One of the most delicious types of products is smoked products.

It doesn’t matter whether you like smoked fish, meat or balyk - sooner or later you will want to cook these products yourself, without chemical impurities, with complete control over the process.

Most devices intended for smoking are quite large in size and are located mainly in summer cottages. What to do if you want smoked products, but don’t have huge territories to own?

Gas smokehouses come to the rescue, they can function anywhere where there is a gas stove, even in a small apartment.

Types of gas smokehouses

There are only three types:

- gas smokehouse with a water seal;

- hot smoked;

- cold smoked.

Smokehouse with water seal

In such smokehouses, cooking becomes extremely simple. The fundamental difference between the devices is the presence of a water seal, which is a shallow groove located in the upper part of the device. The water seal does not allow a large amount of water to evaporate , which means you will have to add it much less often.

Photo 1. Smokehouse with a water seal in a disassembled state. The grate on which food is laid out is visible.

A special grill is installed where the processed products are laid out, after which the smokehouse is placed on the stove and the water seal is completely filled with water. In order for the smoke to escape, you need to put a hose on the fitting and lead it out the window.

Hot smoked

This type of device has a relatively compact size and is optimal for smoking meat and fish. Products prepared by hot smoking are exposed to both smoke and high temperatures, which makes their taste soft and delicate. But the storage time for such delicacies is limited - about 3-5 days , so you should not purchase too large models for a small family.

Cold smoked

The shelf life of cold smoked products is several weeks . But the smoking temperature must be constantly maintained at the same level ( about 40 degrees ). This can only be achieved by increasing the cooking chamber, and, consequently, the size of the mechanism as a whole. The cooking time for smoked products is 2-3 days .

Types of home smokehouses

Depending on the design features, there are:

- electric smokehouses;

- on coals;

- for gas burners.

Features of electric smokehouses

Such units are connected directly to the electrical network and do not require additional heat sources. The heating element, which is located inside, independently heats and cools the air inside. Such a unit costs a lot, but is completely worth the money spent. The temperature is controlled automatically, suitable for both cold and hot smoking.

Coal smokehouses

Coal smokehouse

Charcoal smokers do not require any external heat sources or connections, so they can be placed almost anywhere. In an elongated smokehouse, coals are placed downwards, and sawdust from wood is placed on top. The air does not escape from the chamber, but it is evenly distributed in height and circulates, exposing all the stored food products to smoke.

When choosing a location, keep in mind that there must be a dense and strong base, some kind of substrate, because the heat also spreads to the floor. Make sure there are no flammable things nearby.

Gas smokehouses

A gas smokehouse is the most budget and low-cost option. These are devices designed for use on a hob. They are impressive in size and, as a rule, occupy 2 burners at the same time. Therefore, before purchasing, it is worth calculating what will be more economical: an electric smokehouse or a gas one.

A gas smokehouse with a vertical arrangement is more compact and resembles a pressure cooker in design. This model does not have shelves; instead, there are places for hanging food.

Smokehouses with a chimney outlet to the street or with a hydraulic lock are used in the house.

Home smoking occurs using waste from the processing of oak, alder, and ash. Oak sawdust is a classic and its most common use. Meat and fish turn out incredibly tasty and juicy.

When used indoors, the smokehouse is placed on a gas burner. After gradual heating, the chips begin to smolder, emitting a wonderful aroma and slight heat. The product is coated with all this and gradually cooked. Please note that the burner must be turned on at a low temperature, which should not be changed: the inside of the smokehouse for a gas stove must always be the same degree.

Can be used on an electric oven; it is easier to install and control temperature conditions.

Design and characteristics of a gas smokehouse

The device itself is a rectangular box made of sheet stainless steel. This material is most often used for the production of smokehouses, since it is the most durable, flexible and does not require special operating conditions. Some models have a water seal.

Photo 2. Smokehouse in the process of smoking products: installed on the stove, a hose is connected to the device to remove smoke.

In the cavity of the box there is a special chamber designed for burning wood chips . The most important part of the smokehouse is the smoke exhaust hose, which is usually vented out the window. In the box itself there is a grate on which products to be smoked are placed, and a tray for draining fat. Before starting smoking, the box must be covered with a lid.

How to use this smokehouse

You need to use the smokehouse exactly like any other home-made or factory-made model. The smoking process is quite simple and does not require any special knowledge.

Food preparation

In order for the smoked meat to be sufficiently juicy and tender, it should be prepared in advance.

A few hours before the product is smoked, it must be thoroughly washed, cleaned of fat and films, cut into portions and sprinkled with salt. In order to salt fish, it will take only three hours, it is better to leave chicken in salt for 5-6 hours, for pork it is worth setting aside a day. A less simple option involves soaking certain foods in a water solution. You need to add about 150 grams of table salt and about 20 grams of sugar to the liquid. Additionally, you can add your favorite spices to the mixture. The products should be infused in the resulting solution for two to three days. Then you don’t have to wash them, dry them a little and put them in the smokehouse.

Smoking recommendations

To ensure that no difficulties arise during the smoking process, you should follow some tips.

- There is no need to use pine wood chips as fuel. At high temperatures, it will begin to release resin, which will negatively affect the taste of smoked meats. The ideal option would be alder or poplar, fruit trees.

- Before using wood chips, you should soak them in plain water for a while. During smoking, it should smolder steadily and not burn. If the process goes correctly, the smoke is white.

- It is worth making sure that the lid fits as tightly as possible to the surface of the bucket. If necessary, you can put some weight on top. Often burlap is additionally placed under the lid.

- If the bucket does not come with a lid, then you can use any other one that has a suitable diameter. Otherwise, you can use a stainless steel sheet.

- You need to smoke food over low heat.

- The smoking time will depend on the type of meat or the size of the pieces, but no less than 15 minutes.

Connection to a gas stove

The gas smokehouse does not require any connection to the stove; you just need to place the structure on the stove and turn on the gas. The device can operate on any gas. Wood chips are laid out at the bottom . If you use a water seal, you need to pour water into a special tank.

Important! Smoking devices come in completely different sizes, so before going to the store you need to measure the dimensions of the gas stove ! Ceramic stoves are not suitable for use in smokehouses.

Installing a gas smokehouse, its correct and safe use is a simple process; it is only important to know the exact dimensions of the gas stove and the room in which you plan to place the device.

The sizes of gas smokehouses vary from 450x300x270 mm (the smallest models, ideal for a small family) to 610x310x300 mm (the largest devices).

A separate issue is the correct choice of wood chips.

The best option is fruit chips , which give the dish a special taste and aroma.

Attention! Under no circumstances should you use chips of coniferous or birch - the bitterness contained in the resins will make the smoked products bitter and harsh.

Criteria for choosing a smokehouse for a gas stove

When choosing a smokehouse for home use, you need to consider some criteria. These include:

- taking into account the volume of the product so as not to cook more than required (hot smoked dishes have a short shelf life);

- determining the desired type of smoking (you can purchase a multifunctional design);

- presence of a thermometer and timer.

- installation location: city apartment, private house or cottage.

- unit price.

Advice! An ideal option for the home would be a multifunctional unit used as a multicooker and smokehouse.

The Russian market of smoking devices offers a wide variety of smokers for gas stoves. According to consumer reviews, the following models are among the most popular.

Useful video

Watch a video review of a smokehouse with a water seal: what it consists of, how to properly prepare it for work.

A home smokehouse for a gas stove is designed for one or two burners. A smoking device operating inside a living space must be equipped with a water seal - an element that traps smoke and prevents it from leaking outside. You can make a smokehouse on a gas stove yourself or purchase a ready-made structure.

Smokehouse for a gas stove - how to choose and make it yourself

It's no secret that smoked products have a special taste and aroma. Delicacies prepared in this way are widely represented both in stores and on the food market. However, their quality does not always meet consumer requirements. Unscrupulous manufacturers often violate cooking technology in order to save time and money. Many gourmets have long been passionate about home smoking. It is much more convenient to do this business in your own home or somewhere in the country. Currently, the industry produces smokehouses that can easily be used in a city apartment. A home smokehouse for a gas stove has proven itself to be excellent. Such units will be discussed in this material.

Complete set of gas-powered appliances

The device is a rectangular or cylindrical container made of stainless steel. This material is most often used for the production of smokehouses due to its properties: flexibility, strength, and ease of maintenance. Most of these devices are equipped with a water seal that prevents smoke from entering the living space.

At the bottom of the device there is a chamber into which wood chips are placed. An important element of the device, which is used indoors with a gas stove, is a hose for removing smoke. It is taken out into a powerful hood or window (not the best option).

The design of such a device includes a tray for collecting fat released from meat or fish. Products that are placed in the smokehouse are placed on lattice shelves or hung on hooks.

Devices for cooking smoked meats powered by a gas stove vary in design, size, and functionality.

According to their intended purpose, the following smoking devices are distinguished:

- Devices for hot smoking. They have small dimensions and are characterized by a high speed of preparation of products, since the latter are processed with smoke at a temperature in the range of 60-140°C degrees.

- Equipment for cold smoking. The structures in this case are larger in size. In such smokehouses, products are processed with smoke at low temperatures - no more than 40°C degrees. Meat or fish are located at a considerable distance from the wood smoldering at the bottom.

Devices for gas stoves have different sizes:

- small devices - 400x300x250 mm, volume is 30 l;

- medium – 500x300x300 mm, volume – 30 l;

- large – 600x300x300 mm, volume – 60 l.

Smokehouses in most cases are rectangular, square and cylindrical. The latter are more compact and suitable even for small kitchens.

Which smokehouse to choose

If you love smoked foods, then it is better to learn how to cook them yourself. This will eliminate your doubts about the quality of the raw materials used, the presence of preservatives and aromatic additives. The cost of meat or fish prepared by yourself will be several times cheaper than those purchased in the store, and the taste properties of your own smoked products will win an unconditional victory in this dispute.

There are several options for smoking products. Before purchasing a smoker, you should decide how you will process them. This will determine the type of equipment you decide to purchase.

Hot or cold smoked smokehouse

The smoking mode differs in the choice of temperature and the smoking time of the batch. Based on these criteria, two types of devices are distinguished.

Hot smoked smokehouse

Equipment of this type involves processing meat or fish at a temperature of 70-100°C. Depending on the type of product, it must be kept in the chamber until fully cooked, from 40 to 80 minutes. The device is a rectangular or cylindrical container with shelves for storing pieces prepared for smoking, a tray for collecting dripping fat and a compartment for wood chips.

The chamber is heated due to controlled combustion of fuel. Unsealed boxes are suitable for outdoor installation. If you plan to install the device in a house, you will need a sealed model with a chimney that discharges flue gases outside the building. Products prepared in this way acquire a crispy crust, juicy taste and a characteristic smoky smell. They do not last long and should be used freshly prepared.

A simple version of a hot smoked smokehouse.

When choosing a hot smoked smokehouse, you should pay attention to a number of criteria:

- Material. For reasons of sanitary and hygienic safety, high-quality devices are made from food grade stainless steel AISI 304 or its analogues.

- Wall thickness. To reduce the likelihood of thermal deformations, the body is made of sheets no thinner than 1.5 mm.

- Hydraulic seal. The tightness of smokehouses installed indoors is usually achieved by pouring water into a special recess.

- Pallet size and shape. An open container for collecting dripping fat should prevent it from getting on the wood chips. Otherwise, the products of its thermal decomposition will give the food bitterness and an unpleasant odor.

- Price. The cost of even the most advanced models may well fall within the range of 8-9 thousand rubles.

Cold smoked smokehouse

In devices of this type, products are processed using flue gases with a temperature of about 30°C. The smoking time lasts at least 8 hours, and sometimes reaches several days. The cooking time is calculated based on the average smoking speed of 1 mm thick piece per hour. With the cold smoking method, maximum nutrients are retained in food. The taste is more delicate, and the smell is not so accentuated.

Cold smoked smokehouses can be homemade or factory-made. In homemade smokehouses, to cool the smoke, the combustion chamber is located separately from the smokehouse, connecting them with a chimney that plays the role of a heat exchanger.

Homemade cold smoked smokehouse.

Factory-made models are more compact and are usually equipped with a small compressor that ensures a stable supply of smoke.

Factory cold smoked smokehouse.

The most important details that you should pay attention to when purchasing a cold smoking machine:

- Material. The body and shelves of the smokehouse must be made of stainless steel. The recommended wall thickness is at least 1.5 mm.

- Bunker volume for storing wood chips. It must correspond to the duration of smoking.

- A method for cleaning smoke from tarry substances and soot. Typically, a variant is implemented from a series of plates that force the gas to change the direction of its movement several times. This promotes the precipitation of liquid and solid inclusions.

- Possibility of cleaning internal surfaces. Over time, deposits accumulate inside the device, which is unacceptable. The best models are made collapsible for ease of washing and cleaning.

- Dimensions of the smoking chamber. The volume of the smokehouse should not be too large to ensure a constant exchange of incoming flue gases. To be able to place the maximum number of products in it, shelves, hooks and a tray for collecting fat are provided.

Electric, gas or charcoal smokehouse

There are different ways to generate the required amount of smoke and achieve the desired temperature in the smoking chamber. Depending on the energy source used, there are three types of smokehouses:

Electric smokers

They are equipped with powerful heating elements connected to an alternating current network of 220 volts. Such devices are easy to adjust and allow smoking, at the owner’s request, in a cold or hot way.

Electric smokehouse.

Gas smokehouses

These are the most economical devices to operate, powered by natural or liquefied petroleum gas. The flame heats a layer of stones or other thermally inert material, from contact with which the wood chips poured into the firebox smolder.

Gas smokehouse.

Coal smokehouses

The most popular models run on wood or charcoal. They maintain the temperature required for smoking in the most natural way possible. They are sometimes made multifunctional by adding barbecue, barbecue or grill options.

Coal smokehouse.

Features of connection and operation

There is no need to connect the device to a gas stove. The smokehouse is used and installed as follows:

- Wood chips are poured into the lower part of the device, where a special container is located. It should be lightly moistened with water beforehand, as wood chips that are too dry will quickly burn out. You should also not put wet wood - because of this, the smoke will be too acrid, and the process of cooking smoked meats will be delayed.

- A tray is installed inside the device into which the fat will drain, and covered with foil. It is not necessary to do this, but if you do not use foil, you will subsequently have to wash the baking sheet for a long time to remove the accumulated frozen fat.

- Prepared (salted, pickled and, if necessary, cut into pieces) products are placed on the grid or hooks: fish, lard, meat, chicken, sausages, sausages.

- A special container is filled with water to create a water seal for the smoke.

- Close the smokehouse lid, place the apparatus on the stove, and turn on the gas.

- Place the hose on the fitting located on the top cover and lead its end into the hood above the stove.

The smoke produced under the influence of high temperature envelops the products and gradually fills them with a characteristic smoked taste and aroma. As a source of smoke, shavings and branches of trees such as aspen, beech, oak, alder, and ash are used. Wood from fruit trees is also suitable, but it is better to avoid coniferous trees - they impart bitterness to the finished products and contribute to the appearance of black acrid smoke.

When cooking fish in a gas smokehouse, it should be taken into account that its meat has a delicate structure, so during the cooking process it can fall apart and become soft. To avoid this, you need to tie the carcass with twine or wrap it in a special film.

Features of operation

Like any other household item, a smokehouse requires its own care; there are rules for use and tricks for preparing smoked dishes.

Rules for using the smokehouse:

- The first and most important thing is that you need to monitor the fire under the smokehouse so that it does not go out or get too hot.

- Next, it is important to clean the smokehouse from any remaining fat and smoked meats. So that the new batch does not become saturated with unpleasant odors.

- If the smokehouse is on gas, then the wood chips must be packed in foil, in which holes must be made. It is important that the chips do not come from pine or spruce trees. Because when exposed to high temperatures, they will release resin, which will spoil the taste of the food. The best tree species are: cherry, apple, oak and others. Many people use another trick. In a smokehouse with a water seal, various herbs are added to the water: rosemary, basil, and so on.

- Next, you need to heat the smokehouse to 200 degrees Celsius, then cool to 100. Then smoke in accordance with the temperature specified in the recipe. The same should be done with the smoking time.

- The next important point is to constantly monitor the fuel. The fire should not be very strong and not very weak

Read also: Symbols in the drawing

You need to constantly monitor your gas smoker

Cooking tricks:

- To cook large pieces of meat, the temperature should be slightly higher than indicated;

- Fish is cooked at lower temperatures and in less time;

- Every 1.5-2 hours it is worth coating the meat with marinade for a richer taste and aroma;

- It is not recommended to open the lid again, this cools the smokehouse and disrupts the smoking process;

- It’s worth checking the readiness of the product in an hour and a half. So that it is not spoiled by long smoking.

- It is better to smoke food for a couple of hours a day for a week.

Smoking does not tolerate fuss and haste, so it is necessary to approach this matter with all responsibility.

A gas smokehouse is an ideal option for those who live in an apartment, but at the same time love fresh and home-cooked meat, fish, lard or cheese.

Smoked products have always been in high demand - they decorate the festive table, filling the room with aromas that stimulate a serious appetite. Without a special device - a smokehouse - poultry, fish and pork ham cannot be smoked. There are several quite nice options for such products on sale, but you can try to make the unit yourself if you have the skills to work with welding and metal, and most importantly, a place where to do all the work. We will tell you how a home smokehouse on a gas stove works, look at the most successful options for finished products, and learn how to make such a device yourself.

Smoked mackerel recipe

Mackerel is well suited for hot smoking on gas. Before placing fish carcasses in the apparatus, you need to prepare them:

- You need to take 2 mackerel with a total weight of about 800 g. Clean the carcass and rinse, rub with salt outside and inside. Leave the fish for 5 hours to salt it.

- The salting time can be reduced to 2 hours if you use brine. To prepare it, you need to take 250 g of salt per liter of water, stir everything and place the mackerel in the brine.

- After the allotted time for salting is completed, the carcasses must be removed, wiped off any remaining salt, placed on a cloth or wire rack, and left to dry for half an hour.

While the fish is airing, you can prepare the smokehouse:

- Soak the alder chips, then blot them with a cloth so that they are slightly damp. Place foil on the bottom of the smoking apparatus and wood on it. It should be evenly distributed, in a layer of 2 cm.

- Place a tray on the wood chips to collect grease, which should also be covered with foil.

- Place the mackerel on the grill. Close the device with a lid and fill a special container with water.

- Place the smokehouse on a gas stove, the heat should be medium.

- When smoke comes out of the fitting (this will happen in 5-7 minutes), put a hose on it and take it out into the hood or window so that the smoke does not escape into the room.

Operation and cooking process

To remove smoke, a special hose is used; it is installed in the device (on the fitting), and its other end is led out of the window (or vent).

Chips can be replaced with sawdust, and fruit tree chips can be used to add a refined aroma. It is prohibited to use coniferous trees; in this case, the products will become bitter due to the presence of resins in the needles. Birch is also not recommended.

The size of smokehouses varies from small ones - 400x300x250 mm. up to large sizes 600x300x300 mm. For home use, the best solution would be to choose the “golden mean”. Medium-sized smokers are approximately 500x300x300 mm, they are able to smoke the required amount of food with minimal energy consumption. Smoking occurs at a temperature of approximately 100 degrees, and the device occupies two burners on a gas stove.

A special place for gourmets is occupied by a smoking oven. The cooking process is almost no different. The main difference is the use of pins instead of a grid. The products are hung on these pins, the device is set on the fire and after 30-50 minutes (depending on the complexity of the dish), the aromatic smoked meats can be served. The oven consists of three main parts - a tray with a vertical rod, a cylinder (installed on the tray), and a lid, which is attached to the rod and secures the structure.

How to make it yourself

You can make your own gas smoking device. For this you will need the following materials:

- stainless steel sheet 1.8-2 mm thick - about 1.5 square meters will be required. m of material;

- stainless wire with a thickness of 0.3-0.5 mm and a length of about 10 m;

- stainless steel pipe with a wall thickness of 0.25 mm and a length of 40 cm;

- U-shaped stainless steel profile, dimensions – 3 by 3 cm, length – 2 m;

- stainless steel sheet with a thickness of 1-1.5 mm - approximately 0.2 square meters will be required. m of such material.

The indicated amount of resources is suitable for a structure with dimensions of 600x300x300 mm.

To weld a smokehouse, you will need the following tools:

- First of all, you should weld a rectangular box with a water seal (water container) and side handles for moving.

- Stainless steel strips are welded from the inside of the body, which serve as supports for the grilles. The bottom one should be placed 12-15 cm above the bottom, the top one should be 7-10 cm above the first, but so that it is not close to the lid of the device.

- The water seal is a groove 2-3 cm wide and of similar depth, which runs along the perimeter of the upper part of the body. It can be made from a U-shaped profile.

- A metal tube is installed into the lid of the smokehouse to remove smoke, the diameter of which should be about 1 cm and the length - 4-5 cm. A hose is put on the top of this tube to remove the smoke outside.

- The bottom of the apparatus should be equipped with sides of 1-2 cm, curved upward. It must be removable.

- Smokehouse grates are made of stainless wire.

DIY home smokehouse

A smokehouse is a device that has a simple system and few components. Knowing the operating principle and internal design, craftsmen build smokehouses with their own hands. This saves a lot of money.

Initially, you need to decide which model is needed - vertical or horizontal, its volume, fastenings inside. Depending on the choice, there will be perches for hooks or grates for food inside.

Any smokehouse should have:

- heat receiver;

- place for sawdust;

- lid.

The simplest and most convenient option for an apartment is to weld a rectangular sealed box from metal sheets with the necessary compartments and a water seal.

Dimensions are determined individually based on the dimensions of the slab, ease of use and subsequent storage. The best metal is food grade stainless steel.

Below are instructions for making equipment with parameters:

- height – 300 mm;

- width – 300 mm;

- length – 600 mm.

For a water seal you will need 2 m of channel, with parameters 30x30 mm.

A base, a rectangular body, is made from a stainless steel sheet with an area of 1.5 m2 and a thickness of 2 mm using electric or gas welding. At this stage, a channel is welded along the upper edge of the resulting rectangle to form a water seal.

You need to make a small hole on top of the lid and weld a tube there so that 1 cm goes inside. A hose is attached to this hole to remove excess smoke. Provide handles for more comfortable transportation.

Next, the inside is made - a tray or a regular baking sheet and 2-3 grids to lay the food and collect the fat dripping from it. The resulting structure should move freely, be placed and pulled out of the box, so as not to damage the prepared food. The body and internal filling are made separately for ease of use and cleaning.

Advantages and disadvantages

The advantages of devices that can be used to produce smoked meats using the cold or hot method on gas include the following:

- Versatility. In such devices you can smoke fish, meat, and lard.

- Optimal heat source. The gas stove provides the structure with uniform heating and allows you to regulate temperature indicators.

- Compact and mobile. A smoking device suitable for a gas stove can be used outdoors and taken with you to the countryside or nature.

- Durability. High-quality smokehouses are made of stainless steel, which is a fairly durable material that can withstand high temperatures and mechanical stress, and also prevents corrosion.

- No smoke. The design includes a special hose that eliminates the possibility of smoke entering the room.

- Cooking speed. Fish can be cooked in a smokehouse on a gas stove in 40 minutes. The meat is smoked longer - 2-4 hours, depending on the variety, age and size of the pieces.

- Quality. High taste qualities of finished products, control of their production.

There are not too many disadvantages of smokehouses that are installed on a gas stove. These include the heavy weight of some models, which makes them inconvenient to transport, and the impossibility of using them outdoors.

Smokers operating on a gas stove are convenient devices with which you can prepare various smoked meats at home without the use of liquid smoke and other harmful additives. You can purchase devices for cold or hot smoking or make a similar design from stainless steel yourself.

Many people like smoked products not only because of their taste and aroma, but also because of their fairly long shelf life. In order to always be able to enjoy delicious smoked meats, you can purchase a special smokehouse or build it with your own hands, for example, from an old gas stove.

Mini smokehouse oven

In such a product, a dish can be prepared in just one hour - this becomes possible because the products are located much closer to the smoldering wood chips, and the volume of the smokehouse is only 10 liters. The operating principle is similar to any model - products are hung on vertical rods above the pallet, the top cover is screwed to the central pin.

Read also: Olympox training program preparation for the exam

Such compact smokehouses are produced in the city of Kirov, Ulyanovsk region and are simply called “Selmash”. They can be ordered directly from the factory by mail, the product will arrive packaged in compliance with safety regulations. The diameter of the smokehouse is only 26 cm and fits on one burner. Cost - from 2.6 to 3 thousand rubles.

The process of making a smokehouse from an old gas stove

To ensure that the process of making a smokehouse does not take much time, it is worth preparing all the necessary materials and tools in advance. It is also advisable to familiarize yourself with the most common diagram options that will help during the assembly of the structure.

Scheme and drawings

Schemes and drawings of a gas stove smokehouse are freely available on the Internet. You can choose the most suitable option and assemble a structure for smoking products based on it.

Principle of operation

All smokehouses have the same operating principle. Products prepared in advance must be placed on a special grid or hung with hooks. Then they will be treated with smoke, which is released as a result of smoldering wood chips.

There are two different smoking methods, depending on the temperature of the smoke and the duration of processing - cold and hot.

A smokehouse made from an old gas stove will allow you to quickly prepare high-quality, tasty and completely safe for human health smoked meats at any time convenient for the owner of the structure.

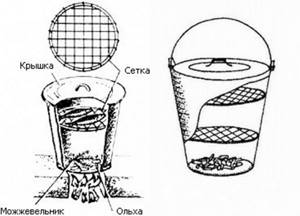

How to make a smokehouse from an ordinary bucket

To make a smokehouse from a bucket, you do not need to buy any special materials. Everything can be found on the farm. The design is distinguished by its mobility and ease of use. It is easy to assemble, and the smoking process itself will not differ from those situations when factory devices are used.

Scheme and drawings

There are quite a lot of different drawings and diagrams of a bucket smokehouse on the Internet.

There is nothing complicated about them and even an inexperienced person who has never smoked food can figure it out.

In order for the design to be effective, it is enough to follow the instructions and tips for assembling it.

What is required for production

A mini smokehouse made from a bucket has many advantages. The main ones include the following.

- Materials accessible to everyone.

- The assembly process is as simple as possible.

- Small size of the finished smokehouse and minimal weight.

- Excellent mobility indicator.

Due to the fact that products retain all their juices during smoking, ready-made smoked products turn out much tastier than store-bought ones.

Another important advantage is the short cooking time.

In order to build a mini-smokehouse, you need to prepare the following materials in advance.

- Enameled or metal bucket.

- A lid with small holes.

- A special stand so that the smokehouse can be placed on a fire.

- Gratings made of metal wire or a simpler option - medium-sized wooden sticks.

https://www.youtube.com/watch?v=1CvB16zZRsE

Step-by-step assembly description

It is probably already clear that you need to put fuel at the bottom of the bucket, which will create smoke.

You need to put in such a portion at once that it is completely enough for the entire smoking process and there is no need to add more. Otherwise, you will have to disassemble the entire structure. The lower part of the bucket will act as a primitive smoke generator. A container is placed above it into which the fat from the food will drip. It is best to use a rosette made of fairly thick foil that will have carved edges. You can buy it in almost any store. The cost of the socket is low, and it will be the most convenient to use. But if you have a bowl or other small container on hand, you can use it. It is worth noting that the grease trap should be located at a height of about 7 centimeters from sawdust or wood chips. The container should not come into contact with the walls of the buckets.

The ideal distance would be approximately 1.5-2 centimeters. Due to this, the smoke can evenly fill the entire volume of the bucket.

Two parallel small welding electrodes can be used as a stand for the grease catcher. They must first be cleaned of the flux layer. In order for them to be at the same distance from the bottom of the bucket, you need to make four holes in the walls, the diameter of which will allow you to easily install the electrodes used. Each electrode should be parallel to the bottom of the container.

After the holes in the bucket are ready, you need to insert electrodes into them and bend their ends so that you get a reliable stand for the container into which the fat will drip.

Next, above the fat catcher, you should place the first grate, on which those pieces of product that will be small in size are laid out. The first tier, as a rule, is made exactly according to the same principle as the stand for the grease catcher. It is worth noting that only approved materials should come into contact with products, so it is best to use small kebab skewers rather than electrodes. To make the first tier, six skewers will be more than enough.

Small foods, such as wings or sausages, can be smoked on 2-3 racks at the same time.

How to make a grate

You can either purchase a ready-made grille, or make it yourself. To make it, you can use either metal or wood. Each option has its own advantages and disadvantages, which are worth knowing in advance.

Metal grate

Metal grating can be made in two different ways.

You can use wire. A round mesh is woven by hand, the diameter of which will be the same as that of the bucket. It is best to make cells of medium size.

A stainless steel sheet is also suitable for the grille. A certain circle is cut out of it and a huge number of small holes are made in it.

Wooden grate

A simpler option is to use wooden sticks. You should choose very large and fairly strong sticks.

It is better not to install thin branches in the structure. They must be folded into a lattice shape and tied with wire in the places where they will be connected to each other.

You should carefully select the size of the sticks so that they match the diameter of the bucket you are using.

Manufacturing options

There are several options for how to make a smokehouse from a gas stove. The design can be additionally equipped with a smoke generator, which will allow you to smoke food at a fairly low temperature. This processing process takes much more time, but the finished smoked meats will be stored several times longer without changing the taste characteristics.

Design with smoke generator

In order to make a structure from an old gas stove that can be used for the cold smoking method, it is worth making a chimney and separately installing a high-quality smoke generator.

A device for producing smoke can be purchased ready-made or made with your own hands from scrap materials.

Converting a stove into a cold smoking device consists of only three simple steps.

- The stove body is installed on a special stand so that it is located slightly higher than the smoke generator being used.

- Holes are made in the side walls, both on the outside and on the inside, at a height of about 3 centimeters. They will be used to connect the chimney.

- Next, the smoke generator is connected to the smoking chamber using a chimney. As a chimney, you can use a regular metal pipe or a special corrugated hose.