Tile adhesives for underfloor heating are available in a wide range on the market, so choosing one can be a challenge. First of all, you need to understand the composition of the funds and the differences between them. After which it is advisable to study the existing rating of manufacturers and select the products that are most suitable in terms of parameters.

When selecting, it is important to take into account not only gender characteristics, but also experience in carrying out a similar procedure . In order for the tile installation to be used for many years, the master must strictly follow the instructions and rules indicated on the packaging and described in this article .

Let's get acquainted with the types of glue

In most cases, it is quite difficult for the buyer to choose the appropriate adhesive, especially if he does not have experience in repair work on laying heated floors. As a rule, formulations are classified according to the main active ingredient. They are of the following types:

- a polymer synthetic type with one main component - resin. The glue comes in the form of a paste, which is sold in a plastic bucket. It is most suitable if the master performing the procedure does not have relevant previous experience, because... Hardening occurs within 20-25 minutes after application. This time allows you to eliminate minimal errors and get rid of surface irregularities;

- polymer - with two different resins. Such a two-component product hardens very quickly, so it should be used immediately after preparation, when all the preparatory steps have already been completed. An important advantage is increased ductility and adhesiveness, which leads to resistance to sudden changes in temperature and the possibility of operation even when laying the material on a complex base;

- cement mortar consisting of fine particles. Despite the large selection of polymer products, this option remains the most popular. Due to the presence of additional modifying substances, the adhesion of the product increases. The key advantage is the ability to calculate the exact dosage of the product so that it is enough for exactly one use, this will allow you to use 1 package several times.

The main element that imparts heat resistance is a plasticizer, which is used as an additive. These substances allow the glue to expand and contract with changes in temperature without losing its adhesive properties.

It is difficult to choose the best adhesive for floors; each of the above types has its own characteristics, advantages and disadvantages.

It is important to know! It is worth noting that when selecting tile adhesive for heated floors, the weight of the facing material is not a priority parameter, as, for example, when selecting adhesive for walls. There are some other characteristics that you need to be aware of.

Types of glue based on basic composition

The adhesives of different brands contain different base components. This breaks the masses into varieties:

- Ready-made one-component adhesive mixture. It is convenient to use as it has a paste-like consistency. Such masses contain resins of artificial origin, acrylic additives, and modifiers. This variety does not set quickly; there is time for adjustment (up to 20 minutes).

- Quick-setting adhesive with two-component structure. The solution is prepared only before application. The base is epoxy resin with polyurethane components. Such masses are resistant to temperature changes, have high adhesion and flexibility. Suitable for complex substrates.

- Cement masses. The base is Portland cement with fine-grained river sand. Plasticizers are used as additives. This variety is considered universal. It is convenient to use, since you can prepare the required amount of solution.

What parameters do we pay attention to when choosing

Special requirements are imposed on the adhesive composition for porcelain tiles on heated floors due to difficult operating conditions. Before purchasing, you need to familiarize yourself with important parameters:

- resistance to temperature changes. As a rule, adhesive for underfloor heating and porcelain tiles themselves have different expansion coefficients. This parameter assumes that as the temperature decreases or increases, the adhesive mass will contract and expand. With low stability, microcracks will form on the adhesive surface, which will ultimately lead to separation and damage to the tile cladding. It is important to choose a mixture with high elasticity, but even then it will be necessary to additionally ensure a strong connection in the areas of the damping joints.

- The degree of adhesion of the glue to the surface. In most cases, cement types cannot provide sufficient adhesion to tiles, so it is advisable to choose polymer types or cement ones, but with the addition of a large amount of plasticizers. They allow you to increase adhesion with smooth artificial stone.

- Strength. As noted earlier, the weight of the tiles is not as important as when laying tiles on walls (due to the force of gravity), but it is still worth considering, especially if choosing adhesive for porcelain tiles. Before purchasing, make sure that the adhesive composition can withstand increased and multidirectional loads. Otherwise, it will disintegrate within the first year of operation.

- Time until completely hardened. It is necessary to select an option whose adjustment time is up to 2 hours, and the possible period of position correction is at least 15 minutes. This will allow you to avoid ineffective waste of expensive material, especially if you are working with such a complex coating as porcelain stoneware. This will also ensure the correct placement of the tile cladding, which will improve the quality of the repair work.

Which tile adhesive is best for heated floors? The one that has the highest values in all of the above parameters.

Common mistakes when laying tiles on heated floors

Having no experience in tiling, mistakes during the work process are not excluded. However, by studying the past experience of other craftsmen, you can prepare in advance for non-standard situations and try to do the job correctly and efficiently the first time.

Expansion joints

Considering that objects expand due to heating, it is necessary to consider laying the tiles in such a way that the integrity of the cladding does not suffer during temperature changes. This problem is solved by forming expansion joints.

A damper tape is placed around the perimeter of a room equipped with a heated floor. Its material is soft and elastic. It will contract when expanding and expand when cooling, and in addition serve as additional thermal insulation.

If the room is large, expansion joints are used to divide it into smaller zones. The seam must pass through all layers of finishing of the main surface and be filled with special compounds that can restore its shape. If you do not think through the installation of expansion joints, the tile will quickly lose its stable position.

Wrong choice of glue

Previously, we looked at the parameters by which it is necessary to select the adhesive mass. The wrong choice of glue will lead to the fact that, under the influence of temperature fluctuations, it will crack, ruining the floor and tiles.

Chips and cracks will gradually begin to form on it, and in some cases, due to mechanical stress (for example, something falling), it may completely break. And this is just the result of the wrong choice of adhesive composition.

Some manufacturers, in order to increase sales, advertise their products under the heading “Universal”. This is partly true, many universal mixtures are suitable for both regular and heated floors, but it is worth understanding that the performance of universal glue is an order of magnitude lower than that of special glue.

In order not to redo the work again, you need to carefully study the characteristics of the consumable material.

Defective tiles

Sometimes situations arise when, upon purchase, a defective tile is discovered. These could be cracks, chips or unevenness. Of course, a cracked product is unsuitable for subsequent installation, but you can work on the deflections if there is no option to replace the purchase. The main mistake when using defective tiles is the standard installation of the material.

The standard method reveals all the irregularities and in the end the result does not live up to expectations. Changing the installation method will help disguise a manufacturing defect.

Laying out tiles in a herringbone pattern - advice from experienced craftsmen. This method is ideal for rectangular tiles with wood-like colors, as it looks more natural, like parquet. Additionally, you can use small inserts to imitate mosaic laying.

To hide unevenness, tiles are also laid offset, diagonally, in a checkerboard pattern. Thus, even if defects are detected, an optimal solution can be found.

Dry glue left in open bag

Sometimes repair work has to be suspended and often consumables deteriorate and become unsuitable for subsequent use. If you do not carefully package the dry mixture and leave it in a room with an unstable microclimate (high humidity), it will harden and turn into stone.

A good adhesive mixture can retain its properties for several weeks even when the package is opened. You can take care of the adhesive mass with careful packaging: roll up the edges of the bag, releasing excess air, wrap it in several layers of plastic film and place it in a dry place until finishing work resumes.

For some reason the glue on the ridges has dried out

This usually happens if you cover large areas with a layer of adhesive while laying the tiles slowly. As a result, the lining quickly falls off due to weak fixation. Beginners should not rush, but do the work gradually, covering small areas of the floor with the solution.

If trouble happens, there is no need to panic. It is necessary to run a notched trowel along the ridges several more times, removing the dry layer and simultaneously applying a fresh mixture. The excess is removed and thoroughly mixed in the overall mixture.

Someone stepped on the not completely frozen floor

And this happens sometimes. An unpleasant situation in which inexperienced finishers try to quickly get to the damaged area of cladding without taking precautions. As a result, neighboring tiles also move, increasing the scale of the problem.

In order not to damage the area around the problem area, it is necessary to place wide boards on adjacent rows to increase the emphasis and carefully remove the problem material. Clean the tiles from the adhesive and carefully install them again in the empty space.

IMPORTANT: you cannot rush when performing “restoration”; it is better to correct the mistake thoughtfully and carefully

Manufacturers rating

Today there are quite a lot of manufacturers of tile floor adhesive on the market: Ceresit, Bergauf, etc. They differ not only in composition and method of application, but also in the scope of operation.

Some types are only suitable for certain underfloor heating and floor tiles, while others have a wide range of applications.

Ceresit

Ceresit glue for heated floors is the most popular imported option. It is manufactured in Germany, but has become widely known among Russian consumers. It has increased elasticity, so it can be used for various types of heated floors and finishing materials.

Ceresite is optimal for porcelain stoneware and ceramic tiles (choose SM models No. 14, 16, 17 or 117). Tile adhesive for marble (CM 115) is also popular.

The advantage of Ceresit for underfloor heating is of the highest German quality, which ensures the possibility of operation for many years.

Another advantage is that it is manufactured exclusively from safe and environmentally friendly components. The produced tile mixture does not harm the environment and health, and also does not emit hazardous substances even with a strong increase in temperature.

However, it is important to strictly follow the instructions on the packaging and in the accompanying instructions. If it is indicated that the mixture is suitable only for concrete, it cannot be used for other surfaces (wood, plastic, metal).

What you need to know about tile floor adhesive CM 14 Extra:

- survivability – 2 hours (time before hardening);

- The master can adjust the placement of tiles within 15 minutes. after initial application;

- when carrying out repair work, the air temperature should be 5-30 degrees Celsius;

- Grouting of seams is allowed no earlier than one day after installation;

- degree of adhesiveness – 0.8 MPa;

- The coating created with Ceresit glue for heated floors can be used at temperatures from -30 to +70 degrees.

Bergauf

This Russian-German brand produces Keramik Express glue. Its distinctive advantage is that the mixture dries quickly; you can walk on the tiles within 4 hours after finishing laying.

This reduces the waiting time before grouting, but also reduces the time required to correct the position of the material. Recommended for craftsmen who already have experience in the relevant work.

What you should know about this tile adhesive for heated floors:

- survivability of the diluted mixture – 45 minutes;

- a one-time covering should be no more than 0.6-0.8 m2;

- changing the position of the material is allowed only for 10 minutes;

- It is allowed to rub damper joints after 4 hours;

- The temperature during operation should be from -10 to +70 degrees.

This tile mixture is the best option for installation on a solid base that is not subject to deformation (for example, concrete).

Knauf

Floor adhesives of this brand are available in a wide range, but for heated floors you will need a special mixture - Knauf Flex. This tile adhesive is excellent for laying on a complex base (gypsum fiber coating or old tiles).

The characteristics are among the best: high elasticity and adhesion (1 MPa), excellent waterproofing.

The prepared solution can be used for 3 hours, correction time is 10 minutes. The permissible temperature during installation is 5-25 degrees, and during operation -30 to +80. Grouting of the resulting joints is allowed only 3 days after installation work.

What is important to know:

- Before laying the tiles, the warm floor must warm up completely at least once, and then cool down for a day;

- If the air temperature in the room when installing tiles on a warm floor is below 10 degrees, you need to turn on the heating to 15 degrees;

- Before placing electric heating mats, it is necessary to prime the base with a special mixture of the same brand;

- If the room humidity is high, the surface must be coated with Knauf Flachendicht.

Litokol

This manufacturer produces a domestic cement mixture for heated floors (model K80). The dry mixture is prepared before starting work. Tile adhesive for heated floors has the following properties:

- Vitality – 20 minutes;

- The adjustment period is 1 hour, which is one of the highest values compared to analogues;

- Room temperature during installation is 5-40 degrees;

- Operation is allowed in a temperature range of -30 to +90 degrees;

- Grouting of seams is possible within a day.

If it was decided to use polymer tile adhesive for the floor, then this manufacturer offers the Litoelastic adhesive mixture. It must be used within 45 minutes after mixing, another 45 minutes are allocated for possible position adjustments.

Unis

The tile adhesive “Yunis” is domestically produced, but the quality is not inferior to the European Ceresit. Most products on sale are universal and suitable for any coating.

The advantage of this tile mixture is that it is completely environmentally safe, which allows it to be used even for finishing heated floors in a child’s room. Another advantage is increased adhesion (1.2 MPa).

Features of Eunice adhesive for heated floors:

- viability of the finished adhesive solution – 180 minutes;

- the period before the applied composition dries on the tile is 20 minutes;

- period of possible correction – 10 minutes;

- grouting of damper joints – every other day;

- Operation is possible at temperatures from -50 to +70 degrees.

There is no need to use such glue for a deformed base.

Prospectors

A Russian manufacturer produces tile adhesive “Starateli Plus”, which is intended for installing the material on the floor. It can only be used on surfaces that are not prone to deformation.

The prepared composition can be used within 4 hours after the solution, and only 15 minutes will be allocated to correct the position of the tile. The adhesion value is 0.5 MPa, this is sufficient for most types of tile coverings.

Founds

The Russian brand Osnovit produces “Maxiplix T-16” specifically for heated floors. It has an increased pot life (4 hours). Correction time – 15 minutes. Optimal for simple coatings (for example, cement screed).

Types of adhesive solutions and their features

To install warm bases, adhesive compositions for tiles intended for such work are used. And yet, what kind of glue should I use to glue tiles onto a heated floor, since there are several types of products on the market? Consider these types:

- One-component - paste-like mixture. The material is convenient to work with: no need to waste time on preparation. Components: acrylic, modifiers, artificial resins. The glue hardens within 20 minutes, this is enough for laying and adjusting the installed tiles.

- Two-component - fast hardening (“reactive”). They usually contain epoxy resin and polyurethane filler. The solution is mixed immediately before finishing work. Withstands high temperatures, has good adhesion and elasticity. Thanks to these properties, the tile covering is strong and durable compared to similar materials.

- Finely dispersed on a cement base. The main components are Portland cement, fine river sand and modifying plasticizers. Mixtures with aluminate (alumina) cement of the highest quality create strong adhesion of the finish to the rough surface. To ensure that the adhesive layer is strong, you should follow the instructions for preparation.

When searching for tile adhesive on your own, you should carefully study the properties, technical characteristics and scope of application. All necessary information about the material is placed on the packaging. In addition to the standard description, there may be graphic symbols.

Choosing the best tile adhesive

To make the right choice of tile adhesive for porcelain tiles on a heated floor, it is necessary to take into account the characteristics of the room (the ability to provide the required temperature during installation and operation), the complexity of the floor covering (concrete screed is the simplest, and old tiles or gypsum fiber surfaces are the most labor-intensive) and the type of heating system floors

Ceresite is well suited for water floors; it can be used even by beginners in laying flooring. For electrical structures, it is recommended to choose Knauf (if an additional screed is not created) or Bergauf (if you plan to create a screed).

If you need to choose a budget option, then you should study Russian brands. For example, “Starateli” glue has increased elasticity and, at the same time, a relatively low cost.

Why do you need special glue?

During operation, a warm floor causes heating of all elements of the floor covering. Materials expand when heated and contract when cooled. The adhesive composition on which tiles or porcelain tiles are laid behaves in a similar way. This is why regular adhesive is not suitable for installing heated floors: it will quickly crack due to its low elasticity during regular heating and cooling.

With a single strong heating, simple glue can completely separate from the surface and crumble. Deterioration of the adhesive composition entails the accumulation of air in the cracks, due to which thermal conductivity decreases.

How to avoid these problems? It is necessary to choose specialized tile compositions that can easily withstand temperature changes within the range of -30... +100 degrees. They have high elasticity, reliably fasten any rough base material (concrete, wood) with finishing, and do not change the thermal conductivity of the entire structure. Adhesives are dry mixtures that must be properly diluted before use, or ready-made canned products.

What is glue used for?

Elastic, heat-resistant adhesive can be used in most types of underfloor heating systems by direct application to heating elements. However, film (infrared) type floors require the use of leveling mixtures before gluing. Otherwise, there is a risk of destruction of system elements, which will quickly fail. When purchasing glue, you need to make sure that it is suitable for a specific type of system, which is always indicated on the packaging.

Installation instructions

To work you will need to prepare the following tools:

- Construction spatula with teeth;

- Adhesive (suitable for underfloor heating systems);

- Ladle, trowel, brush;

- Deep priming agent (it must be compatible with the selected tile adhesive for underfloor heating);

- Mixer;

- A container of suitable volume for preparing tile adhesive;

- Level;

- Tile cutter;

- Facing material;

- Rubber hammer.

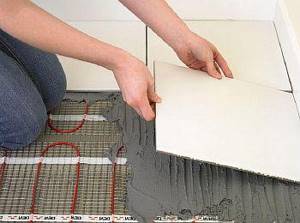

Stages of laying tiles on a warm water floor using glue (using the example of a concrete screed without deformation):

- Removing dust and other debris from the screed (it is best to vacuum it).

- Surface primer to improve adhesion. The mixture should be applied exclusively to dry screed. To check this, you need to cover a certain area with film overnight; if drops appear on it in the morning, you need to additionally dry the floor. The primer should completely cover the surface without the slightest gap.

- Preparation of the adhesive solution. It should be made strictly according to the instructions. Mix all ingredients with a mixer and add water at the end.

- Preparing the tiles. To increase adhesion, priming the inside of the future coating is allowed.

- Apply underfloor heating adhesive to the screed; use a spatula to level the layer. It is not necessary to cover a large area at once; it is better to spread the mixture gradually.

- Apply the mixture to the tiles (the thickness should be minimal - up to 0.5 cm).

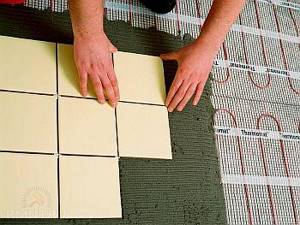

- Lay the tiles, keeping equal gaps between them, using plastic crosses (they can be removed after 2 hours).

- When the tile adhesive for heated floors has completely dried, grout the joints.

Basic techniques for laying tiles on a heated floor

Each stage of laying tiles is a link in one chain. Poor execution of one action can lead to an unsatisfactory result of the entire work, so each step must be performed carefully and accurately.

Surface preparation

Before laying heated floor mats, you must make sure that the base, cleared of the old coating, is perfectly level. If this is not the case, then first of all the surface is primed and leveled. And not only the floor, but also the corners and walls are about 15-20 cm high. After the primer has dried, the surface is filled with a self-leveling floor.

In rooms with high humidity (for example, a bathroom), careful waterproofing of surfaces is required. The final preparation step is re-priming. It is necessary for better adhesion of the tiles to the base.

Installation of heated floor mats

The mats look like a fiberglass mesh with a heating cable attached to it. The mesh can be cut, but the cable must remain intact. The mats are attached to the floor with construction tape.

We also recommend watching - Warm water floor under tiles: installation instructions

Application of adhesive composition

The diluted mass is applied with a spatula onto the heated floor mesh, but it must be remembered that the applied glue sets faster than the one mixed in the container. Therefore, you do not need to cover too large an area with glue, but work gradually. For better adhesion to the tiles, the mixture is applied with a notched trowel and shaped into a ridge.

IMPORTANT: the adhesive is applied only to the floor surface, not to the tiles

Laying tiles

In order for the tiles to lie evenly, it is necessary to use special calibration crosses. They adjust the distance between the tiles, allowing you to even out the gaps. The tiles are laid so that the glue does not protrude from the seams or fill the voids between the cladding parts. The space between the tiles must remain empty for subsequent grouting.

Depending on how long the glue takes to dry, you can calculate the time to eliminate work defects.

Grouting joints

The time when you can start the procedure must be indicated in the instructions. If you apply grout too early, the quality of the tile installation may suffer. Excess grout mixture from the tiles must be immediately removed with a soft cloth before it dries.

Tiles can be laid not only at right angles, but also diagonally, creating various patterns.

Features of application

When laying a warm electric or water floor, beginners quite often make certain mistakes:

- Incorrect installation in the areas of damper joints (here, in most cases, the tiles come off). It is necessary to apply glue on top and elastic sealant on the bottom.

- Use universal glue for any surfaces. It is better to give preference to a highly specialized option; its adhesion is significantly higher than that of universal products.

- Before purchasing tiles for heated floors, make sure there are no defects. If they are discovered after purchase, take this into account when choosing a layout. Also, shortcomings can be compensated for by an increased thickness of the tile adhesive layer.

- Installation of tiles using slightly dried adhesive. In such a case, the ceramic tiles will come off quite quickly; it is better to renew the adhesive layer.

- Walk on the tile until the specified period has passed until it has completely hardened. If a person accidentally steps on the floor covering, you need to carefully remove the slipped tile, replace it and the adhesive layer.

The choice of tile adhesive for underfloor heating must take into account many factors, especially the type of existing subfloor, the type of tile and the type of heating system.

It is also necessary to rely on the relevant experience of the specialist if the procedure is performed independently. If you have no experience, it is better to choose products with a long adjustment and viability time.

Types of floors

There are three types of heated floors: water, electric, infrared. They differ in operating principles and characteristics.

Electric floors

This type of flooring is widespread. When installing the system, a single-core or two-core ultra-thin cable is installed directly under the tile. The advantage of the floor is the ability to install it on an old screed. However, it must be level, without differences, and also have sufficient height (4-5 cm), otherwise the system will not last long.

Water floors

In this system, heating is carried out by circulating hot water in the pipes. During installation, the heated floor is supplied to the central heating system, so in the future it causes virtually no maintenance costs. Over time, the system tubes may become clogged due to deposits, so it is better to immediately install a filter device to prevent clogging.

Infrared floors

In appearance, such floors are a polymer film in the form of 50*50 cm modules. Heating elements are located inside each module. Infrared floors are very economical in terms of energy costs. The only downside is a decrease in efficiency when laying under ceramic tiles and porcelain stoneware: infrared radiation from under these materials is poor.