Procedure for obtaining a certificate of conformity

All gas boilers that are released onto the EAEU market are subject to mandatory assessment in accordance with TR CU 016/2011 (safety of gas consuming devices).

Mandatory certification of equipment that runs on gas is carried out with the assistance of specialists.

To receive the document, the applicant will need to provide:

- information about the company and manufactured devices;

- samples of gas equipment (for research);

- access to the production facility to analyze the state of production (if serial production of devices is planned - for example, domestic gas boilers);

Testing of samples is carried out in specialized laboratories. During the research process, the following indicators are checked:

- mechanical strength of the structure;

- availability of protection against gas leaks;

- moisture resistance of the case;

- resistance to heat and elevated temperatures (fire safety);

- reliability of fastening of parts;

- and others.

The CU TR certificate is registered based on test results - for a period of 1, 3 or 5 years.

After mandatory certification, the applicant can receive a voluntary certificate - this is a tool in competition when participating in tenders, attracting investments, entering new markets, etc.

Mandatory registration of permission from Rostechnadzor

Rostekhnadzor Order No. 112 dated February 29, 2008 (as amended on December 1, 2011) approved specific types of equipment for which a permit for use is required.

UPD: From March 30, 2014, in accordance with Rostechnadzor order No. 601 dated December 12, 2013, order No. 112 was declared invalid.

Rostechnadzor controls devices used at hazardous production facilities: those operating under excess pressure, explosion-proof, mining and petrochemical equipment, lifting structures, etc.

The rules for the use of technical devices at hazardous production facilities are approved in Resolution No. 1540 of the Government of the Russian Federation of December 25, 1998 (as amended on February 1, 2005).

First point

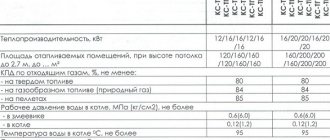

The first paragraph with all its subparagraphs describes the boiler room equipment. Here the data is organized in the form of tables. The first table is devoted to the characteristics of the boiler. It includes:

- Boiler power. This refers to the maximum possible value.

- Load that is connected to the boiler. With it, the equipment must successfully perform its functions.

- What fuel is used? Several types may be listed here, indicating which fuel is the main fuel and which is the backup. For example, the main one is gas. And the backup is electricity. This state of affairs is only possible if the boiler room has several boilers running on different fuels, or one common for both types.

- What coolant is used: water or steam.

- Type of HVO.

- Diaerator type (if available).

- How many cubic meters does BAGV occupy?

- Type and variety of heaters.

- The volume of the fuel oil tank (if available) is measured in cubic meters.

- Data on the presence or absence of additional, in addition to the boiler, equipment or technical additions to the boiler itself.

The first table is immediately followed by a second with additional description including:

- Line number. Each boiler located in the room is described in its own line.

- Boiler type.

- The manufacturer of each product.

- Serial number of the equipment being studied.

- Coolant. It can be water or steam.

- Power.

- Steam pressure at the time of inspection.

- The temperature of water or steam required for normal operation.

- The efficiency of the boiler operation when the main fuel is connected.

- The same data when operating on reserve fuel. Everything is indicated as a percentage.

Also in the first paragraph, the coolant that is supplied to heat-consuming installations and heating networks is discussed in detail. The pressure, temperature graph and flow of water or steam are considered in the form of a table. It also indicates how much is returned to the heating system in the form of condensate.

Suspension and Termination

A license issued by Rostechnadzor may be suspended or revoked if its owner:

- grossly violated licensing requirements and was brought to administrative liability;

- when identifying technical or legal deficiencies at the enterprise, did not eliminate them within the time period prescribed by the inspector;

- decided to cease its activities due to the liquidation or reorganization of a legal entity.

The decision on the status of the license in all these cases is made by authorized members of the commission of federal supervisory authorities.

Second point

The entire second paragraph of the boiler room inspection report is devoted to the attached technical documentation. The inspector determines whether the equipment installed in the boiler room corresponds to the parameters specified in the papers. And if this is so, then does all this correspond to the requirements for the premises?

The following information should also be included:

- Boiler developers, technical specifications for its development. Mandatory - what power was installed for a specific type of equipment.

- Which organization issuing the technical specifications reviewed the project, under what number and when was the conclusion of the conformity assessment body issued?

- Fuel mode.

- Who performed the installation work, with the obligatory license number and the date of completion of the work.

- Which commissioning organization was responsible for the installed equipment subsequently.

- Number and date of permission to admit electrical installations that are present in the premises at the time of inspection.

- Numbers and dates of acceptance certificates for metering devices.

- Permission to operate all boilers stated in the documentation.