While various wood wastes in the form of sawdust and wood chips are quite easy to burn in long-burning boilers specially adapted for this, the situation is different with fine coal and dust. Anyone who has ever tried to fire a stove or boiler with small fractions of coal knows that half of the fuel is wasted, spilling through the grate into the ash pan, and the other half is sintered and blocks the access of air to the firebox. Because of this, the intensity of combustion is sharply reduced. At the same time, it is stupid to throw away such fuel, because it contains a lot of thermal energy. In such a situation, coal briquetting can help, which will be discussed in this article.

About coal briquetting technology

One of the ways to burn coal fines is to light the boiler with wood, and then pour the dusty fraction of fuel on top of the burning logs. But this is too troublesome, since coal dust must be added in small portions, and therefore often.

If you load a large portion, then some of the fuel will definitely spill into the ash pan and go to waste, and the rest of the fuel will fill the cracks between the wood. Air will stop flowing into the combustion zone and, as a result, the firebox will begin to fade.

The best way is to use the pressing method to form briquettes from the fine fraction, which then burn very well, releasing a large amount of heat. Such a solution as coal briquetting was proposed at the beginning of the century before last in Russia by the inventor A.P. Veshnyakov is still successfully used both for industrial purposes and in everyday life. Its essence is that the compaction of fine coal using high pressure on special equipment makes it possible to obtain fuel whose calorific value is no less than that of high-quality coal.

Without going deeply into the intricacies of the technological process and the classification of different brands of fuel, we note that such briquettes are produced in two types:

- with binders for industrial purposes;

- without binders, intended for combustion in domestic boiler systems.

Note.

Briquettes pressed with binders cannot be used in everyday life. When burned, these substances form harmful or toxic compounds, which are captured in industry in various ways. Previously, starches or molasses were also added to household fuel as binders, but this technology is outdated.

Since we are interested in the technology for producing coal briquettes without any additives for household purposes, it is worth considering this. So, the sequence of the process is as follows:

- first, the coal undergoes a grinding operation, with a maximum fraction size of 6 mm allowed;

- the next operation is drying in order to achieve an optimal humidity of 15%. For this purpose, special equipment is used for the production of coal briquettes - steam or gas dryers;

- After drying, the composition is cooled and supplied for pressing. The operation takes place at a pressure of 100-150 MPa in the so-called stamp press;

- final cooling and shipment to the warehouse.

Note.

The traditional technological process is described here, but the requirements for the fraction size and moisture content of the raw materials may vary depending on the equipment used. For example, a modern mini-plant of the Russian company UNITEK requires particle sizes of up to 0.25 mm with a moisture content of 6 to 16%. That is, in this case, the coal briquetting technology should provide for better grinding, but the pressing pressure is applied much lower.

The output is a coal briquette, whose ash content does not exceed 15-20%, the maximum permissible mechanical load is 3 kg/cm2, and when dropped from a height of up to 2 m, the product loses no more than 15% of its mass as a result of impact. The heat of combustion depends on the grades of coal from which the briquette is pressed.

Features of coal briquetting technology

The production of briquettes from coal waste began in the 19th century. Manufacturing involved bonding coal particles and dust together using resin and compacting them with a mechanical press. The disadvantage of such briquettes was the release of harmful tarry products during combustion, because During the manufacturing process, we were not very concerned about the safety rules for coal preparation and briquetting.

Currently, improved technologies are used and, although the production of briquettes has not reached a large-scale level, they are in great demand among consumers. For household use, briquettes are offered without binders or with substances that are safe for human health. Therefore, before purchasing, you should definitely study the information from the manufacturer, especially the item that talks about its composition.

Coal briquetting consists of several production stages:

- drying to remove moisture from raw materials;

- processing of raw materials, grinding them into identical particles;

- adding binding components;

- heating coal to a certain temperature;

- pressing;

- drying to bring the humidity to within 18-20%;

- cooling.

In modern production, it is possible to form briquettes from coal waste without adding binders. This requires special equipment for briquetting coal. In it, raw materials go through only two stages:

- compaction of raw materials to remove voids between particles;

- compression and compaction of the particles themselves under increased pressure up to 100-200 Mn/m2.

The resins released during the process will serve as a fastening component. Briquettes made in this way burn without smoke or releasing harmful substances into the air.

Industrial methods of coal briquetting

Let's consider the technology for producing coal briquettes in a factory using coal tar and coal dust. This is the cheapest raw material, which allows you to organize the production of high-quality briquettes with good heat transfer without investing large amounts of money. To organize the process, a number of installations are used: a crusher, a press and a dryer. The material moves from one stage to another using a conveyor belt.

- First, the coal is washed to remove debris to obtain a clean product without unnecessary impurities.

- Next, the purified raw materials are crushed to particles with a size of 6 mm or less.

- In a steam or gas dryer, the coal is dried to a moisture content of 15%.

- The composition is cooled and goes to the pressing stage under a pressure of 20-150 MPa.

- Finished products are transported to a warehouse for storage.

The technology for producing briquettes for use in industrial enterprises allows the addition of binders such as cement, petroleum bitumen mixture, liquid glass, etc. But purchasing coal briquettes with this composition for heating residential premises is prohibited by the requirements of the SES.

Briquetting coal at home

Previously, to obtain briquettes from coal, you only needed time and your own hands. To do this, coal waste was wetted with water until a thick mass was obtained. They then made cakes from it by hand and dried them in the air. This homemade fuel was successfully used to light stoves and fireplaces.

Not everyone can afford to open a home production facility for enriching and briquetting coal using equipment, so craftsmen have invented their own modern method of producing solid fuel from coal waste. To do this, use one of two types of installations: a manual press or a homemade screw extruder. The advantage of a hand press is that you can make it yourself or buy it inexpensively from a craftsman. The downside is low performance. In order to have enough briquettes for the whole winter, you need to work hard in the summer.

To briquet coal you will need a manual press.

Using an extruder, you can quickly stock up on fuel, because... the entire production process is mechanized. But to manufacture or purchase ready-made equipment for briquetting coal, you will need financial investments, so you need to make calculations whether such a purchase is rational or not. The process of briquetting coal at home is as follows:

- grinding coal using any available method. The smaller its fraction, the better;

- the resulting raw material is mixed with water to such a consistency that the mass molds well;

- the prepared forms are filled with the coal mixture and pressed with a hand press;

- The finished briquettes are removed and dried naturally.

The result is briquetted coal for lighting a home boiler or stove. It cannot be transported, because... the absence of a bonding agent will turn the briquette back into dust.

With the presence of an extruder, the production of charcoal briquetting is greatly simplified and accelerated. The process is similar to the principle of a meat grinder. The prepared coal mass is poured into a special receiving compartment, and good quality sausages come out. Until they harden, you can cut them into briquettes of any size. The strength of the products allows them to be transported without fear of damage.

If you compare home briquettes with industrial briquettes, they are, of course, inferior in quality. But producing such fuel is much cheaper than buying finished products and it burns quite well.

Making coal briquettes at home

It is clear that industrial equipment for coal briquetting is inaccessible to the average homeowner due to its high cost. However, our grandfathers also knew how to make briquettes without any equipment. To do this, coal dust and crumbs were mixed with water in such a ratio that a thick mass was obtained, and then cakes were molded from it by hand. After drying, such products were successfully burned in a home stove. That is, contrary to production technology, the mixture for the production of coal briquettes is not dried, but, on the contrary, moistened.

At home, briquettes are made in 2 ways:

- using a hand press;

- on a homemade screw extruder.

The first method is good because you can buy a pressing machine inexpensively or make it yourself. Its disadvantage is low productivity; in order to make yourself a fuel briquette for the whole season, you will have to work very hard. In the second case, briquetting of coal dust occurs quite quickly, since the entire process is mechanized. But here the cost of the unit comes to the fore; even a homemade installation will require significant costs. You will need to purchase a powerful electric motor, gearbox and other parts.

The algorithm according to which you can make coal briquettes yourself is as follows:

- You must try to grind the coal chips in any available way. The smaller the fraction, the better the quality of the product;

- mix the resulting composition with water. It is not possible to indicate exact proportions, since they depend on the dust content. The main thing is that the mixture is very thick and molded by hand. There is no need to add clay, this will only increase the ash content;

- fill the mold with the composition and operate the manual mechanism;

- Remove the briquetted coal from the mold and leave to air dry.

As a result, we get fragile products that are unsuitable for transportation, but burn well in the stove. One of the ways to briquet coal at home can be found by watching the video:

When a screw press is available, production is greatly simplified and accelerated. Turning on the electric motor, the above mixture is loaded with a shovel into the receiving hopper of the extruder. The output is cylindrical “sausages” of excellent quality. It is worth noting that such briquettes made from coal dust have good strength and can even be transported.

For more information about the operation of the extruder, watch the video:

Production of coal briquettes in a factory

Fine coal fractions and dust are characterized by low density and low specific calorie content. But they can be bought cheaply and then converted into high-quality fuel by compaction in a limited volume. Simply put, to produce pressed coal briquettes, whose density and calorific value are much higher.

This is how factory (left) and homemade (right) coal briquettes burn

To make such briquettes from fine coal with your own hands, you need to figure out how and with what machines they are stamped at the factory. Equipment for the production of heating briquettes is a technological line consisting of the following installations:

- crusher;

- drying chamber;

- briquetting press.

Note. Equipment units are listed in the same order in which they are located according to the technology. The supply of raw materials and its movement between installations is carried out using belt or screw conveyors.

The process of pressing coal fuel occurs as follows:

- In the crusher, fine coal is crushed into particles of the same size, depending on the characteristics of the pressing equipment. The maximum permissible fraction size is 6 mm.

- In the dryer, the moisture content of the raw material is reduced to 15% (maximum).

- The last stage is pressing, performed under pressure from 20 to 120 MPa, depending on the technology used.

Sometimes, to strengthen the final product, organic or mineral binders are added to the raw material, and before compacting the mixture, it is heated to a temperature of 250-350 ° C. There are 2 ways to press coal briquettes for heating:

- on stamp (roll) presses;

- using extrusion machines.

The stamp press compresses the heated coal mixture in special forms, developing a force of 100-120 MPa, after which the briquetted coal undergoes a cooling and packaging process. The output is products in the form of “tablets”, “pads”, cylinders and bricks with holes.

This method of producing coal briquettes is used to produce fuel in large quantities and entails considerable financial and energy costs.

Manufacturing by extrusion involves pressing raw materials with a screw press through a matrix with calibrated holes. At the output we have a cylindrical coal briquette in the form of a “sausage”. This is a cheaper but less productive coal briquetting technology.

Extruders for pressing coal dust

The characteristics of the fuel are influenced by the composition of the original raw material - brown or hard coal, the presence of binders and other factors. But usually the calorific value of a factory briquette is at least 7 kW/kg with a humidity of 8% and a maximum ash content of 8.5%.

ADVANTAGES OF BRIQUETTED COAL

Technical solution:

- Receiving a product of the same size, volume, shape and weight.

- Elimination of the problem of dust formation and defects during transportation.

- Specified hardness and strength of the briquette.

- Recycling waste into commercial products

Consumer and marketing benefits:

- Higher energy value

- Longer burning

- Ash in powder form

- Less CO2 and sulfur emissions

- Easier packaging, transportation, storage

- Ready for automatic feeding into the firebox

- Possibility of packaging for the consumer market

- Export supplies

BRIQUETTING COAL WITH BINDER

The plant for briquetting coal with a binder consists of the following sections:

- coal sorting and grinding area if the coal size is too large

- drying area if the moisture content of the coal is too high

- binder addition area

- briquetting area on a two-roller press

- (optional) post-processing area (cooling, ripening and drying depending on the binder used)

The capacity of a plant for the production of briquettes from coal with a binder can range from several tons per hour to 100 t/h for large presses.

Possible binders

- coal pitch

- petroleum bitumen

- resin

- molasses and lime

- lignosulfonate

- starch

- polymers, etc.

The specific binder for charcoal briquettes is determined by regional availability and end product requirements. The optimal proportions of the binder and the parameters of the finished briquette are determined during pilot testing of coal in France.

Testing of raw materials and binders for coal briquettes

Coal in each specific deposit has individual chemical and physical characteristics, and different binders may be available in each region.

To accurately determine the required composition and characteristics of the equipment, it is necessary to conduct preliminary testing of the customer’s material at the manufacturer’s plant in France. To conduct tests, the customer needs to send coal to France for testing.

As a result of the tests you will be able to:

- determine the required composition and characteristics of the equipment

- determine the type and proportions of the binder

- obtain a finished briquette and determine its characteristics

- calculate accurate economic indicators of production

Also, only through testing is it possible to determine whether coal is suitable for briquetting without a binder and what the technical and economic indicators of production will be in this case, as well as the quality characteristics of the briquette.

COMPARISON OF OPTIONS for coal briquetting with and without binder

Coal briquetting using a binder:

- +

Suitable for any hard or brown coal - +

High productivity (up to 100 t/h) - +

- +

Possibility of obtaining moisture-proof briquettes - +

Low cost of consumables - —

More expensive and complex equipment; binder required

Briquetting coal without binder:

- —

Applicable only to certain coals - —

Drying is required - —

Limited capacity (up to 25 t/h) - —

High specific energy consumption - —

High cost of consumables - +

No binder, simpler and cheaper equipment

The technology of coal briquetting without binder additives seems more attractive at first glance, however, at the same time, energy costs increase significantly, and the productivity and quality of the briquette decreases.

After testing, it usually becomes clear that briquetting using a binder is more economically justified, even taking into account the costs of purchasing, delivering and storing these materials.

Pressing of crushed coal and coal dust

Pressing of coal dust and crushed coal fraction is carried out on two-roller presses that meet industry requirements:

- High performance

- Low specific energy consumption

- High reliability

Our partner is the world leader in the production of this equipment, French.

Post-processing (maturation) of coal briquettes

Depending on the type of coal and binder in the technology, it may be necessary to specially cool and keep the finished briquette for some time in special bunkers, during which the briquette acquires strength.

The holding time is individual and determined at the testing stage.

If you are interested in the technology of producing coal briquettes, we will be happy to answer

Content

Affordable price compared to other types of energy resources, no problems with purchase, good heat transfer are the main reasons why many users prefer to use coal briquettes for heating. The price of more conventional energy sources is constantly increasing, which forces us to look for alternative heat sources. Coal dust is an accessible type of fuel, but its use in its pure form is unprofitable: half of the raw material falls into ash through the grate bars, and the other half is sintered, which leads to clogging of the firebox.

Coal briquettes

One of the options for using coal dust, which allows you to get maximum heat from it, is to pour the fraction on firewood, which is used to pre-heat the boiler. But this is very troublesome, since it needs to be poured often in small portions. Adding a large amount of fines will lead to the fact that it will still spill into the ash pan, turning into waste. And the part that still remains on the wood will fill the gaps between them, blocking the air circulation and causing the firebox to fade.

The solution is to produce briquettes from dust with the addition of auxiliary substances by pressing. The fine fraction processed in this way burns well with high heat transfer.

Coal dust briquetting equipment

Sooner or later, every enterprise engaged in work related to the sale or processing of any type of coal is faced with the problem of accumulation of fine coal and dust. The dust fraction from 0 to 6 mm constitutes on average at least 25% of the total mass of incoming raw materials and, as a rule, entails difficulties in selling this volume or a significant reduction in the cost of its sale.

One of the most effective methods to solve this problem is to use the accumulated coal dust to produce coal briquettes. The production of fuel briquettes, despite all the attractiveness of this idea, does not have such a long history. Real interest in this issue has become acute and relevant only recently, due to a significant rise in fuel prices, including coal products.

Most attempts to organize the production of coal briquettes were frustrated either by the high cost of the technology or by the unsatisfactory quality and characteristics of the resulting briquettes associated with the use of cheap but poorly flammable binders, which repeatedly increased the ash content and minimized sales performance. Our company offers an exclusive set of equipment that allows, using a fairly simple technology, to avoid the use of binders and other foreign impurities in the production of briquettes, with the exception of simple water.

This allows you to ultimately obtain a briquette in composition and characteristics that is in no way inferior to the original graded coal and avoids the usual disadvantages (foreign odor, high ash content, low calorie content, etc.) The main working unit of the proposed equipment is extruder presses, which are specially designed for briquetting rocks, anthracite pellets, coal slurries, brown coal crumbs, peat, etc. The pressing technology is based on adhesive-chemical processes occurring in visco-chemical systems formed by finely dispersed particles of fossil coals, which themselves act as binders. Simply put, during the operation of the press, such physical and chemical conditions are created that force the fossil organic components already included in the coal (phenols, resins, wax, etc.) with the participation of water to polarize on the surface of the particles, causing them to bind to each other. When cooled and dried, the briquette hardens and becomes fixed. Briquetted fuel has high thermal power properties, in particular sufficient mechanical strength, water resistance and heat resistance. When burned, the layer of such fuel has good gas permeability, which ensures a complete degree of combustion even with a relatively high ash content. To achieve maximum productivity of briquetting presses, our company has developed storage hoppers with screw pre-pressers, which ensure uninterrupted supply of the charge under the required pressure and at the designed speed. In addition, the briquetting line includes box conveyors with air coolers and a thermal grotto. To obtain the required moisture content of the mixture, mixing drums with a capacity of up to one ton of finished raw materials have been developed. Due to the simplicity of the technological process, the equipment does not have complex technological components, does not require highly qualified maintenance personnel during operation and repair, and operates reliably in any conditions.

1. Briquetting line 16 tons per shift (shift 8 working hours). The following configuration:

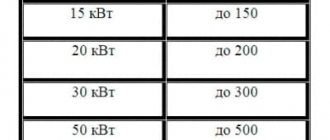

| Equipment | Productivity t/h | Number of units | Energy consumption kW/h |

| Hammer crusher | 2-10 | 1 | 15 |

| Forced mixer | 2-3 | 1 | 3 |

| Extruder press | 2 | 1 | 18 |

| Conveyor dryer (level 2) | 2 | 1 | 20 |

| Belt conveyor | 2 | 3 | 1,5 |

| Cooling conveyor | 2 | 1 | 2,5 |

2. Briquetting line 40 tons per shift (shift 8 working hours). The following configuration:

| Equipment | Productivity t/h | Number of units | Energy consumption kW/h |

| Hammer crusher | 5 | 1 | 22 |

| Forced mixer | 5 | 1 | 3 |

| Extruder press | 5 | 1 | 40 |

| Conveyor dryer (level 3) | 5 | 1 | 30 |

| Belt conveyor | 5 | 3 | 3 |

| Cooling conveyor | 5 | 1 | 3 |

Price list

More about briquetting technology

At the beginning of the last century, Russian researcher A.P. Veshnyakov proposed pressing the fine fraction into elements of a certain shape and size, which in terms of heat transfer were not inferior to the coal itself. The idea has found wide application both in everyday life and in industry.

Coal briquettes on a screening belt

Today, pressed coal is classified depending on the material, environmental friendliness, security, shape and type of packaging. But the two main types are:

- For production with the addition of binding components.

- For home use without additives.

It is important to know that industrial briquettes should absolutely not be used in everyday life. When they burn, a large amount of toxic substances are released, for which special equipment is responsible for removing them under production conditions. Previously, additives in the form of molasses or starch were used in the production of household briquettes. But this technology is a thing of the past.

Safety rules for coal preparation and briquetting

If you decide to use briquetted coal as fuel, you should approach its production with all responsibility. The components for the manufacture of solid fuel are selected depending on the place of its use. The composition of briquettes should not contain harmful components, so as not to be poisoned by the products of their combustion.

A low-quality product may have poor heat transfer and fail to cope with its direct responsibilities of heating the room. Poorly compressed briquettes will quickly turn into dust and go to waste.

Industrial production

Distinctive features of dust and fine coal fraction: low specific calorie content and density. But these materials are considered as cheap raw materials that make it possible to organize the production of coal briquettes. The products will have good density and heat transfer at low cost.

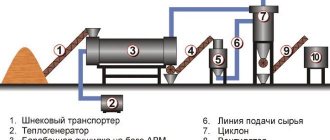

To produce briquettes in a factory, a special production line is used, consisting of a crusher, dryer, and press. The movement of semi-finished products between machines is ensured by a conveyor belt.

Pressed coal without additives is produced in several stages

:

- Grinding raw materials to a particle size of 6 mm and smaller.

- Drying the mixture to 15% humidity using steam and gas dryers.

- Next, the dust is cooled and fed to a stamp-type press, which acts on the mixture under a pressure of 20-150 MPa (depending on what technology is used). After this processing, the finished briquettes are sent to the finished product warehouse for storage.

The purpose of the fuel and the equipment used are the main factors influencing the size of the particles, the level of humidity and the amount of pressure under which they are turned into briquettes. At the same time, the energy intensity of the finished product directly depends on the quality of the raw materials. It is important to use the fine fraction of anthracite, and not brown or other types of coal. For strength, it is permissible to add mineral or organic additives.

Coal briquetting press

Coal briquettes can be compressed in two ways

depending on what briquetting equipment is used:

- Stamp press. The heated coal mixture is filled into special molds, in which it is compressed with a force of 100-120 MPa. After cooling, the briquettes are packaged. The finished product looks like bricks or cylinders with holes, and may look like “tablets” or “pads.” This manufacturing method is suitable for the production of briquettes in large quantities due to the high energy and financial costs.

- Extrusion machine. In this case, the plastic coal mass is pressed through the matrix by a press. A screw-pressed briquette (pini-key) made from coal dust has a cylindrical shape, resembling a “sausage”, with a calibrated hole in the middle. The technology is less expensive, but also less productive.

The technology for producing briquettes for industrial use involves the addition of cement, oil-bitumen mixture, liquid glass and others. The use of these substances in metallurgy is permitted. But you cannot buy coal briquettes with oil bitumen for heating a living space according to the requirements of the SES.

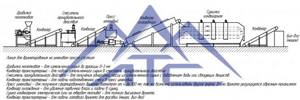

Briquetting line for screening out hard and brown coal

Designed for the production of briquettes of various shapes from screenings of hard coal mixed with binders.

Line composition: A1 BIS feedstock hopper A2 Belt conveyor A3 DU-650 coal crusher A4 Belt conveyor B1 Twin-shaft screw mixer SSh-2000 B2 Belt conveyor B1 Feeder hopper BP-5 B2 Roller briquetting unit UBV-3 B3 Belt conveyor S1 Hopper dispenser continuous action DBND-1500 Zh1 Vegetable oil injection unit VZhIK

PRINCIPLE OF OPERATION:

The feedstock is loaded by a front loader into bin A1. The dual design of the A1 hopper is due to the need to provide a large loading volume at a low height. The height of the bunker is selected based on the average unloading height of front loaders. The design of the bunker can vary depending on customer requirements.

Bunker A1 is equipped with manual gate valves to adjust the volume of raw materials unloaded onto the conveyor belt A2. Belt conveyor A2 is installed directly under the gate valves. The raw material, poured by gravity onto the conveyor belt A2, is fed into the combined crusher A3.

The crushed raw materials are unloaded in a continuous stream onto an A4 conveyor belt placed directly under the discharge opening of the crusher. Belt conveyor A4 transfers crushed raw materials to twin-screw mixer B1.

The B1 twin-screw mixer is designed for mixing crushed coal raw materials with binders. This continuous mixer is a storage tank in which two parallel, horizontal shafts equipped with screw-type blades rotate.

Depending on the production technology, customer requirements and the type of feedstock, both dry and liquid components can be used as binders.

For dry binders, a dispenser C1 is provided, which supplies additives directly to the conveyor belt A4 moving with crushed coal. The binder evenly sprinkles the crushed coal, thereby simplifying the mixing process. The C1 dispenser is equipped with strain gauge sensors.

For liquid binders, an installation for introducing liquid components Z1 is provided, spraying the substance directly into the twin-screw mixer B1. Spray uniformity is ensured by a nozzle and a pressure pump.

Raw materials ready for briquetting are continuously unloaded onto the B2 conveyor belt. The raw materials moved by the B2 conveyor belt are loaded into the B1 feeder hopper. Feeder hopper B1 is necessary for accurate dosing of raw materials into briquetting unit B2, and also as a buffer zone.

The B2 briquetting installation is designed for pressing crushed raw materials with a binder into briquettes of various shapes. The principle of operation is based on briquetting with simultaneous compression of raw materials between rollers rotating towards each other at equal speed. The finished briquettes slide down the unloading grid and are picked up by further inter-operational transport (further inter-operational transport is not included in the configuration of this line). The remaining raw material that has not taken the form of a briquette falls through the unloading sieve and ends up on the attached belt conveyor B3, which returns the mass to the two-roll mixer B1 for further repressing

Briquetting coal at home

Industrial technology is not suitable for briquetting coal at home. The high price of equipment for the production of coal briquettes, high energy costs, and the need to obtain a huge number of permits from government agencies significantly increase the cost of the finished product. But for the purpose of heating a small private house, there is no need to organize large-scale production. To make 3-4 tons of briquettes (winter stock), it is quite possible to make do with improvised means.

Equipment for briquetting at home

The simplest method, which was well known to our great-grandfathers

:

- Coal dust is mixed with clay in a ratio of 10:1 with the addition of a small amount of water to form a thick mass. Clay is a safe binding component that will prevent the briquettes from falling apart. It is important to thoroughly mix all the components of the mixture. A construction mixer is often used for this purpose.

- Next, the solution is poured into molds. These can be either special containers or used equipment (old pots, buckets, boxes). If there are no containers, coal cakes can be formed by hand, as our ancestors did.

- After complete drying, the briquetted coal can be sent for storage.

Despite the fact that, according to production technology, the mixture is dried, during the home preparation of briquettes the mixture is moistened. In this case, homemade coal briquettes have the following distinctive features

:

- Imperfect shape.

- Different levels of humidity and, therefore, heat transfer.

- Low strength, which does not allow briquettes to be transported.

Homemade coal briquette

But these properties do not prevent low-cost products from burning well, especially compared to caked dust. This option is much more convenient and practical.

And if you still want to automate the process somehow, then you can follow the example of home craftsmen and independently make equipment similar to production equipment:

- A machine that allows you to make briquettes manually. Instructions on how to make a machine can be easily found on the Internet. A unit designed for home brick production is well suited for manual pressing. The materials that allow welding the frame are a profile pipe and a 40*40 mm corner. A receiving hopper is mounted on top. A manual mechanism is attached to the side for briquetting the mixture into rectangular or cylindrical products. Technology

: Raw materials are crushed as much as possible. The fine fraction ensures the strength and quality of the briquette. - Adding water will create a sticky mixture. It is acceptable to add clay in small quantities to slightly increase the ash content of the fuel.

- Next, the mixture is poured into a hopper, from where the mold is filled. The briquette is extruded by pressing a lever.

- The reverse movement of the lever causes the briquette to be pushed out of the mold. It is removed and placed in the sun to dry.

- Thick-walled steel pipe for making the body. It is machined inside according to the desired screw size.

Technology for manufacturing coal briquettes without a binder

It is better to entrust the manufacture of the body, matrix, and auger to a good turner. It is important that the pulley diameters ensure a screw rotation speed of no more than 200 rpm. The motor must be grounded before connecting it to the household electrical network.

Production technology

:

- The raw materials are crushed and mixed with water.

- With the engine running, the mixture is loaded into the hopper.

- The emerging “sausages” are cut into pieces of the desired length and laid out on a rack to dry.

It is important to know that the presence of through holes in finished briquettes promotes better combustion and greater heat transfer.

conclusions

If you believe the manufacturers of coal briquettes, the calorific value of this type of solid fuel is even greater than that of other varieties. Theoretically, this statement may be quite realistic due to the fact that only by burning 1 kg of anthracite can 7.7-8 kW be obtained. In terms of specific heat, firewood and wood briquettes lag significantly behind, releasing only 5 kW/kg.

However, an analysis of reviews from owners of solid fuel boilers on thematic forums shows that the demand for coal dust briquettes is lower than for wood for several reasons:

- With their help, it is difficult to light a boiler and when burned, coal gives off little heat.

- Before and during combustion, an unpleasant odor remains in the room.

- Briquettes lose their shape and crumble heavily during transportation.

- Lots of ash.

Combustion of coal fuel in briquettes

A large number of negative reviews (about 70% of the total) can be explained by the fact that manufacturers use low-quality raw materials in order to make more profit. They briquet charge, sludge and other types of coal that are unsuitable for heating premises, and add extra substances to the mass. Briquettes truly made from anthracite are difficult to find. The main feature is the deep black color of the products.

The conclusions are obvious

:

- It is better to make coal briquettes yourself.

- For production it is necessary to buy high-quality raw materials.

- If it is possible to purchase only low-calorie grades of coal, pressing is not economically feasible. Although burning low-quality briquettes along with firewood will reduce heating costs.

Yes, home-made coal briquettes are very different from their factory-made counterparts: they crumble during transportation, are wet, and produce less heat. But this way you can control the quality of the raw materials used, the presence and quantity of additives. Both in a boiler and a stove, “homemade” briquettes burn well, much better than dust, which is simply baked into a cake. In addition, in terms of price, homemade cylinders, bricks or “sausages” are much more profitable.

About the benefits of coal briquettes - conclusions

If we think theoretically and take into account the assurances of coal briquette manufacturers, then in terms of calorific value they should defeat all other types of solid fuel. After all, only pure anthracite is capable of releasing 7.7-8 kW per 1 kg when burned. Firewood, pellets and wood briquettes lag far behind in terms of specific heat of combustion, since they emit no more than 5 kW/kg.

But judging by the reviews of users of solid fuel boilers on thematic forums, the demand for briquetted coal is inferior to any type of wood due to the following reasons:

- they burn poorly and give off little heat;

- form a large amount of ash, and even pebbles, repeating the shape of briquettes;

- crumble into dust during transportation;

- They emit an unpleasant odor before and during combustion.

If you analyze all the reviews about coal briquettes, it turns out that 70% of them are negative. This is primarily due to the fact that fuel producers are trying to make a profit by using waste raw materials - sludge, charge and other obscene varieties of hard and brown coals. Briquettes pressed from anthracite residues are rare.

This suggests a conclusion: if you want to get good fuel, then use the appropriate raw materials for briquetting with your own hands. When you only have dust and fines of low-calorie coal at your disposal, pressing them is not always advisable. On the other hand, such briquettes can be burned together with firewood, reducing the cost of purchasing them.