Covering a house with siding and insulation

There are two main ways to attach insulators.

- On a wooden frame or metal sheathing.

- Adhesive - only suitable for hard, smooth surfaces.

The first method is more reliable and universal. It may be labor-intensive, but, as a rule, it is what is used.

Preparatory work

Start with surface preparation.

- Log house, frame and panel house - first you need to eliminate all defects so as not to waste time dismantling the panels. All excess decor is removed, which will still not be visible under the coating. The voids are expanded and cleared. The mold is removed. Then you need to treat with antiseptics and fire retardants - fire retardants. Cleaned cracks, cracks and chips are covered with wood putty and sealed. If the basement has not been hydro- and vapor-insulated, it is advisable to do so so that moisture does not accumulate inside.

- Brick, concrete, porous blocks - the surface is cleaned, defects are eliminated using cement mixture, plaster and putty. All voids are treated with antiseptics before filling. If necessary, the foundation is waterproofed. If you plan to install a porous mass with glue, the base is primed.

Pixabay

Frame installation

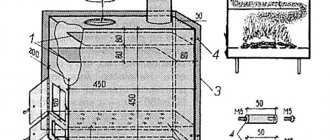

It is necessary for attaching the casing. The material used is a metal profile or wooden blocks with a maximum cross-section of 50x50 mm. To prevent ice from forming inside. Work is carried out at positive temperatures. Metal is more reliable. It is not subject to temperature and humidity deformation, does not dry out and does not lose strength over time. To create the lathing, you will need PS rack parts 50x50 mm and ceiling PP 60x27 mm.

The guides are set in increments of 0.5-0.6 m. For plinths it is 0.4-0.5 m. They are placed perpendicular to the siding panels. It is usually directed horizontally. The bars are coated with antiseptics and secured according to the markings. It is advisable to pre-drill holes for screws in them and in the base. Dowels are inserted into the base.

Metal parts are installed on hangers. First, their locations on the wall are marked, then holes are drilled. Dowels are inserted into them. Step - 0.5 m or less. Suspensions are elongated metal plates. They are bent into the shape of the letter “P”, then guides are inserted into them and screwed in place.

Jumpers are installed to increase the strength of the sheathing. It can perform its task without them, but with jumpers the reliability will increase significantly.

A polyethylene film or porous products based on it, which perform the function of a vapor barrier, are attached to the ground floor and foundation. It is laid overlapping and secured with tape. It should not be pulled. The corners are covered in solid pieces. The seams must be absolutely sealed.

Instagram @remsistem63

Instagram @remsistem63

Frame technologies differ from each other in complexity. The fastest method is suitable for smooth walls. The surface is covered with hard slabs that have a shell, and a sheathing is mounted on top. It can only be used in warm regions, as it does not allow the coating to be made thick enough.

For the middle band, other technical solutions are required. They depend on the material used.

Laying insulation

For mineral wool and polystyrene foam panels, vertical wooden slats are sufficient, the height of which is equal to their thickness. The pitch of the slats is equal to the width of the slabs.

Penoplex is recommended to be attached to a metal frame. Suspensions and horizontal jumpers are used as supports. For fixation, dowels with a wide head that do not fall through the loose porous mass are also used. To ensure that the joints do not coincide, the rows are offset - otherwise the cold will penetrate into the room through the cracks. The voids are sealed with polyurethane foam.

PPU is sprayed onto the sheathing with a spray gun with a nozzle. Only professional builders have such equipment.

Pixabay

Types and characteristics of material

When choosing siding for cladding a house, you should first of all start from the final goal achieved:

- a durable façade that will not lose its original appearance for several years;

- natural finish;

- design that corresponds to modern fashion trends;

- strengthening the protective functions of the facade.

The result will depend on the properties of the material used to cover the house. And also on the project and its operating conditions. At first glance, all panels are identical in appearance. A closer look reveals significant differences:

- in strength indicators:

- load on the subsystem;

- care requirements.

Vinyl siding

It is made from a compound based on vinyl mass with various plasticizers, additives and dyes. The panel consists of an inner and outer layer. Their formulation differs in composition, since the functions performed are different. The outer side resists peeling, warping and fading. The inner side is responsible for strength, resistance to mechanical stress and temperature changes. Two different compositions of the compound are fused together using the co-extrusion method, resulting in a panel with improved properties of the outer and inner sides.

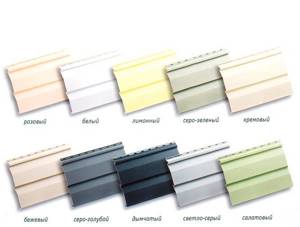

Thanks to the composition and various additives, during its production it is possible to achieve color and texture similarity between panels with different textures: wood, stone, brick. The wealth of shades allows you to choose vinyl siding to suit any building design. The panels are lightweight, resistant to external atmospheric conditions, and can be used at temperatures ranging from -50 to +50 ºС. The advantage is the low cost of the material.

Among the disadvantages, it should be noted that it is necessary to take into account the coefficient of linear expansion during installation, since deformations may occur during temperature changes. The material has low resistance to mechanical stress and a short service life.

Wood siding

The popularity of wooden siding is due to its environmental friendliness and high aesthetic properties. The main disadvantages are susceptibility to rot and decomposition, which shortens the life of the skin and causes many problems during maintenance. In the production of modern wooden panels, thermowood and impregnated wood are used, which significantly improves their technical characteristics.

Thermowood is a material from which moisture and substances that contribute to its decomposition have been removed in an airless environment.

Impregnated wood is impregnated under vacuum conditions with a composition that prevents rotting, decomposition, the development of mold and other influences.

Metal siding

Metal cladding can be used not only for cladding domestic buildings, but also for industrial buildings, since it meets fire safety requirements and has a long service life. Steel, aluminum, and zinc alloys are used for cladding. The main disadvantage is low sound insulation during precipitation and the likelihood of corrosion.

Aluminum siding is the most popular among private home owners. It has a variety of color and texture variations, is not susceptible to mold and insects, and has a low cost compared to other alloys. The main disadvantage is its susceptibility to deformation, in which it cannot be restored.

Fiber cement siding

It is made from a mixture of cement, sand, water and cellulose fiber. It is environmentally friendly, and its high decorative properties allow it to replace expensive finishing stone. Positive traits:

- easy to install;

- natural;

- not subject to corrosion;

- resistant to precipitation;

- not susceptible to the development of biological organisms;

- non-flammable;

- does not require maintenance.

The material has no disadvantages, but is practically not used in Russia.

DIY vinyl siding installation: fittings and fasteners

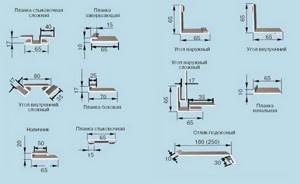

The fittings help make the facade more beautiful, serve for decorative finishing, and also help in the process of installing siding. Currently, there are various profiles, using which you can finish the facade of a building of any shape:

- corners (external and internal)

- start strip

- end strip

- F-profile

- end mounting strip (G-bar)

- connection strip (H-bar)

- chamfer or cornice strip

- drain

- platband

- window trim

So, we have made the sheathing, and now it’s time to install the lower edge of the facade, which is to be covered with cladding panels.

We determine the most pinched place and make a mark, which we project along a horizontal line to each corner of the building. Next, you need to measure a distance from the marks upwards equal to the width of the starting strip and at the obtained level, pull the thread or mark it using a tapping cord. It is from the resulting line that the upper edge of the initial rail will pass.

The starting bar is mounted with self-tapping screws 20 cm apart along the previously marked line. It is also necessary to provide a temperature gap of 6-10 mm, which is made between the starting strips docked with each other.

Next, you need to fix the corner profile, which should be 5-6 mm from the top of the wall and the same distance from the bottom of the starting strip.

First you need to secure the corner with self-tapping screws by the edge and carefully align it with the vertical using a level or plumb line. After leveling, the profile is attached to self-tapping screws every 20 cm, which must be inserted into the very center of the holes.

When you need to combine the corner strips, they are installed with an overlap of 20 mm. Before connecting, you need to cut 25 mm from the fastening edge of the top strip. This connection method will prevent moisture from getting under the siding.

If windows or doors are located in openings, then a special strip is used during finishing, which hides the slope and decorates the outer corner.

The finishing panel is attached near the frames themselves. If the sheathing and windows are on the same line, then the connection between the siding and the window is made using platbands.

If there is enough space, you can finish the slopes using an external corner profile mounted along the wall line and a G-profile, which is installed directly against the frame. This method involves hiding the slope with siding elements.

The profile, which is mounted above windows or doors, must be cut from the inside and the resulting elements bent towards the side panels.

To drain precipitation, a drain panel should be secured under the window. Along the perimeter of the windows and doors, horizontal fittings are installed, inside which you need to insert a finishing strip that will secure the strips of panels.

The end profile is also installed on the top edge of the wall, where it connects to the installed roof box.

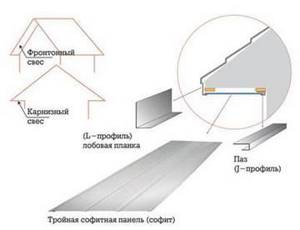

G-panels can be used to decorate facing strips and in cases where the wall is in contact with enclosing elements. They are used mainly on gables, near windows and doors that protrude into the siding, as well as on the sides of walls and when covering soffit.

Waterproofing, vapor barrier, wall insulation

A layer of waterproofing is installed under the metal siding on the insulation : the water that gets under the ridge of the roof in the form of snow or rain flows down the walls.

At the same time, when it hits the waterproofing layer, it falls down to the foundation and into the drainage system. At the same time, the waterproofing layer protects the insulation ; it also does not prevent the escape of vapors from the room.

If there is no insulation, it is still necessary to install waterproofing under the metal siding.

Along with the waterproofing layer, it is recommended to lay a vapor barrier layer under the insulation to remove wet vapors from the side of the building and protect the insulation from them.

Siding elements

Drainage

This element serves to protect the base and foundation of the building from moisture. It is a painted metal corner. Drainage drains are leveled along the entire perimeter of the building. Insulation and siding of a house should begin with drainage.

Then the initial or starting rail is attached to them. The rigid design of the drain allows it to be set strictly at level, which simplifies the installation of the soft starting rail.

Starting rail

This rail is attached directly to the drainage system while maintaining the level. This is where siding installation begins. The lower starting level is corrected by releasing the sheathing to the required level if the walls have a slope.

The siding panel is inserted into the starting rail until it clicks. After installing all the elements, install the panels from below into the lock, also until they click. On a blank wall, the panels are stacked up to the roof, and on a wall with windows – up to the bottom of the window.

Siding corners

The siding must be closed on the sides and ends of the building. To protect against side winds and water, wide siding angles are used. To properly install the sheathing, you need to attach the corner of the siding to the wall surface and make the necessary notches. The panels extend into the corners by 10 mm and should not rest against its walls.

Soffit

A soffit is needed for lining the roof overhangs from below. The difference between soffits and panels is that soffits have perforations for natural ventilation. The fastening technology is the same as for all elements, only the edges of the spotlights are inserted into the J-rail.

Fastening the panels after installing all the elements will not be difficult. This is easy and simple to do, just like insulating plastic windows or insulating a loggia.

Insulation of the house followed by cladding with siding panels

Installation of siding panels

When starting to cladding the facade, it is important not to forget to provide a compensation gap, which will save the plastic panels from deformation under the influence of temperatures. Installation of façade siding panels is carried out in a horizontal position, leading them around the corners or around the corner and the connecting strip, and then lowering them until they click. Then, through the holes provided in the panel, the mounted part is screwed to the sheathing. In the same way, subsequent parts of the sheathing are attached up to the roof.

Important! In order to avoid possible inaccuracies in installation, be sure to check your actions with the level.

Preparatory work

Before directly installing the cladding, you must perform the following steps:

The main material of the walls is freed from the old cladding, as well as from the dust and dirt present on it. Rotten or moldy areas are cut off and sanded down to “healthy” wood

The inspection should be carried out with the utmost attention: even a small colony of microorganisms hidden under the siding will have time to cause considerable damage to building structures before being discovered. Next, the walls must be thoroughly lubricated with antiseptic impregnation. After the impregnation has dried, the walls are covered with a waterproofing, vapor-permeable membrane. Be careful: this film must be installed with the correct side

At this stage, it will be enough to grab it lightly, for example, with a construction stapler. In the future, the membrane will be more firmly fixed by the frame.

Installation of waterproofing

Frame installation

First of all, you need to decide on the frame material. Wood is cheaper and easier to work with, but two circumstances must be taken into account:

- The maximum permissible humidity for timber is 20%, and it must be dried in the open air. Finding such material is not so easy, since, as a rule, freshly sawn wood with a moisture content of over 50% goes on sale. A frame made from it will undergo the shrinkage already mentioned here, that is, it will dry out and become deformed.

- Even after treatment with the most effective antiseptic impregnation, the wooden frame will not be durable, since it does not have waterproofing protection.

Slats in a wooden frame have to be installed quite often - every 30 cm.

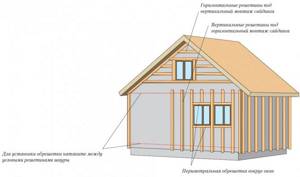

Frame installation diagram for horizontal siding

The frame elements are installed perpendicular to the siding panels. That is, if the cladding will be mounted horizontally (the most common option), then the slats or frame profiles should be screwed vertically to the walls. The construction of the frame begins with the installation of elements at the corners of the building, then the profiles framing the window and door openings are screwed in. After this, you can install intermediate elements.

When the profiles are positioned vertically, their installation is controlled using a plumb line, and when the profiles are positioned horizontally, using a building level.

Home with vertical vinyl siding

Laying insulation

There are quite a lot of insulation materials that can be applied to the wall under siding. These are ordinary polystyrene foam sheets, various mineral and basalt wool, as well as more modern expanding solutions , which foam after application, filling the entire space.

The choice of insulation depends on the availability of a particular material in stores, on the personal preferences of the consumer, as well as on the sheathing. If tile insulation is selected, it should fit in one block between the individual guide bars. It is not allowed to assemble insulating material from several pieces.

When choosing the density of insulation, do not forget that the higher the building, the denser the insulating material should be , otherwise in the upper part it will simply begin to fall off the walls or crush the lower rows. The permissible minimum for insulating materials, which is provided for by the siding installation technology, is 30 kg/m.

A layer of protective film is applied to the insulation , which is convenient to attach to the wooden sheathing using an industrial or construction stapler. Often, as protection, a diffuse membrane is applied to the heat-insulating material. This seemingly porous material does not interfere with the removal of moisture from the premises, while completely protecting it from its penetration from the street. High-quality membrane materials are able to completely repel water falling on them, and also participate in the thermoregulatory process.

Return to content

What siding should I use for cladding?

The modern market offers a huge selection of panels in a wide variety of colors and textures. Siding can successfully imitate wood, brick and stone surfaces.

What siding to use for cladding

The standard thickness of the facing panel is 1 mm. Width and length indicators are not subject to standardization and depend on the preferences of a particular manufacturer. The most common cladding panels are about 3-4 m long and about 20-25 cm wide. A large dimensional grid will allow you to choose the panels that will be most convenient to use for cladding your home.

Siding

Residential buildings are usually finished using vinyl or any other base siding. When choosing a specific option, all other things being equal, give preference to vinyl panels.

When choosing vinyl siding, be sure to pay attention to the appearance of the elements - the coloring of the panels must be strictly uniform

Facade panels

Expensive siding usually has the same color on both sides. For more budget-friendly materials, the inside is often a little lighter than the outside.

It is not recommended to use panels with a glossy finish. Such material will become very hot in the sun, to the point of deformation. Therefore, the best choice is siding with a matte finish.

Vinyl siding

Make sure all panels are the same thickness. The parameters of their nail holes should also be identical.

Before purchasing a material, check its ductility. To do this, you can bend the thin part of the panel near the nail hole. If the edge breaks, you should refuse to purchase such panels. If the material bends, but remains intact, you can safely use such siding for cladding with insulation.

Vinyl siding Nordside

Types of siding and areas of its application

Siding refers to polyvinyl chloride or metal panels used to decorate the facade of a building and capable of imitating a variety of materials with their decorative design: a cut of natural wood, stone.

Main characteristics of siding:

- In some cases, plain siding is used. On the positive side, siding is characterized by a number of its technical properties.

- This is durability and sufficient strength, which helps the material to withstand direct mechanical stress and adverse environmental factors.

- Siding does not rot and fungus does not develop on its surface. The decorative design of the finishing panels will not lose its attractiveness throughout the entire period of operation.

The modern building materials market offers the following types of siding:

- Polyvinyl chloride - made of PVC material and its decorative design can resemble the pattern of a cut of wood, natural stone or brick. PVC panels are used to decorate almost all types of buildings, from residential buildings with different service life to commercial and warehouse buildings. It is possible to install siding yourself with insulation.

- Metal - made from steel, aluminum, zinc by cold rolling molding, has an anti-corrosion coating. Metal panels are durable and resistant to aggressive environmental factors, and therefore this material belongs to the category of industrial goods and is suitable for finishing the facades of production workshops. The product has a high specific gravity compared to its polyvinyl chloride counterpart, and after deformation it cannot be restored.

- Wooden - used only for decorating private buildings. Without fail, the panels are treated with an antiseptic and dried under high pressure. The price for this material is quite high.

Note! In addition, siding may differ in the method of installation and fastening. Thus, horizontal panels and plinth material are used for finishing residential buildings. Vertical material is intended for non-residential and industrial buildings.

Selection of facade panels

In this section we will briefly describe all the advantages and disadvantages of siding made from various materials:

Vinyl panels

Positive traits:

- Lightweight - do not bear any load on the walls and foundation.

- Simple installation - when using siding up to 3 meters in length, you can handle the installation work alone.

- Hundreds of different colors.

- UV resistance: PVC panels do not lose their color for many years.

The disadvantages include:

- Fragility of the structure - any mechanical impact will lead to the surface being deformed. However, vinyl siding cannot be repaired.

- When installing panels on an uneven surface in the first winter, most of them will be damaged, since polyvinyl chloride becomes brittle in the cold and bursts under pressure.

Metal and aluminum products

Pros:

- They are durable and do not depend on temperature changes; they do not become more fragile in severe frost.

- They are not afraid of moisture, dirt and insects, and are not classified as materials susceptible to mold and mildew.

Minuses:

- Additional load on the foundation, which must be taken into account at the design stage.

- Facade panels freeze in the cold, creating additional “load” on the thermal insulation material.

- Cannot be repaired if dents or cracks appear.

Wood siding

There is no need to talk about environmental friendliness and quality of the product - log siding is an excellent option for lovers of natural materials, however, a couple of points should be noted that may negatively affect your choice:

- Wood requires care - once every 2-3 years it is necessary to treat it with special impregnations and products that provide protection from fire and insects.

- It is necessary to renew the paint on the surface, therefore, every 5-6 years (depending on the quality of the paint).

Expensive to maintain, but beautiful on the outside

What kind of insulation is used

The choice of insulating material should be given special attention. The durability and performance characteristics of the home depend on this.

The most common types of insulation: ecowool, basalt wool, expanded polystyrene

Types of insulation:

- Basalt, slag, glass wool, other types of mineral wool.

- Extruded polystyrene foam, polystyrene foam.

- Penoizol, polyurethane foam, ecowool.

Be sure to read about the features of insulating the facade of a house with polystyrene foam in addition to this material.

This is what the production of fiber insulation looks like

Fiber insulation is produced from glass production waste and mineral fibers. They are chemically inert, fireproof, weatherproof, and do not allow water to pass through. At the same time, they are able to “breathe”, are environmentally friendly, and perfectly absorb sounds and noise. Available in the form of slabs and mats of varying hardness and thickness.

Rolled materials are attractive due to the presence of additional layers of foil and fiberglass, which reliably protect the room from moisture. However, a small thickness of up to 20 mm is not always suitable for harsh climates.

Extruded polystyrene foam is a material with a high-density cellular structure. Available in the form of slabs, they are characterized by low thermal conductivity, resistance to mechanical damage, and water resistance.

The main advantage of polystyrene foam is its price and ease of installation.

The affordable price of polystyrene foam attracts many developers. It has high heat protection, fire resistance, and strength. The material is light in weight, cuts with a regular knife, and is easy to install.

Covering a house with siding and insulation

There are two main ways to attach insulators.

- On a wooden frame or metal sheathing.

- Adhesive - only suitable for hard, smooth surfaces.

The first method is more reliable and universal. It may be labor-intensive, but, as a rule, it is what is used.

Preparatory work

Start with surface preparation.

- Log house, frame and panel house - first you need to eliminate all defects so as not to waste time dismantling the panels. All excess decor is removed, which will still not be visible under the coating. The voids are expanded and cleared. The mold is removed. Then you need to treat with antiseptics and fire retardants - fire retardants. Cleaned cracks, cracks and chips are covered with wood putty and sealed. If the basement has not been hydro- and vapor-insulated, it is advisable to do so so that moisture does not accumulate inside.

- Brick, concrete, porous blocks - the surface is cleaned, defects are eliminated using cement mixture, plaster and putty. All voids are treated with antiseptics before filling. If necessary, the foundation is waterproofed. If you plan to install a porous mass with glue, the base is primed.

General information

Nowadays, there is a wide variety of materials designed for cladding houses. Siding is one of the leaders in this area. He does an excellent job of both decorating a building and insulating it. Adding additional warmth and comfort to your home is one of the most important responsibilities of a good owner. Savings on heating in winter and savings on air conditioning in summer will have a positive impact on the family budget.

Especially considering the current gas prices. The insulation for the facade is located on the outer street side of the building, which will not affect your normal life in any way.

This is not a complete list of the variety of these products.

Materials for insulating external walls under siding

Types of insulation:

- Mineral wool insulation. They are made from metallurgical waste, silicates and other rocks. The thermal conductivity of the material is 0.042 W/m*K. Mineral wool has good fire-fighting properties. The main disadvantage is the high water absorption coefficient (about 70%).

- EPPS (extruded polystyrene foam). Low thermal conductivity (0.03 W/m*K); water absorption does not exceed 2%; ease of installation. These advantages and the high density of the material (up to 40 kg/cub.m) provide it with high thermal insulation properties. A significant drawback is the high degree of flammability.

- Expanded polystyrene is suitable for insulating foundations and rooms with high humidity.

- Styrofoam. It has a low level of thermal conductivity (0.035 W/m*K) and water absorption. The material contains many gas bubbles. The buyer can choose slabs of different thicknesses and densities. The disadvantage of polystyrene foam is that rodents love it.

- Polyurethane foam. It is obtained by mixing two substances - a polyol and an isocyanate. Low thermal conductivity, good noise insulation, high density, low degree of water absorption. It does not lend itself to mold, rot, and does not harbor rodents or insects. Its disadvantages: it is destroyed under the influence of UV; When attaching siding, the integrity of the layer is compromised, and this reduces the effectiveness of the material.

The first two types of insulation have better sound-insulating properties than polystyrene foam and polystyrene foam, but at the slightest wetness they lose their thermal insulation properties. Therefore, it is better to install mineral wool with special membranes. Foam and EPS may require additional sound insulation during installation.

When choosing between rolled and slab materials, the following should be taken into account: rolled mineral wool serves more effectively on horizontal surfaces, does not fit well at joints, and to prevent the dew point from being in the room, the material must be laid in two layers. Slab insulation does not have such disadvantages, so it is more often used for wall insulation.

The environmental friendliness of the material plays an important role. Here the winners are basalt insulation, polystyrene foam and polyurethane foam.

About the choice of insulation material

The choice of the latter depends on the taste preferences of the home owner, the climatic characteristics of the region where the building is located, and the desired temperature conditions inside the building. In this matter, you should refer to the relevant regulatory documents (SNiPs and GOSTs), which spell out the main characteristics of thermal insulation materials and provide formulas for calculating the required thickness of the insulating layer.

Do-it-yourself siding installation with insulation is carried out on the basis of materials whose characteristics are given in the table below:

| Material name | Thermal conductivity coefficient, W/ (m*K) | Characteristic |

| Mineral wool | 0,056-0,07 | It is distinguished by its affordable price and ease of installation. Mineral wool is hygroscopic, therefore the presence of a waterproofing layer is mandatory. It is vapor permeable. Service life up to 10 years |

| Styrofoam | 0,047-0,052 | The material is universal, characterized by high density and strength, can be installed without lathing (with glue), it does not absorb water, increases the sound insulation characteristics of walls and is not vapor permeable. Service life up to 30 years. |

| Extruded polystyrene foam | 0,031 | This slab material has a closed-cell structure, which has a positive effect on its service life. When installing insulation, there is no need for lathing on the siding. Positive characteristics:

Negative points: high cost, vapor tightness. |

| Penoizol | 0,035 – 0,047 | This is a foam insulation material that is applied directly to the surface to be treated under pressure. Within a few minutes it gains the necessary strength. Advantages:

Moisture-resistant, vapor-proof. |

| Glass wool | 0,035—0,070 | The fibrous material is moisture resistant, has soundproofing characteristics, is fireproof, does not form condensation on its surface, and is vapor permeable. |

Note. The further installation scheme for siding with insulation depends on the type of thermal insulation material chosen.

Which siding to choose?

If timber or a solid log was used as a building material, then it is best to use vinyl siding to cover the erected log house.

Panels made of polyvinyl chloride reliably protect the building from adverse weather conditions.

They are light enough, so they do not create additional load on the foundation. Plastic panels are easy to install and clean. Such cladding will significantly extend the life of a wooden house and give it a unique appearance. Sheathing an old wooden house will give it a fresh look.

Wooden siding is ideal for covering a frame house. This type of cladding looks truly expensive and impressive. The sheathing is installed very quickly. In this case, the panels can be installed both vertically and horizontally.

Excellent breathability and the absence of toxic fumes are the main advantages of wooden siding. For cladding a frame house, experts recommend purchasing panels made from beech, spruce, pine or larch wood.

As for a brick building, when choosing a finishing material, you should take into account the purpose of the building. If this is an industrial building, then it is best to finish it with metal siding. It is better to cover a residential brick house with vinyl siding. It will allow you to successfully imitate other expensive materials.

To decorate houses made of foam blocks and aerated concrete, you can successfully use vinyl, metal, and basement siding. Simplicity of installation, as well as excellent performance characteristics, of the installed panels will help improve the facade of the house, it will look beautiful and stylish.

A high-quality frame for siding, where insulation is necessarily present, can significantly reduce heat loss and improve the waterproofing of the building.

Features of high-quality siding:

- Same panel thickness. This cladding will not deform and will serve the building owner for as long as possible.

- The presence of a uniform layer of paint. If the panel is unevenly painted, then most likely low-grade raw materials were used in the production process. Such panels cannot withstand mechanical loads, quickly lose their color and become deformed when temperatures fluctuate.

- Surface structure. There are no chips, stains or cracks on high-quality panels. They should not delaminate.

- Plastic. All cladding parts must demonstrate flexibility and strength.

- Availability of certificates. When purchasing material for cladding a house, feel free to ask for a quality certificate. The document must contain, certified by seal, expert conclusions that confirm the fire resistance and hygiene of the product.

Types of siding for finishing

Before we begin analyzing the siding installation process, we will look at the product catalog from which you can choose the appropriate material for yourself. So, there are several types of siding for finishing houses. If you take into account the cladding of a timber house, then you will be presented with the following types for work:

- vinyl siding. It is 100% plastic. Its advantage is that plastic does not interact with moisture in any way. She doesn't harm him. The panels themselves are light in weight, look beautiful and are practical. The main advantage of vinyl siding is its high resistance to external factors. By covering your house with vinyl siding that imitates timber, you will create the illusion of rounded timber, since the materials can only be distinguished externally from a close distance;

- metal siding. The material is based on a sheet of metal, which is additionally coated with several layers of polymer during manufacturing. The steel sheet is protected by galvanizing, after which it is primed and a base coat is applied. This can be various kinds of drawings, imitation of wood or other material. To prevent the coating from fading, it is covered with layers of polyester. The metal siding under the beam is also made in such a way that it is quite difficult to distinguish it from the real one, as can be seen from this photo.

Vinyl products are not as durable as metal ones. However, they are less expensive and will not rust over time. And the weight of the materials is different, so the load on the building from vinyl siding will not be so great. Both the first and second types are distinguished by their positive characteristics. Externally, they perfectly replicate timber, are durable, reliable, versatile, and caring for the material is as easy as shelling pears.

If we talk about dimensions, the range of sizes is quite large. If the block house is produced with a length of 2–6 m, then the siding is imitation timber 0.5–6 m, with a thickness of 0.5 mm. In unforeseen circumstances, you can cut the material yourself to fit it to size.

Advice! When working with metal products, it is important to protect the area from corrosion after cutting. Otherwise, the material will begin to rust and will not last long.

It is convenient for even one person to work with the material. The thing is that due to its small thickness, the material has an acceptable weight. It ranges from 2.5 to 4 kg/m2. With these parameters, finishing a house made of timber with siding will be done quickly and easily.

I would like to draw attention to one more feature of the materials. They are divided into the following types:

- Imitation for profile timber. The siding has a square or rectangular cross-section, so the front side is made flat, as seen in the photo.

- Imitation of rounded timber. Such products have a semicircular cross-section, characteristic of rounded logs.

Despite these distinctive features, installation of siding under timber does not change in any way. We are talking only about the aesthetic side.

Preparatory work

The technology requires careful preparation of the base. The work may vary depending on the material from which the walls of the house are made.

Wooden base

To qualitatively sheathe such a structure, you need to perform the following steps:

- The general condition of the coating and foundation is assessed. This must be taken responsibly, because problems can only be eliminated by disassembling the casing and removing the insulation.

- The surface is cleared of all unnecessary elements and decorative elements are removed.

- Cracks and crevices are opened and cleaned well.

- The wood is carefully treated with antiseptic compounds. It is also recommended to impregnate with fire retardants.

- After drying, the damage is covered with a special wood putty.

- All cracks are carefully sealed.

- As additional protection, the basement part (foundation) is waterproofed.

Before cladding a wooden house, all cracks and cracks must be sealed with special putty or sealant.

Similar measures are carried out with a frame or panel house, provided that the outside is completely covered with slabs.

Frame installation

Finishing a wooden house begins with the installation of guides. The vast majority of siding requires the sheathing to be mounted vertically. Its pitch is selected depending on the insulation. The clear distance between the guides should be a couple of centimeters less than the width of the mineral wool. For polystyrene, the distance is selected exactly to match the width.

To make wooden sheathing, bars measuring 40x40 mm or 50x80 mm are most often taken. When using the metal version, you will need a set of special profiles of different sections.

The frame slats are installed in increments of 40 cm, incl. around openings. There should not be any slats at the very bottom

Nails or self-tapping screws are used to attach the frame to a wooden wall. The former must have an anti-corrosion coating made of zinc or aluminum. Before fastening the sheathing with a construction stele, a vapor barrier is installed. To do this, you can use regular plastic film, but it is better to buy a special vapor barrier membrane. The choice of materials in a wooden house should be taken extremely responsibly. It is not recommended to use those that will block the movement of air through the walls. For this reason, membrane is better than film.

When finishing a wooden house with siding, the vapor barrier is attached with an overlap of 10 cm. Before starting work, it is recommended to read the manufacturer’s instructions. Next, the guides are attached at the required increments, starting installation from the corners. Levelness is checked using a building level.

Insulation is placed between the sheathing guides. It is better if it is mineral wool due to its good air permeability. A layer of waterproofing and wind protection needs to be fixed on top of the wool. The best option would be modern vapor diffusion (not to be confused with vapor barrier) windproof membranes.

General information about Siding material

Types of siding

Based on the material used, siding is divided into types:

- metal,

- wooden,

- plastic,

- cement,

- basement

Characteristics of metal siding

Types of metal used

Panels for cladding houses and buildings are made from various types of metals:

- Aluminum.

- Steel.

- Zinc.

They are usually coated with paint with a protective varnish, or a polymer composition. Aluminum, zinc and polymer-coated panels are significantly more expensive than painted steel panels.

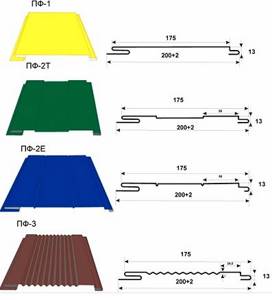

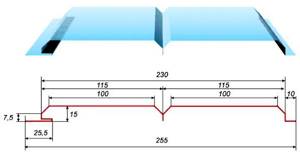

Types of produced sizes

Now let's look at the dimensions of the siding. The width of the panels is usually from 100 to 300 mm. It is rare that panels are made 500 mm wide.

Standard width of panels that are often used:

- Full width - 211 mm.

- Useful (finish) width – 188 mm.

The thickness of the metal panels, no matter what material they are made of, is 5 mm. The length offered by the manufacturer ranges from 0.5 meters to 6 meters.

Experts recommend using a length of about 3 meters.

Types of external attractiveness

During production, metal siding can be shaped into any shape such as rounded wood, logs, or brickwork. That is, set any texture, relief, color and shade.

The material also has perforations along the top edge, which simplifies the installation process on the frame, and also hides the screw heads for aesthetic beauty. Plus, this perforation reduces the stress on the plates that occurs during expansion and contraction from thermal fluctuations.

These plates also have special holes designed to remove excess moisture from the skin.

Calculation of materials and components

Before buying material, you should draw up a plan with clear dimensions and calculations of the amount of material.

To do this, we make a detailed drawing on a piece of paper, indicating the height of the building, the width of the walls, the sizes of windows and doors. To calculate the number of elements, you need to find out the usable area.

It is calculated by the formula:

S total = S walls - S openings

If you are planning to cover a brick house with metal siding and do it yourself with your own hands, it is good to draw up a diagram of the location of the strips of material on the walls. This diagram will also help with installation.

Now we will calculate the auxiliary components:

- Finish and starting slats . As the name suggests, they are used for fastening the initial panel and for the final completion of the installation of the panels. It is calculated as follows: the length of the perimeter of the house is divided by the length of the slats, and we get the required amount.

- Internal and external corners . Used to decorate the corners of buildings. For decoration, it is better to use whole guides, since the seams will be visible and the aesthetic appearance will be disrupted. Therefore, the number of angles is equal to the number of profiles.

- J-profile . Used to complete the vertical plane of window, door openings and diagonal gables. The length of all the listed elements in linear meters is added up and divided by the length of the J-profile.

- H-profile . Used to connect the siding panels themselves. Usually sold individually. The quantity can be calculated according to your scheme.

- Window profile . Used in cases where the depth of door or window openings is deeper than 20 mm. A J-profile can be used as an alternative if the width is appropriate. Also sold individually.

- Platbands . Used for finishing openings. Sold individually.

Also, different batches of the same color may have different shades and it will be very difficult to choose a color scheme.

Pros and cons of metal siding

Advantages

Let's consider the main advantages of metal siding:

- Ideal for any climate conditions. Ability to operate in temperature ranges from -50 to +50 degrees Celsius.

- When using siding, we create a ventilated facade, which allows the wall and insulation to freely remove excess moisture, and hence fungus and mold do not appear.

- The service life of the material is over 50 years.

- High levels of strength and practicality. Siding is not exposed to direct sunlight. The material is absolutely not flammable, and thanks to the high-quality coating it does not rust.

- Possibility to carry out work at any time of the year. Convenient finishing of houses with complex geometry.

- Simplicity and speed of installation technology. Possibility to do the work with your own hands.