Installing a shower tray is a serious undertaking. Especially for novice home craftsmen who do not know which way to approach this plumbing fixture. Calling specialists requires money, and the qualifications and integrity of untested craftsmen can be unpleasantly surprising. To protect yourself from unprofessionalism, just brush up on your theory a little, roll up your sleeves and start doing the work yourself.

Design Features

Production technology

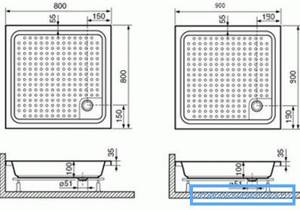

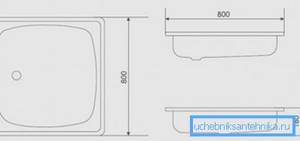

Products of this type are among the most popular on the market. In addition, if we accidentally make a mistake and type in a search engine something like “steel shower tray 900×900 mm”, we will still take a fairly wide sample of tens or hundreds of models.

The steel pallet itself has a relatively simple design.

It is produced in a factory using the stamping method with subsequent processing:

- In most cases, a steel sheet with a thickness of 1.5 to 3 mm is taken as the starting material . The sheet is cut into blanks, the size of which allows the manufacture of a container of the appropriate dimensions.

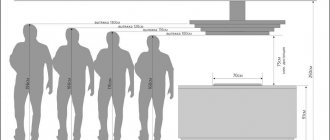

Note! Most of the models on the market have a square shape and sizes from 70x70 to 90x90 cm. Huge products and rectangular pallets whose width exceeds their length (for example, 120x90 cm) are less common.

- Steel blanks are subjected to primary heat treatment, after which they are fed under a press . Along with this, the sides of the pallet are formed in a couple of steps, a hole is made for drainage, and a relief is applied to the bottom.

- Upon completion of stamping, the edges of the sides and holes are cleaned , and after that an anti-corrosion compound is applied to all surfaces. Much more often it is enamel, but from time to time passivating agents based on zinc are also used.

- In addition, in many cases, fasteners for installing legs and upper guides used to fix the shower enclosure are welded to the pallet.

Note! Models without legs are installed on side walls, which are much more often welded to a stamped blank. But such products have a drawback: they can only be mounted on a pre-leveled surface, while pallets with legs allow position adjustment.

The result is a fairly strong, reliable and stable product that is relatively easy to install and can withstand the most intensive use.

Forms and varieties

As we noted, most pallets are in the shape of a square or rectangle. Such products are relatively inexpensive and easy to manufacture and install. But they are not overly practical, because with classic corner installation they take up quite a lot of space.

Corner models with a trapezoidal or rounded front part are a couple more expensive. They are more compact, and therefore they are chosen for installation in small bathrooms.

Another parameter influencing the choice is the depth of the base. If you want to protect your bathroom floor from drops and splashes as much as possible, then a deep tray (up to 150 mm from the top edge of the side to the bottom at the drain hole) is ideal for you. But in an outdoor shower it is possible to use small (up to 80 mm) models.

In addition, it is worth paying attention to the material from which the structure is made. There are two options, and the most ergonomic way to compare them is in the table below:

| Product type | Highlights |

| Stainless steel |

|

| Dark metal with enamel |

|

But, whatever the anti-corrosion protection of the metal from which the pallet is made, its effectiveness depends on the thickness of the base.

This is explained simply:

- In most cases, these products have a fairly large area (80x80 cm or more), and are installed on a frame laid along the edges.

- Under the influence of enormous loads, the narrow (less than 2 mm) metal in the middle part begins to bend, and the elastic anti-corrosion composition that is not enough becomes covered with microcracks.

- Over time, these cracks increase in size, leading to peeling of the enamel.

This is why experts strongly advise against saving on purchasing narrow pallets. It goes without saying that their price will be lower, but the service life will also be reduced by an order of magnitude.

Pallet installation method

Tools needed

Installing a steel shower tray with your own hands is not only completely possible, but also quite simple.

We will need the following tools and consumables:

- For a model without legs - a screed to level the floor.

- A pipe with a diameter of 50 mm for connecting the siphon to the sewer...

- A special siphon that is installed under the shower stall.

- FUM tape for sealing pipe threads.

- Sealant (it is best to use moisture-resistant, silicone-based).

- Roulette and level.

Advice! The tray, purchased separately, must be measured in advance so that all other elements that we will make for the shower stall fit in size.

Installation algorithm

Instructions for installing similar products with your own hands suggest the following sequence of actions:

- First, we check the floor level. The structure on legs can be fixed to virtually any surface, but models with a massive base require leveling by pouring screed.

Note! Because it takes at least 7 days for the screed to gain sufficient strength, it must be filled in advance.

- Then head to collect the pallet. In most cases, before installing it, we need to attach the legs to it by inserting them into the intentionally made grooves and securing them with fixing screws.

- We install the product in the chosen location, after which we attach a siphon to it to drain the water, sealing all connections with rubber gaskets. It is most ergonomic to do this before final fixation, while the tray can still be tilted.

- We connect the siphon outlet to the sewer pipe. In most cases, a rubber cuff is used for this purpose, which allows you to quickly disassemble the system to clear the sewer blockage.

- Smooth the tray by turning the screws on the legs. At the same time, we make sure that the drain level does not fall below the level of the siphon entrance to the sewer.

- We do a test drain, letting water into the pan under low pressure. If there are no leaks anywhere, we completely fix the legs and install the side panels or cover the edges with tiles.

Installation of a ceramic shower tray: sophisticated luxury

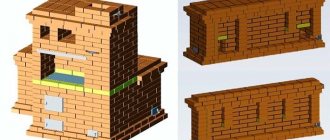

Made from ceramics, natural or artificial stone, they make the interior interesting and sophisticated. But these products have a feature that must be taken into account during installation - heavy weight. Therefore, they have to build a parapet of bricks or other masonry material. The video at the end of the article will clearly demonstrate this method of installing a shower tray with your own hands, but for now let’s pay attention to the description.

Models from well-known brands may have factory-prepared cavities in the thickness of the material in which the siphon is placed. In this case, it is enough to lay the pallet on tile adhesive, having first leveled the base.

READ How to install snorkel on l200

In the same way, you can install any steel shower tray without legs if there are no other materials at hand.

Advantages and disadvantages

Steel products have many advantages:

- Firstly, they are significantly stronger than acrylic and plastic models. So if in your family there are people weighing well over 100 kg, then you will not find an alternative. A shower cabin 800x800x1975 mm with a steel tray is the minimum you need!

- Secondly, most of the models are installed in almost an hour and a half. It goes without saying that from time to time difficulties arise at the stage of leveling the base, but if you purchase a structure with legs, you can adjust its position by rotating several screws.

- Thirdly, the trays can be used both as an independent plumbing fixture and as part of a shower stall. The second option, of course, is preferable from the point of view of comfort, but if you need to equip a shower with minimal money, then just a tray with plastic curtains around the perimeter will be enough.

As for the disadvantages, they are as follows:

- Tendency to corrosion when the enamel or passivation layer of dark steel is damaged.

- Limited number of design solutions.

- High volume of sound when a jet of water falls.

But we can compensate for the last minus by applying a layer of polyurethane foam to the underside of the pallet before installation. The remaining shortcomings can be fully tolerated by properly using the structure and avoiding damage to the anti-corrosion layer.

Steel shower trays

Characteristics and Features

If we look at shower bowls and divide them into groups according to the materials from which they are made, we will notice that steel products will be the most budget-friendly:

| Material | Price, rubles |

| Acrylic | 6000 – 20 000 |

| Cast stone | 20 000 – 50 000 |

| Ceramics | 10 000 – 40 000 |

| Enameled steel | 2000 – 10 000 |

Cheapness is one of the indisputable advantages of steel models, but it can also have the opposite effect: most buyers believe that low cost is a sign of low quality.

This is not entirely true, and often the low price is caused by the peculiarities of product production, the cost of materials, as well as (and this is especially important) existing market trends and the related marketing policies of product manufacturers.

In the case of steel pallets, it cannot be said that they are definitely worse than their analogues, but in some positions, metal models do lose. Their lineup is not that diverse, especially in terms of design. It is quite difficult to find a bowl of an unusual shape; square and rectangular shapes predominate on sale; corner models are much less common.

There is also a limitation on the depth of the vessel, and it is almost impossible to find really deep steel shower trays, since this parameter is limited to 160 mm. At the same time, models with a maximum depth of 130 mm are more common, and any pallet with a depth of more than 40 mm is called deep. However, this feature is not unique to this class.

On the other hand, steel is an excellent structural material, which is characterized by high strength and durability, which is not afraid of high temperatures, shocks, falls of heavy objects, fungal infections and other similar influences. Low cost makes steel models especially in demand for installation in country and country showers.

The products are made from carbon steel coated with anti-corrosion wear-resistant enamel. If you think of a cast iron bathtub, you can imagine what we are talking about. The bowl can be equipped with a frame for installation, special legs or supplied without them.

Important! By the way, bathtubs can last for decades and still look good, so stereotypes about the quality of steel bowls are largely far-fetched.

Advantages and disadvantages

Installation

Installation of steel pallets is done in two ways: on a podium made of brick or concrete, as well as on a special steel frame with legs. It is advisable to choose a model with a frame and adjustable legs.

If there is no frame at the installation site, a brick podium is first laid out. To do this, the floor is stripped of finishing down to a clean screed, on which a ceramic brick structure is laid (silicate brick is not suitable due to its low moisture resistance).

The design is a parapet 0.5 - 1.5 bricks high around the perimeter of the bowl:

Inside the structure, a sewer pipe with a water seal is laid to the riser (a neck is brought outside into which the drain pipe will fit) and filled with cement mortar. The height of the pouring should be such that the bowl rests on it with its bottom and the sides rest on the curb.

To fix the bowl to the brickwork, you can use silicone sealant, cement adhesive, epoxy resin or polyurethane foam. Connections to the wall must be treated with silicone.

Important! Before final fixation, it is necessary to test the structure for leaks. Only after this can the pallet be fixed with glue and the joints sealed with silicone.

At the end, the podium is covered with tiles or other material, and the joints with the walls are decorated with ceramic or plastic skirting boards.

Ideas for a summer shower in the country (photo)

Often in local areas they do without specially constructed premises, arranging a summer shower in the dacha with their own hands in a variety of lightweight ways.

Makeshift bucket shower

The simplest option, which does not require work on the construction of a separate cabin, is an ordinary bucket with small holes punched. It is hung at a convenient height, warm water is poured in and the impromptu shower is ready. You can install posts around which the fabric is stretched to limit the view.

Options for organizing a summer shower from a bucket

Arrangement of a shower near the house

Another type of simple design for a summer shower is to build it near the blank wall of a gazebo or house. Pre-tile it to protect it from moisture. A wooden pallet is placed on the compacted earth. You can make a concreted platform on which a rubber mat is placed.

Four supports are dug in and surrounded by boards or metal. A container with a shower head into which water will be poured is fixed directly to the wall. Also, hooks for washcloths and shelves are nailed to the wall to organize detergents, and hooks for towels are attached to the outside.

Cozy and simple summer shower attached to the house

Cabin with removable walls

A summer shower stall can be quickly built if you stretch a moisture-proof fabric over an installed metal profile frame or attach plastic polycarbonate sheets. This material can be easily removed for the winter and will not cause any difficulties for re-installation the following year.

Shower cabin made of polycarbonate for seasonal use in the country

Construction made of sticks and bamboo

Some gardeners use unusual materials, for example, making a stylish frame from thin branches, bamboo sticks or reeds. This type of fencing looks aesthetically pleasing. You can decorate the outside with hanging pots with flowering plants.

It is important that the summer shower in the courtyard of the house fits harmoniously into the overall design of the garden

An unexpected solution in the design of a country shower

Sheet metal fencing

You can do without a frame if you install the metal profile sheet in a semicircle. But in this option it is impossible to install a tank. More often, such a fence is made if it is possible to connect to a water supply or if a blank wall of the building is used to secure the tank.

Shower panel

The role of the panel for fixing the shower head can be played by a wooden, stone, or brick partition. Its construction does not require much time and you can get by with a minimum of material. This creates a separate zone that allows you to quickly cool off under running water.

An important advantage is the ability to design the panel in any style using tiles, mosaic panels, shells and even plastic bottle caps. Such a decorative element becomes the highlight of the entire landscape.

A lightweight and modern version of a summer shower

Unusual use of a surfboard as a shower panel

A shower with one wall is a convenient model for those who love simplicity and restraint.

The use of non-standard plumbing accessories adds an original touch. With their help, it is possible to create an imitation of a miniature waterfall, tropical rain or light refreshing drizzle. However, this option has a serious drawback, which is the lack of wind protection and external visibility.

Room in a house with a separate entrance

There will be no need for installation work on the construction of buildings if you allocate a small room for an outdoor shower in your dacha, equipping it with a door opening directly onto the street.

Shower pump

A convenient and cost-effective shower model is one that operates on the principle of a foot-operated car pump. The hose is lowered into a container with water warmed in the sun. It is served by performing pumping movements with the legs.

Your hands are free, which makes it easy to hold the second hose with shower head. This design is easily portable and can be used anywhere in a summer cottage. To enhance convenience, purchase a model with an electric pump.

A shower with a pump is an excellent alternative for those who like to quickly freshen up in summer

Shower on the terrace

If it is possible to install a water supply, install a shower stand directly on the veranda attached to the house. In such a situation, it is necessary to provide for unimpeded drainage of water from the floor and good waterproofing of the walls.

An outdoor shower in this layout is a real gift for those who value comfort and order.

Summer shower in classic Finnish style

Shower stand

A simplified version such as a stand on which a shower head is mounted is also used in the country. It is installed in places where there are water supply lines that provide water supply and drainage of used liquid.

You can equip the stand with a tank in which water will be heated by the sun's rays. A rational solution is when the stand itself directly serves as a water reservoir.

The ease of use of such a shower design is undeniable.

Shower in front of the fence

If your summer cottage is surrounded by a high enough solid fence, you can freshen up by installing a shower counter directly in front of it. Reliable protection from prying eyes will be provided and there will be no need to build a separate room for water procedures.

Polished metal in tandem with natural stone always looks brutal and quite modern

The shower near the fence is not only functional, but also very convenient

Shower connected to the house

A successful example of a solution for arranging a summer shower is the practical use of a house wall. You can mount a pipe into the wall and hang a shower head, ensuring the supply of cold and hot water from the water supply.

The owner of the house who is a little familiar with the basics of plumbing should have no problems with arranging such a structure

Successful application and use of a narrow passage near the house

A shower in the wall of a house looks great in any design

Option for the elderly

To provide not only a refreshing shower, but also comfortable conditions for elderly household members, the summer cabin is equipped with a bench. It is made from high-quality polished wood.

A shower with a bench is the best option for older people

Simple and compact shower construction

The selection of an option for a country shower that brings coolness, freshness, and relaxation depends on the characteristics of the site, existing buildings, and the type of fence. If it is not possible to build a stationary booth, they turn to various ideas for using lightweight structures that can be easily erected from scrap materials.

Conclusion

A shower tray made of enameled steel is a budget-friendly and quite acceptable quality option that is perfect for both a suburban area and a city apartment. The video in this article will help you install the product in the shower yourself.

The main stage of work when installing a cabin in a bathroom is installing a shower tray. You can do this yourself if you comply with the technological requirements.

Installation of a shower tray

The easiest way to install acrylic, ceramic or steel products is that you don’t need unique knowledge or complex tools. But with certain skills in construction and renovation, it is possible to equip a bathroom with a concrete tray decorated with ceramic tiles. The installation of a shower tray made of marble or cast iron must be carried out by specialists due to the large weight of the products.

Instructions for installing a shower tray with your own hands: video tutorial

For readers who prefer a visual demonstration to detailed descriptions, we have prepared a short and understandable video tutorial. Despite the short duration, it shows all the stages of building a retaining wall, installing a shower tray with your own hands, and also provides recommendations on the necessary materials and tools.

Share your experience in self-assembly with users in the comments to the article, because a lively discussion is the best way to birth the truth. If you have not yet chosen a shower tray, be sure to take a look at this publication, where all possible sizes, shapes and materials of these plumbing products are analyzed.

Source

Choosing the right model

Shower trays come in various shapes - square, rectangular, with rounded edges. The choice here depends on the wishes of the owner. It is much more important to take into account the depth of the structure when installing:

- Deep trays resemble small bathtubs. They have high sides (from 20 cm) and rest on a powerful frame with six height-adjustable legs

Prices for deep shower trays

Products with medium depth have side heights from 10 to 20 cm. Their support system can be the same as deep ones or like shallow ones.

- The sides of small or low structures are small; they are also sometimes equipped with legs. But in most cases they have no support. And under them it is necessary to lay a special foundation.

- mechanical deformations from the feet of people washing;

- surface cracking due to temperature changes;

- need for a solid foundation.

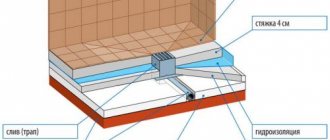

In some cases, a waterproofed floor with drains for draining water acts as the bottom of the shower stall.

Pallets are also built-in and removable. This point must be taken into account during installation.

The thickness of the walls of the selected plumbing element is no less important.

Pallets with thin walls are made of acrylic and plastic. The advantages of such models include ease of transportation and installation, as well as a budget price. But thin-walled models have a number of disadvantages:

The coating on steel pallets may peel off and rust stains may appear in damaged areas. Acrylic analogues are easy to scratch if, for example, you decide to wash your beloved dog.

Ceramic trays or those made from brick and concrete are more durable. The most durable are cast iron models.

How to choose a shower tray, video:

Which base for a pallet is better?

Installation of a shower tray can be done in various ways:

- on a brick foundation;

- on plastic support parts;

- on a metal frame.

The base is selected depending on the model’s configuration and its technological characteristics. The need for a foundation is due to the fact that the drain hole must be located above the level of the sewer line so that the water drains well. Experts believe that the angle of inclination from the bottom to the entrance to the sewer line should be at least 3 degrees. If it is impossible to make a pedestal or lower the sewer inlet, you will need a special pump to pump out the water.

Most deep models are equipped with a special metal profile frame. But if the tray is thin-walled, the feet of bathers will quickly push the bottom between the guides, especially if the owners of the bathtub are not of fragile constitution. In these places, acrylic options may even develop through cracks. Therefore, deep, thin-walled pallets also require a stable foundation.

Installation of a ceramic shower tray is possible without a foundation, directly on a flat floor without an installation gap.

Here it is necessary to monitor the quality of laying the sewer lines so that the drain hole is higher than the outlet and the water quickly leaves the container. The element itself is attached to the floor using glue or cement tile mixture.

Cast iron elements are usually simply placed on the floor. Their height is sufficient for reliable drainage into the sewer. The same applies to stone products. But there may be a problem with the siphon. It will have to be installed directly on the floor surface or connected to a flexible unit and hidden in a specially equipped niche in the wall.

Let's look at how to install different types of foundations when installing shower trays.

Metal or plastic frame

If you choose this type of base, it won’t take much time for installation. The main actions here will be:

- Leveling the legs using a building level.

- The installation of the shower tray itself.

- Connecting to the sewer and fixing the drain hole.

An extruded polystyrene board can be placed under the bottom to insulate the area. Polyurethane foam is used in the same way. This is especially important when installing steel pallets. It will also help reduce the sound of falling water.

Once the installation of the shower tray is complete, you need to check its stability. If the pallet wobbles or creaks, additional supports from steel angles or brick columns will be required.

To secure the thin bottom and give the structure stability, you can make removable formwork and pour concrete. The installation of the shower tray will be carried out on the resulting pedestal. This method has disadvantages: it is impossible to check and eliminate the leak. Replacing a sewerage unit and installing a siphon is also quite difficult. Alternatively, you will have to use flexible connections and hide the siphon in a niche in the wall.

Installing a shower tray on a brick foundation

This is an excellent solution for most pallets, allowing you to eliminate any deformation and extend the life of your plumbing fixtures. The main thing is to choose the place where the siphon will be installed.

In this case, the bricks are laid not only around the perimeter of the product. Otherwise, the bottom will bend over time. In structures with legs, to eliminate this drawback, additional support is provided in the center. Since there is a convexity there, such a model cannot be installed on a flat brick foundation. It is necessary to provide a recess for this tubercle.

The correct technique for creating a brick foundation is as follows:

- Draw the foundation lines according to the required dimensions.

- Mix the cement mortar for masonry.

- Apply several strokes of the composition to the floor using a spatula.

- Lay the first row of bricks, starting from the corner, and tap them with a mallet for a better fit to the floor. The thickness of the seam should be 5–7 mm.

Installation of the shower tray is carried out after 3 days, when the masonry is completely standing.

If the pallet is semicircular, at the bend the bricks are laid out in a fan with the butted edges facing outwards.

A welded frame made of metal corners 20 by 20 mm can act as a support in the center of the bottom. It is installed between rows of bricks and secured to the floor with dowel nails. Acrylic should be protected from friction on metal surfaces with a layer of insulating rubber glued to the metal.

A deep tray on a high foundation will require the creation of a ladder to the entrance to the shower stall. Steps can be made of concrete or bricks and covered with tiles. The walls behind the pallet are finished with tiles or other waterproof material. The tile adhesive must also have excellent moisture resistance.

Construction of a shower at the dacha: photo report

It was decided to use the fence at the far end of the site as one of the walls of the shower. It was decided to have a shower with a locker room - it’s much more convenient.

The soil is sandy, the water drains very quickly, so only one tire was buried for drainage. Rainfall tests have shown that no more is required. Much more water was poured than I had in the barrel, but there were no puddles.

One tire was buried for drainage

Three more were added to the existing post (from the fence). We used a round pipe (it had been in the shed for a long time). Holes 70-80 cm deep were dug under the pillars. The pillars were installed in them and covered with crushed stone. The crushed stone was compacted and filled with concrete.

Three pillars are buried

Then we welded the frame. A rectangular pipe 60*30 mm was used. This is a bit much for this design, but we used what we had: the remains from the construction of the fence.

During welding, the level was maintained

Having welded the floor frame and thereby marking its level, we formed a drain. They filled in the missing height with bricks (battle, remains). Everything was filled with concrete, forming a drain into the tire.

We leveled the floor in the second half and left it to set. We started processing wood. Purchased aspen board. It was first treated with sandpaper attached to a grinder. Afterwards it was impregnated with a protective composition.

While the impregnation dries, we continue to weld the metal frame for the shower. The middle piping was welded from the same profile pipes. Then it was used as a scaffold for working at heights. Already dried boards were placed on the piping pipes. The top trim was welded from this pedestal.

The middle harness was used to weld the top

The frame is almost ready. All that remains is to weld the frame for the barrel at the top.

Finished shower frame

Above the shower area, reinforcement was added to the top trim in the middle. Two corners are also welded on. The thickness of the metal is about 6 mm, the width of the shelf is 8 cm. The distance between them is less than the diameter: so that the barrel rests on it sideways.

The metal used is old, so it is covered in rust. It was cleaned with a grinder. Then the shower frame was painted three times with anti-rust paint. It was chosen in blue because it was planned to cover the shower with blue polycarbonate.

Painted with blue anti-rust paint

The polycarbonate was mounted with self-tapping screws. No special or regular washers were used during installation. This is a violation of technology, which can lead to it cracking in sunny weather. This material has a large thermal expansion, which is enhanced since in this case it is fixed to a metal frame.

The barrel in the barn has been washed. The pipes are welded to it. One is for filling water, the second is for connecting a watering can. After this, the barrel is painted black.

The barrel is painted black for faster water heating

Source

DIY installation of different types of pallets

Each shower cabin comes with instructions for assembling it. Additional tools and materials are also indicated there. But if you decide to choose your technology, then you should take care of selecting suitable tools and consumables. In most cases you will need:

- building level;

- screwdriver;

- marker;

- drill and hammer drill;

- pliers;

- adjustable wrench;

- sealant.

If you need to do brickwork, you will additionally need a mortar mixture and a trowel.

Preparatory work

Regardless of the type of tray, it is necessary to prepare the bathroom for its installation. To do this you should:

- waterproof the floor and walls;

- check the possibility of connecting to the water supply system and sewer lines (pipes should have convenient outlet openings for easy connection of hoses);

- Close all pipe openings with plugs during installation work.

An important point is the electrical wiring. It must be hidden and moisture-resistant, with a minimum number of twists. For the connection, you should choose a three-core copper wire with a cross-section of 2.5 mm and double insulation. It is laid directly from the electrical panel with the installation of a residual current device.

Installing an acrylic shower tray (step by step instructions)

Most modern shower cabins are equipped with acrylic trays. They are easy to assemble:

- Turn the element upside down and install the legs. They can be fixed to the pallet itself. But more often - on a steel or metal frame.

Types of shower trays and corners

Shower trays differ in the material they are made from. Plumbing fixtures can be made of metal, stone, plastic. The cost, weight, service life, and installation features of the product directly depend on the material. In order to make the right choice, you should study their characteristics.

Cast iron. The inner surface of the tray is covered with enamel. The products are distinguished by their reliability and increased wear resistance. This is the most durable and durable option. The disadvantage of cast iron structures is their significant weight, which makes it difficult to both install the shower tray and transport it.

Steel. Compared to cast iron counterparts, such pallets are much lighter and cheaper in cost. The disadvantages of steel structures include less durability compared to cast iron, as well as a high noise level from flowing water. To reduce sound discomfort, many manufacturers resort to technologies for coating walls with various soundproofing compounds, which reduces the noise level, making the surface smooth and pleasant to the touch. When choosing an installation option for such a model, it is recommended to find out how to install a shower tray on bricks. A solid brick foundation allows you to use the plumbing product for many years.

Ceramic. The material is particularly aesthetically pleasing. Ceramic products fit perfectly into the interior of the bathroom, are characterized by hygiene and resistance to wear. The glaze does not require maintenance - it can be easily cleaned with any detergent. The material has only one drawback: it does not withstand strong impacts. If heavy objects fall, the surface may become cracked or cracked during careless transportation and installation.

Acrylic. The most popular type of shower trays today. The advantages are low price, large selection of shapes and colors, lightness of designs, low noise level when falling jets of water, practicality. However, they can sag and crack under load, which is a significant drawback of the products. Installation of acrylic shower trays involves strengthening the base and supporting the central part of the tray.

Marble. The most expensive type of shower trays are made from natural stone. They are characterized by beauty, durability, resistance to mechanical damage, and hygiene. The products are very heavy. It is better to entrust their installation to professionals, as they can crack if installed improperly.