Construction of your own home or major renovation of an apartment is not complete without one of the most important stages - insulation. The level of comfort of homeowners depends on the quality of this operation. Improper conduct of the event will greatly “backfire” in the near future: condensation will constantly accumulate in the room, and the insulation, saturated with water, will not be able to serve as protection from the cold. To protect yourself from unpleasant consequences, always use a vapor barrier. But it is with this procedure, which seems very simple, that the main question arises for those who do the work of insulating a house with their own hands. Which side should I attach the vapor barrier to avoid problems? To understand, you need to learn as much as possible about vapor barrier films.

Functions of vapor barrier films

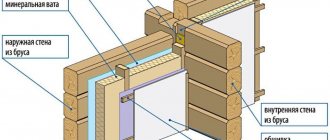

Without understanding the purpose and characteristics of vapor barrier materials, finding the right answers will be difficult, so first you need to understand the tasks that these films perform. For example, mineral wool thermal insulation materials (plates, rolls) are very popular, but they have a huge drawback. These insulation materials are hygroscopic: they are able to absorb water vapor accumulating in the air. But they perform their work efficiently only in a dry state. Damp mineral wool cannot maintain its stated thermal conductivity.

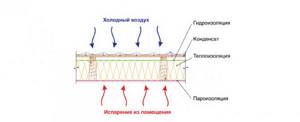

Inside the walls, where cold air from the street and warm air from the room meet, water vapor begins to condense. If such a “dew point” is located inside the thermal insulation layer, then the material inevitably gets wet. The result is the loss of its protective properties, its deformation and shrinkage. Even after partially drying, mineral insulation is no longer able to do its job well: thermal conductivity increases in the area where it gets wet.

Vapor barrier prevents moisture insulation material, as well as elements of the roof, floor and walls. Thanks to this protective layer:

- Comfortable conditions are provided inside the room - optimal humidity;

- there is no danger of the appearance or growth of black mold colonies;

- heating and air conditioning costs are significantly reduced.

For brick, gas and foam concrete walls, vapor barrier is no less important. These membranes allow the dew point to be moved beyond or to the edge of the insulating layer. This protection ensures the strength of structures for a long time.

How does vapor barrier work and why is it needed? Features of the use of various materials.

The construction of comfortable modern houses involves the widespread use of a variety of insulating materials. Otherwise, you are unlikely to enjoy living in such a house. But no matter what high-quality and expensive materials are used in the house for noise and heat insulation, the house will not be complete without a competent vapor barrier device. But how does vapor barrier work, so that its absence has such a negative effect?

We will try to explain the operating principles and design features in this article.

In a warm living room, steam is generated and circulates in the air. In general, this steam has fairly decent pressure on the ceiling and walls. Thus, he tends to leave the room by breaking out. Therefore, insulating materials must have a high ability to pass steam where it wants to go.

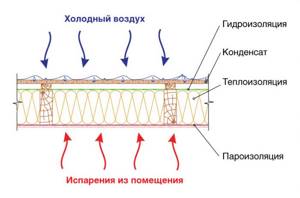

If the temperature outside is above zero, then steam very easily passes through the ventilation and thermal insulation. At sub-zero temperatures it is much more difficult for it to do this, since it is retained directly in the material. It would seem that this does not sound so scary, but the process of condensation begins to occur inside. As a result, first the insulation gets wet, and then the wall (or roof). As a result, significant damage occurs to both. To eliminate the problem at its roots, it is necessary to add special materials to the insulating structure that prevent moisture from entering the insulation.

Vapor barrier is a set of works to protect surfaces separating warm areas from cold ones from steam. In private homes, these are any surfaces that warm air reaches and with which it comes into contact. For example, it is very important to provide vapor barrier to roofs and basement floors. If the attic of the house is not heated, then the floors here must also be insulated from steam. But for carrying out work inside the walls, there are two options for the development of events. If the house is insulated from the street using wood, then a vapor barrier, in principle, is not needed. Whereas in all other cases you cannot do without it.

Regardless of the nature of the surface, vapor barrier operates according to the same principle. Namely, the material protects the structure, which has insulation, from exposure to steam. For this principle to work, it is necessary to lay the vapor barrier directly on the side where there is warm air. A simple example is the design of an attic floor. Here everything happens according to the following scheme: lining of the internal ceiling, above – a layer of vapor barrier material. Above the material is insulation, and above the latter, directly, is the attic floor. Here, as when working on other surfaces, it is very important that the vapor barrier film (or other material) lies in a continuous layer. Cracks, breaks and other violations of integrity are simply unacceptable. We will talk in more detail a little further about how to secure the material to the floor, ceilings, walls and roof. Let's just say that a construction stapler is usually used, along with a thin lath. These tools allow you to carefully adjust the tension.

How to properly carry out roof vapor barrier work.

Vapor barrier and waterproofing of roofs and walls are a necessary component of the overall insulation system. The basis of design is the calculation of thermal properties. The calculation is carried out based on several criteria that rely on the thermal conductivity of the atmosphere inside the house. The main purpose of roofing vapor barrier and waterproofing work is to fully protect the insulation from moisture. And the presence of full thermal insulation of the roof is a prerequisite for the space under the roof to serve as an additional barrier to the heat leaving the house. In addition, this allows you to arrange an additional living space here - an attic. The attic is an excellent attribute of a good residential cottage.

Protecting the roof from moisture formation will help preserve the original beneficial properties of the thermal insulation material for a long time. Indeed, with an increase in humidity inside the insulation by only five percent, heat loss occurs approximately ten times faster. In addition, the absence of a properly installed vapor barrier will lead to the formation of condensation directly on the roofing. In addition to obvious damage to the insulation, corrosion processes are activated here, which will ultimately lead to the destruction of the roofing material.

The difference between vapor barrier and waterproofing

Both types of material perform the same function - serve as a barrier to moisture. Vapor barrier protects against water vapor occurring indoors. Waterproofing ensures the safety of the floor, walls, rafter system, it protects from external threats - from rain, snow, dew, and from high water that rises during prolonged rains.

The vapor barrier in this duet is the strictest “guard”, since it does not allow either steam or water to pass through. Waterproofing can only retain liquid; steam can pass through it freely. Since both materials invariably take part in insulation, it is necessary to write a few words about the “responsibilities” and place of work of these films.

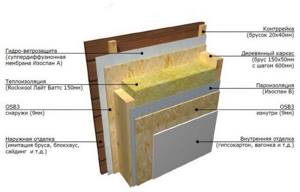

A hydrobarrier is placed in front of (or under) the thermal insulation: it does not allow water to pass through, but allows steam to escape. This property helps the moisture-loving insulation maintain its normal condition. The vapor barrier laid on the insulation does not allow water or steam to pass through. If a small amount of moisture does leak out (for example, through imperfectly closed joints), then the waterproofing material will “mercifully” allow it to evaporate.

Where is the vapor barrier membrane used?

The small thickness of the membranes allows them to be used in all types of multilayer structures - frame houses and buildings made of SIP panels, walls and ceilings insulated from the inside. It is used:

- for the attic floor, if the attic is not heated;

- for the roof of the roof, if a warm attic is built;

- for the ceiling - if the upper floor is not constantly heated;

- for interior walls - especially in rooms with high humidity.

For the floor, a vapor barrier can be used on the outside of the insulation if the subfloor is not in contact with the ground, but from the inside it is better to cover the insulation with vapor-permeable waterproofing to ensure ventilation.

When is vapor barrier needed?

The correct answer is always. This stage does not depend on the type of insulation, nor on its price and quality. Now there is a “mighty bunch” of thermal insulators that are most often chosen to preserve heat. This list includes mineral wool, ecowool, polystyrene foam and polystyrene foam, including its extruded variety.

Mineral wool is very popular, but due to its “indifference” to moisture, it has to be protected. Ecowool, consisting of cellulose fibers, can absorb moisture while remaining dry. This insulation is an exception to the rule. It does not always need a vapor barrier, but it is necessary in very cold climate zones, in those rooms where the humidity level is very high.

The use of polymer materials that are insensitive to moisture makes the problem a little easier, but does not solve it completely, and besides, such walls breathe worse. Protection of building structures (for example, vulnerable wood) is the second factor that speaks in favor of vapor barrier, so its presence in the cake is a must. External insulation does not require this protection: the material copes with unfavorable conditions on its own. Interior spaces need vapor barrier.

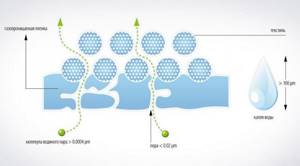

Membrane structure and operating principle

The membrane consists of several layers of film with microscopic perforations. The holes are not able to let a drop of water through, but easily allow steam to pass through. Inside the membrane, moisture is distributed over the entire area, evaporates, or flows down through internal channels.

Vapor barrier prevents the penetration of wet vapors into the heat-insulating layer and prevents condensation from falling on wooden and metal structural elements. When wet, thermal insulation ceases to perform its function, accumulates moisture and becomes a source of threat to the wooden and metal structures of the building. Over time, wet insulation develops mold, which spreads to nearby areas and can affect a large area.

A properly installed vapor barrier becomes an impenetrable obstacle to moisture and locks it in. Moisture remains outside the heat-insulating cake, but this leads to the accumulation of vapors inside the room. If some of the moisture nevertheless penetrates into the thermal insulation (through fastening holes, at the junction of the strips, small damage in the film), it is blocked there and begins its negative destructive effect. Ordinary PVC film often provokes such consequences.

A vapor barrier membrane has the property of allowing moisture to pass in one direction, preventing its reverse penetration. Manufacturers even regulate the degree of this penetration, producing vapor barrier materials with different technical characteristics. This allows you to select a membrane with the parameters required in each specific case. Thanks to the correct choice of vapor barrier, optimal ventilation conditions are created in the room while simultaneously conditioning the internal heat-insulating layers. At the same time, the vapor barrier must be attached in strict accordance with the technology, otherwise moisture penetration bridges will arise, which will significantly reduce the overall effectiveness of the protection.

Types of materials

Which side should I attach the vapor barrier? The answer depends on what type of vapor barrier is chosen for the job. There are many such materials, but they are all divided into 3 main types.

- Film. This is a long-known traditional barrier. It is not for nothing that such films are called blind vapor barriers: they do not allow a single molecule of vapor to pass through. They are made from butylene or polyethylene, or their derivatives. The main advantage of this type is its low price. Vapor-proof films can be reinforced (three-layer) and ordinary.

- Vapor condensate films have two layers: a smooth inner layer and a rough outer layer. The outer surface allows droplets of condensation to dry in place without flowing down. To avoid the greenhouse effect due to a solid vapor barrier, it is necessary to create an air gap.

- Diffuse membranes. These are “breathable” materials: they, unlike impermeable films, allow a minimal amount of steam to pass through them, which evaporates instantly and does not linger inside. Diffuse membranes are classified as types with limited vapor permeability. They are made from polypropylene and polymer film. This type also has two sides.

- Energy-saving or reflective films. The outer layer of this type of vapor barrier is metalized; this protection allows the material to withstand high temperatures and reflect heat back into the room. Such excellent qualities are the reason for the frequent use of films when insulating baths and saunas.

Due to their excellent performance characteristics, breathable multilayer membranes are most in demand.

Why do you need a vapor barrier membrane?

Vapor barrier is used to protect hygroscopic (moisture-absorbing) insulation (mineral wool, expanded clay, ecowool, sawdust). Moisture enters the insulation not only from the outside in the form of precipitation, but can also accumulate as a result of normal human activity - cooking, using the shower, and even normal breathing!

The relative humidity in rooms especially increases with the onset of cold weather - the lower the temperature, the more moisture begins to condense on colder surfaces.

Unprotected insulation absorbs moisture from the premises, but cannot quickly evaporate it. This increases thermal conductivity, which negates all the properties of the insulation. If the insulation material remains damp for a long time, the interior decoration of the premises will also become damp. Mold and mildew will begin to develop on it, which can lead to serious illnesses for humans.

Types of membranes, areas of their application

There are several types of such films, each of them has its own sphere of “activity”. The correct choice of side also depends on the variety.

- “A” - vapor-permeable membranes, their purpose is to remove steam. Films are used for arranging ventilated facades: they act as a water barrier, but are capable of allowing steam to pass through in doses. These membranes are used for the roof, but not on the inside of the building, but on top of the thermal insulation material - directly under the roofing. Such films are mounted with the smooth side facing it and the rough side facing the insulation.

- "B" (or "AM"). These films are full-fledged vapor barriers, they also have different sides. Unlike previous products, they are always mounted to the heat-insulating material with a smooth surface. Manufacturers, to make work easier, make them multi-colored and put logos on the front (outer) side. These products require a ventilation gap.

- "C" and "D". The first materials were two-layer membranes. Due to their increased strength, they are used for facades and roofing. Their task is protection from bad weather - precipitation and wind. “D” is a laminated high-strength vapor barrier made from polypropylene. It is chosen for rooms with high levels of humidity, to protect the insulation under the roof.

They are one-sided and two-sided. The first materials allow steam to pass only in one direction. They are attached so that this working layer faces the room. Such products always have markings on this surface; it gives the master the opportunity to quickly find his way. Types “C” and “D” - more often double-sided membranes are capable of transmitting steam equally regardless of the position of the vapor barrier, so in this case the fixation side does not play a role.

Simple films with absolutely identical sides are a reliable barrier to steam; there is no difference in how they are attached. Energy-saving vapor barrier is always applied with a heat-insulating layer inside the room. Steam and condensate products - with the rough surface facing outwards.

Vapor barrier materials are divided depending on the degree of vapor permeability. The high indicator allows them to be mounted directly next to the thermal insulation; it is necessary to leave free space impenetrable for ventilation. The ventilation gap is 15-50 mm, it does not allow condensation to accumulate.

Briefly about the main thing

A residential building located in a cold climate is isolated not only from water in its liquid state, but also from steam. If this is not done, then over time the frame of the living space itself may begin to collapse due to the constant ingress of moisture from the inside.

To understand which side to lay the vapor barrier on, you first need to look at its color and tactile sensations when running your hand over it. After the required side has been determined, the work is carried out carefully and slowly. The technology for carrying out the work varies depending on where the film is installed - on the ceiling, floor or facade.

When working, it is important to avoid the most common mistakes. Otherwise, the quality of the material may quickly deteriorate due to the appearance of frost and even ice on it.

Ratings 0

What are the distinctive features of the parties?

You can almost always determine the sides of a vapor barrier material yourself. If there are no instructions, then you should remember a few simple tips:

- A rolled vapor barrier usually rolls out “correctly” itself: with the side that should be located next to the insulation.

- For vapor barriers that have sides with different colors, the lighter one is mounted to the thermal insulation.

- If the material has different surfaces, then the smooth one should “look” at the heat-insulating material, the fleecy, rough one should look outward.

These recommendations answer the question of which side to attach the vapor barrier, but it all depends on the purpose that the material should serve, on the location, conditions and a specific surface.

Checking the operation of the vapor barrier

There is a simple way to make sure that the material actually does its job. To test its effectiveness, cut off a small piece of vapor barrier, then take two identical transparent containers. For example, jars or glasses. Boiling water is poured into the first dish, covered with a vapor barrier material, and a second glass is placed on top, but turned upside down.

If the vapor barrier is of high quality, then the top glass will remain completely dry. When drops appear on the glass, it is possible that the wrong surface of the vapor barrier, which has one-way conductivity, was simply selected. Then the material is turned over to the other side, and testing continues. Normal material will prove its worth. If the situation has not changed, then there is only one conclusion - this sample has double-sided vapor conductivity.

Which side should I attach the vapor barrier?

You can find out which side to attach the vapor barrier correctly if you read the recommendations of the manufacturer of a particular material in advance. However, if this is not possible, and there is no marking on the product, then it is better to follow the rules common to the installation of all types of vapor barriers.

Vapor barrier and roof

Most of the year, warm air from indoors tends to find its way out, and internal structures only help, since they transfer heat relatively easily. Rising upward, this flow gradually dissipates and is absorbed by the unprotected thermal insulation material. If the insulation is covered with waterproofing from the outside, then a vapor barrier film is mounted on it with a reflective or rough surface “looking” into the house.

Both smooth sides mean there is no reason to worry: in this case, installation of either side is possible. The only requirement for such a material is high strength: it will not allow it to tear when fixed with staples. The weight of the insulation will also not become a threat. Heating, or lack thereof, in the attic is another important factor.

If the room is heated, then the film is laid with the reflective side inward so that there is a ventilation gap of at least 15 mm between it and the insulation. If the roof gets very hot and condensation accumulates on the outside, the vapor barrier is mounted in reverse. A material with a rough surface is ideal.

Insulation of the ceiling or floor

In this case, the question of which side to attach the vapor barrier has two answers, depending only on the functions of the room. The reflective or rough side is chosen for the interior space, where conditions are normal. If the room is located above humid and hot rooms (for example, above a steam room), then when insulating the floor, the opposite is true. The vapor-proof film is installed arbitrarily.

Vapor barrier for walls

In this case, the goal is always the same: to preserve the maximum amount of heat inside the room. Dense, often reinforced films are used as vapor barriers. The question of the side is not fundamental here, since this type of vapor barrier is effective in any position.

Video description

This video demonstrates the principle of operation of vapor barrier films and tested samples from different brands:

Installation features

The vapor barrier is laid under tension without sagging on the inside of the room, close to the insulation; on the outside, a ventilation gap must be installed. The canvas is fastened to the sheathing using a stapler (construction staples), self-tapping screws or nails in combination with wooden slats, with special tape or with an adhesive compound that is applied at the factory. The edges are overlapped to a width of 100-150 mm.

Fixing the fabric with an overlap using factory markers Source ecoteploiso.ru

Junctions with adjacent structures and seams between canvases must be sealed with specialized glue or tape. A small gap is left between the protection and further finishing.

Is a mistake on the side a tragedy?

No. There is no point in being sad and rushing to redo incorrect work. If the “warm pie” is arranged according to all the rules, then the “wrong” side will not play a special role. For example, you can take films with an anti-condensation surface and products without it. As practitioners say, there is no difference between them. The condition of the thermal insulation material in both cases remains the same.

Experienced builders believe that the culprits behind the talk about the “correctness” of the parties are manufacturers who position their product as a super invention that can solve all problems. If we talk about vapor barrier, its correct installation is important. Complete sealing of joints, the absence of “wound” holes in the film and ventilation gaps, if needed, guarantee the absence of any “creep” of water droplets. Otherwise, you will only have to sin on yourself, and not on the material and the wrong side of it.

How to choose a membrane

When choosing a vapor barrier membrane, you need to pay attention to:

- Sd index - the higher it is, the lower the vapor permeability;

- temperature range - especially important for buildings that are heated irregularly;

- strength - vapor barrier will be effective only if the integrity and tightness of the film is maintained.

The price of the material also plays an important role in the choice. First of all, you need to focus on the conditions: is the room heated, what temperature conditions are maintained in it, what are the air humidity levels, etc.

You can read more about choosing a vapor barrier in the article “How to choose a vapor barrier film.”