Inside any storage water heater there is a metal rod - an anode made of a magnesium-aluminum alloy. The element serves as protection for the tank and is gradually corroded during operation. It is important not to miss the moment of final destruction - to promptly replace the magnesium anode, and at the same time clean the container and tubular electric heater (abbreviated as heating element) from scale. We do not invite plumbers; we carry out the work ourselves and completely free of charge.

What is a magnesium anode for?

The magnesium anode protects the water heater from corrosion and prevents the formation of scale on the surfaces of the heating element and the walls of the water heater tank.

The thing is that in cold water there is oxygen in dissolved form. When heated, it begins to release and oxidize everything possible. This is a powerful oxidizing agent that neither stainless nor enameled steel, from which the walls of water heater tanks are made, can resist. If you give oxygen a lighter object to oxidize, for example, a piece of magnesium, then oxygen will first destroy it, while the walls of the tank will remain intact. It is this role that the magnesium anode plays, becoming the object that corrodes in the first place.

In addition to magnesium anodes, aluminum anodes, as well as anodes with a combination of aluminum, zinc and tin, have become widespread. The type of anode you choose depends on the quality of the water, the location of the anode rod, and how easy it is to access the installation site.

Filling with water and checking functionality

Hang the electric titanium in place.

Connect the hoses and open the cold water and begin to fill the tank. The hot water tap must also be open to allow air to escape. At the same time, make sure that there are no leaks anywhere. As soon as water comes out of the “hot” tap, the boiler is full. There is no need to close the tap immediately; let all the “slurry” spill out and finally flush the tank and pipes.

Only when clean water comes out do you turn off the mixer.

After this, the water heater must stand for at least half an hour or an hour so that condensation leaves all surfaces and there is confidence that there are no leaks.

You can then apply voltage by plugging the titanium into an outlet. To check the operation of the thermostat, use the control knob to force the adjustment to maximum and minimum.

In this case, the boiler on/off light should light up.

If the boiler operates quietly, without making any sounds, and it is not clear to you whether it is heating or not, you can check the energy consumption using the meter.

At maximum heating power of the heater, the counter will spin or blink much faster. This means that the heating elements work as they should.

So self-repair can save you a significant amount of money, the main thing is not to make some mistakes.

How to determine when it's time to change the anode?

Magnesium anodes in a water heater typically last between three and five years, but their lifespan actually depends on the manufacturer, the quality of the water, and how much water flows through the water heater. Most manufacturers recommend checking the magnesium anode every two years. If necessary, replace it

If sodium is added to the water (for example, when using a water softener), the anodes can corrode faster: in as little as six months if the water is excessively soft! Try not to over-soften the water and check the anode more often if you have a water softener (at least every six months).

When the magnesium anode in your boiler is used up to the point that it needs to be replaced, you may notice a brown tint to your hot water, which is the result of internal rust that the anode can no longer absorb.

You may also hear a clanging sound coming from the water heater tank. As the magnesium anode corrodes (especially in aluminum models), it corrodes and can break off, settling at the bottom of the tank. When the water heater fills with water, the broken parts of the rod can hit the walls of the tank, creating noise.

Here is a list of signs that it is time to replace the magnesium anode:

- Your water heater is over 5 years old and you have never replaced the anode before;

- The water heater makes loud and repeated clanging sounds when heating;

- Hot water has a brown tint

- The hot water began to smell like rotten eggs;

- The anode currently installed looks completely corroded.

Checking and replacing the magnesium anode is a simple step, but is often ignored until the water heater is damaged.

Price

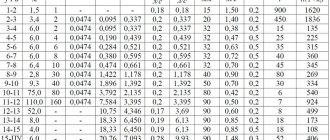

Currently, magnesium anodes are produced and sold, which differ in the length of not only the anode itself, but also the internal pin. The standard length of the purchased anode for water heating equipment can vary in a fairly wide range - 10-60 cm with a pin length of 1.0-23 cm.

Among other things, the anodes differ in terms of overall diameter - 1.4-2.2 cm, and in the diameter of the threaded connection of the stud - “M-4”, “M-5”, “M-6” and “M-8” .

The average cost of the most common models of protective magnesium anodes for household storage boilers:

- 100 mm with D14+20 mm and “M-4” - 200-220 rubles;

- 100 mm with D18+180 mm and “M-6” - 230-250 rubles;

- 100 mm with D18+230 mm and “M-6” - 250-270 rubles;

- 110 mm with D21.3+10 mm and “M-5” - 320-330 rubles;

- 120 mm with D16+10 mm and “M-6” - 150-160 rubles;

- 140 mm with D14+20 mm and “M-4” - 130-140 rubles;

- 145 mm with D25+10 mm and “M-5” - 290-310 rubles;

- 200 mm with D16+35 mm and “M-6” - 280-290 rubles;

- 200 mm with D18+180 mm and “M-6” - 290-310 rubles;

- 200 mm with D16+10 mm and “M-4” - 290-310 rubles;

- 210 mm with D22+10 mm and “M-6” - 360-380 rubles;

- 210 mm with D18+10 mm and “M-4” - 310-320 rubles;

- 230 mm with D22+10 mm and “M-5” - 380-400 rubles;

- 300 mm with D21+10 mm and “M-8” - 440-460 rubles;

- 660 mm with D21.3+13 mm and “M-8” - 810-830 rubles.

Safe operation of the device during pressure drops when heating water is ensured by a safety valve for the water heater. Read in detail about the purpose and installation of the device.

Don’t know which electric heated towel rail is best to choose for your bathroom? Read this article.

Such a noticeable variation in size and cost is not accidental, and makes it quite easy to independently select the most optimal magnesium anode option for water heating devices that differ in length, shape and structural characteristics.

Step-by-step procedure for replacing the anode

First of all, you need to find out where the anode is located in the heater and how to properly remove and replace it. Information about this should be included in your device's instruction manual. If this manual is not available, the standard procedure for replacing a magnesium anode is described below, which is almost the same for all storage wall-mounted water heaters.

Step 1 – Turn off the power to the water heater and the water supply

First you need to disconnect the water heater from the network and shut off the cold water supply to the water heater, and then open the mixer. This is how we release excess pressure from the water heater.

Then we close the hot water inlet. We install a flexible liner on the cold water pipe, or on the drain pipe, or on a special outlet for draining water (you can use a drain hose instead) and stretch it to the sink.

Step 2 - Drain the tank

In order for the water to start draining, you need to unscrew the hot water outlet. So we let air into the water heater, and water begins to flow into the sink. In this case, a few drops may pour out of the hot water pipe, but the main flow of water will go through the drain hose. This is due to the different heights of the hot and cold water pipes in the water heater. The hot water pipe ends at the top of the internal tank, and the cold water pipe ends at the bottom, so we drain through it if there is no drain pipe provided.

After the water has drained, you can unscrew the drain hose. Now we unscrew the American connection at the cold water inlet, while a little more water may pour out of the tank. After this, you can remove the water heater. Since water is still present in the internal tank, albeit in small quantities, when removing the water heater from the wall, it is better to clamp the cold water pipe with your hand.

Step 3 – Remove the old anode

Let's start replacing the magnesium anode in the boiler. It is necessary to unscrew the screw that holds the cover and pick it up with a knife or screwdriver. Under the cover we will see wires. First of all, it is necessary to remove the contacts from the heating element. To do this, we unscrew them with a Phillips screwdriver. Next you need to remove the thermostat sensors. The number of sensors depends on the specific water heater model.

We unscrew the nuts that attract the heating element. The size of these nuts depends on the water heater model. It is better to remove the bolts and nuts after unscrewing them so that they do not get lost or fall inside.

Remove the flange and remove the heating element. The remains of the anode are visible on it. We wash the heating element from the anode residues under running water. After washing the heating element, it will be clear that only a pin remains of the anode. You can also wash the water heater itself. Pour water into it and turn it over to throw out the dirty water with the remains of the anode.

Unscrew the remaining pin from the anode. To do this, unscrew the nut and remove the old stud.

Step 4 - Install the New Anode

Since we have a thread in the anode socket, a new one can be installed without a nut - you just need to screw it into the heating element group. There is no need to tighten the anode all the way - just fix it.

After screwing the anode, we wipe the seat of the heating element and put the heating element back.

Next, we assemble everything in reverse order. We return the flange and screw it in. Be careful that the flange should not pinch the wires and temperature sensors. Do not over-tighten the flange nuts. We put back the temperature sensors, and then fix them with the mounting strip. Then we return the contacts of the heating element, lay out all the wires and screw on the cover. After this, you can hang the water heater back in its place.

Step 5 – Restore water supply and heat

We return the pipes to the water connections. After connecting the pipes, we open the faucet and turn on the water supply to the water heater, and then open the water supply from the water heater. This way we bleed air from the internal tank of the water heater. We wait until the water flow stabilizes and flows in an even stream.

After this, you can close the mixer, turn on the water heater and start heating.

Comments:

Yeah, Thermex. What installation, what service - one song with swearing. Their fastenings on some models are unreliable, and disassembling/assembling is a pleasure.

Conventional round Termex water heaters are no different from Ariston or Gorenje, except for the price. I chose this one for myself and don’t regret it. I've been using it fine for 3 years.

Oleg, well, they’re round. And 3 years is not an indicator. Just soon you will start replacing heating elements and you will understand the difference between Ariston and Termex

It is unlikely. I’d better call a specialist for this who will sort it all out.

Oleg, well, if so, then yes. Then you can take the cheapest options and use it without any problems, and if it breaks, call a specialist. Or even place such a specialist at home, so as not to call every day. And then today the cheap boiler broke down, tomorrow the stove, then the Chinese TV stopped working, and then, you see, you’ll have to reflash a cheap Chinese smartphone

I have a problem with the gasket, I noticed when I was changing the “original” heating element that the pressure washer “lays” somehow crookedly./one side is pressed tighter than the other/ I bought a heating element, a gasket, and began to change it - the same story. I have a horizontal Thermex. Maybe you know the installation trick so that the gasket fits “evenly” into the HV heating chamber.

I have a 50L flat Thermex. disassembled today 12/08/16. The RCD knocked out, a 1.3 kW heating element burned out, the second 0.7 kW was intact. I have used the water heater for 4 years. On the burnt one there was no anode at all, but on the second one it was “eaten up”. I replaced it without any problems in 20 minutes (I installed a new one with an anode and bought it for 730 rubles, and for the second one only a magnesium anode for 183 rubles, supposedly all made in Italy), except for a trip to the store and I did it for the first time, intuitively. The problem is different: it has a tank in the form of 2 pipes (and not, as usual, one container), connected by two overflows, each with a heating element inserted into it, respectively 1.3 kW and 0.7 kW. Washing them is one problem, your hand can’t fit into the holes, you pour in water and shake... in short, there’s one problem with washing the tank(s)

Thermex water heater is a complete crap! A bunch of nuts, useless electrodes, a bunch of wires, etc. and so on. Purely in Russian: reinvent the wheel and finish something of your own! I recommend that buyers pay attention to the Real water heater. I have a VM 390. It has been working properly for 7 years now and there are no problems with disassembly: getting the ten takes about 5 minutes at most. I took off the cover, unscrewed 3 wires, pulled out the thermostat and unscrewed the heater. True, for this I had to buy a 55 head. And no anodes-cathodes!

I don’t know, 12 years of using Termex and no complaints. I replaced the heating elements once.

I’ve had a “Real” since 2000, I’ve never washed it or changed the heating elements. Two years ago the tank leaked and had to be replaced. I bought Termex for 80 liters for 22,000 rubles, it was flat and hot water flowed through all the connections, naturally flooding the neighbors. The temperature was 57 and the flow was still 90. Now, having read how to change the heating element, isn’t it better to buy a new one? It’s a pity that they stopped producing our Real.

Hello I have a question. I replaced the heaters with Thermex 50 l, when turned on the ouzo is triggered, there are no leaks anywhere, tell me what the reason is

Termex. 14 years of operation. Knocks out the RCD. Today I took it apart. There were no special problems. Both shadows burned out. Tomorrow I'll go look for them. Overall I'm happy with the water heater.

Leave a comment Cancel reply

Fuel-free generator - a way to make money on illiteracy

What happens if the anode is not replaced in a timely manner?

The magnesium anode is “self-destructive” and continues to corrode until there is nothing left of it. When there is no magnesium alloy left on the anode, the water heater tank may begin to rust.

Another possible problem if the anode is not replaced in a timely manner is the possibility of it breaking off and falling to the bottom of the water heater. This may not seem like a big problem at first, but this broken anode rod can bounce around inside the water heater when exposed to water. This can lead to cracks in the tank coating, which will become a source of corrosion of the base metal, shortening the service life of the device.

All this explains why it is so important to regularly check and replace the magnesium anode in your water heater to extend the life of your water heater.

Disadvantages of anodic sacrificial protection against corrosion

If the shift in the anode potential to the negative side exceeds a certain value, so-called overprotection is possible, which leads to the release of hydrogen at the cathode, a change in the composition of the near-electrode layer, and other processes.

All these processes contribute to the peeling of the protective (insulating) coating in the tank and the acceleration of corrosion of the protected metal. To eliminate overprotection and prevent underprotection, the magnitude of the potential difference between the anode and cathode must be within certain limits depending on a number of factors that may vary. Moreover, in the case of a significant change in these factors, it is necessary to change the value of the anode potential. That is, the magnitude of the potential difference between the anode and cathode must be measured, monitored and regulated.

High-price water heaters use more advanced, adjustable cathodic corrosion protection. The potential shift of the protected metal object is carried out using an external direct current source. The potential difference between the titanium anode and the water heater tank is regulated electronically according to a given program.

The practice of operating budget water heaters with sacrificial protection indicates that it is not always possible to eliminate overprotection by using a magnesium anode recommended by the manufacturer.

For a simple, protective method of protecting water heaters, the only way to prevent overprotection and reduce the potential is to replace the magnesium anode with an aluminum electrode.

Kinds

It is imperative to install a sacrificial anode for a boiler covered with ordinary metal. After all, such material without additional protection has a short service life. Even if the inside of the tanks is covered with a layer of stainless steel, this still will not save the water heater. Therefore, you need to buy additional parts so as not to spend money on repairs later. Any heater manufacturer puts forward its own recommendations on how to select the anode size. In principle, anodes can be divided into two types - magnesium and titanium.

Magnesium anode

The magnesium anode, as mentioned above, is made of an ordinary rod or, in other words, a rod, inside of which there is a threaded steel pin. The studs themselves can be of different diameters and different lengths

It is worth paying attention to this when buying a new anode, because if its size is many times larger, it will not fit into the hole in the tank. However, there are some designs where you can install even two anodes

In floor-standing gas or electric structures with a large volume, they are changed only from above.

The anode rod is very large, approximately one meter long. Therefore, replacing it will be problematic in rooms with low ceilings. Since the water heater itself has a height of up to two meters, plus a meter-long rod must also be inserted into it. For such purposes, multi-section protective magnesium anodes began to be produced.

They are made from a plastic tube with micropores. Magnesium granules are poured inside this tube. The advantage of this new product is that there is no sediment left inside. In addition, magnesium can be added to the tube as it is produced. Magnesium powder is sold separately.

A high-quality aluminum water heater does not need such additions. But at the same time, the high price makes it inaccessible to ordinary people. But an ordinary boiler, supplemented with a magnesium anode, will be affordable for almost everyone. At the same time, it is no worse in functionality. The principle of its operation is that active magnesium atoms leave the anode and themselves produce oxide. The iron atoms remain completely intact.

Titanium anode

But a titanium-coated anode works on a slightly different principle. It is used as a measuring and supply electrode. In this case, the current is supplied by a voltage source located outside, and it is also regulated by external electrical control. After some time, the current stops flowing and then the titanium anode analyzes the condition of the internal parts of the structure. It identifies what kind of violation occurred during a given period and then with great accuracy regulates the possible feed force to restore the damage.

The titanium coated anode is not subject to destruction and therefore does not need to be replaced at all. It works throughout the entire service life of this structure. The greatest demand is for heaters for 50 liters of water, supplemented with such an anode. They are not only compact, but also easy to use. By the way, to make sure that the anode is really titanium, you can use a magnet. This material has a weak magnetic field, so it is not magnetic at all.

Aluminum

This is another version of the protective electrode, coated with aluminum coating. It is also made in the form of an ordinary threaded rod.

When water is heated, the metal expands and the alloy of the body lengthens, losing its characteristics. Microcracks form on the surface of the tank. After which the oxygen in the water begins to oxidize the metal, causing irreversible corrosion processes.

The steel body and the electric heating element create a galvanic couple, with the body becoming the anode. To prevent it from being destroyed under the influence of water, the manufacturers placed an alloy containing aluminum near the heating element.

It takes on the role of an anode - as a result of which all aggressive oxygen is consumed for its oxidation, and the container remains intact. The aluminum anode prevents the boiler elements from oxidizing, but it has a very sophisticated design and is easily damaged by mechanical shock.

The essence of water heater protection ↑

The purpose of installing a magnesium anode in a water heater is now clear. And to understand how metal is protected from corrosion, just remember your school chemistry lessons.

The iron from which the internal tank is made interacts with oxygen present in the water during operation. As a result, iron oxide is formed. Thus, iron, exposed to oxidative processes, is an anode.

Manufacturers, when installing a magnesium part in a tank, pursue two goals:

New and used magnesium anodes

- Magnesium gives up electrons from its atoms much more easily than iron. You can even say that iron simply does not have time to interact with oxygen. Thus, magnesium acts as a sacrificial anode that dissolves to protect other metal components from corrosion. Since magnesium reacts instead of iron in chemical reactions in the boiler tank, the inner surface of the container remains untouched.

- Tap water contains not only oxygen, but also dissolved calcium salt. It settles in the form of scale on the internal parts of the water heater. When interacting with the hot surface of the heating element, scale turns into real calcium stone, thereby reducing the thermal conductivity of the heater, as a result, the heating element fails. The use of a magnesium anode helps solve this problem as well - its electrons, by displacing calcium ions, transform scale from solid salt into a loose substance that is easy to remove from the internal parts of the boiler.

Magnesium anode and heating element assembly

However, during its operation, the protective anode is quickly destroyed, as a result of which its periodic replacement is required.

Otherwise, the service life of the device will depend only on the quality of the internal coating, as well as the material of the tank walls, temperature conditions and water composition.

It is after this period that the rod becomes very loose and begins to crumble easily. The element is replaced with a rod with similar geometric parameters. At the same time, it is necessary to remove scale from the inner surface of the container and heating element each time. This will significantly extend its service life and also improve the quality of hot water.

Tips for use

To ensure that the boiler really works for a long time, follow these tips:

- Always monitor the condition of your device no matter how old it is. Hissing from the boiler may indicate that the heating element (heating element) needs repair or replacement.

- Salt deposit problem. Even with the use of anodes, it is impossible to completely avoid the appearance of salt deposits. Its quantity depends on the quality of the liquid in the water supply system. If there are too many salts in the water, then even the best magnesium rod will not cope.

- Experts advise disassembling the boiler from time to time and looking at the degree of wear of the special rod. The first check should be done after six months of operation of the water heater. If the degree of wear of the anode is close to 50%, then after another 5-6 months it will need to be replaced.

The storage water heater must not be turned on unless it is equipped with a magnesium anode. Sometimes the user removes a worn rod but does not install a new one due to the fact that there is no time to purchase and replace the part. In such a situation, the boiler is turned on without an anode, which is very bad. Magnesium anodes are sold in almost all plumbing stores and are inexpensive, so it is better to replace the rod in a timely manner than to later eliminate the results of the boiler operating without this element. It is not necessary to invite specialists to replace a worn-out part. No special knowledge or rare tools are needed for this purpose.

It is only important to carefully follow safety precautions. When replacing the anode, all water valves must be tightened and the boiler must be turned off from the power supply.

Manufacturers of water heating equipment advise descaling at least once a year. If you do this more often, this will only have a positive effect on the life of the device. With constant operation of the boiler, plaque settles at the bottom, which deteriorates the characteristics of the device. If you regularly clean the storage tank, you can get rid of this problem.