve chamber, the water level in the valve drops, the float lowers and, through a hinged lever, opens the air release hole on the outlet valve. As air leaves the chamber, the water level rises and the valve returns to the upper position.

We have already described the design of the boiler safety group above when we talked about protection against high coolant pressure. Ideally, if you have installed a safety group, it has an automatic air release valve. Just make sure that the safety group is installed at the top of your heating system. If not, we recommend installing a separate automatic air release valve and forever solving the problem of finding air pockets in your heating system.

Solid fuel boiler piping - Automatic air release valve

Two-position thermostats - thermostats for a gas boiler

The electromechanical two-position room thermostat Protherm Exabasic for a gas boiler is simple, cheap, but temperature fluctuations in the heated room will be significant - about 2-3 °C.

The electronic two-position room thermostat Protherm Exacontrol provides higher accuracy and stability of maintaining the temperature in the room, and has the function of protecting the heating system from freezing. The display shows the current room temperature.

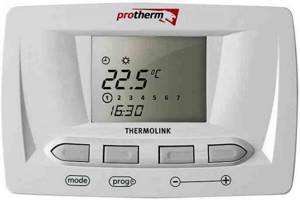

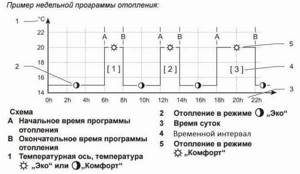

Thermolink S is an electronic two-position programmable controller, differs from previous models in that it allows you to adjust the temperature according to one week program with the possibility of combinations of three different time intervals (morning, afternoon, evening).

Weekly program for regulating heating temperature in a house or apartment using the Protherm Thermolink S room thermostat

In addition, it is possible to set one of three temperature modes: “Comfort”, “Eco” (economy) or “Vacation” mode.

The Thermolink S controller supports the function of protecting the heating system from freezing when the room temperature drops to 3 °C.

The display shows the current room temperature, as well as the time and day of the week.

Features of operation of a boiler with a two-position thermostat

On-off thermostats have a relay with contacts at the output. The contacts can be in one of two positions: closed or open. Connected to the boiler, closed thermostat contacts switch on the boiler heating mode. When the contacts open, the heating mode is switched off. The boiler operates in cycles - on/off. There are no changes in the heating mode settings on the boiler itself.

The cyclical operation of the boiler under the control of a two-position room thermostat can hide the clocking of the boiler, which occurs due to a significant discrepancy between the capacities of the boiler and heating devices (read the beginning of the article about clocking).

Many even argue that boiler clocking can be eliminated not by adjusting the gas valve, but by installing a room thermostat.

However, if the boiler power significantly exceeds the power of the heating devices, then the frequency of operation cycles of the boiler with a two-position thermostat increases. The boiler turns on and off more often. In addition, the range of temperature fluctuations in the room expands.

Correct adjustment of the power of a gas boiler is also necessary when the boiler is operating under the control of a room thermostat.

The sensitivity of the electronic two-position room thermostat is 0.5 °C. The thermostat switches contacts when the room temperature changes by half a degree.

Summer operating hours

At home, heating is not needed in summer. There is no desire to wash dishes in cold water or take a cold shower. For such purposes, a summer mode was invented, when the heating of the room is in hibernation mode (sleep mode). But when you open a hot tap, the water begins to heat up (for double-circuit boilers).

When summer comes, the heating circuit does not switch off automatically. There are three options for the development of events:

- let it be as it is;

- switch to hot water mode;

- turn off the boiler completely.

In the first case, the heating mode will be active. In this mode, the heating circuit will always be on and internal checks of the equipment will continue to be carried out. Don't waste resources just like that.

Switching to summer mode (hot water mode) is available if the boiler allows it. You will receive hot water, the heating will be turned off. The boiler performs a minimum of conservation procedures.

Interface boiler temperature controllers

Programmable thermostat Protherm Thermolink P

The programmable thermostat Protherm Thermolink P allows you to set the temperature according to one week program with the possibility of combinations of 3 different time intervals (morning, afternoon, evening).

It is possible to set one of three heating temperature modes: “Comfort”, “Eco” or “Vacation” mode. It is possible to adjust the hot water temperature.

The Thermolink P thermostat supports the function of protecting the heating system from freezing when the room temperature drops to 3°C.

The display shows the current room temperature, as well as the time and day of the week.

The Thermolink RC interface controller is a modification of Thermolink P with similar properties and parameters, but with a wireless connection to the boiler.

The difference between the interface Thermolink P and the two-position Thermolink S

The Thermolink P room temperature controller is connected to the boiler via the eBus interface. This bus is used to exchange data between the microprocessors of the thermostat and the boiler. The thermostat has the ability to change boiler settings.

S two-position thermostat maintains the required temperature in the room by turning the boiler on and off at a certain moment.

The Protherm Thermolink P with interface (eBus) provides room temperature control by changing the boiler settings - the boiler burner power and coolant temperature change. The boiler operates continuously, not in cycles.

In addition, to change the boiler settings, the owner does not have to run to the boiler room. Custom boiler settings can be changed directly on the thermostat. For example, adjust the hot water temperature. Automatic boiler diagnostic codes are also displayed on the thermostat display.

The interface controller can work in conjunction with an external air temperature sensor connected to it.

Manufacturers and efficiency of boilers

There are things that, at first glance, do not directly affect the efficiency of boilers. It’s like you take in one hand a passport for a boiler of some Ukrainian KAZ, you see the declared efficiency is not bad (say 92%), and in the other hand a passport from a German Bosch or an Italian brand boiler, where the declared efficiency is also 92%, and you feel a catch, but you can't figure out where he is. Let's figure it out together.

We know very well the mentality of Ukrainians and Germans, and we know how they do it “with us” and how they do it “with them”. Therefore, despite the declared efficiency, a German boiler will in any case be more economical and more reliable than a Ukrainian one. This will be due to a number of indirect reasons - there was a screw that was not tight enough, there it was too tight. Here more heat escapes into the chimney, there the regime does not hold, and so on. and so on.

How much more economical a German will be than a Ukrainian is difficult to deduce. Nevertheless, a gas boiler, like a car, is bought for a long time. And in the long term, with a constant increase in energy prices, even a difference of at least 5% is very noticeable.

For a brief overview of the main manufacturers, you can read the review of floor-standing gas boilers, where, using the example of floor-standing boilers, you can form an opinion on the main brands. After that, get acquainted in more detail with any of the main brands presented on our market, where a review has been compiled for each manufacturer.

Setting weather control on the boiler

In order for the temperature in the house to remain constant, the temperature of the heating water in the system, when the outside temperature changes, must change according to a certain law. This pattern is determined by the magnitude and nature of heat loss from the building, as well as the parameters of the heating system.

The dependence of the heating water temperature on the outside temperature is depicted on the graph as a heating curve. The slope of the heating curve is completely individual for each building.

Heating curves for some parameter values in line d.43 of the service menu of the Protherm Gepard (Panther) boiler..

To work with an outside temperature sensor connected to the boiler, the heating curve for the house is selected in two steps.

Step 1. In line d.43 of the service menu, select the parameter that sets the slope of the heating curve (in the graph above). Factory setting of the parameter =1.2. Select a parameter that corresponds to the heating curve passing through the known intersection point on the graph of the heating water temperature and the outside temperature. These temperatures (this point) are determined by calculation. Often calculations are not done and this point is not known in advance.

Typically, the heating curve slope parameter in line d.43 is selected empirically. Leave the factory setting of the parameter in line d.43 and observe in which direction the room temperature changes when the outside temperature fluctuates. If, as the temperature outside decreases, the temperature in the room increases, then it is necessary to reduce the slope of the heating curve, i.e. decrease the value of the parameter in line d.43, and vice versa. The task is to select a parameter value at which a change in the outside temperature will not lead to temperature fluctuations in the house. At this step, the main thing is to achieve stability of the temperature in the room, without paying attention to the absolute value of this temperature.

Step 2. In line d.45 of the service menu, select the base temperature of the heating curve in the range of 15 - 25 oC. Factory setting of the parameter =20. The parameter in line d.45 sets the absolute value of the room temperature. If, after selecting the slope of the heating curve in step 1, the room temperature is stable but low, then the temperature parameter in line d.45 is increased, and vice versa. In this case, the heating curve on the graph rises or falls, but its slope does not change.

If you call line d.47 in the service menu, the display screen will display the temperature, which is measured using an outside temperature sensor.

Read: How to enter the service menu of the Protherm Gepard (Panther) boiler

Adjusting the maximum heating power of a Gepard or Panther boiler through the service menu

At the first stage, in the service menu, as described above, we find line d.0 , press the “mode” button and look at the value of the boiler power parameter, kW, on the display. In our example, the factory setting =15 was visible. It is necessary to set a new boiler power value equal to the power of the heating devices connected to the boiler. This setting will only work in heating mode.

If the power of the heating system corresponds to the operating range of boiler power

The maximum power of the heating system in the house may fall within the operating power range of the boiler specified in the instructions. For example, the total maximum power of radiators in a house is 11 kW. The operating power range of the Protherm Gepard 23 MTV boiler is 8.5 - 23.3 kW.

In the service menu, as described above, find line d.0, press the “mode” button and look at the value of the boiler power parameter, kW, on the display. For example, the factory setting =15 will be visible. Using the “-” button we set the new boiler power value = 11.

I recommend trying to set the boiler power to 20 - 30% less than the heating circuit power, for example, d.00 = 9 kW. This power should be enough to compensate for heat losses at home, since the power of radiators is usually chosen with some reserve.

Increasing the anticycling time

At the second stage, we increase the anticycling time in line d.02 of the service menu.

Factory setting d.02 = 20 minutes. According to the schedule (see above), we determine that, for the heating water temperature set on the display of 70 ° C, restarting the burner is possible after 4 - 5 minutes, not earlier.

In line d.02 we set a new value for the anticycling time, for our example the maximum possible = 60 minutes. Line d.67 displays the time in minutes until the boiler is turned on again. Breaks in burner operation became approximately 10 minutes long. Twice as much as with the factory setting, which is still too often.

Increasing the anti-cycling time results in the burner turning on later, at a lower heating water temperature. The heat flow from the boiler to the heating circuit is reduced.

Thus, by selecting the settings of the boiler power and anti-cycling time through the service menu, we ensure that the cycle duration between turning on the boiler burner is at least 15 minutes. That is, the boiler should be turned on no more than four times within one hour.

I note that not all brands of gas boilers have the ability to adjust the anti-cycling time. In this case, you only have to select the boiler power settings.

On some brands of gas boilers, the rotation speed (performance) of the circulation pump is set manually using a switch on the pump. To reduce the boiler clock, it is recommended to increase the pump speed.

Setting up a Gepard or Panther gas boiler for power below the minimum

At the third stage , the minimum boiler power is adjusted .

Such adjustment is not necessary in all cases, but only when the first and second stages do not bring the required result. As in our case, when at the first stage we use the “-” button to set a new boiler power value = 9 (the minimum possible setting corresponds to 8.5 kW). The newly established maximum heating power of the boiler (8.5 kW) is still very different from the power of the heating devices (4 kW).

It should be noted that adjusting the boiler power using the method described below is also useful in other cases, since it allows, through an experiment, to adjust the heating power of the boiler in accordance with the actual power of the heating circuit. The actual power is usually less than the calculated one.

Before carrying out work on setting the minimum burner power, you must:

- Fully open thermostatic and other valves on radiators and set the room thermostat to maximum temperature. The thermostat that controls the heated floors is set to the maximum permissible temperature so as not to overheat the floors.

- In the user menu of the boiler, set the maximum operating temperature, which is set by the owners in the coldest weather, adding another +5 °C. Usually this is not less than 65 °C. If the owners do not remember it, or on a new boiler, set the factory setting of the maximum temperature of 75 ° C in the menu. The boiler burner will have to automatically turn off at a temperature 5 °C higher, i.e. at 80 °C.

- Cool the heating circuit to a heating water temperature below 30 °C.

Next, we start the burner in heating mode, select line d.52 , press the “mode” button and see on the display the value of the gas valve stepper motor position parameter in the factory minimum power mode.

By removing the front cover of the boiler, we visually observe the size of the flame in the burner. In our example, the factory setting was displayed on the display, the number = 72, and the flame height in the burner was quite high.

Using the “-” button we set a new parameter value in line d.52, for example =20. 3 seconds after the change, when the new value is automatically confirmed, we observe a significant decrease in the flame height in the burner. This indicates that the useful power of the boiler with the specified setting will be greatly reduced.

Next, observe on the display the increase in temperature in the direct heating pipeline at the outlet of the boiler. Typically, the temperature increase stops when it reaches a value less than the set value, for example 52 °C. The boiler is running, but the temperature does not increase (or changes very, very slowly). This means that a power balance has been achieved between the boiler and the heating system at this established water temperature. At this moment, we increase the parameter in line d.52 of the service menu, set a new value = 30 - the temperature begins to rise again and stops again, for example at 63 ° C. Again we add the parameter value in line d.52 =35 and so select the parameter until the temperature stops at a value slightly higher than the maximum, for example 77 °C. In this way, a balance is achieved between the power of the boiler and the heating circuit at maximum operating temperature. The boiler power will be set to the minimum level required to operate with the connected heating circuit. In this case, the cyclic operation of the boiler will be minimal.

If the radiators do not warm up well in height, the temperature difference in the forward and return pipes at a maximum temperature is more than 15-20°, then increase the response pressure of the bypass valve. Read below on how to adjust the bypass valve. The water temperature in the forward and return pipelines can be seen on the display if you enter the service menu, lines d.40 and d.41.

In case of adjusting the bypass valve, the gas valve setting in line d.52 must be repeated.

In our example, the burner heated the water to a maximum temperature of 77 oC with a minimum parameter value in line d.52 equal to =28 (factory setting was =72). With a lower parameter value, the burner could not heat the water to the specified temperature. And at a higher value, the burner heated the water to 80°C and the boiler automatic switched off the combustion.

It should be noted that the method described above for adjusting the gas valve, which allows you to balance the boiler power with the power of the heating circuit through an experiment, is not included in the recommendations of the boiler manufacturer. This is the idea of the author of the article, successfully implemented when setting up autonomous heating systems with gas boilers.

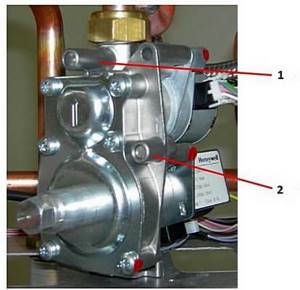

Factory calibrated gas valve

The boiler manufacturer prescribes calibration of the minimum power on the gas valve as follows:

In line d.00 of the service menu, set parameter =9, which limits the boiler power to the minimum level specified in the instructions. Turn on the boiler in heating mode.

A pressure gauge tube is connected to the upper fitting at the gas valve outlet. Before connecting, it is necessary to unscrew the locking screw on the fitting 1-2 turns.

Call line d.52 of the service menu. And using the + and - the value of the line parameter d.52 , set the minimum pressure at the gas valve outlet specified in the boiler operating manual. For example, for a Gepard 23 MTV boiler, the minimum pressure in front of the burner is 1.5 mbar or 15.5 mm water column.

This setting will ensure that the boiler operates with the minimum power specified by the manufacturer - 8.5 kW. The boiler manufacturer's service instructions do not answer the obvious question of what to do if the power of the heating circuit connected to the boiler is less.

In our example, after setting and setting parameter =28 in line d.52 , measuring the pressure at the outlet of the gas valve in front of the burner showed a value of 4 mm.water column.

Readers in the comments ask the question: “Isn’t such a significant decrease in gas pressure on the burner dangerous for the boiler?” Boilers have many different protections, but there is no protection against low gas pressure on the burner. From this we conclude that low pressure in itself is not dangerous for the boiler. It is important to ensure stable ignition and stable combustion of gas, since the boilers have appropriate protection.

A home mechanic can roughly assess whether the gas valve settings correspond to the factory settings without resorting to measuring the gas pressure on the valve.

To do this, set parameter =9 in line d.00 of the menu and turn on the boiler in the minimum heating power mode. Record gas meter readings. After 15 minutes (1/4 hour), the meter readings are recorded again and the gas consumption during this time is determined. For example, we determined the gas consumption from the meter to be 0.289 m3/15 min. This value is multiplied by 4 and the gas consumption calculated for 1 hour in the minimum power mode is 1.156 m3/hour. Compare the obtained value with the data from the factory instructions. For example, the standard gas consumption in minimum power mode for the Gepard 23 MTV boiler is 1.15 m3/hour. Gas consumption according to the meter readings approximately corresponds to the factory norm. We conclude that setting the gas valve in minimum power mode meets the requirements of the factory instructions. If not, then the gas consumption is adjusted by changing the parameter in line d.52.

Similarly, based on gas consumption, you can evaluate the setting of the gas valve at maximum power by switching the boiler to DHW mode.

Power 23.3 kW. corresponds to a maximum pressure at the valve outlet of 85 mm.water.

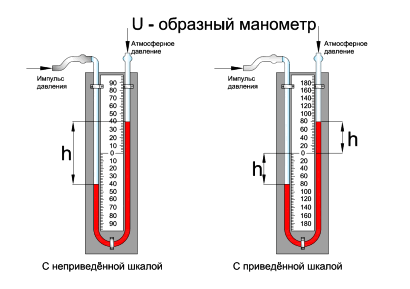

U-shaped pressure gauge

A simple pressure gauge for measuring a gas valve can be made from a clear plastic tube, filled with water and bent into a U shape. One end of the tube is placed over the valve fitting and the other is left open. A ruler is used to measure the difference in water levels in the branches of the tube. The measured distance will be equal to the pressure in millimeters of water column - mm.water column.

A tube with an internal diameter of 8 mm can be tightly pulled onto the gas valve fitting. For a tube of a different diameter you will have to select an adapter.

At the end of the measurements, do not forget to carefully tighten the screw on the measuring fitting and check its tightness.

Connecting a thermostat and outdoor temperature sensor to a gas boiler

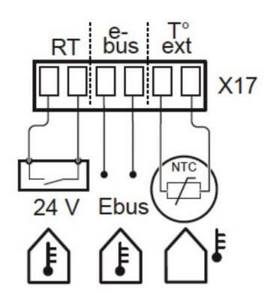

The wires from the two-position thermostat are connected on the block to the RT terminals, instead of a jumper.

The wires from the Thermolink P interface thermostat are connected to the same block, but to the terminals marked “e-Bus”. The jumper between the RT terminals is left in place.

An outdoor temperature sensor can be connected to the Toext terminals.

Connecting a two-position wireless thermostat to the boiler - video

The wireless room thermostat consists of two blocks.

The executive unit is installed near the boiler and connected to the boiler by wires, to the same terminals as a conventional wired thermostat. To power the executive unit, it is also connected to a 220 volt power supply.

The measuring (control) unit with a display is mounted on the wall of a heated room. The signal from the measuring unit goes to the executive unit via a radio channel.

Polypropylene strapping

Plastic pipes have replaced metal pipes everywhere, including for water pipes. For heating, multilayer reinforced products that can withstand high pressure are used. Thanks to soldering connections, a monolithic piping of a gas heating boiler with polypropylene is obtained. Schemes are created of any complexity and in a short time.

Important! The simpler the heating system design, the more reliable it is, and the higher the performance. Unlike the coolant, gas is connected to the boiler through a metal pipe with a paronite gasket

The seal is airtight and does not burn

Unlike the coolant, gas is connected to the boiler through a metal pipe with a paronite gasket. The seal is airtight and does not burn.

Standards for air temperature in residential areas of the house

In a private house, when setting up a heating system, it is recommended to focus on the indoor air temperature standards established by GOST 30494-2011. Interstate standard. Residential and public buildings. Indoor microclimate parameters":

| The name of a room | Temperature (оС), optimal / permissible |

| Living room | 20-22 / 18-24 |

| The same, but in areas where the outside air temperature of the coldest five-day period is -31 °C or lower | 21-23 / 20-24 |

| Kitchen, toilet | 19-21 / 18-26 |

| Bathroom, combined toilet | 24-26 / 18-26 |

| Staircase, lobby | 16-18 / 14-22 |

| Pantry | 16-18 / 12-22 |

In addition to temperature, another important parameter of the indoor microclimate is relative air humidity. The standard also regulates the relative air humidity during the heating period for living rooms - the optimum is 45-30%. The permissible air humidity in all rooms of the house should be no higher than 60%.

Measurement of temperature and air humidity should be carried out in the center of the room at a height of 1.7 m, in cloudy weather and outside air temperature below -5 ° C.

Optimal microclimate parameters are a combination of values of microclimate indicators that, with prolonged and systematic exposure to a person, provide a normal thermal state of the body with minimal stress on the thermoregulation mechanisms and a feeling of comfort for at least 80% of people in the room.

Acceptable microclimate parameters are combinations of values of microclimate indicators that, with prolonged and systematic exposure to a person, can cause a general and local feeling of discomfort, deterioration of well-being and decreased performance with increased stress on the thermoregulatory mechanisms and do not cause damage or deterioration in health.

In residential buildings in accordance with SP 60.13330.2010 “SNiP 41-01—2003 Heating, ventilation and air conditioning” during the cold season of the year, when there are no people in them, it is allowed to reduce the microclimate, taking the air temperature below the standard, but not below: 15 ° C - in residential premises; 12 °C - in public, administrative and domestic premises. The normalized temperature in the premises must be ensured before use.

In the basement of the house, the air temperature should not be lower than +5 °C.

Tips for the developer

How to reduce the high gas consumption of a boiler for heating a house:

- Choose the power of one gas boiler that is minimally necessary to compensate for heat losses at home. When installing two boilers, their total power must be equal to the minimum required.

- In order to save gas and comfort, it is beneficial to use a heating and hot water system with a single-circuit boiler and boiler. When the heating system power is less than 15 kW. It is better to avoid using a double-circuit boiler; a system with a boiler will be most profitable.

- Choose a gas boiler with an open combustion chamber, atmosphere.

- When choosing a boiler brand, among other characteristics, be sure to evaluate the boiler efficiency indicated in the technical documentation.

- Clean the boiler heat exchanger to remove soot annually.

- Monitor the serviceability and immediately eliminate defects in the air supply and flue gas exhaust systems of the boiler.

- Be sure to connect a room thermostat and an outdoor temperature sensor to the boiler. Installing a simple two-position thermostat and an outdoor temperature sensor will pay for itself in one to two years.

- Install a thermostatic valve on each radiator in all rooms (except the room with a room thermostat). This will allow many rooms to avoid overheating and maintain a lower temperature.

- Equip rooms with heated floors with automatic room temperature regulators with protection against floor overheating.

Only in this way, bit by bit, having fulfilled these conditions, can the gas consumption associated with the operation of the heating system be reduced to a minimum.

More Articles on this topic:

⇒ DHW boiler for a double-circuit boiler or water heater ⇒ Descaling the heat exchanger of a gas boiler or water heater ⇒ Setting up and adjusting the power of a gas boiler ⇒ Faults and error codes of a gas boiler Ariston, Protherm, Baxi ⇒ Setting the pressure in a heating system with a membrane expansion tank

Read page: Page 1, Page 2

More articles on this topic

- Installing a boiler in a private house in the attic

- Attic floor on wooden beams

- Installation of plastic windows at the dacha

- How to remove old wallpaper from a wall or ceiling

- How to remove the smell of hydrogen sulfide from water in a well, boiler, well

- Materials for the construction of a single-layer external wall of a house

- Sheathing, wall cladding with basement siding

- Frame house with communications - features and advantages

General description and operating principle

Liquefied gas is a natural resource, artificially cooled to a temperature of -160 °C for ease of storage and transportation.

A boiler using this type of fuel is a traditional heat generator in appearance, design and type. It burns gaseous fuel and directs the resulting heat to warm up the heat exchanger.

Boilers operating on liquefied gas can be switched to traditional main gas in the future if such communications appear near a residential premises. To do this, you will need to replace several working elements and reconnect the equipment to the centralized gas system

From there, the useful resource is “taken” by the coolant and transports it along the loop communications, thus heating houses and heating domestic water, if this is provided for by the design of the equipment.

Specific features of operation

The first main difference between the unit and analogues operating on traditional main gas is the ability to function efficiently even with reduced fuel pressure. The second is a special nozzle in which the nozzle holes have a reduced diameter, suitable specifically for a propane-butane mixture.

In order for the boiler to cope with heating a residential building and heating water for plumbing and domestic needs, it will need to be provided with the required volume of fuel. To do this, you will have to build a gas tank on the site (a reservoir located underground) or connect the equipment to propane cylinders

Some manufacturers of traditional gas boilers complete their products with injection systems so that, if necessary, customers can convert the equipment to liquefied fuel.

True, you will additionally have to install a special nozzle, reconfigure the gas valve and replace some parameters in the electronic board of the heat generator. But after all these steps, the boiler will work in a new mode, and customers will be able to effectively heat their homes with liquefied gas.

Installing a gas tank is one of the most effective ways to provide the boiler with working fuel. The storage volume can be chosen so that it will have to be refilled once a year or even less often, spending from 20 to 60 minutes on this

The uninterrupted operation of the device is guaranteed by the presence of constantly supplied fuel. These can be ordinary gas cylinders, combined into groups of 2 to 15 pieces, or different types of gas holders.

The supply lines are connected to the boiler via a gas reducer. It controls the supply of fuel and ensures its reasonable consumption - within 1.8-2.0 m3/h.

To quickly and inexpensively equip a fuel tank, you can purchase a mobile gas tank. It will instantly solve the problem with resource storage and will allow you to provide heating for a dacha or a not too large country house

The main functionality also includes a safety unit, consisting of safety valves, a temperature controller, flame and pressure sensors. A system equipped with these elements is easy to operate and does not create any problems for the owners during use.